Wholesale Drywall Paper Tape Manufacturer In China

- 16 years + of manufacturing experience.

- OEM&ODM, fast delivery.

- Custom logo & package.

- Free sample & wholesale price.

- CE, ASTM, SGS, ISO, BSCI and other related certifications.

years

Manufacturing Experience

Projects

We had finished

Clients

Over the world

Satisfaction

Drywall Paper Tape Factory & Manufacturer

As a leading drywall joint paper tape manufacturer in China ,NQ stands as a foremost authority in the production of drywall joint paper tape.NQ equipped with the latest machinery and technology, allowing us to offer reliable and efficient manufacturing solutions.

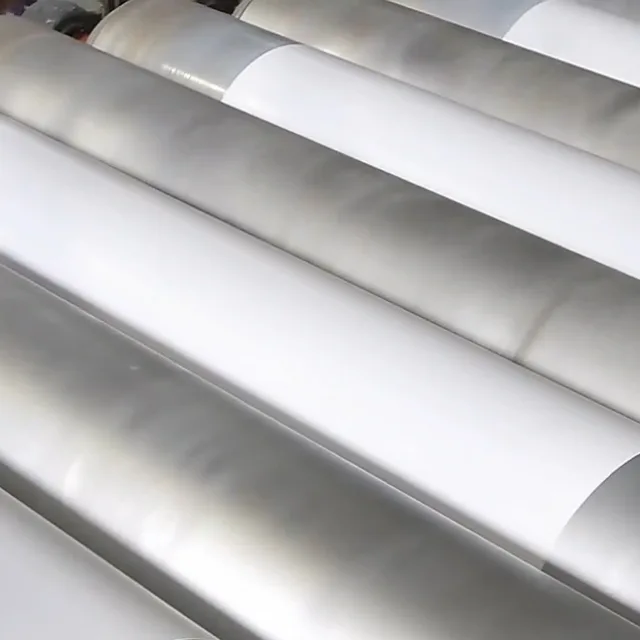

Caulking Tape Slitting Machine

Our sewing tape scuttling machines can efficiently and accurately cut kraft paper and other materials into the required seam tape, providing you with efficient and high quality assurance.

- ISO 9001, CE, SGS and ASTM standards

- 20 automated weaving production lines to ensure on-time delivery

- Using high-quality long-fiber kraft paper with special coating treatment

- In-house rigorous testing laboratory with 6-step internal inspection, in line with ASTM C474 standards.

Professional

Advanced manufacturing technology

High Quality

High quality CE, ASTM, SGS, ISO, BSCI certification

Cost Effective

Direct factory price

Customized

Different sizes, colors, designs, OEM/ODM

Service

Excellent customer service

Drywall Paper Tape Series

The gypsum paper tape produced by our factory has become the preferred material in the gypsum board construction industry for its excellent quality and numerous advantages. It is made of high-quality kraft paper with exceptional durability and crack resistance. In addition, it is seamlessly combined with a joint compound to provide strong adhesion and stability to the wall. In addition, the gypsum paper tape is environmentally friendly, and its recyclable and biodegradable characteristics align with the modern green building concept. Our factory adheres to strict production quality control standards to ensure that the quality and performance of gypsum paper tape are always reliable, providing you with long-term quality assurance and after-sales service support.

Boost Your Business With Custom Drywall Paper Tape

Size Customization

We provide customized drywall paper tape services to meet your personalized needs and improve your construction efficiency and convenience.

The common width of drywall paper tape is 50mm, and the standard length is 20m, 50m, 75m, 90m, 150m. We can customize the width to 45mm, 50mm, 52mm, and the length to 20m-300m.

Paper Tube Customization

Considering your material selection, production process, and cost factors, we provide customized services for paper tubes. Paper tubes with wall thickness between 0.5mm and 25mm and inner diameter between 4mm and 500mm can be customized.

Package Customization

To meet your personalized needs, we can add your brand logo, pattern, and text on the packaging, and you can also choose the size and color of the packaging, such as color box packaging. To provide you with the best packaging solutions and meet your diverse needs, the width and length of the drywall paper shrink film, shrinkage ratio, material (polyethylene (PE), polyvinyl chloride (PVC), etc.) and thickness, printing, and pattern, performance (waterproof, moisture-proof, anti-fouling, anti-static, etc.) can all be customized.

