- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

Fiberglass is stronger than steel but lighter than aluminum—sounds intriguing, right? This remarkable material is used in everything from building construction to aerospace engineering. With its unique combination of strength, lightness, and flexibility, fiberglass continues to shape industries worldwide.

In this guide, we’ll explore what fiberglass is made of, how it’s created, and why it’s become an essential material for so many applications. Ready to dive deeper into the science behind fiberglass? Let’s get started!

Table of Contents

ToggleFiberglass is a strong, lightweight material made from fine glass fibers that are woven together and often coated with a resin. It’s known for its incredible versatility and is used in a wide variety of industries, including construction, automotive, and marine. But what makes it so special? Let’s take a closer look.

Fiberglass is a composite material made from a combination of glass fibers and resin, designed to offer strength, durability, and flexibility. Here’s a breakdown of its key components:

The core of fiberglass is glass fibers, which are thin strands of glass formed through a specific manufacturing process. These fibers are known for their exceptional tensile strength and flexibility.

These glass fibers are drawn into fine threads that can be woven into fabrics, mats, or chopped into small pieces, depending on the application.

Resin is used to bind the glass fibers together and enhance the fiberglass material’s overall strength. There are two primary types of resin used in fiberglass production:

Epoxy Resin: Known for its superior strength and resistance to environmental factors such as moisture and heat. Epoxy-based fiberglass is commonly used in aerospace, automotive, and marine applications where durability is key.

Polyester Resin: More affordable and often used in general applications like boat hulls and insulation. It offers good mechanical properties but is less resistant to heat and chemicals compared to epoxy resin.

The resin hardens when mixed with a catalyst and forms a strong matrix that holds the glass fibers in place, giving the material its final shape and strength.

In addition to glass fibers and resin, various additives are included depending on the intended use of the fiberglass. These may include:

These additives help tailor the fiberglass material for specific requirements, enhancing its performance and extending its lifespan.

The process of making fiberglass is a fascinating combination of science and craftsmanship. Here’s a step-by-step walk-through of how fiberglass is manufactured, from raw materials to the final product.

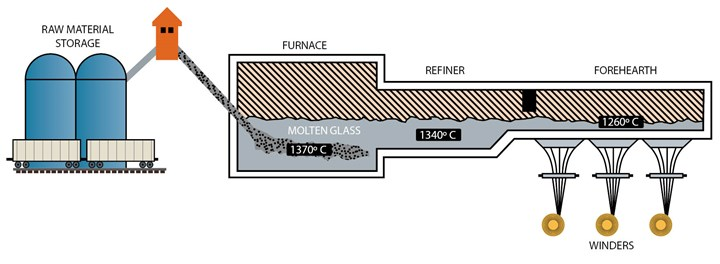

The first step in making fiberglass is melting the raw materials into molten glass. This is where it all begins!

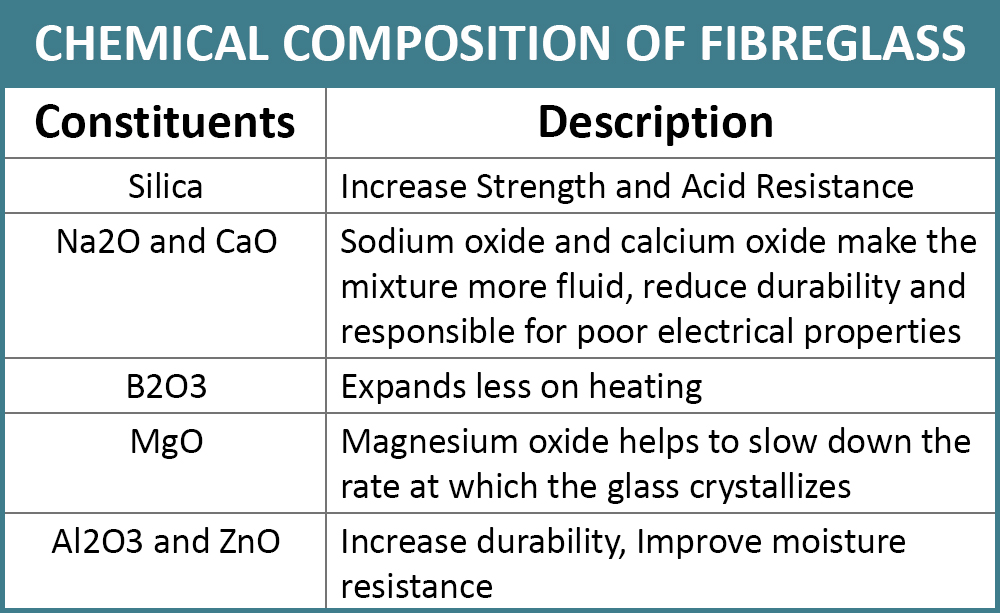

• Raw Materials: The main ingredients include silica (sand), soda-lime, boron, and other compounds. These are mixed in the right proportions to ensure high-quality glass fibers.

