- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

Our fiberglass tapes come in resin, PTFE (Teflon), and epoxy-coated types, offering high strength, heat resistance, chemical durability, and long-term stability. Ideal for insulation, sealing, reinforcement, and structural repairs across industrial, electrical, and marine applications.

Please note the minimum order quantity for our Fiberglass Mesh Tape. There is no minimum order quantity for regular stock Fiberglass Mesh Tape. The minimum order quantity for custom Fiberglass Mesh Tape needs to be confirmed based on actual conditions, as custom requirements vary.

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

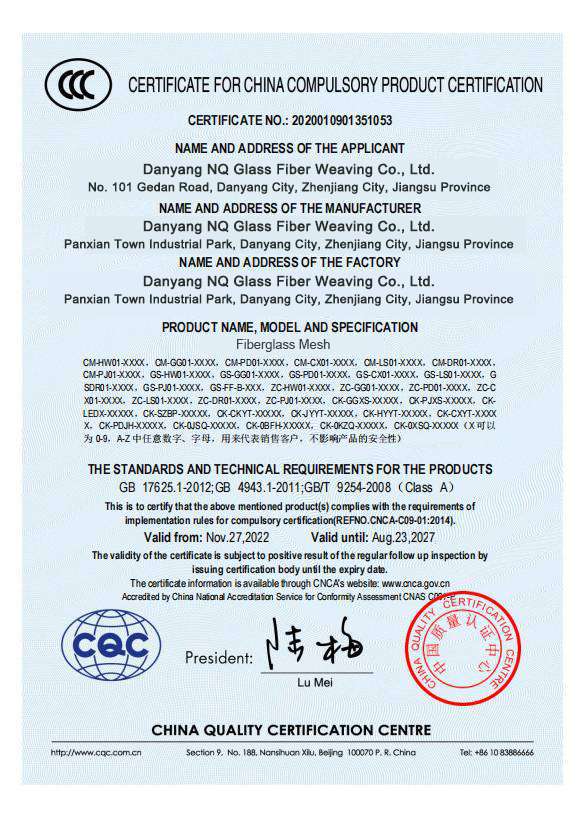

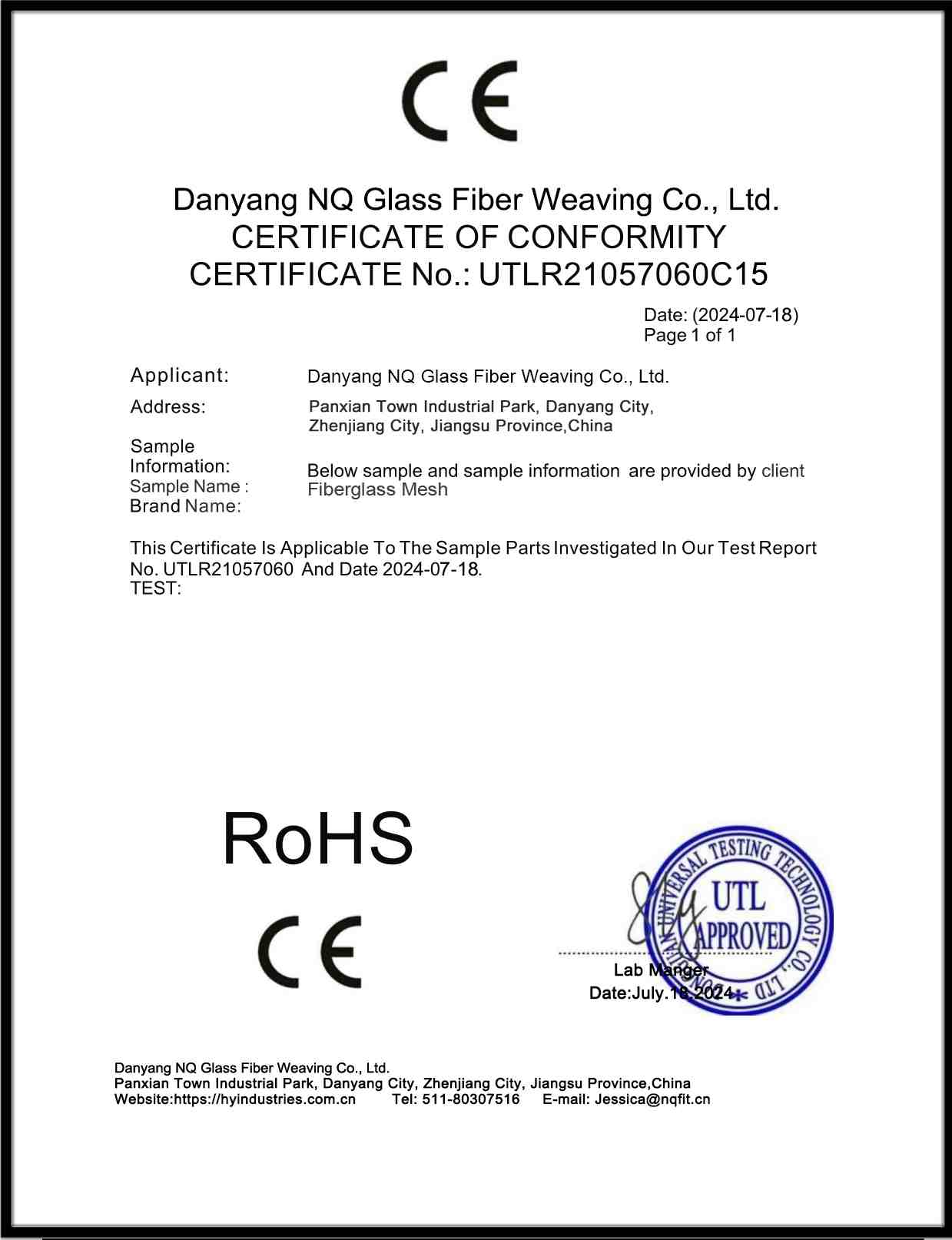

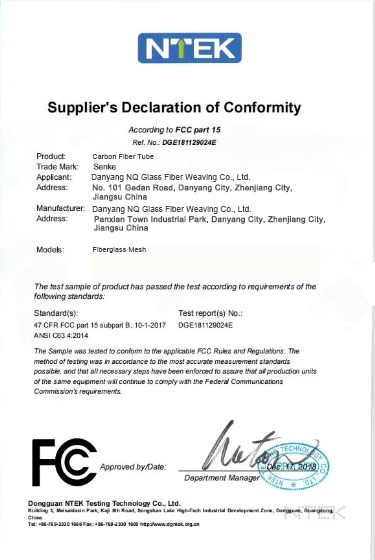

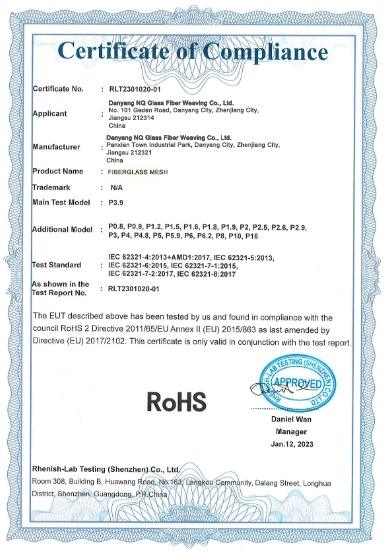