Drywall Paper Tape Specifications

Product Name | Paper Tape |

Material | Kraft Paper |

Feature | Waterproof |

Application | Drywall Joints; Gypsum Plank Joints.Used for drywall joint treatment, crack repair, corner reinforcement and special area treatment to improve the overall performance and beauty of the wall. |

Color | White |

Packing | Carton Box or OPP Bag |

Packing | 20roll/ctn,customizable |

Width | 50mm,customizable |

Length | 30m/75m/90m/150m,customizable |

Brand Name | NQ |

Model Number | 50MMX50M,50MMX75M |

Weight | 130g/m2,140g/m2 |

Width | 50mm, 52mm |

Product Name | Drywall Paper Tape |

Application | Used for drywall joint treatment, crack repair, corner reinforcement and special area treatment to improve the overall performance and beauty of the wall. |

Color | White |

Hot Size | 50mmx75m, 50mmx150m |

Performance Characteristics | With high quality kraft paper as the base material, it has high tensile strength, water resistance and good crack control ability. |

Width | customized size |

Length | Customized Size |

Packing | shrink film + carton |

Label | customized |

Feature | High tensile strength ,resist cracking,stretching,wrinking and tearing |

Self -adhesive | No |

NQ Drywall Paper Tape High Quality Production Process

1. Raw Material Preparation

Choose high quality wet wallpaper as raw materials. For Drywall Paper Tape, pulp with specific strength and toughness may require. Prepare raw materials, such as cleaning and crushing to ensure the purity and uniformity of the pulp.

2. Pulp Preparation

The prepared raw material pulp is made into the concentration and texture of the pulp required for production by grinding, screening and other processes. According to product requirements, a specific enhancer or adhesive may also be needed to increase the strength and viscosity of the dry wallpaper belt.

3.Molding And Drying

Use a special molding equipment to evenly apply the pulp to the substrate (for drywall paper tape, the substrate may be a special fiber cloth or non -woven fabric) to form continuous belt products. Through the hot air drying system or other drying equipment, the wet paper belt quickly dry until the appropriate water content to ensure the strength and stability of the product.

4. Glue And Composite

Apply a special layer of special adhesive on the surface of the dry paper belt to enhance its adhesion to the surface of the dry wall. For drywall paper tape, which requires a composite multi -layer material, the composite process is required to firmly combine each layer of materials.

5. Cut And Wound

The tape that is coated with a compound paper band is accurately cut according to the scheduled width. The cut paper belt is rolled into curls to facilitate storage, transportation and use.

6.Quality Inspection And Packaging

Strict quality inspection of the finished product drywall paper tape, including testing of indicators such as appearance, size, viscosity. The qualified products will be packaged in a bag or box, label and instructions, and finally enter the warehouse to wait for sales.

THE ADVANTAGE OF THE FIBERGLASS MESH

High Intensity And Durability

The drywall tape is made of unique high-intensity paper fiber. It has excellent tensile strength and can effectively enhance the stability of the gypsum plate joint. This durability ensures that the seams are not easy to crack during extended -term use, reducing your needs for maintenance and repair, thereby saving you time and cost.

Easy To Construct

The drywall paper tape is designed with easy-to-use features, such as the middle fold line, which makes it easier to apply in corners. In addition, it comes in various sizes, such as the standard 50mm width and optional lengths of 30m, 75m, 150m, etc., to meet the needs of different construction scenarios. This flexibility improves construction efficiency, reduces construction difficulty, and provides a smoother construction experience.

Excellent Anti Crack Performance

To address the problem of cracking at the edges when using water-based compounds, our drywall paper tape uses special processing, such as perforated design, to reduce moisture absorption and effectively prevent cracking at the joints. This feature is essential to maintaining the flatness and aesthetics of the wall and improves your satisfaction with the final decoration effect.

Environmental Protection And Health

We use environmentally friendly materials to produce drywall paper tapes to ensure that the product does not release harmful substances during use and meets national and international environmental standards. This creates a healthy and safe living environment for you, in line with your pursuit of environmental protection and health.

Cost Effectiveness

Although the initial investment for high-quality drywall tape may be slightly higher than for regular products, its superior durability and crack resistance means a longer lifespan and lower maintenance costs. This provides significant cost benefits in the long run, making it a cost-effective option.

Wide Applicability

The dry wallpaper belt is suitable for plaster plates in home decoration and is widely used in various occasions, such as commercial spaces and public buildings. Its multi-scene characteristics meet your different needs and provide you with a more comprehensive solution.

SF

Warehouse and factory

Total annual revenue

Skilled worker

Partner With NQ To Elevate Your Project To Success

NQ has won wide choice and trust from customers worldwide due to its advantages, such as high quality, technological innovation, a well-known brand, perfect after-sales service, environmental sustainability, and global market coverage.

Premium quality: The use of water-based high-tech materials to ensure product stability and durability. Ensure the flatness and adhesion of the drywall tape during construction.

Efficient & Quality:We have 25 production lines with optimized production processes to improve equipment utilization and achieve large-scale production, thereby reducing overall costs. Ensure the whole process of quality control high standards, improve product quality.