• High-Temperature Furnace: The materials are placed in a furnace, where they are heated to temperatures around 1,400°C to 1,600°C. This intense heat causes the raw materials to melt into a liquid form, creating molten glass.

Once melted, the glass is ready to be drawn into fibers. It’s the strength and flexibility of these fibers that give fiberglass its unique properties.

After the glass has melted, the next step is to turn it into fine fibers. This is done by drawing the molten glass through a series of small holes, also known as spinnerets.

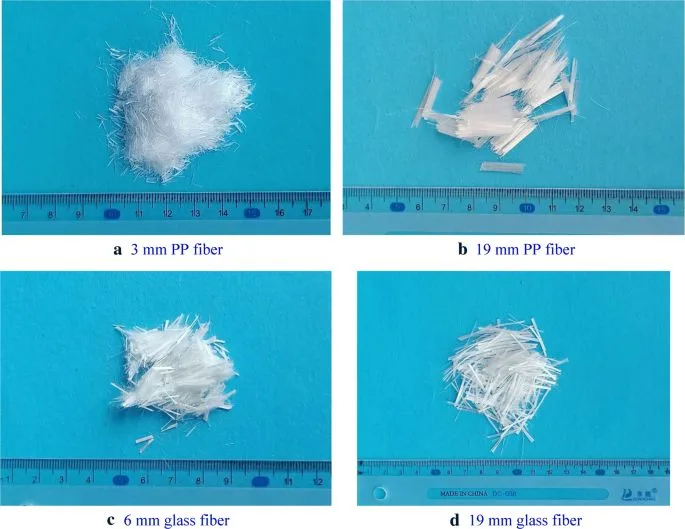

• Drawing Process: The molten glass is pulled into long, thin strands of fiber. The fibers are drawn out under mechanical tension, making them incredibly fine—about 5 to 20 microns in diameter.

• Cooling: As the glass fibers are drawn out, they cool rapidly and solidify. This cooling process gives the fibers their final form.

At this stage, the fibers are strong and flexible, which is why fiberglass can be used in so many different applications.

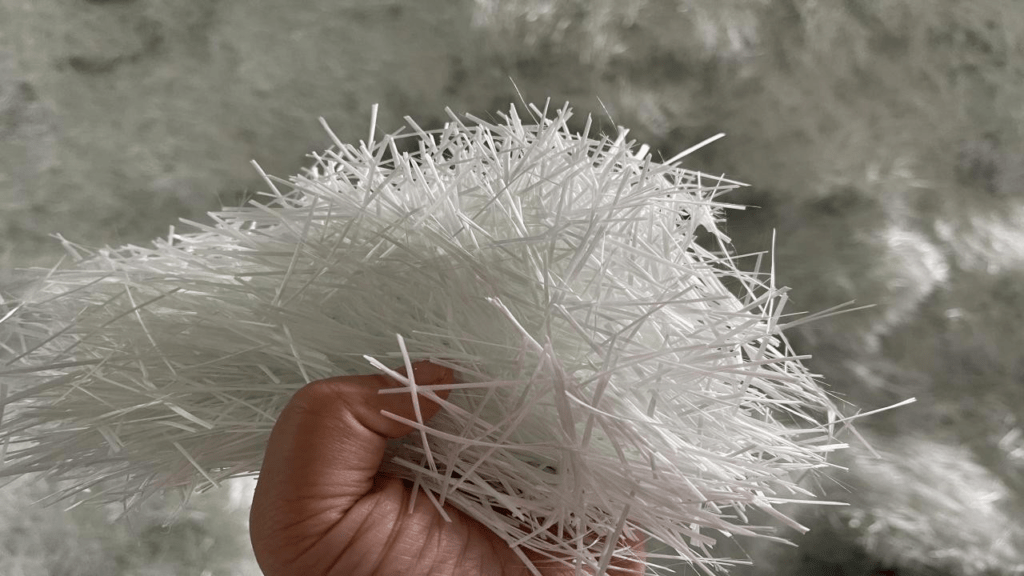

Once the fibers are drawn, the next step depends on how the fiberglass will be used. The fibers can either be woven into mats or chopped into smaller pieces.

• Weaving: For certain applications, the fibers are woven into sheets or mats. This woven fiberglass is highly flexible and strong, making it perfect for products like automotive parts, boats, and insulation.

• Chopping: Alternatively, the fibers can be chopped into small strands. These chopped fibers are used to make products like molded parts, plastic reinforcements, and construction materials. The chopped fiberglass provides strength and durability in bulk applications.

The final step in making fiberglass is impregnating the fibers with resin. This gives fiberglass its final strength and durability.

• Resin Application: The glass fibers (whether woven or chopped) are coated with a resin, usually epoxy or polyester. This resin acts as a binder, holding the fibers together and providing rigidity.

• Curing: Once the resin has been applied, the fiberglass is placed in a mold or laid flat, and the resin is allowed to cure. The curing process hardens the resin, binding the glass fibers together and creating a strong, durable material.

