- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

Fiberglass is a lightweight, durable composite material made from fine glass fibers woven together and bonded with resin. It is known for its strength, flexibility, and resistance to heat, moisture, and corrosion, making it widely used in construction, automotive, and aerospace industries.

Fiberglass consists of two primary components:

Fiberglass was first developed in the 1930s by Owens Corning, a leading manufacturer in glass fiber technology. The Material originates from the melting and spinning of silica-based glass, which is then woven into thin strands and reinforced with resin to form strong, flexible sheets or molded components.

The fiberglass manufacturing process involves:

Since then, fiberglass has become an essential material in construction, transportation, and industrial applications due to its versatility and high performance.

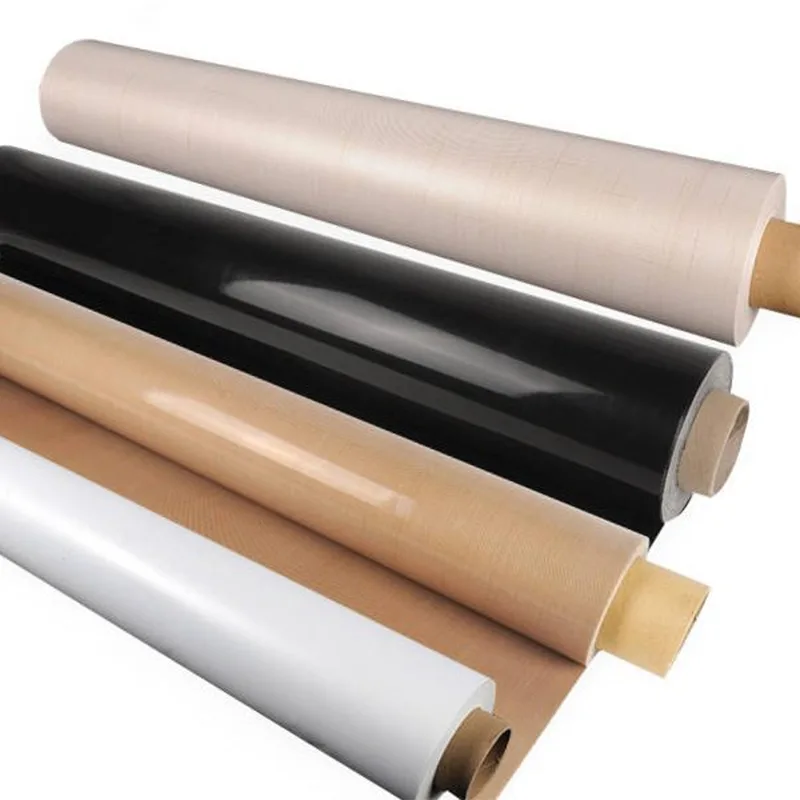

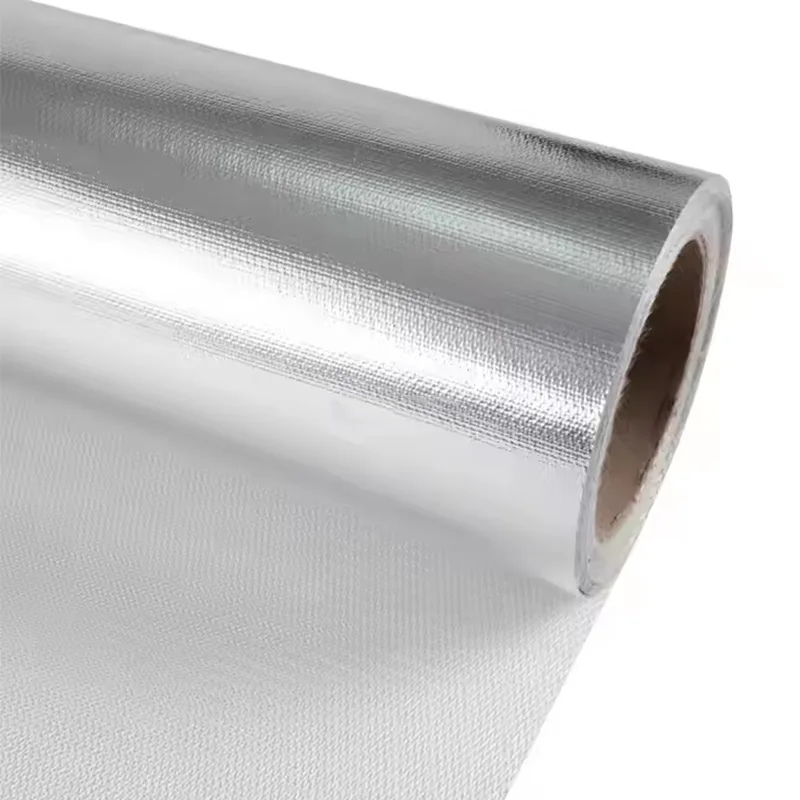

Fiberglass can have different appearances depending on its form and application. It typically falls into three main categories:

The texture of fiberglass varies based on its finish:

Identifying fiberglass can be tricky, but these methods can help:

Using these tests, you can quickly determine if an object is made of fiberglass or another material.

Fiberglass is classified into different types based on its composition, strength, and resistance properties. Below is a comparison of the three most common types:

Type | Composition | Strength & Durability | Key Applications |

E-Glass (Electrical Glass) | High in silica and alumina, low alkali content | High tensile strength, lightweight, and corrosion-resistant | Insulation, general-purpose composites, aerospace, and automotive parts |

S-Glass (Structural Glass) | Higher silica content than E-glass, boron-based | Stronger and stiffer than E-glass, better impact resistance | High-performance applications like aerospace, defense, and marine |

C-Glass (Chemical Glass) | High lime and boron oxide for chemical resistance | Resistant to acidic and alkaline environments, but weaker than S-glass | Industrial corrosion-resistant coatings, tanks, and pipelines |