Expert Guidance: NQ provides all-round support from product consultation, purchase suggestions, construction guidance to after-sales maintenance to ensure that you have no worries during use.

Certificate

WHAT PEOPLES SAY ABOUT US

“I would like to express my sincerest gratitude to the NQ team! Since we established a cooperative relationship with NQ, the drywall paper tape products provided by NQ have been an indispensable and important part of our business, bringing excellent user experience and satisfactory decorative effects to our customers. I especially want to thank NQ for its strict control of product quality. For every order, whether a large or small batch, NQ can ensure the stability and consistency of the products, which gives us confidence in the sales process. Customer feedback on NQ products has been very positive. ”

John Smith

Entrepreneur

“Since the inception of our collaboration, the drywall paper tape products supplied by NQ have undeniably played a pivotal role in significantly enhancing and diversifying our product offerings. This strategic partnership has not only bolstered our market presence but has also ushered in a new era of construction excellence and customer satisfaction that was previously unattained. The transformative impact of NQ’s products on our clientele’s projects is a testament to the unparalleled quality, innovation, and reliability that NQ consistently delivers.”

David Thomas

Entrepreneur

“We would like to take this opportunity to express our heartfelt gratitude to NQ for the invaluable contributions they have made to our business since the inception of our cooperative relationship. From the beginning, NQ has stood as a pillar of support, driving our business development forward with their exceptional product quality, robust production capacity, and unparalleled customer service.”

Richard Jones

Entrepreneur

Application Of Drywall Joint Paper Tape In Construction And Restoration Industry

As a powerful manufacturer of drywall paper tape, we are committed to providing you with high-quality, high-performance drywall paper tape products. Whether it is building decoration, wall repair or renovation projects, drywall paper tape will be your ideal choice. Whether it is home decoration, commercial space or public places and industrial plants, drywall paper tape can provide excellent repair effects and bring a smooth and beautiful appearance to the wall.

Auxiliary Material For Wallpaper Construction

Drywall paper tape enhances wallpaper adhesion, preventing edge lifting and peeling. It smooths seams for a seamless look and offers moisture and mildew resistance, extending wallpaper lifespan and keeping walls dry.

Drywall paper tape 45mm/50mm/52mm(width)*30m/75m/150m(length)

Decorative Material With Similar Functions To Wallpaper

Drywall paper tape is a versatile wall decoration material with various colors and patterns, offering a wallpaper-like effect. Its durability makes it ideal for humid, dusty, or high-maintenance areas.

Drywall paper tape 45mm/50mm/52mm(width)*30m/75m/150m(length)

Creative And Personalized Applications

Drywall paper tape is a DIY-friendly decor option that can be easily cut and shaped for custom designs on walls and furniture. Various colors and textures create unique styles like retro, modern, or minimalist.

Drywall paper tape 45mm/50mm/52mm(width)*30m/75m/150m(length)

DRYWALL PAPER TAPE SUPPLIER FAQ

What is your MOQ?

Our MOQ is usually 1x20ft container.But we accept lower quantity for your trial order. Please feel free to inform us your plan for

purchasing, we will offer the price correspond to your qty. And we hope your would increase your order qty after you check our

product quality and know our services.

What is the shipping port?

We ship the goods via Shanghai port.

How many colors are available?

We can do custom color when reach our MOQ qty.

Our regular colors are white, yellow, green, blue, orange, red etc.

What format of the file do you need if I want to do my own design?

For printing label design, we need AI or PDF file for set up the print-plate.

What is your delivery time?

The time of delivery is about 20~30days after we receive the deposit.

What is your sample time?

Usually we will take 7-10 days to make the samples.

Which Shipment way is available?

By sea to your designated port.

Which Payment way is workable?

1. Irrevocable L/C, Cash, PayPal, Credit card and T/T money transfers.

2.30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo.

3.L/C ( Irrevocable LC at sight)

If you need custom size such as gram weight and mesh size etc or private logo pls feel free inquiry us!

DRYWALL JOINT PAPER TAPE FAQ

What is paper drywall tape used for?

Paper drywall tape is a specialized material used in drywall installation and finishing to reinforce seams and corners between drywall panels. Its primary functions include:

Reinforcing Joints: When embedded in joint compound, paper drywall tape strengthens the bond between adjacent drywall sheets, reducing movement and minimizing the risk of cracks.

Creating Clean Corners: Paper tape is particularly effective for forming sharp, clean corners. Its flexibility allows it to be easily folded, ensuring precise corner joints that enhance the overall appearance of the drywall installation.

Providing a Smooth Finish: The slightly rough texture of paper tape promotes better adhesion with joint compound, resulting in a smooth and seamless finish that is ideal for painting or other wall treatments.