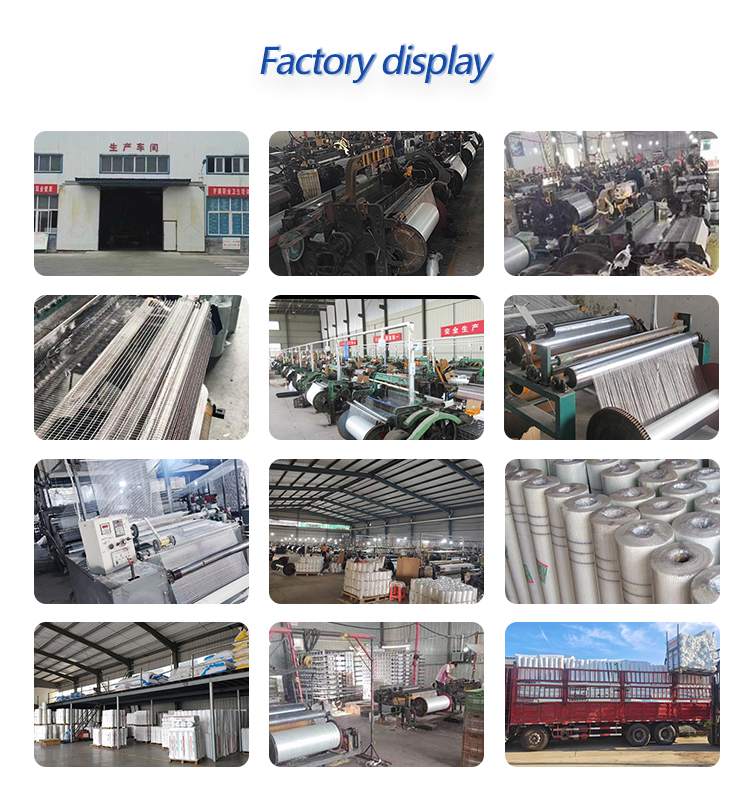

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Fiberglass manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

Fiberglass Resin Tape Performance

Fiberglass Tape Coated with Teflon (PTFE) Performance

Fiberglass Tape Coated Epoxy Performance

Mesh size | 5×5 MM, 4×4 MM, 3×3 MM |

Weight/square meter | 60g-300g,customize |

Width | 0.5m-2m,customize |

Application | Construction, packaging, electronics and automotive industries for wall enhancement, waterproofing, insulation and fixing. |

Length | 50m-300m,customize |

fiberglass sample | free sample |

packing | Plastic Bag , PE Bag , Woven Bag |

colors | White Blue Orange Yellow etc |

Customer Logo | customize |

Fiberglass Tape | Density Count/25mm | Unit Weight | Tensile Strength N/5CM X20CM | Tensile Strength N/5CM X20CM | Woven Structure | Content of Resin % | |

