Products Categories

Featured Products

Thin Wall Carbon Fiber Tube

Thin Wall Carbon Fiber Tubes are made from high-strength carbon fiber, offering an excellent strength-to-weight ratio and superior stiffness. Their corrosion resistance and precise dimensions reduce maintenance and improve durability. The lightweight design helps lower overall product weight, enhancing performance and service life, making them ideal for high-performance, lightweight structural applications.

Product MOQ

Please note our minimum order quantity of Carbon Fiber Tube. For the conventional Carbon Fiber Tube in stock, there is no MOQ. For customized Carbon Fiber Tube, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

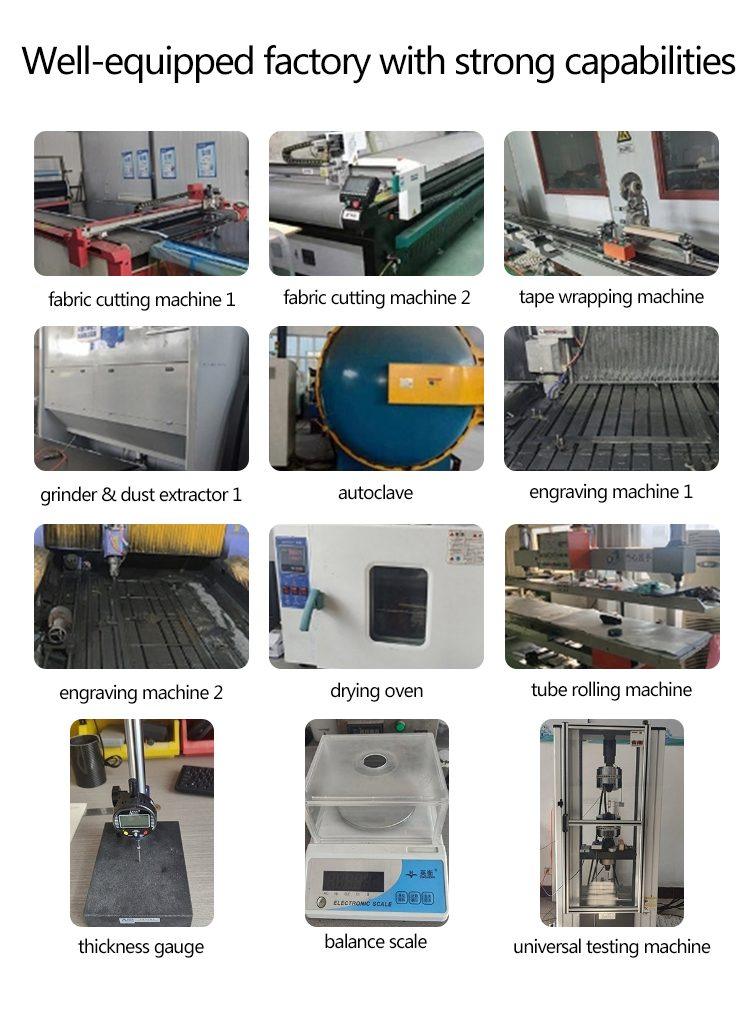

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

- Thin Wall Carbon Fiber Tube, as a tubular structure made of carbon fiber composite materials, is characterized by its thin walls, lightweight, and high strength. It is primarily constructed from continuous carbon fibers or carbon fiber chopped strands through processes such as weaving, layering, and subsequent high-temperature curing and finishing to form a tubular product with high strength, high modulus, and low density.

- In terms of factory customization, the ability to customize Thin Wall Carbon Fiber Tubes largely depends on the precision of production equipment, mastery of process technology, and the selection of raw materials. First, high-precision production equipment ensures dimensional accuracy and shape stability of the carbon fiber tubes. Second, advanced process technology enables precise control of the structure and properties of the carbon fiber tubes. Finally, high-quality raw materials serve as the foundation for manufacturing high-performance carbon fiber tubes.