It’s important to note that while paper drywall tape offers excellent performance in dry areas, it may not be the best choice for high-moisture environments like bathrooms or basements, where fiberglass mesh tape might be more suitable due to its resistance to mold and moisture. citeturn0search7

Do you mud over paper drywall tape?

Yes, when installing drywall, it’s essential to apply joint compound (commonly known as “mud”) over paper drywall tape. This process, known as “bedding,” involves pressing the tape into wet mud to ensure a strong bond and prevent future cracking. Here’s how it’s typically done:

Apply the First Layer of Mud: Using a taping knife, spread a thin layer of joint compound over the drywall seams where you plan to place the tape.

Embed the Paper Tape: While the mud is still wet, place the paper drywall tape over the seam. Gently press it into the mud with the taping knife, ensuring there are no bubbles or wrinkles.

Cover the Tape with More Mud: After embedding the tape, apply another layer of joint compound over it. Smooth it out evenly, ensuring the tape is fully covered.

This method reinforces the joints between drywall panels, creating a seamless and durable surface suitable for painting or further finishing.

Should you wet drywall paper tape?

Wetting paper drywall tape before application is a debated practice among professionals and DIY enthusiasts. Some suggest that moistening the tape can help eliminate bubbles and ensure better adhesion. For instance, Family Handyman recommends wetting the tape to prevent troublesome bubbles after the joint dries.

However, others caution against pre-wetting, arguing that it can make the tape more difficult to handle and may not yield significant benefits. A discussion on the DIY Chatroom forum highlights that wetting the tape can become sloppy and heavy, making it harder to work with.

Ultimately, whether to wet drywall paper tape depends on personal preference and experience. If you choose to pre-wet, briefly running the tape under water and allowing any excess to drip off before applying it to the wall can help prevent issues like bubbling. It’s advisable to test both methods to determine which works best for your specific project.

For a visual demonstration and further insights, you might find this video helpful:

Which is better paper tape or mesh for drywall?

When choosing between paper and mesh drywall tape, consider the following factors:

Strength and Durability:

Paper Tape: Offers superior strength, reducing the likelihood of cracks over time. It’s particularly effective in high-stress areas.

Mesh Tape: While convenient, it may not be as durable as paper tape. To enhance its strength, it’s advisable to use quick-setting joint compound when applying mesh tape.

Application and Handling:

Paper Tape: Requires embedding in joint compound, which can be challenging for beginners. However, it provides a smooth finish, especially in corners.

Mesh Tape: Features a self-adhesive backing, simplifying application. It’s especially useful for small repairs and patching holes.

Moisture Resistance:

Paper Tape: Not recommended for damp areas like bathrooms or basements, as it may not withstand moisture well.

Mesh Tape: Generally offers better moisture resistance, making it more suitable for humid environments.

Cost and Time Efficiency:

Paper Tape: May require more time to apply due to the need for embedding in joint compound.

Mesh Tape: Typically faster to apply, which can be beneficial for larger projects or quick repairs.

Conclusion:

For high-durability and professional-quality finishes, especially in corners and seams under stress, paper tape is preferred.

For ease of use, speed, and applications in moisture-prone areas, mesh tape is a suitable choice.

Assess your project’s specific needs, your experience level, and the environment to determine the best option.

Mesh vs paper drywall tape

When choosing between paper and mesh drywall tape, consider the following factors:

Strength and Durability:

Paper Tape: Offers superior strength, reducing the likelihood of cracks over time. It’s particularly effective in high-stress areas.

Mesh Tape: While convenient, it may not be as durable as paper tape. To enhance its strength, it’s advisable to use quick-setting joint compound when applying mesh tape.

Application and Handling:

Paper Tape: Requires embedding in joint compound, which can be challenging for beginners. However, it provides a smooth finish, especially in corners.

Mesh Tape: Features a self-adhesive backing, simplifying application. It’s especially useful for small repairs and patching holes.

Moisture Resistance:

Paper Tape: Not recommended for damp areas like bathrooms or basements, as it may not withstand moisture well.

Mesh Tape: Generally offers better moisture resistance, making it more suitable for humid environments.

Cost and Time Efficiency:

Paper Tape: May require more time to apply due to the need for embedding in joint compound.

Mesh Tape: Typically faster to apply, which can be beneficial for larger projects or quick repairs.

Conclusion:

For high-durability and professional-quality finishes, especially in corners and seams under stress, paper tape is preferred.

For ease of use, speed, and applications in moisture-prone areas, mesh tape is a suitable choice.

Assess your project’s specific needs, your experience level, and the environment to determine the best option.

how to use drywall paper tape

- Prepare the Seams:

- Ensure the drywall seams are clean and free from dust or debris.

- Apply a thin layer (about 1/8 inch) of joint compound (mud) along the seam using a drywall knife.

