Products Categories

Featured Products

Octagonal Carbon Fiber Tube

Octagonal carbon fiber tube is a high-performance composite tube made from premium carbon fiber and epoxy resin, featuring a unique octagonal cross-section. It offers lightweight construction, high strength, excellent rigidity, and superior dimensional stability, along with strong corrosion and aging resistance. The tube provides stable structure and reliable performance.

Product MOQ

Please note our minimum order quantity of Carbon Fiber Tube. For the conventional Carbon Fiber Tube in stock, there is no MOQ. For customized Carbon Fiber Tube, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

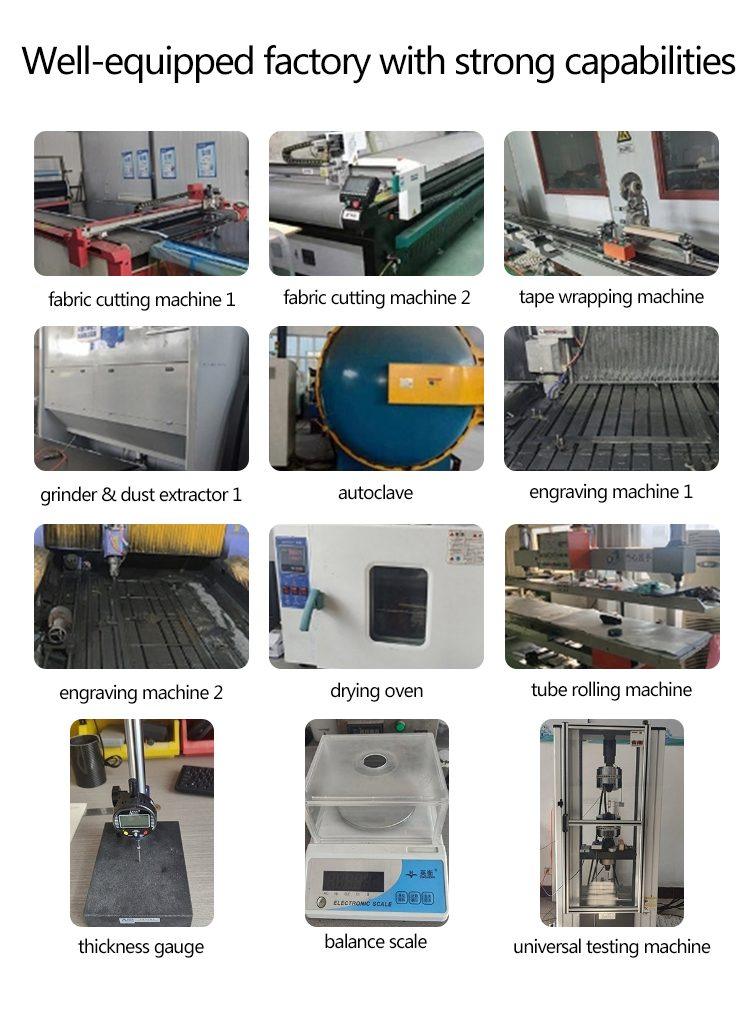

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

- The Octagonal Carbon Fiber Tube is a carbon fiber tube with an octagonal shape that possesses the typical characteristics of carbon fiber materials, including high strength, high modulus, lightweight, corrosion resistance, and excellent high-temperature performance. The octagonal design may be chosen for specific structural or performance requirements, such as enhancing structural strength in certain directions or optimizing fluid dynamics.

- In terms of customization, factories offer significant flexibility due to the high processability of carbon fiber materials. The Octagonal Carbon Fiber Tube can be customized according to specific demands, including different dimensions, wall thicknesses, lengths, and surface treatments. Additionally, some factories possess advanced production techniques, such as 3K braiding technology, which can provide Octagonal Carbon Fiber Tubes with superior surface quality and structural strength.

