Drywall Metal Corner Tape Manufacturers and Suppliers

- 16 years + of manufacturing exprience.

- OEM&ODM, fast delivery.

- Custom logo & package.

- CE, ASTM, SGS, ISO, BSCI and other related certifications.

- Custom Sizes and Specifications

years

Manufacturing Experience

Projects

We had finished

Clients

Over the world

Satisfaction

Drywall Metal Corner Tape Manufacturers For Wholesale

As a leading Metal Corner Tape factory in China, NQ is a professional manufacturer and exporter of high-quality Metal Corner Tape products. We have the capability to meet customers’ needs for wholesale and customized solutions for Metal Corner Tape.

High-Precision Automated Production Machines

Our machines integrate various automation devices such as precision cutting, forming, gluing, laminating, etc., to achieve intelligent monitoring of the production process, and can better provide you with high-quality products.

- ISO 9001, CE, UL certification, ASTM standard, ISO 8353:2024 international standard.

- 25 automated weaving production lines to ensure on-time delivery.

- Use materials such as corrosion-resistant and high-strength galvanized steel or aluminum alloy.

- Internal strict testing laboratory for 4-step internal inspection.

Professional

Advanced manufacturing technology

High Quality

High quality CE, ASTM, SGS, ISO, BSCI certification

Cost Effective

Direct factory price

Customized

Different sizes, colors, designs, OEM/ODM

Service

Excellent customer service

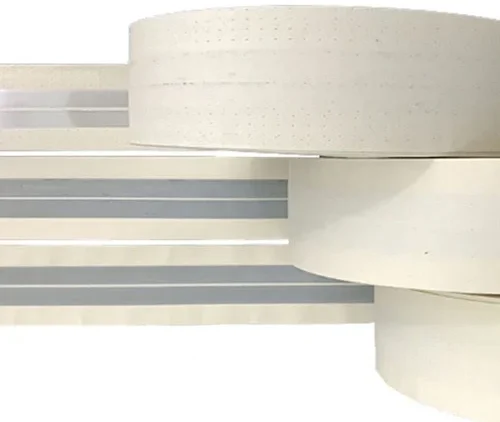

Drywall Metal Corner Tape We Made

NQFIBER offers high-quality drywall metal corner tapes featuring robust materials, strong adhesion, and high strength. The metal strips are securely bonded to the paper backing through advanced processes, preventing delamination during use and providing stable support and protection. These tapes are widely used in construction and interior decoration to enhance and protect corners. Available in various sizes, such as 50mm x 30m, NQFIBER also provides customizable designs to align with your brand image. As a leading manufacturer, they offer competitive wholesale prices, making bulk orders cost-effective for businesses.

Boost Your Business With Custom Drywall Metal Corner Tape

Size Customization

We provide customized services including metal corner tapes of different paper weights, widths and lengths.

Common sizes include 2 inches x 100 feet, 50 mm in width, 30 meters, 40 meters, 70 meters, 90 meters in length, etc. The weight is 145 ± 5 grams per square meter.

The width of the galvanized steel sheet is 5 cm and the thickness is 0.26-0.28 mm. The paper thickness is 210-230μm.

Customization of Metal Strips

Our metal corner guards come in a variety of metal strips, including galvanized steel and aluminum.

Aluminum is low-density and lightweight yet as strong as steel. Our galvanizing process effectively isolates air and moisture, protecting the steel strip from corrosion and extending its life. Thus, it provides superior corrosion resistance compared to our competitors.

Packaging Customization

We will package the gypsum board metal corner tape in rolls; each roll usually contains a certain length of metal corner tape. Then, these rolls are packed into sturdy cardboard boxes or plastic containers; each box contains one or more rolls.

You can also package them in sealed or plastic bags; each bag contains one or more rolls and is equipped with a moisture barrier.

You can choose custom packaging boxes. Our professional design team will tailor the packaging format to your needs, including corporate logos, brand elements, etc.