- Embed the Paper Tape:

- While the joint compound is still wet, place the paper drywall tape over the seam.

- Gently press the tape into the compound with your drywall knife, ensuring there are no air bubbles or wrinkles.

- For inside corners, fold the tape to fit the corner and press it into the compound.

- Apply Additional Joint Compound:

- Using the drywall knife, apply a thin layer of joint compound over the embedded tape, covering it completely.

- Feather the edges of the compound to blend it smoothly with the surrounding wall surface.

- Allow to Dry and Sand:

- Let the joint compound dry completely, which may take several hours or overnight.

- Once dry, lightly sand the area with fine-grit sandpaper to remove any bumps or imperfections.

- Apply Additional Coats:

- Repeat the process of applying joint compound, drying, and sanding at least one more time to achieve a smooth and seamless finish.

Can you use paper drywall tape on outside corners?

- Metal or Vinyl Corner Beads: These corner beads are specifically designed to protect and reinforce outside corners. They are typically attached using joint compound, offering a clean and durable finish.

- Paper-Faced Corner Beads: Combining the strength of metal with the ease of paper, these beads are set in joint compound and provide a strong, crack-resistant corner.

- Preparation: Ensure the corner is clean and free from debris before applying the corner bead.

- Application: Apply joint compound to the corner, press the corner bead into place, and cover it with additional compound.

- Finishing: Once the compound dries, sand the area smoothly and apply additional coats as necessary for a seamless finish.

Why Use Corner Bead for Outside Corners?

Corner beads are essential for protecting and finishing outside corners in drywall installations. They serve two primary purposes:

Protection: Outside corners are vulnerable to damage from impacts, which can lead to dents, chips, or cracks. Corner beads act as a protective barrier, shielding these areas from everyday wear and tear.

Aesthetic Finish: Corner beads provide a clean, straight, and professional appearance to drywall corners. They eliminate the need for repeatedly cutting and filling gaps, resulting in a seamless and polished look.

By incorporating corner beads, you enhance both the durability and visual appeal of your drywall corners, ensuring they withstand physical contact and maintain a refined finish over time.

Can you use all-purpose joint compound with paper tape?

Yes, you can use all-purpose joint compound with paper drywall tape. All-purpose joint compounds are versatile and suitable for embedding paper tape, finishing joints, and covering fasteners. For example, Freeman Ready-Mix All Purpose Joint Compound is specifically formulated for embedding paper drywall tape and finishing joints.

However, it’s important to note that while all-purpose compounds are suitable for most applications, some manufacturers advise against using them with fiberglass mesh tape. For instance, Freeman Ready-Mix All Purpose Joint Compound is not intended for embedding fiberglass tape.

In summary, all-purpose joint compound is compatible with paper drywall tape and is commonly used for this purpose. Always follow the manufacturer’s guidelines for best results.

how to apply paper tape to drywall?

- Drywall joint compound (mud)

- Paper drywall tape

- Utility knife

- Drywall taping knife (4 to 6 inches)

- Mud pan

- Sanding block or pole sander

- Dry cloth or sponge

- Prepare the Seams:

- Ensure all drywall panels are securely attached to the studs.

- For butt joints (where two square-edged panels meet), apply a thin layer of joint compound over the seam to fill any gaps.

- Mix or Thin the Joint Compound:

- If using ready-made joint compound, thin it slightly to achieve a pudding-like consistency. If mixing from powder, follow the manufacturer’s instructions to reach the desired texture.

- Apply the First Layer of Compound:

- Using your taping knife, spread a thin layer (about 1/8 inch) of joint compound along the seam where you plan to apply the tape.

- Ensure the compound fully covers the area behind the tape to prevent dry spots, which can lead to tape failure.

- Cut and Position the Paper Tape:

- Cut the paper tape to the length of the seam.

- Center the tape over the seam, ensuring equal overlap on both sides.

- Embed the Tape:

- Using the flat side of your taping knife, press the paper tape into the wet joint compound, starting at one end and working your way to the other.

- Apply firm pressure to eliminate air bubbles and ensure good adhesion.

- If wrinkles occur, gently lift the tape and reposition it.

- Smooth and Remove Excess Compound:

- With the beveled edge of your taping knife, apply additional joint compound over the tape, embedding it fully.

- Smooth the surface, removing excess compound to leave a thin, even layer.

- Feather the edges to blend seamlessly with the surrounding wall.

- Allow to Dry:

- Let the joint compound dry completely. Drying times can vary based on temperature and humidity but typically range from 24 to 48 hours.

- Apply Additional Coats:

- Once dry, lightly sand the area with a fine-grit sanding block to remove any bumps or imperfections.

- Apply a second, slightly wider coat of joint compound, feathering the edges further.

