- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

Fiberglass mesh glass fiber woven fabric is as the backing material, high

resistance to immerse the son emulsion coatings. Thus has a good fight

alkaline, flexibility and railroad cars/containers to high fineness, can be widely

used for internal and external wall thermal insulation, waterproof building.

crack, etc.

Product features:

1Good chemical stability. Akali resistance. acid resistance, water resistance, cement erosionand other chemical corrosion and so on.

2 High strength, high modulus and light weight.

3Better dimension stability, hard, flat, not easy to contract deformation and positioning

4Good impact resistance. (due to its high strength and toughness)

Fiberglass self-adhesive drywall mesh tape

Color: white & custom

Width:10cm-120cm

Gram weight: 65gsm 75gsm

Instruction of application:

1.We must be clean and dry.

2.Center and apply tape over the lenght of the joint, Pressing firmly.

3.Apply a generous first coat of compound over the tape and through themesh, making sure to completely fill the joint crevice. When the joint has beencompletely filled, wip off any excess compound with drywall knife leaving enoughto cover the tape.

4.Let dry completely, the sand slightly.

5.Apply sufficient thin finishing coats to produce a smooth wall surface.6.Cut or butted boards do not have a tapered edge. Therefore, special caremust be taken to assure proper compound penetration of all joints, This may result inslight build-up of compound that will require an increased amount of edge feathering.

Metal corner tape is used for protecting the internal or externalcorners of the drywall, it is made of paper joint tape bondwith two corrosion resistant metal strips, it can protect anydegrees of the corners, after useit the corner will be planar.straight and more splendid, because it is easy to apply, so it isvery wonderful materials for protecting corners !

Product features:

1Metal types: Galvanized steel or Aluminum steelStandard size: 50mm x 30mPackage: one roll to a box, 10 boxes to a carton

2Roll shape, easy to carry;

3Easy to cut, reduce waste;

4Applicable to a variety of corner;

Drywall paper tape is a material used to repair and reinforce the joints of drywall (also known as drywall or drywall). It is made of fiber paper with strong tensile strength anddurability.Drywallpaper tape is often used in the joint treatment process of drywall construction. When installing gypsum board, there will be gaps between the board and the board, and these gaps can be connected and reinforced using paper tape for subsequent filling and plastering.

Product features:

1. High tensile strength: It has strong tensile performance and can effectively strengthen the drywall joint.

2. Strong durability: It has good durability and can maintain long-term stability.

3. Easy to use: easy to use, the construction process is simple and fast.

4. Good crack prevention effect: can effectively prevent drywall joint cracking and deformation.

5. Moisture resistance: has a certain moisture resistance, adapt to a certain humidity environment.

6. Improve wall quality: It can improve the overall quality and beauty of the wall.

Aramid tape is a kind of synthetic material with good high temperature resistance, mainly used in the manufacture of high temperature and corrosion resistant products, such as seals, valve parts and so on. Aramid strips usually have excellent mechanical strength and chemical stability, and can work under extreme conditions, so they are widely used in chemical, petroleum, aerospace and other fields.

Product name:Aramid webbing tape

Material:Aramid

Color:Yellow

Feature:Firefight, High strength, Wear-resistant, etc

Shape:Square Rectangular

Keywords:Aramid tape

Length:Customized Length

Usage:Minitary, fire protection, safety, lifting, outside sports

Thickness:0.3mm-5mm(Accept custom)

Width:Customized Width

Aramid fabric is a type of fabric made from aramid fibers. Aramid fibers are high-performance, heat-resistant synthetic fibers that are commonly used to make protective clothing such as firefighting suits. Aramid fabric has excellent abrasion resistance, tensile strength, and heat resistance properties, making it ideal for applications in aerospace, military, firefighting, and other industries.

