Products Categories

Featured Products

Carbon Fiber Round Tube

Carbon Fiber Round Tube is made from high-strength carbon fiber, offering excellent stiffness, lightweight performance, and corrosion resistance. It features a smooth surface with clear carbon fiber weave and is available in various sizes and weave patterns with customization options.

- Lightweight & Strong – Superior strength-to-weight ratio.

- Durable – Corrosion and rust resistant.

- Precision Manufactured – Consistent diameter and wall thickness.

- Smooth Surface – Clean, professional carbon fiber finish.

- Customizable – Multiple sizes and weave options available.

Product MOQ

Please note our minimum order quantity of Carbon Fiber Tube. For the conventional Carbon Fiber Tube in stock, there is no MOQ. For customized Carbon Fiber Tube, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

- Carbon Fiber Round Tube, often abbreviated as CFRT, is a tubular structure made from carbon fiber composite materials. Carbon fiber, a lightweight yet extremely strong material, surpasses the strength of some metals while maintaining a significantly lower density. When combined with resin matrices, it forms carbon fiber composite materials that possess excellent performance characteristics. These materials inherit the advantages of carbon fiber, such as its high mechanical strength, lightweight nature, corrosion resistance, high temperature tolerance, and good electromagnetic shielding properties, making them suitable for a wide range of applications.

- CFRT not only inherits the benefits of carbon fiber but also gains enhanced structural stability and load-bearing capacity due to its unique tubular design. It can provide outstanding strength and stiffness while maintaining a lightweight structure, making it a popular choice for components that require high load-bearing capacity or excellent mechanical performance.

- Moreover, CFRT boasts excellent designability and processability. By adjusting the weaving pattern of the carbon fiber and the proportion of resin matrices, CFRTs with different performance characteristics can be produced to meet the specific needs of various industries. In addition, CFRT can be processed through various methods such as cutting, drilling, and bending to create components of various shapes and sizes.

- In conclusion, Carbon Fiber Round Tube, as a high-performance composite material, possesses advantages such as lightweight, high strength, corrosion resistance, and high temperature tolerance. Its customizable nature further expands its applicability, making it widely used in aerospace, automotive manufacturing, sports equipment, medical devices, and other industries.

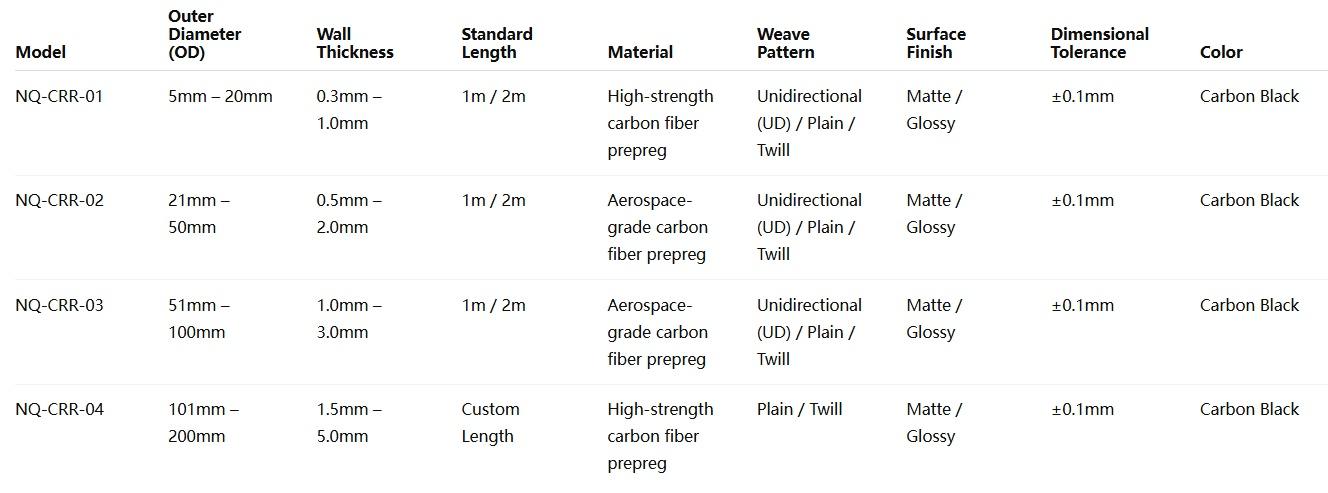

Specification

- Outer Diameter (OD): Typically ranges from 5mm up to 200mm or more, customizable according to project requirements.