- Repeat the drying and sanding process.

- Apply a third coat if necessary, ensuring the seam is smooth and flush with the wall surface.

- Final Sanding and Cleaning:

- After the final coat dries, sand the area smoothly, being careful not to damage the surrounding drywall.

- Wipe away any dust with a dry cloth or sponge.

- Finish the Wall:

- Once the seams are smooth and clean, the wall is ready for priming and painting.

- Always work in a well-ventilated area to ensure proper drying and to minimize inhalation of dust.

- Maintain a consistent thickness of joint compound to avoid visible seams after painting.

- For a visual demonstration and more detailed guidance, consider watching the following tutorial:

Drywall paper tape vs mesh tape

When finishing drywall seams, both paper and mesh tapes are commonly used, each offering distinct advantages and considerations.

Paper Drywall Tape:

Strength and Durability: Paper tape provides superior tensile strength, reducing the likelihood of stretching, rolling, or tearing.

Application: It requires embedding in a layer of joint compound, which not only secures it in place but also adds an extra layer that helps prevent future cracking.

Corners: Paper tape is preferred for inside corners due to its ability to form crisp, clean 90-degree angles.

Moisture Sensitivity: It’s not recommended for areas exposed to moisture, such as basements and bathrooms, as it may not withstand damp conditions.

Mesh Drywall Tape:

Ease of Use: Mesh tape is self-adhesive, simplifying application by sticking directly to the drywall without the need for an initial layer of joint compound.

Flexibility: Its fiberglass composition offers flexibility, making it suitable for quick repairs and applications where ease of use is prioritized.

Durability Concerns: While convenient, mesh tape may not provide the same level of durability as paper tape, potentially leading to issues like stretching or tearing under certain conditions.

Choosing Between Paper and Mesh Tape:

Professional Preference: Many professionals favor paper tape for its strength and ability to create sharp corners, despite requiring more time to apply.

DIY and Quick Repairs: Mesh tape may be suitable for DIY projects or quick repairs due to its ease of use and faster application.

In summary, if durability and precise cornering are your priorities, paper tape is the recommended choice. If you require a quicker, more straightforward application, mesh tape might be more suitable.

Certainly, here’s a comparison between paper drywall tape and mesh drywall tape:

| Feature | Paper Drywall Tape | Mesh Drywall Tape |

|---|---|---|

| Material | Made from paper, requiring a layer of joint compound beneath it for adhesion. | Composed of self-adhesive fiberglass, allowing direct application to drywall without additional compound for sticking. |

| Strength | Offers higher tensile strength, reducing the likelihood of stretching, rolling, or tearing. This strength is enhanced by embedding it in joint compound, which also helps prevent future cracking. | Provides adequate strength for most applications but may not be as robust as paper tape, especially in high-stress areas. |

| Application | Ideal for inside corners due to its ability to crease easily, ensuring a tight fit. Requires embedding in joint compound, which can be challenging for beginners. | Suitable for flat seams and small repairs, as its self-adhesive nature simplifies application. However, it may be less effective for inside corners. |

| Moisture Resistance | Less resistant to moisture; not recommended for areas exposed to dampness, such as basements or bathrooms. | More resistant to moisture, making it suitable for areas like bathrooms or kitchens where humidity is higher. |

| Cost | Generally more affordable, making it a cost-effective choice for large projects. | Tends to be slightly more expensive due to its self-adhesive properties but can save time during application. |

| Durability | Less prone to mold and decay when properly installed, especially in dry environments. | More susceptible to mold and decay over time, particularly in humid conditions, which may affect its long-term durability. |

How to fix paper tape bubbles in drywall?

1.Cut the Bubble: Use a utility knife to carefully slice the bubble open without damaging the surrounding tape.

- Apply Joint Compound: Push joint compound into the cut to fill the void and smooth it out.

- Re-embed the Tape: Press the tape down firmly, ensuring there are no more bubbles.

- Feather the Edges: Apply a thin layer of joint compound over the area, feathering it out beyond the tape edges.

- Sand Smooth: Once dry, lightly sand the area for a seamless finish.

- Prime and Paint: After sanding, prime and paint as needed.

Q10:How to put on drywall paper tape?

A:1.Prepare the Area: Ensure the drywall seams are clean and free of dust.

2.Mix Joint Compound: Stir or mix your joint compound until smooth.

3.Apply a Base Layer: Use a taping knife to spread a thin layer of joint compound over the seam.

4.Cut the Tape: Measure and cut lengths of paper tape to fit the seams.

5.Embed the Tape: Press the tape into the wet compound, smoothing it out to eliminate bubbles.

6.Cover the Tape: Apply another thin layer of joint compound over the tape, feathering the edges.