Drywall Metal Corner Tape Specifications

Product name | Metal Corner Tape |

Material | Kraft+metal |

Use | Masking Adhesive Side: Single Sided |

Application | Prevent wall cracking and damage. Used for crack repair, used to deal with some special shape of the corner, such as arc corner, ceiling and wall junction. |

Feature | Waterproof Design |

Width | 50mmm Length:30m |

Size | 50mm*30M colour: ivory |

Thickness | 0.25mm |

Brand Name | NQ |

Material | Stainless steel, Aluminum Alloy, Galvanized Plate |

Material | Aluminium /Galvanized Steel and Paper |

Metal Thickness | 0.26mm-0.28mm, etc. |

Length | 20m,25m,30m, etc. |

Weight(30m) | Around 1.6kg(Steel)/0.8kg(Aluminium) per roll |

Application | Suitable for home, office, commercial space and other interior decoration process, as well as new building construction and old house renovation and renovation projects. Suitable for crack repair, can also be used to deal with some special shape of the corner, such as arc corner, ceiling and wall junction. |

Quantity/carton | 10 rolls |

Carton size | 40x20x30cm |

Characteristics | Excellent tensile strength |

NQ Drywall Metal Corner Tape High Quality Production Process

1.Raw Material Selection and Inspection

We use high-quality galvanized steel strips or aluminum alloy strips as the metal substrate and environmentally friendly high-strength backing material to ensure that it meets product standards such as tear strength and air permeability to ensure quality.

2. Composite Process

An advanced precision glue coating machine is used to evenly apply environmentally friendly polyurethane or acrylic adhesive to the metal strip. It is processed under appropriate temperature and pressure to fully cure the adhesive and ensure a firm bond between the metal strip and the substrate.

3.Precise Cutting and Shaping

High-precision CNC cutting machines are used to accurately cut composite materials according to product specifications to ensure that the corner guards are accurate in size and have smooth edges. Special molds shape the corner guards on demand to adapt to different corner guard structures.

4.Strict Quality Inspection

Perform a comprehensive visual inspection of the cut and formed gypsum board metal corner bead to ensure no scratches, bubbles, or delamination defects. Perform a tensile strength test using a universal material testing machine to evaluate the tensile properties of the corner bead.

5.Packaging and Labeling

Choose environmentally friendly, waterproof, and dustproof packaging materials such as PE film and kraft paper to protect the corner tape from the influence of the external environment, and use professional label printers to print product labels.

6.Shipping and Logistics

The packaged corner tapes are transported to the finished product warehouse for storage. The warehouse has a temperature and humidity control system and fire and theft prevention facilities. According to customer requirements, the appropriate transportation method (land, sea, air) and logistics company are selected.

The Advantage Of The Metal Corner Tape

High Strength and Durability

Galvanized steel or aluminum strips are used as reinforcement materials. These materials have excellent strength and durability and can withstand daily wear and impact. Long-term adequate protection of corners reduces the cost of frequent repairs or replacements due to corner damage and prolongs service life.

Easy Installation and Flexibility

The metal corner strip is designed to be flexible and can be easily installed without special tools. Its bendability enables it to adapt to corners of different angles and shapes, simplifying the construction process, improving efficiency, and saving time and labor costs.

Precise Cutting and Material Saving

Metal corner guards are generally packaged in the form of rolls. They can be accurately cut to the required length according to actual needs to avoid waste, ensure accurate control of material usage, reduce unnecessary waste, reduce decoration costs, and improve economic benefits.

Aesthetic and Decorative Appeal

The surface of the metal corner tape is smooth and flat, primarily in white, which can be paired with various paint colors to enhance the visual effect of the renovation project, meeting your personalized aesthetic needs for decoration.

Environmental Friendliness and Safety

It adopts environmentally friendly materials, is non-toxic and harmless, and meets environmental protection standards. Its solid structure can effectively prevent the corner strips from falling off and causing injuries, ensuring the health and safety of the living or working environment.

Wide Applicability and Compatibility

The metal corner tape is suitable for various wall materials such as gypsum board, wood panels, tiles, and more, perfectly combining with different renovation materials. It meets the needs of diverse renovation projects, enhancing flexibility and compatibility and ensuring consistency and integrity in corner protection.

SF

Warehouse and factory

Total annual revenue

Skilled worker

Partner With NQ To Elevate Your Project To Success

Premium quality: With 25 production lines, we use high-quality kraft paper as the base material, corrosion-resistant steel strip or aluminum strip collagen, automatic feeding, gluing, lamination, cutting, winding, and other processes to ensure product dimensional accuracy and surface finish.

Competitive price: We have established an intelligent monitoring system to continuously track various parameters in the production process, discover and solve them in time, and help you reduce production costs while ensuring quality.

Fully Customize: The regular size is 50mm in width and 30m in length. We can also provide customized services for your requirements, such as weight, texture length, etc.

