Products Categories

Featured Products

Filament Wound Carbon Fiber Tube

Color customization

Carbon Fiber tubes come in a variety of colors, including the usual black, white, blue, red, yellow, color, and a variety of other color options. Customers can customize unique colors according to specific needs to match specific application scenarios or brand styles. The factory will use advanced technology and high-quality materials to ensure the stability and durability of customized colors, and provide customers with personalized carbon fiber square tube products.

Product MOQ

Please note our minimum order quantity of Carbon Fiber Tube. For the conventional Carbon Fiber Tube in stock, there is no MOQ. For customized Carbon Fiber Tube, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

The Filament Wound Carbon Fiber Tube (FWCF Tube) is a tubular product crafted with precision using carbon fiber filament winding technology. It stands out for its remarkable customizability and exceptional performance. Whether it’s the dimensions, properties, or surface quality, the FWCF Tube can be tailored precisely to meet specific customer requirements. By adjusting the winding angles, layers, and resin matrix types, it achieves varying mechanical properties and chemical stability.

Boasting high strength, lightweight construction, excellent stability, and corrosion resistance, the FWCF Tube exhibits immense potential for applications across multiple industries. Its manufacturing process adheres strictly to production techniques and quality control protocols, ensuring consistent and reliable product quality.

Specification

- Outer Diameter

- Standard range: 10mm to 300mm

- Tolerance: ±0.1mm (tighter control available upon request)

- Custom diameters available

- Wall Thickness

- Range: 1.0mm to 10.0mm

- Multi-layer winding ensures uniform thickness

- Tolerance: ±0.05mm, ideal for high-precision structural fit

- Tube Length

- Standard lengths: 1000mm / 1500mm / 2000mm

- Max customizable length: up to 6000mm (subject to shipping method)

- Ends are clean-cut and flat; custom length processing available

- Winding Angle

- Standard angles: ±30°, ±45°, ±60°

- Bi-directional or multi-angle winding available

- Custom fiber orientation ratios available based on design needs

- Fiber Type

- High-strength carbon fiber: T300 / T700 / T800 / M-series

- Optional hybrid construction with glass fiber or aramid

- All raw materials sourced from reputable global suppliers

- Resin Matrix

- High-performance thermosetting epoxy resin

- Resin content: 30% to 40%, precisely controlled

- Optional high-temp or chemical-resistant formulations

- Surface Finish

- Options: Glossy / Matte / Sanded / Satin

- Clear visible weave (e.g., 3K twill or plain), aesthetic consistency

- Additional coatings: UV-resistant, sealed finish, or customized paint

- Dimensional Accuracy

- Roundness tolerance ≤ 0.15mm

- Straightness deviation ≤ 1mm per meter

- Suitable for tight-fit assembly or precision machining

- End Finish

- Standard: Clean cut, deburred

- Optional: Angled cut, slotted, chamfered, or capped

- Can be customized for fittings, joints, or end sealing

Main applications

Aerospace Industry

- In the aerospace industry, the FWCF Tube is highly favored due to its high strength, lightweight properties, and excellent corrosion resistance.

- It is used in manufacturing critical components of missiles, space platforms, and launch vehicles, such as fairings, composite brackets, and instrument pods, providing structural support and protection for spacecraft.

- The use of carbon fiber reinforced plastic (CFRP) enables spacecraft to achieve lightweight, compact, and high-performance designs.

Automotive Manufacturing

- In automotive manufacturing, the FWCF Tube is utilized in the production of high-performance body structures and chassis components.

- It reduces vehicle weight, improving fuel efficiency and handling performance.

- At the same time, its high strength and corrosion resistance contribute to increased safety and durability.

Sports Equipment

- High-end sports equipment, such as bicycles, golf clubs, and fishing rods, extensively employ the FWCF Tube.

- It provides sufficient stiffness and toughness while maintaining a lightweight design.

- The addition of carbon fiber material significantly enhances the performance and aesthetics of sports equipment.

Wind Power Generation

- In the wind power industry, the FWCF Tube is used in manufacturing critical components of wind turbine blades.

- Its high strength and lightweight properties allow wind turbine blades to operate stably in harsh natural environments.

- The corrosion resistance of carbon fiber material also extends the service life of wind turbine blades.

Other Fields

- Beyond the above-mentioned industries, the FWCF Tube finds numerous applications in other areas.

- For instance, in public infrastructure, it can be used to construct bridge supports, tunnel linings, and building structures.

- In medical and industrial equipment, it serves as precision mechanical parts and instrument components.