7.Let It Dry and Sand: Allow it to dry completely, then lightly sand for a smooth finish.

8.Repeat if Necessary: Apply additional coats as needed for a seamless look.

How to mud drywall with paper tape?

1. Prepare the Seam: Clean the drywall edges and ensure they’re straight.

2.Mix Joint Compound: Stir the joint compound until it’s smooth and workable.

3.Apply First Coat: Use a taping knife to spread a thin layer of joint compound over the seam, about 2-3 inches wide.

4.Embed the Tape: Press the paper tape into the wet compound, smoothing it down to eliminate air bubbles.

5.Cover the Tape: Apply another layer of joint compound over the tape, feathering out the edges with your knife.

6.Let It Dry: Allow the compound to dry completely, which may take several hours.

7.Sand Smooth: Lightly sand the area to remove any rough spots.

8.Repeat: Apply additional coats as needed, sanding between each layer for a smooth finish.

Are there drywall paper tape holders?

Yes, there are specialized holders designed to dispense paper drywall tape, enhancing efficiency during drywall installation. These holders, often referred to as drywall tape reels or dispensers, securely hold standard rolls of paper tape and can be attached to a belt for hands-free operation. They typically accommodate rolls up to 500 feet in length and feature quick-loading designs for easy tape changes.

Examples of Drywall Tape Holders:

QWORK Drywall Tape Holder: A heavy-duty reel that holds up to 500 feet of tape, featuring a belt clip for easy access.

MARSHALLTOWN Paper Taper™: Designed to dispense flat and folded tape rolls up to 500 feet, it includes a tension arm, belt clip, and metal cutting blade.

Buddy Tools TapeBuddy Drywall Tape Dispenser: Simplifies drywall taping by holding both the mud pan and tape spool, reducing mess and waste.

These tools are available at various hardware stores and online retailers, including Amazon and The Home Depot. When selecting a tape holder, consider factors such as capacity, material durability, ease of use, and compatibility with your preferred tape size.

Is paper or fiberglass drywall tape better?

When choosing between paper and fiberglass mesh drywall tape, it’s important to consider the specific requirements of your project, as each type has its own advantages and ideal applications.

Paper Drywall Tape:

Strength and Durability: Paper tape is slightly stronger and more versatile, providing a robust bond that is less prone to cracking over time.

Inside Corners: Its ability to fold neatly makes it ideal for creating sharp, clean inside corners, ensuring a professional finish.

Application Process: Requires embedding in a layer of joint compound, which can be more labor-intensive and may present a learning curve for beginners.

Fiberglass Mesh Drywall Tape:

Ease of Use: Self-adhesive and easier to apply, making it suitable for quick repairs and for those new to drywalling. citeturn0search8

Moisture Resistance: Offers better resistance to moisture, reducing the likelihood of mold growth, which makes it suitable for areas with higher humidity.

Strength Considerations: While it provides adequate strength, it is more elastic, which can lead to joint movement and potential cracking under stress. It’s recommended to cover mesh tape with setting-type compound to enhance its durability.

Conclusion:

Use paper tape for applications requiring maximum strength, such as inside corners and butt joints, especially in areas subject to stress.

Use mesh tape for quick repairs, flat seams, or in moisture-prone areas like bathrooms and kitchens.

Ultimately, the choice between paper and fiberglass mesh drywall tape depends on your project’s specific needs, your experience level, and the desired balance between ease of use and long-term durability.

Which side of paper drywall tape faces out?

- Seam Side Against the Wall: Paper drywall tape typically features a slight seam or bulge along its center. This seam should face the wall, ensuring the tape adheres securely when embedded in joint compound.

- Smooth Side Facing Out: The smooth, non-seamed side of the tape should face outward, toward you. This orientation allows for a smooth application of joint compound and facilitates a seamless finish after sanding and painting.

Why use paper tape on drywall?

Using paper tape on drywall offers several advantages:

1.Strength: It provides strong joints that can better withstand stress and cracking.

2.Smooth Finish: When properly applied, it creates a seamless look, allowing for a smoother final surface.

3.Less Shrinkage: Paper tape expands and contracts with the drywall, minimizing the risk of cracking over time.

4.Cost-Effective: Generally less expensive than fiberglass tape, making it a popular choice for many projects.

5.Versatility: It can be used for a variety of joints and seams, making it suitable for most drywall applications.

How to paper tape drywall seams?

Applying paper drywall tape is a crucial step in achieving smooth and durable drywall seams. Here’s a step-by-step guide to help you through the process:

Materials Needed:

- Drywall joint compound (mud)

- Paper drywall tape

- Utility knife

- Drywall taping knife (6 to 10 inches)

- Mud pan

- Sanding block or pole sander

- Dry cloth or sponge

Step-by-Step Instructions:

- Prepare the Seams:

- Ensure all drywall panels are securely attached to the studs.