Product name:Aramid fabric

Material:Aramid

Color:Yellow

Feature:Firefight, High strength, Wear-resistant, etc

Shape:Square Rectangular

Length:Customized Length

Usage:Minitary, fire protection, safety, lifting, outside sports

Thickness:0.3mm-5mm(Accept custom)

Width:Customized Width

Keywords:Aramid fabric

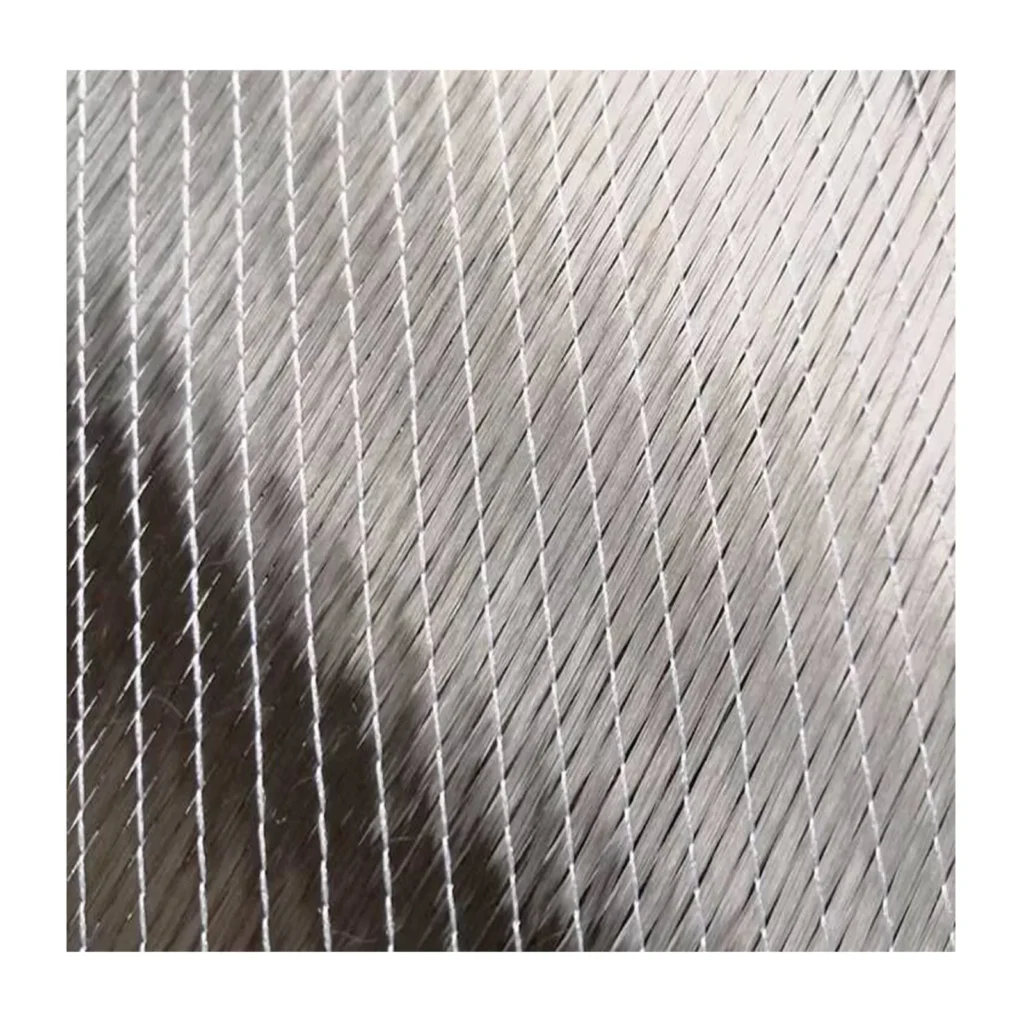

Carbon fiber multi-axial fabrics are usually braided by yarns at different angles to form layers of fibers in multiple directions. Common knitting angles include 0°, 90°, ±45°, etc. Such a braided structure makes the carbon fiber multi-axial fabric have better strength and stiffness in all directions, can withstand stress in multiple directions, and provide greater design freedom.

The use of carbon fiber multi-axial fabric can effectively improve the strength, stiffness and durability of composite materials. It is widely used in aerospace, automobiles, ships, sports equipment and other fields, for the manufacture of various composite components, such as body parts, wings, blades, sports equipment and so on.

Product features:

1. High strength and stiffness: excellent tensile strength and compressive strength.

2. Lightweight: compared with traditional materials, it has a lighter weight.

3. Excellent fatigue performance: It can withstand long-term cyclic load and is not easy to fatigue damage.

4. Good chemical resistance: It has good stability to acid, alkali, solvent and other chemical substances.

5. Design flexibility: It can be designed according to the needs of the opposite sex to meet the performance requirements in different directions.