S-glass is preferred for high-strength applications, while E-glass is the most widely used due to its balance of cost, durability, and performance. C-glass is ideal for chemical-heavy environments where corrosion resistance is needed.

Fiberglass is a key reinforcement material in composite structures. It is combined with resins to form strong, lightweight materials used in various industries:

Fiberglass composites are preferred for their high strength-to-weight ratio, corrosion resistance, and versatility in demanding applications.

Fiberglass is known for being lightweight yet incredibly strong, making it an ideal material for various industrial applications.

Material | Density (g/cm³) | Tensile Strength (MPa) | Key Properties |

Fiberglass | 1.5 – 2.6 | 345 – 4,500 | Lightweight, high tensile strength, corrosion-resistant |

Aluminum | 2.7 | 90 – 570 | Lightweight, corrosion-resistant, ductile |

Steel | 7.8 | 400 – 2,000 | Very strong, heavy, corrosion-prone unless treated |

Plastic (ABS, PVC, etc.) | 0.9 – 1.5 | 20 – 80 | Lightweight, flexible, lower strength than fiberglass |

Fiberglass provides the strength of metal with a fraction of the weight, making it popular in aerospace, automotive, and construction.

No, fiberglass is not plastic, but it is often combined with plastic to form fiberglass-reinforced plastic (FRP) composites.

Key Differences

FRP is widely used in automotive, marine, and industrial applications. It offers high durability, chemical resistance, and lightweight properties.

No, fiberglass is non-conductive, making it an excellent electrical insulator.

Fiberglass is preferred in construction and industrial applications where electrical safety is crucial.

Fiberglass is vital in modern construction due to its strength, durability, and versatility. Key applications include:

Fiberglass in construction ensures energy efficiency, long-lasting structures, and improved safety.

Fiberglass is widely used in the automotive and aviation industries due to its lightweight, strength, and durability:

Fiberglass components in cars and aircraft lead to improved fuel efficiency, reduced wear-and-tear, and enhanced safety.

Fiberglass is a popular choice in residential construction and home furnishings due to its affordability, durability, and insulation properties:

Fiberglass contributes to better home comfort, energy savings, and long-lasting products.