- For butt joints (where two square-edged panels meet), apply a thin layer of joint compound over the seam to fill any gaps.

- Mix the Joint Compound:

- Stir the joint compound thoroughly to achieve a creamy, pudding-like consistency. If it’s too thick, add a small amount of water and mix well.

- Apply the First Layer of Compound:

- Using your taping knife, spread a thin layer (about 1/8 inch) of joint compound along the seam where you plan to apply the tape.

- Ensure the compound fully covers the area behind the tape to prevent dry spots, which can lead to tape failure.

- Cut and Position the Paper Tape:

- Cut the paper tape to the length of the seam.

- Center the tape over the seam, ensuring equal overlap on both sides.

- Embed the Tape:

- Using the flat side of your taping knife, press the paper tape into the wet joint compound, starting at one end and working your way to the other.

- Apply firm pressure to eliminate air bubbles and ensure good adhesion.

- If wrinkles occur, gently lift the tape and reposition it.

- Smooth and Remove Excess Compound:

- With the beveled edge of your taping knife, apply additional joint compound over the tape, embedding it fully.

- Smooth the surface, removing excess compound to leave a thin, even layer.

- Feather the edges to blend seamlessly with the surrounding wall.

- Allow to Dry:

- Let the joint compound dry completely. Drying times can vary based on temperature and humidity but typically range from 24 to 48 hours.

- Apply Additional Coats:

- Once dry, lightly sand the area with a fine-grit sanding block to remove any bumps or imperfections.

- Apply a second, slightly wider coat of joint compound, feathering the edges further.

- Repeat the drying and sanding process.

- Apply a third coat if necessary, ensuring the seam is smooth and flush with the wall surface.

- Final Sanding and Cleaning:

- After the final coat dries, sand the area smoothly, being careful not to damage the surrounding drywall.

- Wipe away any dust with a dry cloth or sponge.

- Finish the Wall:

- Once the seams are smooth and clean, the wall is ready for priming and painting.

Additional Tips:

- Always work in a well-ventilated area to ensure proper drying and to minimize inhalation of dust.

- Maintain a consistent thickness of joint compound to avoid visible seams after painting.

- For a visual demonstration and more detailed guidance, consider watching the following tutorial:

By following these steps, you can achieve professional-quality drywall seams that are smooth and ready for finishing.

Can paper drywall tape go over paint?

Applying paper drywall tape over painted surfaces is common during drywall installation and repair. However, to ensure optimal adhesion and a seamless finish, proper surface preparation is essential.

Preparing Painted Surfaces for Paper Drywall Tape:

Clean the Surface:

- Ensure the painted area is free from dust, dirt, and grease.

Assess Paint Sheen:

- If the existing paint has a glossy or semi-gloss finish, its smooth surface may hinder the adhesion of joint compound and tape.

Sand the Area:

- Lightly sand the painted surface with medium-grit sandpaper (e.g., 80-grit) to create a slightly rough texture. This enhances the bond between the paint, joint compound, and tape.

Clean After Sanding:

- Remove any sanding dust with a damp cloth and allow the area to dry completely.

Applying Paper Drywall Tape:

- Embed the Tape: After preparing the surface, apply a layer of joint compound to the seam, press the paper tape into it, and then cover with additional compound.

Proper preparation ensures that the paper drywall tape adheres effectively, resulting in a smooth and durable finish.

Can you use regular notebook paper as drywall tape?

Using regular notebook paper as a substitute for specialized drywall tape is not advisable. Drywall tapes are specifically engineered to reinforce joints and seams, ensuring durability and a seamless finish. Here’s why notebook paper isn’t suitable:

Key Differences:

Material Strength: Drywall tapes are crafted from robust materials like kraft paper or fiberglass mesh, designed to withstand the stresses placed on wall joints. Regular notebook paper lacks this strength and may tear or disintegrate when exposed to joint compounds.

Moisture Resistance: Drywall tapes are formulated to retain their integrity when wet, as they are embedded in joint compound. Notebook paper is not designed for such conditions and may deteriorate, compromising the joint’s durability.

Adhesion Properties: The surfaces of drywall tapes are designed to bond effectively with joint compounds, promoting a strong bond. Notebook paper lacks these properties, leading to potential adhesion failures.

Recommended Practice:

For optimal results, it’s best to use materials specifically designed for drywall applications. Specialized paper joint tapes are available that are strong, moisture-resistant, and provide the necessary adhesion for a lasting finish.

In summary, while notebook paper might seem like a convenient alternative, it doesn’t meet the structural and performance requirements necessary for drywall taping. Investing in proper drywall tape will ensure the longevity and quality of your wall finishes.