- Furthermore, factories can customize carbon fiber tubes according to specific customer needs, such as altering the tube diameter, wall thickness, length, and other dimensional parameters, or adjusting the arrangement and density of carbon fibers to meet the requirements of different applications. During the customization process, factories can also provide technical consultation and after-sales service to ensure that customers can fully utilize the performance advantages of carbon fiber tubes for optimized product design and manufacturing.

- In summary, Thin Wall Carbon Fiber Tube, as a high-performance composite tubular structure, possesses extensive customization capabilities and promising application prospects.

Specification

- Outer Diameter (OD): 1mm – 100mm (customizable)

- Wall Thickness: 0.2mm – 2.0mm

- Inner Diameter (ID): Calculated based on OD and wall thickness

- Length: Standard 1000mm; custom lengths up to 3000mm or more

- Carbon Fiber Type: T300 / T700 / Toray or equivalent high-strength carbon fibers

- Weave Styles:

- Unidirectional (UD)

- Twill Weave (3K/6K/12K)

- Plain Weave (3K/6K/12K)

- Resin Matrix: High-performance epoxy resin (optional high-temperature or flame-retardant systems)

- Tensile Strength: ≥ 1000 MPa

- Flexural Strength: Up to 1200 MPa

- Elastic Modulus: 60 – 120 GPa

- Density: Approx. 1.5 – 1.6 g/cm³

- Surface Options: Glossy, matte, sanded, 3K twill/3K plain texture

- Outer/Inner Diameter Tolerance: ±0.05mm to ±0.1mm

- Concentricity Tolerance: ≤ ±0.1mm

- Roundness & Straightness: Maintained by precision-controlled mandrel winding or roll-wrapping

- Custom Dimensions: Tailored OD, ID, wall thickness, and length

- Fiber Orientation Options: 0°/90°, ±45°, or hybrid lay-up for enhanced strength and stiffness

- Machining Services: Precision cutting, drilling, slotting, sealing, and surface coating

- Optional Treatments: UV protection, high-temperature resistance, electrical insulation or conductivity

Main applications

Aerospace Industry

- Due to its high strength, high modulus, and low density, Thin Wall Carbon Fiber Tube finds extensive use in the aerospace industry.

- As a crucial structural material, it plays a significant role in missiles, space platforms, and launch vehicles.

- The application of carbon fiber tubes significantly reduces the weight of spacecraft, improving flight efficiency and enhancing structural strength.

New Energy Equipment

- In the wind power sector, Thin Wall Carbon Fiber Tube is used to manufacture wind turbine blades, leveraging its lightweight and high-strength properties for greater efficiency and durability.

- Carbon fiber tubes are also applied in other new energy equipment, such as fuel cells, supporting the development of new energy industries.

Automotive Industry

- The automotive industry increasingly utilizes Thin Wall Carbon Fiber Tube for body structures, chassis components, drive shafts, and more.

- The lightweight nature of carbon fiber tubes helps reduce the overall weight of vehicles, improving fuel efficiency and reducing emissions.

- Additionally, the high strength and modulus of carbon fiber tubes contribute to a more robust and stable vehicle structure.

Sports Equipment

- Thin Wall Carbon Fiber Tube is widely used in sports equipment, including golf clubs, bicycle frames, fishing rods, and more.

- The lightweight yet highly durable nature of carbon fiber tubes enhances the performance of sports equipment, improving athletes’ competitive edge.

Other Fields

- Carbon fiber tubes are also applied in public infrastructure, medical devices, engineering machinery, and other areas.

- The superior properties of carbon fiber tubes offer numerous possibilities for product design and manufacturing in these diverse fields.

Features

- High Strength-to-Weight Ratio

Carbon fiber tubes provide superior strength while being significantly lighter than metals. This helps buyers reduce product weight without compromising durability, ideal for aerospace, robotics, and sports equipment. - Excellent Stiffness and Rigidity

Thin wall carbon fiber tubes maintain high stiffness, ensuring structural stability and precision. Buyers benefit from enhanced performance in applications requiring minimal deflection, such as drone arms and camera rigs. - Corrosion and Chemical Resistance

Unlike aluminum or steel, carbon fiber tubes resist corrosion and chemical damage. This improves product longevity and reduces maintenance costs, especially in harsh or outdoor environments. - Fatigue Resistance and Durability

These tubes withstand repeated stress and vibration without cracking or weakening. Buyers enjoy longer service life and reduced replacement frequency in demanding industrial or automotive uses. - Precision Manufacturing and Custom Sizes

Available in tight tolerances with customizable diameters and wall thicknesses, carbon fiber tubes fit exact design requirements, saving buyers time in assembly and ensuring consistent quality.