Customization: Depending on the intended use, other additives such as flame retardants, UV stabilizers, or plasticizers may be mixed in to enhance properties like fire resistance, UV protection, or flexibility.

The manufacturing process can vary slightly depending on the specific type of fiberglass being made:

Woven Fiberglass: In this case, the fibers are woven into fabric-like sheets, making them suitable for applications requiring high strength and flexibility.

Chopped Fiberglass: Chopped fibers are mixed with resin and pressed into molds to create rigid, molded parts that are often used in products like car parts, insulation boards, and pipes.

Once the fibers are impregnated with resin and cured, the fiberglass is ready to be used in a wide range of applications. The result is a lightweight, strong, and versatile material that’s perfect for everything from building materials to automotive components.

Fiberglass is more than just a versatile material—its unique properties make it a top choice in various industries, from construction to automotive. Here’s a look at some of the key benefits that make fiberglass so valuable:

One of the standout features of fiberglass is its impressive strength-to-weight ratio. It’s much lighter than metals like steel or aluminum, but it still offers comparable (or even superior) strength.

• Strength: Despite being light, fiberglass can withstand heavy loads and is incredibly durable.

• Lightweight: This makes it ideal for applications where reducing weight is essential—such as in the automotive industry or aircraft manufacturing.

Fiberglass is highly resistant to corrosion, which makes it perfect for environments where materials are exposed to moisture, chemicals, or harsh weather conditions.

• Rust-Free: Unlike metals like steel, fiberglass won’t rust or degrade when exposed to water.

Long Lifespan: This makes fiberglass an excellent choice for marine applications, water treatment systems, and construction in coastal or humid environments.

Fiberglass is an outstanding thermal and electrical insulator, which is one of the reasons it’s so widely used in the construction industry.

• Thermal Insulation: It helps keep buildings warmer in the winter and cooler in the summer, reducing the need for extra heating or cooling.

Electrical Insulation: Fiberglass is non-conductive, which makes it ideal for electrical applications, such as circuit boards and wires.

Fiberglass is relatively inexpensive compared to other high-performance materials like carbon fiber or metals.

• Affordability: While still offering impressive strength and durability, fiberglass is a more budget-friendly option for large-scale applications.

• Durability: Its long lifespan and low maintenance needs make fiberglass a cost-effective investment over time.

Fiberglass is incredibly versatile and can be molded into a variety of shapes and sizes, making it suitable for a wide range of applications.

• Molding Flexibility: Fiberglass can be formed into complex shapes, making it useful in everything from aerospace components to automotive body panels.

• Customization: It can be reinforced with additional materials, such as resins, to meet the specific requirements of various industries, including construction, automotive, marine, and sports equipment.

While fiberglass itself is not biodegradable, it is recyclable, and advancements are being made in making the recycling process more efficient.

Sustainability: Many fiberglass manufacturers are looking into ways to recycle old fiberglass products, reducing waste and minimizing the material’s environmental impact.

Once installed or integrated into a product, fiberglass requires very little maintenance. Its resistance to corrosion, moisture, and UV degradation means that it can perform well over time without frequent upkeep.

• Durable Finish: Fiberglass doesn’t warp, rot, or shrink, making it an excellent long-term solution for construction materials or outdoor furniture.

Fiberglass’s lightweight strength, corrosion resistance, insulating properties, and versatility make it a go-to material across various industries. Whether you’re looking to reduce the weight of a vehicle, improve insulation in your building, or create corrosion-resistant products, fiberglass is a reliable and cost-effective choice.

Now that you have a deeper understanding of fiberglass and its manufacturing process, it’s time to consider how you can incorporate this versatile material into your projects. Whether you’re in construction, automotive, or marine industries, fiberglass can offer significant advantages in terms of strength, cost-effectiveness, and durability.

Looking for more insights? Explore our detailed guide on fiberglass applications to discover how it can transform your product designs and boost performance.

Connect with an NQ expert to discuss your product needs and get started on your project.

Yes, fiberglass is a composite material. It combines glass fibers for strength and resin to hold them together, creating a durable and versatile material.

Fiberglass is commonly used in the following industries:

Its strength, lightweight nature, and corrosion resistance make it ideal for these applications.

Yes, fiberglass is generally safe to use, but there are some precautions to consider, particularly during manufacturing or installation:

When handled properly, fiberglass is a safe and reliable material for use in many applications.

Yes, fiberglass can be recycled, but the process is more complex than recycling materials like metals or plastics. Fiberglass is made from a combination of glass fibers and resin, which makes it difficult to break down and repurpose in its entirety. However, there are methods being developed to recycle fiberglass efficiently:

While fiberglass recycling is not yet as widespread as other materials, efforts to improve the process are ongoing, making it a more sustainable choice for the future.

In summary, carbon fiber is stronger and lighter but more expensive, while fiberglass is more cost-effective and impact-resistant.