- Wall Thickness: Usually between 0.3mm and 5mm, adjustable to meet different strength and weight criteria.

- Length: Standard lengths include 1 meter, 2 meters, and custom lengths available upon request.

- Material Composition: Made from aerospace-grade carbon fiber prepreg with epoxy resin matrix, cured under controlled high-temperature and pressure conditions.

- Weave Patterns: Multiple options including unidirectional (UD), plain weave, twill weave, and satin weave to optimize mechanical properties and appearance.

- Surface Finish: Available in matte or glossy finishes; surface smoothness and carbon fiber pattern clarity ensured by advanced manufacturing techniques.

- Mechanical Properties: High tensile strength (typically > 5000 MPa), excellent stiffness (modulus > 200 GPa), and superior fatigue resistance.

- Corrosion Resistance: Naturally resistant to corrosion, chemicals, and environmental degradation.

- Thermal Stability: Maintains mechanical properties across a wide temperature range (-60°C to +120°C typical).

- Color: Standard carbon black; optional coatings or paints can be applied for UV protection or aesthetic needs.

- Tolerances: Dimensional tolerances typically ±0.1mm for diameter and wall thickness, ensuring precise fit for engineering applications.

- Customization: Full customization support for diameter, wall thickness, length, weave pattern, and finish to match specific project or industry standards.

Main applications

Aerospace Industry

- CFRT is widely used in the aerospace industry due to its lightweight, high strength, heat resistance, and corrosion resistance properties. It can be used as support structures for aircraft fuselages, wings, and engine components, reducing the overall weight of the aircraft and improving flight efficiency.

- According to reference data, carbon fiber accounts for approximately 15% of the applications in the aerospace industry, demonstrating its significance in this field.

Wind Turbine Blade Manufacturing

- CFRT plays a crucial role in the manufacturing of wind turbine blades. Its high strength and lightweight properties enable wind turbine blades to resist harsh weather conditions such as strong winds while reducing the overall weight and cost of the wind turbine equipment.

- Reference data indicates that carbon fiber accounts for up to 26% of the applications in the wind turbine blade industry, highlighting its primary role in this sector.

Sports and Recreation Industry

- CFRT is an essential component in the manufacturing of sports equipment, such as bicycle frames, golf clubs, and fishing rods. Its lightweight yet robust properties make these equipment lighter, more durable, and enhance athletes’ performance.

- Reference data suggests that carbon fiber accounts for approximately 18% of the applications in the sports and recreation industry, indicating its widespread use in this field.

Automotive Industry

- CFRT is increasingly being used in the automotive industry, such as for body structures, chassis, and suspension systems. Its lightweight and high-strength properties contribute to reducing vehicle weight, improving fuel efficiency, and enhancing safety and stability.

- Although direct applications of carbon fiber in the automotive industry account for only 7% according to reference data, the growing trend of automotive lightweighting suggests a promising future for CFRT in this sector.

Other Industries

- CFRT also finds applications in pressure vessels, medical devices, transportation infrastructure, and other fields. Its corrosion resistance, heat resistance, and other properties enable these equipment to maintain stable performance in harsh environments.

- According to reference information, carbon fiber also has extensive applications in pressure vessels, carbon/carbon composites, transportation construction, and other areas.