Warp | Weft | g/m2 | Warp | Weft | |||

RD55-8**8 | 8 | 8 | 55 | 550 | 450 | leno | 28±2 |

RD60-8*8 | 8 | 8 | 60 | 550 | 450 | leno | 28±2 |

RD60-9*9 | 9 | 9 | 60 | 550 | 500 | leno | 28±2 |

RD65-9*9 | 9 | 9 | 65 | 550 | 550 | leno | 28±2 |

RD70-9*9 | 9 | 9 | 70 | 550 | 600 | leno | 28±2 |

RD75-9*9 | 9 | 9 | 75 | 550 | 650 | leno | 28±2 |

RD110-5*5 | 5 | 5 | 110 | 1000 | 1000 | leno | 28±2 |

For more product specifications, please contact our professionals!

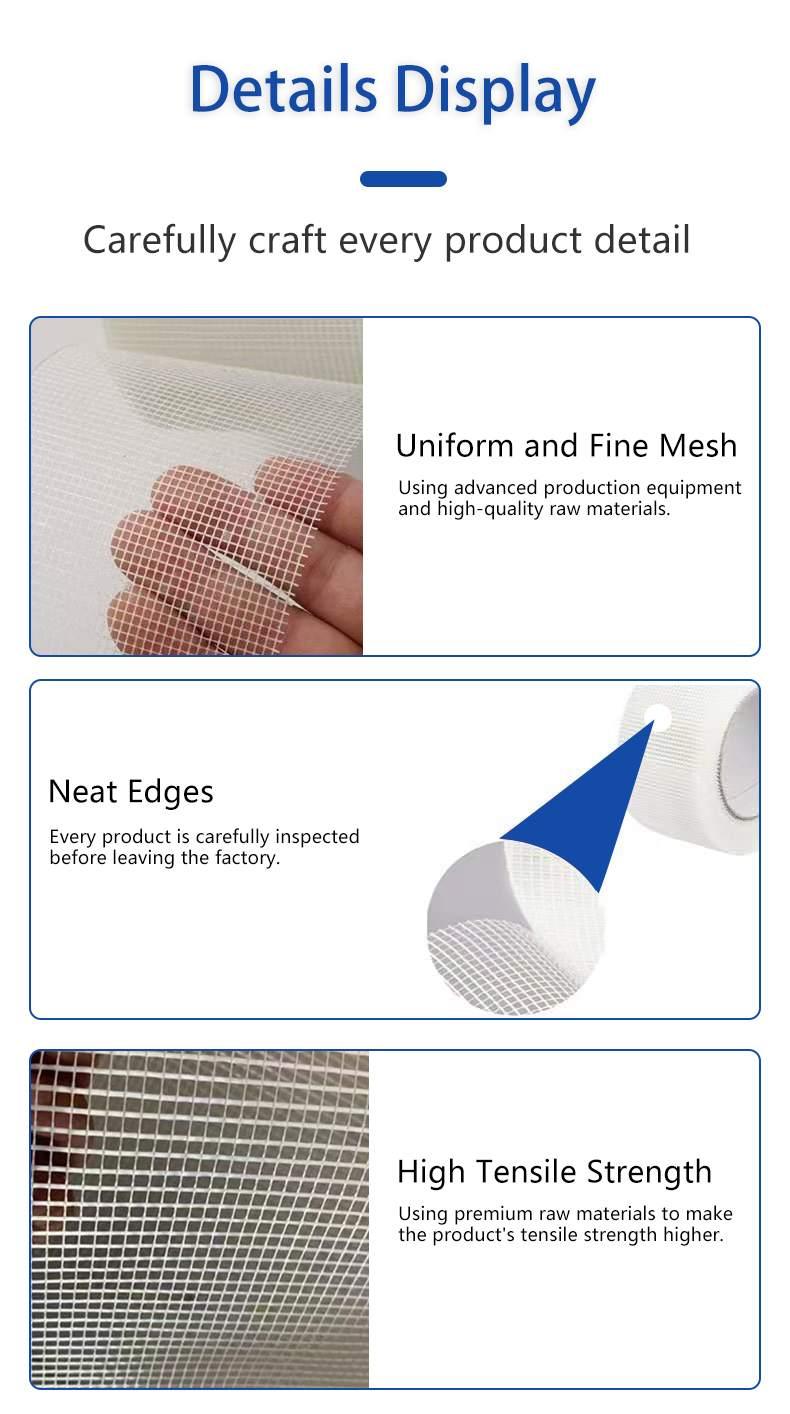

Effortless Reinforcement with Premium Adhesive-Backed Fiberglass Mesh Tape

High-strength Fiberglass Mesh Tape offers superior alkali resistance and crack prevention with an easy self-adhesive backing for fast, hassle-free installation. Reduce labor and material costs while ensuring durable reinforcement for drywall joints. Choose our reliable tape for efficient, high-quality results every time.

© All Rights Reserved.