Features

- High Strength-to-Weight Ratio

- Offers excellent tensile and compressive strength with minimal weight

- Ideal for weight-sensitive structural designs requiring mechanical rigidity

- Exceptional Dimensional Stability

- Low thermal expansion ensures size consistency under temperature changes

- Maintains precise geometry even in long tubes or varying environments

- High Torsional and Axial Strength

- Filament winding allows optimized fiber orientation (±30°, ±45°, ±60°)

- Enhanced torsion resistance and axial load capacity, especially in multi-layer construction

- Superior Fatigue and Impact Resistance

- Multi-angle winding enhances resistance to cyclic loads and sudden impacts

- Reliable for long-term, repeat-load applications

- Excellent Corrosion and Chemical Resistance

- Resin matrix provides strong resistance to moisture, solvents, and chemicals

- Suitable for outdoor, marine, or industrial exposure

- Customizable Structural Performance

- Fiber type, winding angle, layer thickness, and resin system are all configurable

- Enables tailored mechanical properties for your specific project needs

- Consistent Quality with Precision Manufacturing

- Tight control on diameter, wall thickness, roundness, and straightness

- Filament winding ensures repeatable, defect-free inner and outer surfaces

- Smooth Internal & External Finish

- Available with glossy, matte, or sanded surface

- Clean weave pattern or full resin coat for aesthetic and functional finish

- Wide Compatibility for Machining & Assembly

- Easy to cut, drill, and bond with compatible adhesives or fasteners

- Suitable for integration into mechanical assemblies, jigs, or housings

- Thermal & Electrical Insulation

- Naturally non-conductive and heat-resistant, depending on resin system

- Can replace metal tubes in electrically sensitive or thermally dynamic environments

Product Name | High strength carbon fiber tube |

Surface | Glossy,matte,woven textureBlack or colorful, etc. Custom-madeis welcome |

Specification Length | Various styles are welcome to customize |

Service | Various specifications can be customized according to yourneedsSelection of high quality materialsProvide professional and attentive serviceFine workmanship well-made products more practical |

Advantage | Corrosion resistance, light weight, high strength, not easyto wearand tear, strong designability, good thermal and electrical |

For more product specifications, please contact our professionals!

By adopting CNC precision processing technology and automatic detection systems and integrating automated winding, curing, and cutting processes, the production speed is increased by 20% to 30%. Multi-station collaborative operation reduces manual intervention and reduces the error rate.