Features

- High Strength-to-Weight Ratio

Provides exceptional strength while being significantly lighter than metals like steel or aluminum, improving overall efficiency. - Excellent Stiffness and Rigidity

Superior modulus ensures minimal bending or deformation under load, ideal for structural applications. - Corrosion and Chemical Resistance

Naturally resistant to rust, moisture, and many chemicals, extending service life even in harsh environments. - Thermal Stability

Maintains mechanical properties across a broad temperature range without warping or degradation. - Fatigue Resistance

Withstands repeated stress cycles, ensuring durability and reliability over time. - Dimensional Precision

Manufactured with tight tolerances for consistent size and shape, enabling easy integration and assembly. - Aesthetic Finish

Smooth surface with clear carbon fiber weave pattern, combining functionality with professional appearance. - Customizable Properties

Options for different weave types, thicknesses, and finishes to meet specific strength, flexibility, or visual needs.

For more product specifications, please contact our professionals!

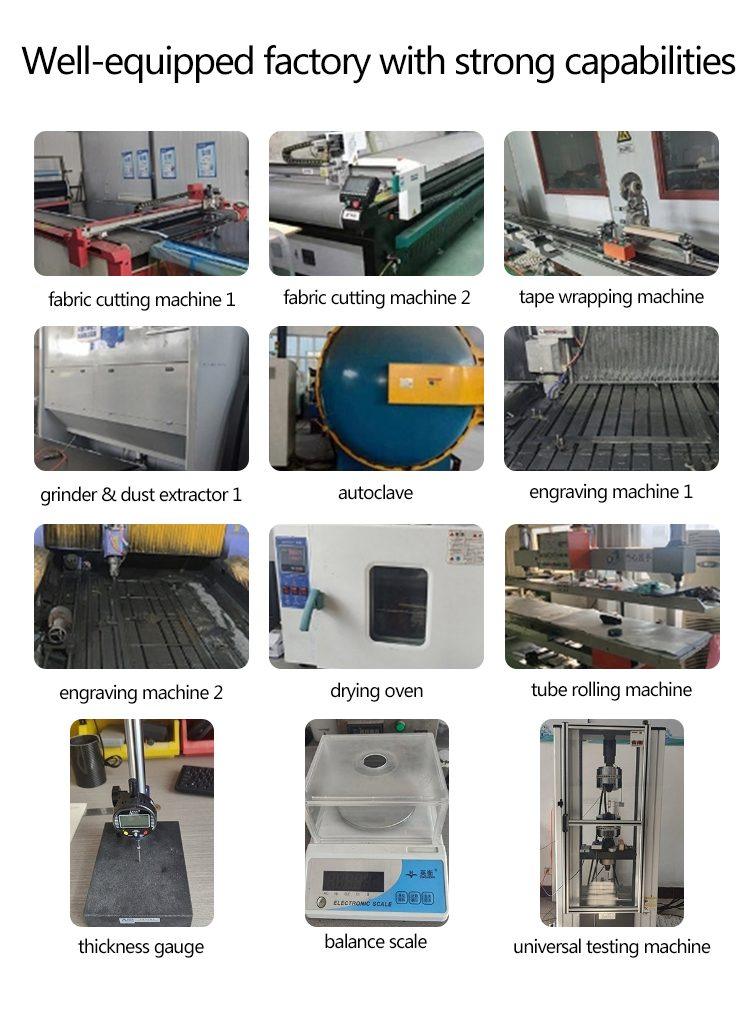

By adopting CNC precision processing technology and automatic detection systems and integrating automated winding, curing, and cutting processes, the production speed is increased by 20% to 30%. Multi-station collaborative operation reduces manual intervention and reduces the error rate.

- Compatible with carbon fiber prepregs such as T300, T700, T800

- Supports a variety of resin systems such as epoxy and phenolic

- ISO 9001, CE, SGS, and ASTM standards

- 40 automated production lines to ensure on-time delivery

- In-house Strictly Testing Lab for 6-step internal inspection

Enhance Performance, Simplify Processing, Reduce Costs

Experience the power of Carbon Fiber Tubes—lightweight, ultra-strong, and corrosion-resistant. Perfect for industries demanding high performance and durability. Elevate your products with precision-engineered tubes that combine advanced materials with cutting-edge manufacturing. Choose carbon fiber tubes for unmatched strength, reduced weight, and superior reliability.