6. Electrical conductivity: It has good electrical conductivity and can be used for electromagnetic shielding and electrostatic dissipation applications.

Carbon fiber surface mat is a kind of felt-like material made of carbon fiber bundles by precision weaving or pressing.

Carbon fiber surface felt is usually used for thermal insulation, heat preservation, fire protection and other applications in high temperature environments, and can also be used as a strengthening layer of composite materials.

Its surface is flat and uniform, has good tensile strength and wear resistance, and is suitable for special needs in various industrial fields. In aerospace, automobile manufacturing, ship construction, energy industry and other fields, carbon fiber surface felt is widely used in parts manufacturing, insulation materials, composite material strengthening and so on, playing an important role.

Product features:

1. High strength: excellent tensile strength and wear resistance.

2. Light weight: Light weight is conducive to reducing the overall weight.

3. High temperature resistance: can maintain stability in high temperature environment.

4. Smooth surface: It has a smooth and even surface texture.

5. Wide range of uses: suitable for heat insulation, heat preservation, fire prevention and other application scenarios.

6. Reinforcement material: can be used as a reinforcement layer of composite materials.

Carbon Fiber Tube is a tubular product made of carbon fiber as a raw material. Carbon fiber tube with light weight, high strength, corrosion resistance, tensile resistance and other excellent properties, widely used in aerospace, navigation, automobile, sports equipment, mechanical equipment and other fields.

Product features:

1. Light weight and high strength: with excellent strength and stiffness, lighter than metal.

2. Corrosion resistance: Good resistance to chemical corrosion and oxidation.

3. High temperature performance: can maintain stability in high temperature environment.

4. Strong customization: length, diameter, wall thickness and other specifications can be customized according to demand.

5. Diversified applications: widely used in aerospace, navigation, automobiles, sports equipment and other fields.

6. Flexible manufacturing: It can be customized to meet the specific needs of different fields.

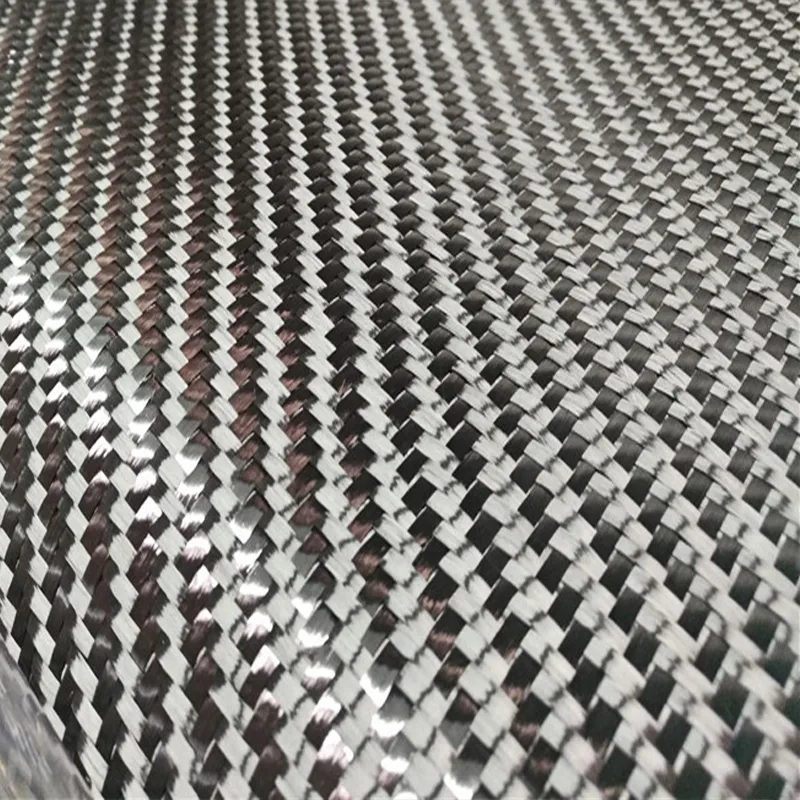

Carbon fiber woven fabric is a kind of material that uses carbon fiber as raw material and is woven by special process. It has the characteristics of light weight, high strength and good rigidity, and is often used in aerospace, automobile manufacturing, sports equipment and other fields, and can provide excellent strength and rigidity support. Carbon fiber bidirectional braided cloth is commonly used in the manufacture of reinforced composite materials, which can provide uniform strength support in different directions, and is a commonly used high-performance material.