- Compatible with carbon fiber prepregs such as T300, T700, T800

- Supports a variety of resin systems such as epoxy and phenolic

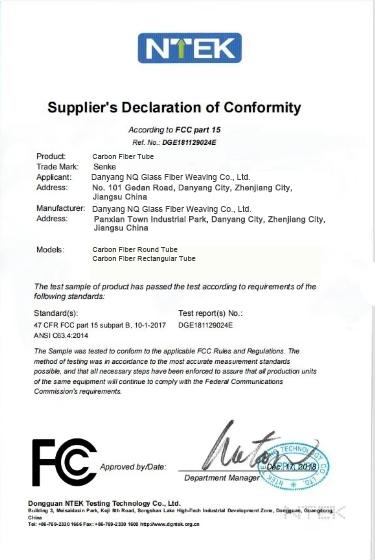

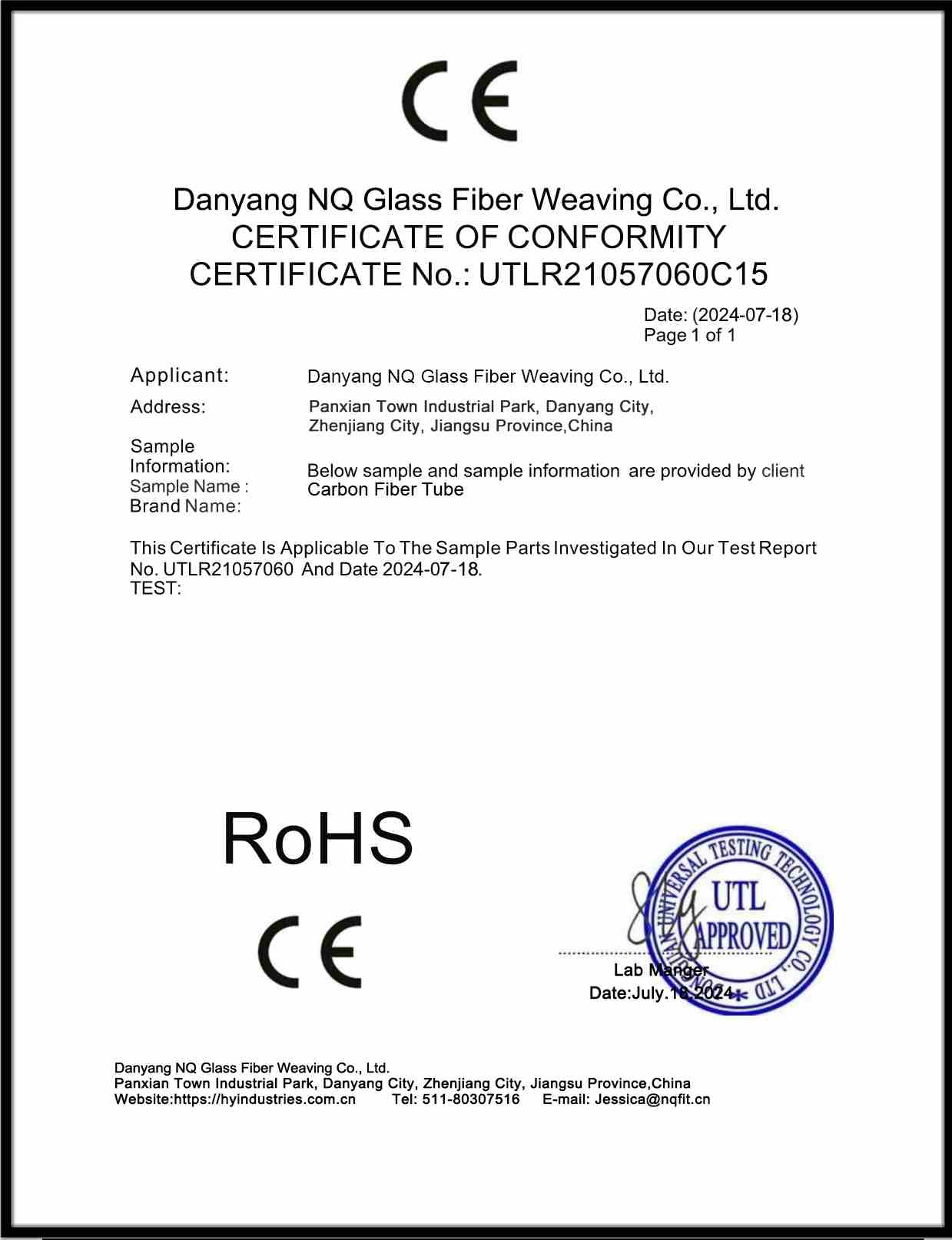

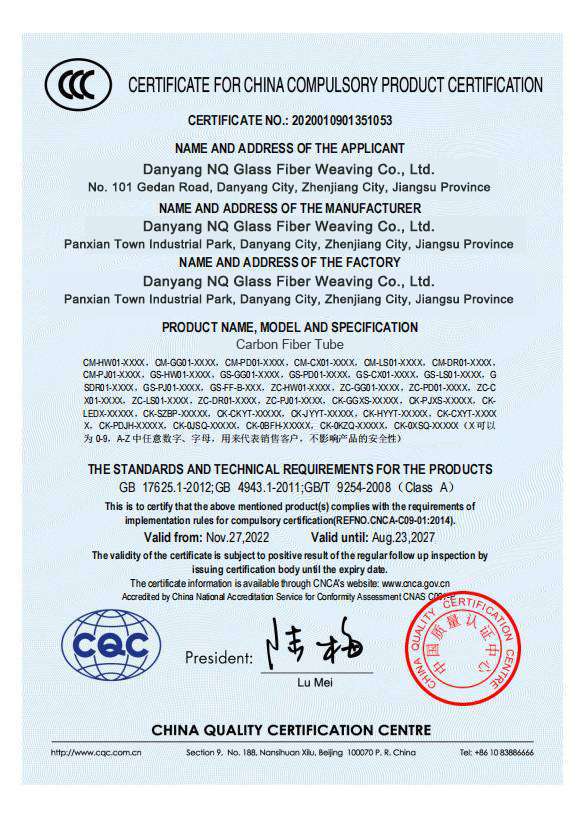

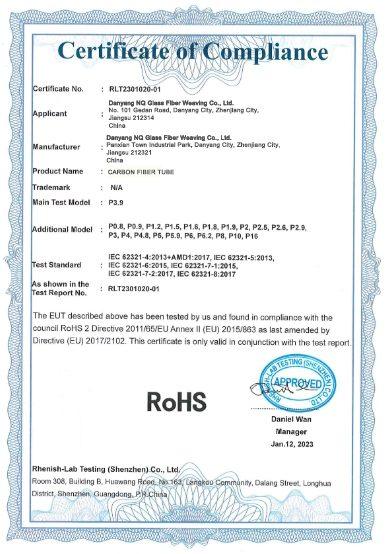

- ISO 9001, CE, SGS, and ASTM standards

- 40 automated production lines to ensure on-time delivery

- In-house Strictly Testing Lab for 6-step internal inspection

Enhance Performance, Simplify Processing, Reduce Costs

Experience the power of Carbon Fiber Tubes—lightweight, ultra-strong, and corrosion-resistant. Perfect for industries demanding high performance and durability. Elevate your products with precision-engineered tubes that combine advanced materials with cutting-edge manufacturing. Choose carbon fiber tubes for unmatched strength, reduced weight, and superior reliability.