Certificate

What Purchaser Say About Us

“Before using NQ Metal Corner Tape, we sought a cost-effective and reliable wall corner protection solution. NQ exceeded our expectations with a high-quality, cleverly designed product that is easy to install. Our clients in interior decoration and construction appreciate its effective protection and punctual delivery, making it an indispensable part of our business.”

Alex Johnson

Entrepreneur

“As a home decor distributor, I value products that truly benefit my customers. NQ Metal Corner Tape combines style with practicality, fitting seamlessly into any decor while protecting corners. Its reliable quality and prompt customer service make it a standout product we proudly recommend.”

Sophia Marquez

Entrepreneur

“In the Middle East, building materials must withstand extreme climates and daily wear. NQ Metal Corner Tape delivers its strong, durable metal design that protects corners from impacts and scratches. It adapts easily to various corner shapes, streamlining installation. Reasonably priced and supported by reliable logistics, it’s a valuable investment. We’re delighted and look forward to a long-term partnership.”

Mohammed Ali

Entrepreneur

Application Of Metal Corner Tape

Building Decoration And Protection

In construction and decoration projects, Metal Corner Tape is commonly used for corner protection. Whether indoors or outdoors, corners are the most susceptible areas to impacts and wear. Using metal corner tape can effectively protect corners from damage and extend the lifespan of decorative materials.

- Width: 25–50mm, with 50mm preferred for standard applications.

- Length: Supplied in rolls up to 30 meters or more.

- Thickness: Typically 0.3–0.5mm for durability.

Drywall Construction And Repair

In drywall (gypsum board) construction, Metal Corner Tape is an essential material. It is used to reinforce the joints of drywall panels, particularly at corners, to prevent cracking at the seams.

- Width: 25–50mm, with 50mm preferred for drywall seams.

- Length: Rolls are generally at least 30 meters.

- Thickness: 0.3–0.5mm, designed to withstand shrinkage and temperature changes.

Industrial Packaging And Transportation

In the field of industrial packaging and transportation, Metal Corner Tape can be used to reinforce and protect the corners of packaging boxes or goods. Especially during the transportation of heavy or fragile items, metal corner tape can effectively reduce the risk of damage during transit.

- Width: Customized, generally starting at 25mm; 75mm+ for heavy or large boxes.

- Length: Supplied in rolls with customized, often longer lengths for extensive packaging needs.

- Thickness: Typically 0.5–1.0mm or more for enhanced impact and vibration resistance.

Frequently Asked Questions

Below you can find some frequently asked questions about shipment and MOQ. If you have any further questions, please feel free to contact us.

What is your MOQ?

Our MOQ is usually 1x20ft container.But we accept lower quantity for your trial order. Please feel free to inform us your plan for

purchasing, we will offer the price correspond to your qty. And we hope your would increase your order qty after you check our

product quality and know our services.

What is the shipping port?

We ship the goods via Shanghai port.

How many colors are available?

We can do custom color when reach our MOQ qty.

Our regular colors are white, yellow, green, blue, orange, red etc.

What format of the file do you need if I want to do my own design?

For printing label design, we need AI or PDF file for set up the print-plate.

What is your delivery time?

The time of delivery is about 20~30days after we receive the deposit.

What is your sample time?

Usually we will take 7-10 days to make the samples.

Which Shipment way is available?

By sea to your designated port.

Which Payment way is workable?

1. Irrevocable L/C, Cash, PayPal, Credit card and T/T money transfers.

2.30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo.

3.L/C ( Irrevocable LC at sight)

If you need custom size such as gram weight and mesh size etc or private logo pls feel free inquiry us!

Metal Corner Tape FAQ

What is the metal corner for drywall called?

Metal corner beads are the traditional and most common choice for protecting drywall corners. Made from materials like galvanized steel or aluminum, they provide durability and a clean, straight edge for taping.

Advantages of Metal Corner Beads:

- Durability: They offer excellent protection against impacts and help prevent cracks in drywall corners.

- Precision: Metal corner beads assist in achieving sharp, crisp 90-degree angles, enhancing the overall appearance of the drywall installation.

Installation Considerations:

- Handling: Care should be taken during transportation and installation to prevent bending or twisting, as metal corner beads can be prone to such issues.

- Attachment Methods: They can be attached using nails, screws, staples, or adhesives.

- Joint Compound Application: After attachment, joint compound is applied around the metal flange to create a smooth, finished corner.