Product features:

1.High strength: has excellent tensile strength, can provide good structural support.

2. Light weight: light weight is conducive to reducing the overall product weight and improving product performance.

3. Good rigidity: It has good rigidity and stability, which can effectively improve the strength and durability of the product.

4. Corrosion resistance: Excellent corrosion resistance, suitable for a variety of harsh environments.

5. Good wear resistance: It has good wear resistance and extends the service life of the product.

6. High temperature performance: can maintain stable performance in high temperature environment, suitable for applications under high temperature conditions.

Glass fiber axial fabric is a bidirectional reinforced glass fiber fabric made of direct glass fiber yarn arranged in the radial (0°) and latitudinal (90°) directions and warped by sewn thread. Warp knitted composite fabric can be made of short cut layer or nonwoven fabric, etc. The products are mainly used in pipeline, pultrusion profile, FRP sheet, wind power and sports equipment.

Product features:

1. Heat resistance: has good high temperature resistance, suitable for use in high temperature environment.

2. Insulation: with excellent insulation properties, it is often used in the manufacture of electrical insulation materials.

3. Mechanical properties: It has high tensile strength and stiffness to provide good structural support.

4. Tensile strength: has good tensile properties, can be used to strengthen the manufacture of materials.

5. Wear resistance: It has good wear resistance and extends the service life of the product.

6. Chemical corrosion resistance: It has certain chemical corrosion resistance and is suitable for applications in harsh environments.

Glass fiber fabric prepreg refers to impregnating glass fiber fabric with epoxy resin or phenolic resin as matrix under certain conditions to make semi-cured sheet products of resin matrix and glass fiber fabric, and is the intermediate material for manufacturing composite materials. The prepreg has the characteristics of high strength, low density, good plasticity and long life of the finished product. The products are mainly used in sports equipment, automobile appearance parts, insulation products, 3C electronics, transparent plates and other fields.

Product features:

1. High strength: The glass fiber has a high tensile strength, and the preparation process of the prepreg makes it better combined with the resin to provide excellent strength.

2. Light weight: Compared with traditional metal materials, glass fiber cloth prepreg has a lighter weight, helping to reduce the weight of the overall product.

3. Good rigidity: Glass fiber has good rigidity and stability, and can provide strong structural support.

4. Corrosion resistance: glass fiber has good resistance to chemical corrosion and is suitable for a variety of harsh environments.

5. High temperature resistance: glass fiber has good high temperature resistance and can maintain stable performance in high temperature environment.

6. Processability: the prepreg form makes the material easy to process and form, which can meet the complex shape and design needs.

Glass fiber multiaxial fabric is a multi-layer fabric made of glass fiber direct yarn evenly arranged at 0°, 90° and ±45° and in the direction. It can be divided into two-axis, three-axis and four-axis fabrics according to the product structure, and can also be combined into multi-axial composite fabrics such as short-cut layer or nonwoven fabric. Products are mainly used in wind power generation, pipeline, automotive parts, pultrusion profiles, FRP sheets and sports equipment and other fields.

Product features:

1. Multi-directional strength: It has a uniform distribution of strength in multiple directions to provide a full range of structural support.

2. Orientation: Fiber lamination from different angles can be selected according to the needs to meet the strengthening needs of specific directions.

3. Good formability: suitable for complex shape and surface molding, improve production efficiency.

4. Wear resistance: It has good wear resistance and extends the service life of the product.

5. Light weight: Compared with traditional materials, glass fiber multi-axis braided cloth is light in weight, which helps to reduce the overall product weight.

6. Chemical corrosion resistance: It has certain chemical corrosion resistance and is suitable for application in various environments.