- Moreover, factories can also customize the Octagonal Carbon Fiber Tube to meet specific mechanical, thermal, or electrical properties required by customers. This can be achieved by adjusting the carbon fiber content, resin type, or additive formulations. Such customization capabilities enable the Octagonal Carbon Fiber Tube to fulfill various complex and specialized application needs.

Specification

- Side Length:

Typically ranges from 5 mm to 40 mm, customizable upon request. - Flat-to-Flat Width:

Approximately Side Length × 2.414, based on octagonal geometry. - Wall Thickness:

Standard options include 0.5 mm, 1.0 mm, 1.5 mm, and 2.0 mm, with multi-layer designs available. - Length:

Standard lengths are 1000 mm and 2000 mm, with custom lengths up to 3000 mm+. - Material:

- Carbon fiber types: T300, T700, T800 high-strength carbon fabrics

- Resin system: Primarily epoxy resin, offering excellent mechanical properties and corrosion resistance

- Surface Finish:

- Glossy

- Matte

- Visible weave patterns (3K Twill, Plain weave)

- Manufacturing Process:

- Roll-wrapping

- Compression molding

Main applications

Aerospace Industry

- The Octagonal Carbon Fiber Tube finds crucial application in the aerospace industry due to its lightweight, high strength, corrosion resistance, and high-temperature tolerance. It is an ideal material for manufacturing structural components of aerospace vehicles. For instance, it is used in missile weaponry for components like missile body fairings and composite brackets. In space platforms, it is extensively utilized in satellite and space station structures such as load-bearing cylinders and honeycomb panels. It also plays a pivotal role in the construction of carrier rockets, including the rocket body fairing and instrument compartment.

Automotive Industry

- In the automotive industry, the Octagonal Carbon Fiber Tube is primarily applied for vehicle lightweighting. Carbon fiber composite materials possess excellent specific strength and specific modulus, enabling significant weight reduction of the vehicle body, thereby reducing fuel consumption and enhancing performance. Carbon fiber wheel hubs also contribute to improved driving safety and durability.

Sporting Equipment

- The Octagonal Carbon Fiber Tube is increasingly used in the manufacturing of sporting equipment. Its high strength and lightweight properties make it a perfect choice for high-performance sports equipment. For instance, in cycling, fully carbon fiber bicycles are favored by professional cyclists for their lightness and sturdiness. In golf clubs, the application of carbon fiber material results in clubs that are more lightweight, flexible, and enhance ball speed and accuracy.

Energy Sector:

- In the energy sector, the Octagonal Carbon Fiber Tube is utilized in the construction of solar panels and wind turbine support structures. Carbon fiber exhibits excellent electromagnetic and mechanical properties, enhancing the photovoltaic conversion efficiency and seismic resistance of solar panels. Its lightweight and high-strength characteristics also ensure stability and durability in wind turbine support structures.

Navigation and Power Systems

- The Octagonal Carbon Fiber Tube also plays a significant role in navigation equipment and power systems in the aviation industry. Carbon fiber materials possess low damping properties and excellent electromagnetic shielding capabilities, making them ideal for navigation equipment. Furthermore, carbon fiber composite engine blades exhibit better heat resistance and corrosion resistance, improving engine efficiency and longevity.

Features

- Lightweight yet Strong

Offers a high strength-to-weight ratio, reducing overall product weight without compromising durability—ideal for cost-effective transportation and handling. - Superior Structural Rigidity

The octagonal shape provides enhanced stiffness and resistance to bending and torsion compared to circular tubes, improving product reliability. - Precise Fit and Easy Assembly

Flat faces on the octagonal profile enable better alignment and secure connections, simplifying installation and reducing assembly time. - Excellent Corrosion and Chemical Resistance

Made with high-quality carbon fiber and epoxy resin, it withstands harsh environments, minimizing maintenance and replacement costs. - High Dimensional Stability

Maintains shape and performance under temperature changes and mechanical stress, ensuring consistent quality and long service life. - Customizable Specifications

Available in various sizes, wall thicknesses, and finishes, allowing buyers to tailor tubes to their exact project needs and optimize performance. - Enhanced Aesthetic Appeal

Smooth finishes and visible weave patterns add a premium look, enhancing product value for end users.