For a visual guide on installing metal drywall corner beads, you might find the following video helpful:

How do you fix metal corners on drywall?

Here’s how you fix metal corner guards on drywall

Preparation:Gather the necessary tools and materials, such as screws, expansion anchors, a level, a plumb bob, metal corner tape (with high-strength interlaced fiber joint paper tape and two parallel hot-dip galvanized steel strips), etc.Clean the wall surface to ensure it is dust-free, clean, and free of oil stains.

Measurement and Positioning:Use a tape measure to measure the length and width of the wall corners. Determine the installation location and spacing based on the dimensions of the metal corner tape.Use a level and a plumb bob for precise positioning to ensure that the metal corner guards are installed level and vertical.

Installing the Furring Strips (if needed):Install furring strips on the wall with a spacing of 65cm or less. Secure the furring strips to the wall using screws or expansion anchors.Adjust the levelness and verticality of the furring strips using a level and a plumb bob to ensure they are firmly and evenly installed.

Installing the Metal Corner Guards:Place the metal corner tape at the determined location and cut it according to need to ensure it matches the length and width of the wall corners.Secure the metal corner guards to the furring strips or wall using screws or other fasteners to ensure they are firmly fixed.

Trimming and Adjustments:After installation, check the condition of the metal corner guards to ensure they are flat, secure, and free of warping or deformation.Make minor adjustments if necessary to ensure the metal corner guards fit tightly and seamlessly against the wall.

Completion and Cleanup:Once the installation is complete, clean the workspace, removing any excess screws, screw caps, or debris.Keep the wall clean and tidy to ensure the installation effect and service life of the metal corner guards.

In summary:The key to fixing metal corner guards on drywall lies in preparation, precise measurement, secure installation, and trimming and adjustments. By following the correct steps and using the appropriate tools, you can ensure that the metal corner guards are installed flat, securely, and beautifully, providing sturdy corner protection for the drywall.

Which is better, paper or metal corner bead?

When selecting corner beads for drywall applications, understanding the differences between paper-faced and metal options is crucial. Each type has its unique characteristics, advantages, and considerations.

Paper-Faced Corner Beads:

Advantages:

Smooth Finish: Designed to blend seamlessly with drywall, paper-faced beads provide a smooth surface ideal for joint compound application.

Enhanced Bonding: The paper surface creates an excellent bond with joint compound, ensuring a strong and durable corner.

Considerations:

Impact Resistance: Paper-faced beads may be more susceptible to dents and damage from impacts.

Installation Sensitivity: Proper handling is crucial during installation to avoid damage.

Metal Corner Beads:

Advantages:

Durability: Metal beads offer high resistance to impact, making them suitable for areas prone to wear and tear.

Structural Stability: They provide a rigid structure, ensuring that corners maintain their shape over time.

Considerations:

Installation Complexity: Installing metal corner beads can be more challenging, requiring precise handling and additional fasteners.

Potential for Rust: In humid environments, metal beads may be susceptible to rust, which can compromise their integrity.

Vinyl Corner Beads:

Advantages:

Moisture Resistance: Vinyl beads are less prone to rust and corrosion, making them suitable for high-moisture areas.

Flexibility: They offer flexibility, which can be beneficial in environments where building materials may shift.

Considerations:

Bonding Issues: Joint compound may not bond as effectively to vinyl, potentially leading to adhesion problems.

Thickness: Vinyl beads are often thicker, which may require additional joint compound to cover properly.

Comparison Summary:

| Feature | Paper-Faced Beads | Metal Beads | Vinyl Beads |

|---|---|---|---|

| Durability | Prone to dents and damage; suitable for low-traffic areas. | Highly durable; ideal for high-traffic and high-impact areas. | Resistant to rust; suitable for moist environments. |

| Installation | Easy to install; bonds well with joint compound. | Requires precise installation; may need additional fasteners. | Installation is straightforward; ensure proper bonding with joint compound. |

| Cost | Generally cost-effective; suitable for budget-conscious projects. | Higher initial cost; offers long-term durability. | Typically moderately priced; offers benefits of both paper and metal options. |

| Application | Best for indoor corners with low to medium traffic. | Suitable for both indoor and outdoor corners, especially in high-traffic areas. | Ideal for areas exposed to moisture or where flexibility is needed. |

| Maintenance | May require more maintenance in high-impact areas. | Low maintenance; ensure protection against rust in humid conditions. | Regular inspection is recommended to ensure proper bonding and coverage. |

Do you overlap metal corner bead?