For more product specifications, please contact our professionals!

By adopting CNC precision processing technology and automatic detection systems and integrating automated winding, curing, and cutting processes, the production speed is increased by 20% to 30%. Multi-station collaborative operation reduces manual intervention and reduces the error rate.

- Compatible with carbon fiber prepregs such as T300, T700, T800

- Supports a variety of resin systems such as epoxy and phenolic

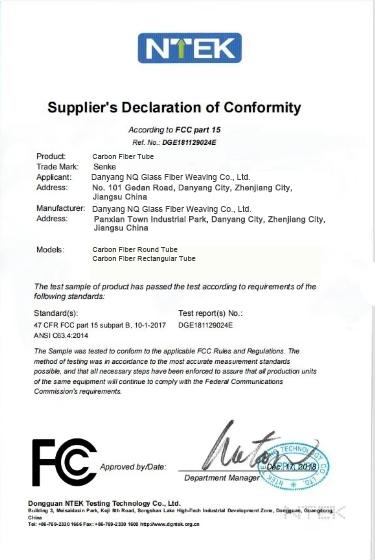

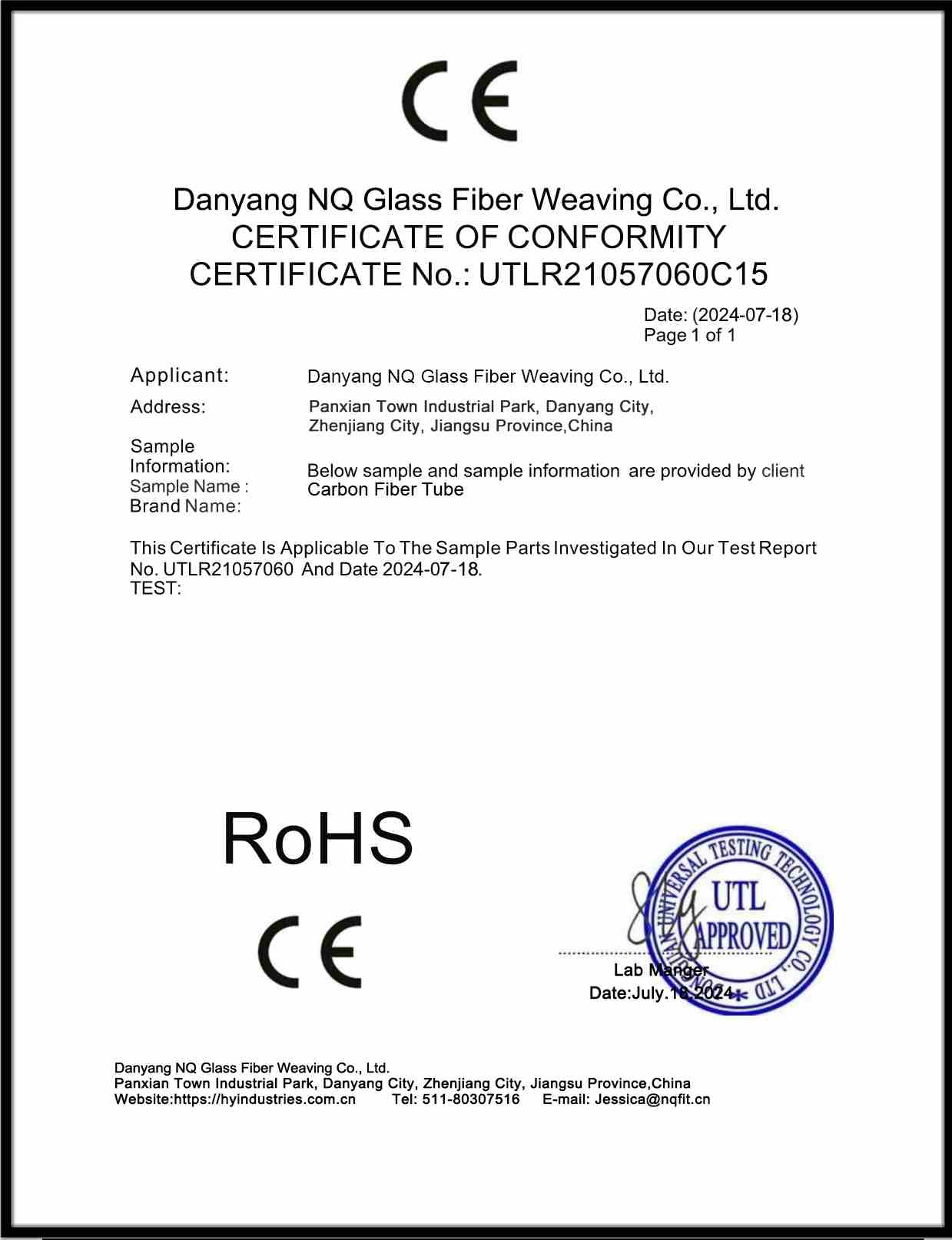

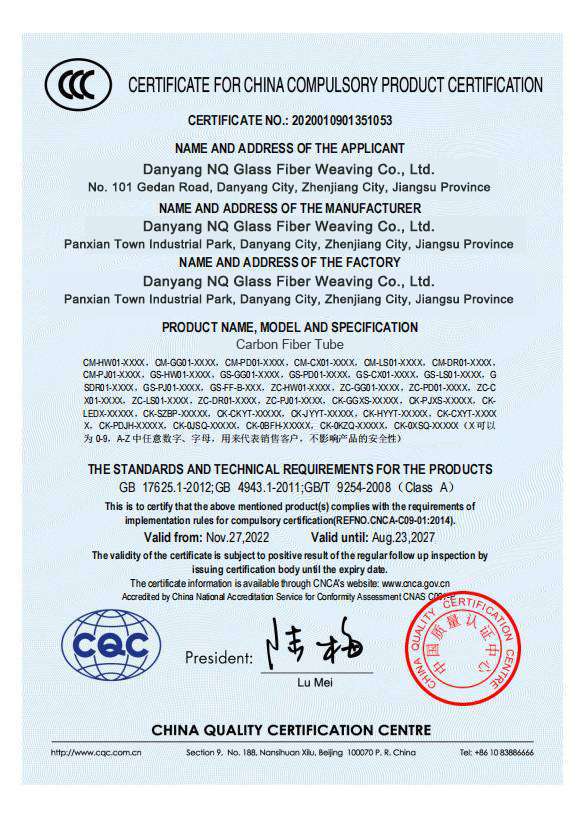

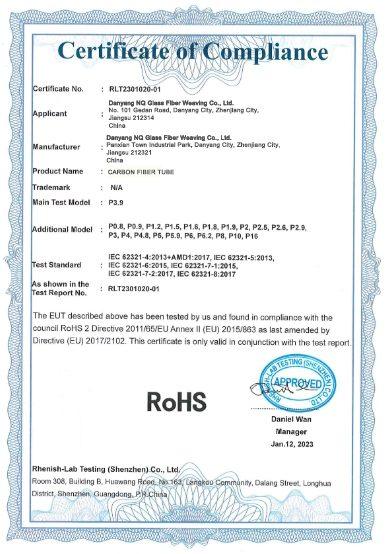

- ISO 9001, CE, SGS, and ASTM standards

- 40 automated production lines to ensure on-time delivery

- In-house Strictly Testing Lab for 6-step internal inspection

Enhance Performance, Simplify Processing, Reduce Costs

Experience the power of Carbon Fiber Tubes—lightweight, ultra-strong, and corrosion-resistant. Perfect for industries demanding high performance and durability. Elevate your products with precision-engineered tubes that combine advanced materials with cutting-edge manufacturing. Choose carbon fiber tubes for unmatched strength, reduced weight, and superior reliability.