For more product specifications, please contact our professionals!

By adopting CNC precision processing technology and automatic detection systems and integrating automated winding, curing, and cutting processes, the production speed is increased by 20% to 30%. Multi-station collaborative operation reduces manual intervention and reduces the error rate.

- Compatible with carbon fiber prepregs such as T300, T700, T800

- Supports a variety of resin systems such as epoxy and phenolic

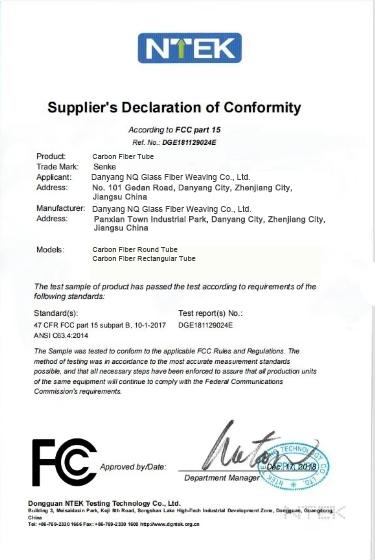

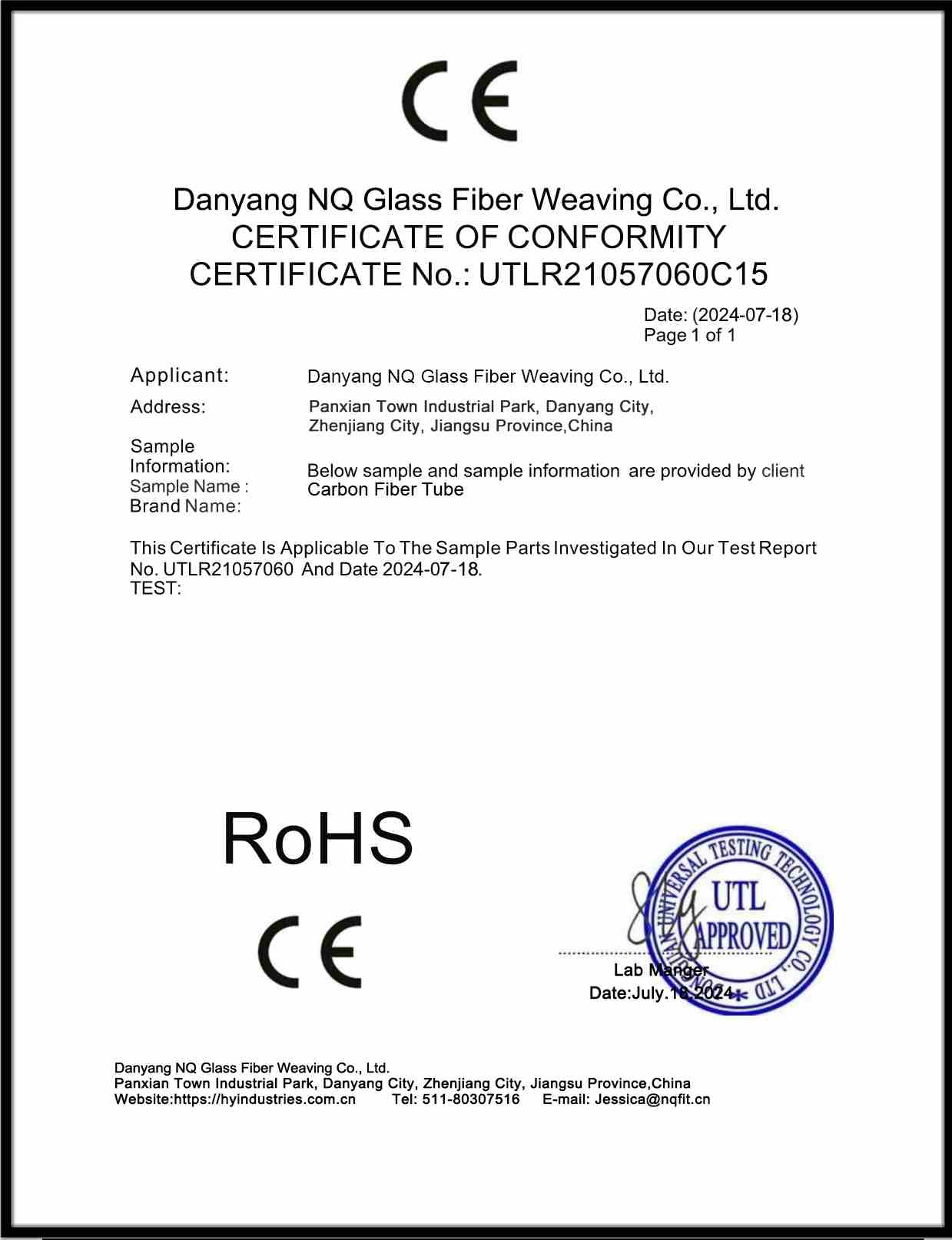

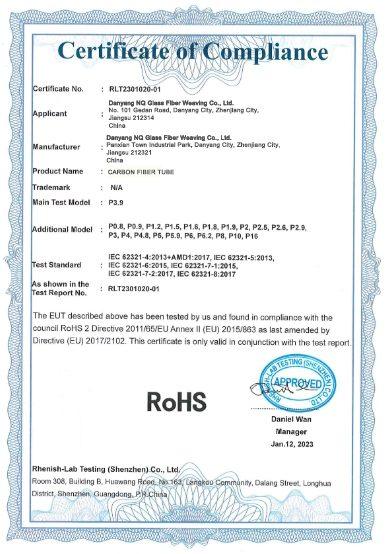