When installing metal corner beads on drywall, it’s important to ensure that the pieces meet neatly without overlapping. Overlapping can lead to uneven surfaces and complicate the finishing process. Instead, the ends of the corner beads should butt up against each other, creating a clean joint.

Installation Tips:

Butting Joints: When two pieces of corner bead meet, they should align directly without overlapping. This approach simplifies the application of joint compound and helps achieve a smooth finish.

Splicing Longer Runs: For corners longer than the standard length of corner beads (typically 8 feet), it’s advisable to cut a small piece (about 2 to 3 inches) of bead and place it under the butt joint. This technique ensures a seamless connection between the pieces.

Avoid Overlapping: Never overlap pieces of metal corner bead. If the corner requires a 90° angle, both pieces should be cut at 45° angles to fit together precisely.

By following these guidelines, you can achieve clean and professional results when installing metal corner beads on your drywall projects.

Do you tape over metal corner bead?

Yes, when installing metal corner beads on drywall, it’s essential to cover them with joint compound (mud) to create a seamless and durable finish. This process involves embedding the corner bead into the compound, ensuring it is securely attached and that the corner is smooth and protected.

Installation Steps:

Apply Joint Compound: After securing the metal corner bead to the drywall, apply a thin layer of joint compound over the bead. This embeds the bead into the compound, providing a strong bond and a smooth surface.

Feather the Edges: Use a drywall knife to spread the compound evenly over the bead, feathering the edges to blend seamlessly with the surrounding wall. This technique helps in achieving a smooth transition between the corner and the wall surface.

Allow to Dry and Sand: Let the compound dry completely, then sand the area to remove any imperfections. This step ensures a smooth base for subsequent coats of compound.

Apply Additional Coats: Apply one or two more coats of joint compound, allowing each coat to dry and sanding between applications. This builds up a smooth, durable finish over the metal corner bead.

By following these steps, you ensure that the metal corner bead is properly taped and finished, resulting in a clean and professional appearance for your drywall corners.

What is the easiest corner bead to use on drywall?

- Simplified Installation: Paper-faced corner beads are easier to install compared to traditional metal corner beads. They require fewer tools and less time, making them suitable for both professionals and DIY enthusiasts.

- Enhanced Durability: These beads are less prone to cracking and chipping, ensuring that your drywall corners maintain their integrity over time.

- Seamless Finish: The design of paper-faced corner beads allows for a smooth transition between the bead and the drywall, resulting in a professional appearance.

- Preparation: Ensure that the drywall corners are clean and free from debris before application.

- Applying Joint Compound: Apply a layer of joint compound to the corner area where the bead will be placed.

- Positioning the Bead: Press the paper-faced corner bead into the wet joint compound, ensuring it aligns properly with the corner.

- Finishing: Once the bead is in place, apply additional joint compound over it, feathering the edges to blend seamlessly with the surrounding wall.

Do you tape over metal corner bead?

- Apply Joint Compound: After securing the metal corner bead to the drywall, apply a thin layer of joint compound over the bead. This embeds the bead into the compound, providing a strong bond and a smooth surface.

- Feather the Edges: Use a drywall knife to spread the compound evenly over the bead, feathering the edges to blend seamlessly with the surrounding wall. This technique helps in achieving a smooth transition between the corner and the wall surface.

- Allow to Dry and Sand: Let the compound dry completely, then sand the area to remove any imperfections. This step ensures a smooth base for subsequent coats of compound.

- Apply Additional Coats: Apply one or two more coats of joint compound, allowing each coat to dry and sanding between applications. This builds up a smooth, durable finish over the metal corner bead.

Which is better, joint compound or spackle?

Joint compound and spackle are both materials used to repair and finish drywall, but they serve different purposes and are suitable for different types of projects.

Joint Compound:

Composition: Made from gypsum and limestone, joint compound is primarily used for larger drywall installation projects.

Use Cases: Ideal for sealing drywall seams, covering corner beads, and applying over drywall tape. It’s also suitable for larger repairs and creating a smooth surface over extensive areas.

Drying Time: Requires a longer drying period, often up to 24 hours, especially for thicker applications.

Application: Applied in multiple layers, with each layer requiring drying and sanding before the next application.

Advantages: Provides a durable and smooth finish, essential for preparing large wall areas for painting or further treatment.

Considerations: Due to its thinner consistency, it may have higher shrinkage when dry and can be harder to smooth out.