Glass fiber unidirectional fabric is made of glass fiber direct yarn evenly arranged in the direction of 0° or 90° after sewing and knitting. It can be processed into unidirectional composite fabric with short cut layer or nonwoven fabric. Products are mainly used in winding pipes, pultrusion profiles, FRP sheets and sports equipment and other fields.

Product features:

1. Excellent strength: Very high strength in the direction of the fiber, providing excellent tensile and rigid properties.

2. High modulus: with high stiffness and stability, it can provide solid structural support.

3. Directivity: The fibers are arranged in a single direction, so that the material has a clear orientation and can meet the strengthening needs of a specific direction.

4. Good formability: suitable for complex shape and surface molding, improve production efficiency.

5. Lightweight: Compared with traditional metal materials, glass fiber unidirectional braided cloth is light in weight, which helps to reduce the weight of the overall product.

6. Corrosion resistance: good resistance to chemical corrosion, suitable for a variety of harsh environments.

7. Easy to stack and laminate: One-way cloth can be easily stacked and laminated with other materials to form a composite structure.

Glass fiber chopped strand mat is made by cutting the glass fiber raw yarn into a certain length and then applying powder or emulsion to bond it. It can be combined with polyvinegar surface felt to make polyvinegar chopped strand mat. Products are mainly used in hand paste FRP, auto parts, ships and yachts, sanitary ware, mechanical plates, pultrusion profiles and other fields.

Product features:

1. Fast penetration: It has good resin penetration, which is conducive to resin penetration and molding in the production process.

2. Formability: easy to form, suitable for complex shape and surface manufacturing, improve production efficiency.

3. Good coverage: It can cover the uneven part of the surface and provide uniform strengthening support.

4. Chemical corrosion resistance: It has certain chemical corrosion resistance and is suitable for use in various harsh environments.

5. Heat resistance: It has good heat resistance in a certain temperature range, and is suitable for application in high temperature environment.

Glass fiber Knitted combo mat is knitted by cutting the glass fiber ply yarn to a certain length and stitching it with knitted thread. Glass fiber surface felt, carbon fiber surface felt or polyacetate surface can be used to produce knitted (stitched) composite felt. The products have the characteristics of high strength, quick penetration of resin, smooth surface of finished products, etc., mainly used in winding pipes, pultrusion profiles, environmental protection equipment, car plate and other fields.

Product features:

1. Multi-layer structure: It is braided by multiple layers of fibers in different directions to provide a full range of strengthening support.

2. Uniform distribution: The fibers are evenly distributed throughout the structure, providing balanced strength and stiffness.

3. Good formability: suitable for complex shape and surface molding, can meet various design requirements.

4. Lightweight: Compared with traditional materials, glass fiber knitted composite felt is light in weight, helping to reduce the overall product weight.

5. Wear resistance: It has good wear resistance and extends the service life of the product.

6. Corrosion resistance: It has certain resistance to chemical corrosion and is suitable for use in various harsh environments.

7. Easy to stack and laminate: Knitted composite felt can be easily stacked and laminated with other materials to form a composite structure.

Glassfiber surface mat is made of wet forming process, the product has the characteristics of flat surface and corrosion resistance. According to the product use can be divided into surface felt, roof felt, floor felt, insulation felt and so on. The products are mainly used in winding pipes, insulation and sound insulation, new building materials, new energy vehicles, environmental protection and other fields.

Product features:

1. Flat surface: It has a flat and smooth surface, which can provide a good appearance.

2. Uniform distribution: The fibers are evenly distributed throughout the structure, providing balanced strength and stiffness.

3.Good penetration: It has good resin penetration, which is conducive to the penetration and curing of the resin.

4. Enhance adhesion: It can enhance the adhesion between the resin and improve the durability and stability of the material.

5. Wear resistance: It has good wear resistance and extends the service life of the product.

6. Corrosion resistance: It has certain resistance to chemical corrosion and is suitable for use in various harsh environments.

7. Easy to operate: the surface felt has good clementability and plasticity, easy to operate and apply.

Glass fiber twisted fabric is a flat multidirectional reinforced fabric made of single or double twisted yarn of glass fiber woven by air jet or rapier loom, and its organizational structure is plain, twill and satin. The products are mainly used in glass fiber prepreg, aerospace, electronic appliances, sports equipment, new energy vehicles, photovoltaic and other fields.