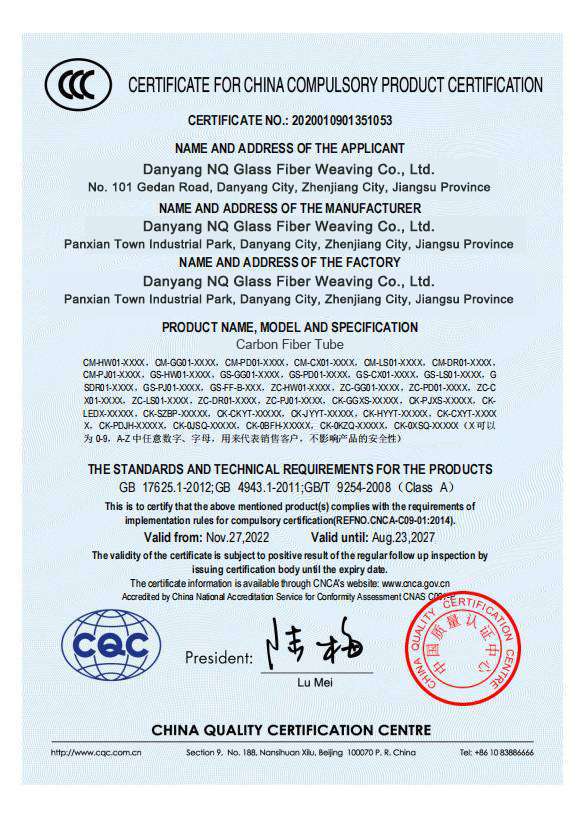

- ISO 9001, CE, SGS, and ASTM standards

- 40 automated production lines to ensure on-time delivery

- In-house Strictly Testing Lab for 6-step internal inspection

Enhance Performance, Simplify Processing, Reduce Costs

Experience the power of Carbon Fiber Tubes—lightweight, ultra-strong, and corrosion-resistant. Perfect for industries demanding high performance and durability. Elevate your products with precision-engineered tubes that combine advanced materials with cutting-edge manufacturing. Choose carbon fiber tubes for unmatched strength, reduced weight, and superior reliability.