Spackle:

Composition: Typically composed of gypsum and binding agents, spackle is designed for smaller repairs.

Use Cases: Best suited for filling small holes, dents, and minor cracks in walls and ceilings, such as nail holes or small gouges.

Drying Time: Dries much faster than joint compound, often within 30 minutes to a few hours, depending on the product and application thickness.

Application: Easier to apply and usually requires only one layer for small repairs.

Advantages: Convenient for quick fixes and touch-ups, especially in areas that are already painted or finished.

Considerations: Not suitable for large-scale repairs or for use over drywall tape.

Choosing Between Joint Compound and Spackle:

For Small Repairs: Use spackle to quickly fill minor holes and cracks.

For Large Projects: Use joint compound for taping seams, covering corner beads, and preparing extensive wall areas.

Here is a comparison between joint compound and spackle, highlighting their primary differences to assist you in selecting the appropriate material for your project needs:

| Property | Joint Compound | Spackle |

|---|---|---|

| Uses | Ideal for large drywall projects, including sealing seams, covering corner beads, and preparing extensive wall areas. | Best suited for small repairs such as filling nail holes, minor cracks, and small dents in walls and ceilings. |

| Composition | Made from gypsum and limestone, resulting in a thinner consistency. | Composed of gypsum and binders, giving it a thicker, toothpaste-like consistency. |

| Drying Time | Longer drying time, often requiring several hours or even days, depending on application thickness and environmental conditions. | Dries quickly, typically within 30 minutes to a few hours, making it suitable for rapid repairs. |

| Shrinkage | May experience some shrinkage upon drying, necessitating multiple layers with sanding between applications to achieve a smooth surface. | Minimal shrinkage, usually requiring only one application that can be painted over without sanding. |

| Application | Requires some expertise to apply effectively, making it more suitable for professionals or experienced DIYers. | Easy to apply, ideal for beginners or quick touch-ups. |

| Cost | Generally lower in price per unit; however, the need for multiple applications can increase the overall cost. | Higher cost per unit, but typically results in lower overall expense due to less material usage. |

| Durability | Provides a sturdy and smooth finish, suitable for large-scale wall treatments. | Suitable for small repairs; may not be as durable in high-traffic areas. |

Summary:

Joint Compound: Best for extensive drywall projects requiring a durable and smooth finish, such as new drywall installations or significant repairs.

Spackle: Ideal for minor, quick repairs like filling small holes or cracks in already finished walls.

Why does corner bead crack?

Drywall corner beads, which reinforce and protect the corners of drywall installations, can develop cracks due to several factors:

Improper Installation: Incorrect attachment or inadequate fastening of the corner bead can lead to movement, resulting in cracks. Ensuring the bead is securely nailed or screwed into place is crucial.

Structural Settling: As a building settles over time, minor shifts can occur, placing stress on corner beads and causing them to crack.

Impact Damage: Corners are susceptible to physical impacts from furniture, doors, or other objects, which can dent or crack the corner bead.

Moisture Exposure: Moisture can weaken the materials surrounding the corner bead, leading to expansion, contraction, or warping, which may cause cracks to form.

Temperature Fluctuations: Significant changes in temperature can cause building materials to expand and contract. If corner beads are not installed with appropriate allowances for movement, this can lead to cracking.

Addressing these issues during both the installation and maintenance phases can help prevent the development of cracks in drywall corner beads.

What is metal corner tape?

Metal corner tape is a drywall finishing product designed to reinforce and protect the corners of drywall installations. It consists of a sturdy paper joint tape embedded with two parallel corrosion-resistant metal strips, typically galvanized steel. This combination provides enhanced durability and strength to both interior and exterior corners.

Key Features of Metal Corner Tape:

Enhanced Durability: The metal reinforcement offers superior protection against impacts and wear, extending the lifespan of wall corners.

Flexibility: Designed to conform to various angles, metal corner tape is suitable for standard 90-degree corners as well as custom shapes like archways and curves.

Ease of Application: Installation involves embedding the tape into joint compound, simplifying the finishing process for drywall projects.

Common Applications:

Wall Corner Protection: Safeguards both interior and exterior corners from damage during construction, renovation, or daily use.

Architectural Features: Ideal for enhancing the durability of custom drywall designs, including archways, vaulted ceilings, and bay windows.

By integrating metal corner tape into your drywall finishing process, you can achieve robust and aesthetically pleasing corner joints that stand the test of time.