Making fiberglass involves several key steps, starting from raw materials and ending with a finished product. Here’s an overview of the standard manufacturing process:

Fiberglass manufacturing is a highly controlled process that ensures various products’ strength, flexibility, and durability.

Creating fiberglass at home is possible with the right materials and tools, but it requires careful handling and safety precautions. Here’s a simple DIY guide to get started:

Creating fiberglass at home is a labor-intensive process that requires patience, precision, and attention to detail. Still, it can be a rewarding DIY project for making custom parts or repairs.

Fiberglass is not inherently dangerous, but improper handling can lead to health risks. Here are some common concerns and myths about fiberglass:

While handling fiberglass safely is essential, it is not classified as dangerous when used correctly.

Fiberglass fibers are tiny and can easily get trapped in skin and clothing, leading to irritation. Here’s how to safely remove them:

Getting Fiberglass Out of Skin

Do Not Rub: Rubbing the affected area can push fibers deeper into the skin.

Use Tape: Press duct or masking tape onto the affected area. Pull the tape off slowly to remove the fibers.

Rinse with Cold Water: Wash the area with cold water and mild soap to remove any fibers on the surface. Avoid using hot water, as it may open pores and increase irritation.

Use a Fine Scrub Brush: If fibers remain, gently scrub the skin with a soft brush (like a nail brush).

Apply soothing lotion (such as aloe vera) to relieve irritation after cleaning: After cleaning.

Getting Fiberglass Out of Clothes

Shake Clothes Outside: Take the clothes outdoors and shake them vigorously to dislodge loose fibers.

Wash with Cold Water: Wash the clothes separately in cold water with mild detergent.

Use a Lint Roller: After washing, use a lint roller or sticky tape to pick up any remaining fiberglass fibers.

Dry Carefully: Avoid using a dryer, which can push fibers deeper into the fabric. Instead, air dry the clothes outdoors.

When working with fiberglass, it’s essential to use the correct protective gear and follow best practices to ensure safety:

By following these safety guidelines and wearing the right protective gear, you can safely work with fiberglass without putting yourself at risk for harm.

Depending on the specific type of fiberglass you need, you can purchase it from various local retailers and online suppliers. Below are popular sources of NQ Fiberglass Fabric and NQ Fiberglass Mat.

You can easily purchase NQ Fiberglass Fabric directly from NQ’s official website. It is available for construction, automotive, and composite material applications.

You can purchase directly from these product pages, which offer detailed information on each product’s specifications, features, and applications.

Purchasing online allows for easier comparison of prices, quantities, and product specifications, and it offers a broader selection of materials that may not be available locally.

Fiberglass comes in various forms and compositions, depending on its intended use. Here’s how to choose the right type for your specific project:

Fiberglass is a versatile, strong composite material made from glass fibers and resin. It’s used in various applications, including construction, automotive, aerospace, and insulation. With its lightweight nature and strength, fiberglass is an ideal choice for reinforcing structures, creating energy-efficient homes, and producing durable automotive and aviation components. Different types of fiberglass, such as E-glass and S-glass, have specific properties that make them suitable for various industries.

Fiberglass is also a composite material that offers exceptional resistance to environmental factors, heat, and stress. While it’s challenging to recycle, ongoing efforts are being made to improve the recycling process for fiberglass, contributing to a more sustainable future.

Fiberglass materials can cause skin irritation and respiratory issues if not handled correctly. Always wear protective gear, such as gloves and masks, to prevent irritation. If fiberglass comes in contact with the skin, use gentle adhesive tape to remove fibers and clean with soap and water. Proper ventilation and safety precautions should be followed when working with fiberglass products to ensure a safe and efficient experience.

To learn more about fiberglass and explore a wide range of high-quality fiberglass products for your construction, automotive, and insulation needs, check out NQ Fiberglass Fabric and NQ Fiberglass Mat.

For further information and expert guidance, visit our FAQ section or browse our comprehensive product pages to find the right fiberglass solutions for your needs.

Connect with an NQ expert to discuss your product needs and get started on your project.

Table of Contents

Toggle© All Rights Reserved.