Product features:

1. High strength: Excellent tensile strength and bending strength to provide excellent mechanical properties.

2. Good flexibility: with high flexibility and adaptability, it is suitable for applications that require bending or curved shapes.

3. Corrosion resistance: It has certain resistance to chemical corrosion and is suitable for use in various harsh environments.

4. Good wear resistance: It has good wear resistance and extends the service life of the product.

5. Lightweight: Compared with traditional materials, light weight helps to reduce the overall product weight.

6. Easy to process: twist fabric is easy to cut and sew, easy to process and manufacture.

7. Good formability: suitable for the forming and manufacturing of various complex shapes and structures.

Glass fiber woven roving combo mat is made of glass fiber woven roving combo mat and short cut layer. Glass fiber woven roving combo mat can be added to the surface to make multi-layer composite products. It has the characteristics of high product strength, fast resin penetration, and can reduce layup operation, etc. It is mainly used in the fields of new energy vehicles, pipeline repair, pultrusion profiles, environmental protection equipment, and cabin plates.

Product features:

1. High strength: high tensile strength and bending strength, providing excellent mechanical properties.

2. High stiffness: It has high stiffness and can provide good support performance.

3. Strong directivity: The fiber is woven in a specific direction and has obvious directivity, which is suitable for applications requiring specific strength directions.

4. Good formability: easy to form, suitable for the manufacture of complex shapes and structures.

5. Corrosion resistance: It has certain resistance to chemical corrosion and is suitable for use in various harsh environments.

6. Lightweight: Compared with traditional metal materials, light weight helps to reduce the overall product weight.

7. Easy to stack and laminate: It can be stacked and laminated with other materials to form a composite structure.

Glass fiber woven roving, also known as glass fiber plaid cloth, is made of glass fiber roving without twist by high-speed rapier loom woven into the flat two-way reinforced fabric, its structure is plain and twill. The products are mainly used in glass fiber prepreg, FRP sheet, environmental protection equipment, winding pipes, auto parts and ships and yachts and other fields.

Product features:

1. High strength: with high tensile strength and bending strength, providing excellent mechanical properties.

2. Strong rigidity: It has high rigidity and can provide good support performance.

3. Strong directivity: The fiber is woven in a specific direction and has obvious directivity, which is suitable for applications requiring specific strength directions.

4. Corrosion resistance: It has certain resistance to chemical corrosion and is suitable for use in various harsh environments.

5. Good wear resistance: It has good wear resistance and extends the service life of the product.

6. Lightweight: Compared with traditional metal materials, light weight helps to reduce the overall product weight.

7. Easy to stack and laminate: It can be stacked and laminated with other materials to form a composite structure.

Our MOQ is usually 1x20ft container.But we accept lower quantity for your trial order. Please feel free to inform us your plan for

purchasing, we will offer the price correspond to your qty. And we hope your would increase your order qty after you check our

product quality and know our services.

We ship the goods via Shanghai port.

We can do custom color when reach our MOQ qty.

Our regular colors are white, yellow, green, blue, orange, red etc

For printing label design, we need AI or PDF file for set up the print-plate.

The time of delivery is about 20~30days after we receive the deposit.

Usually we will take 7-10 days to make the samples.

By sea to your designated port.

1. Irrevocable L/C, Cash, PayPal, Credit card and T/T money transfers.

2.30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo.

3.L/C ( Irrevocable LC at sight)

If you need custom size such as gram weight and mesh size etc or private logo pls feel free inquiry us!

16 years + Manufacturer of Fiberglass mesh & Tapes Products, Don’t miss the opportunity to get the best quality products with the most competitive price.

Factory add:Fangxian Town, Danyang, Jiangsu, China, 212333

16 years + Manufacturer of Fiberglass mesh & Tapes Products, Don’t miss the opportunity to get the best quality products with the most competitive price.

Factory add:Fangxian Town, Danyang, Jiangsu, China, 212333

Danyang NQ Sport And Fitness Co., Ltd

16 years + Manufacturer of Fiberglass mesh & Tapes Products, Don’t miss the opportunity to get the best quality products with the most competitive price.

Factory add:Fangxian Town, Danyang, Jiangsu, China, 212333