China Carbon Fiber Tube Factory and Manufacturer

- 16+ years of manufacturing expertise.

- Customized packaging and color options (black, red, white, blue,etc.).

- Logo Customization

- OEM & ODM services with fast delivery.

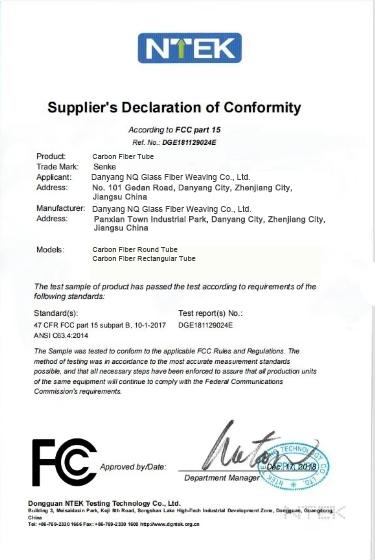

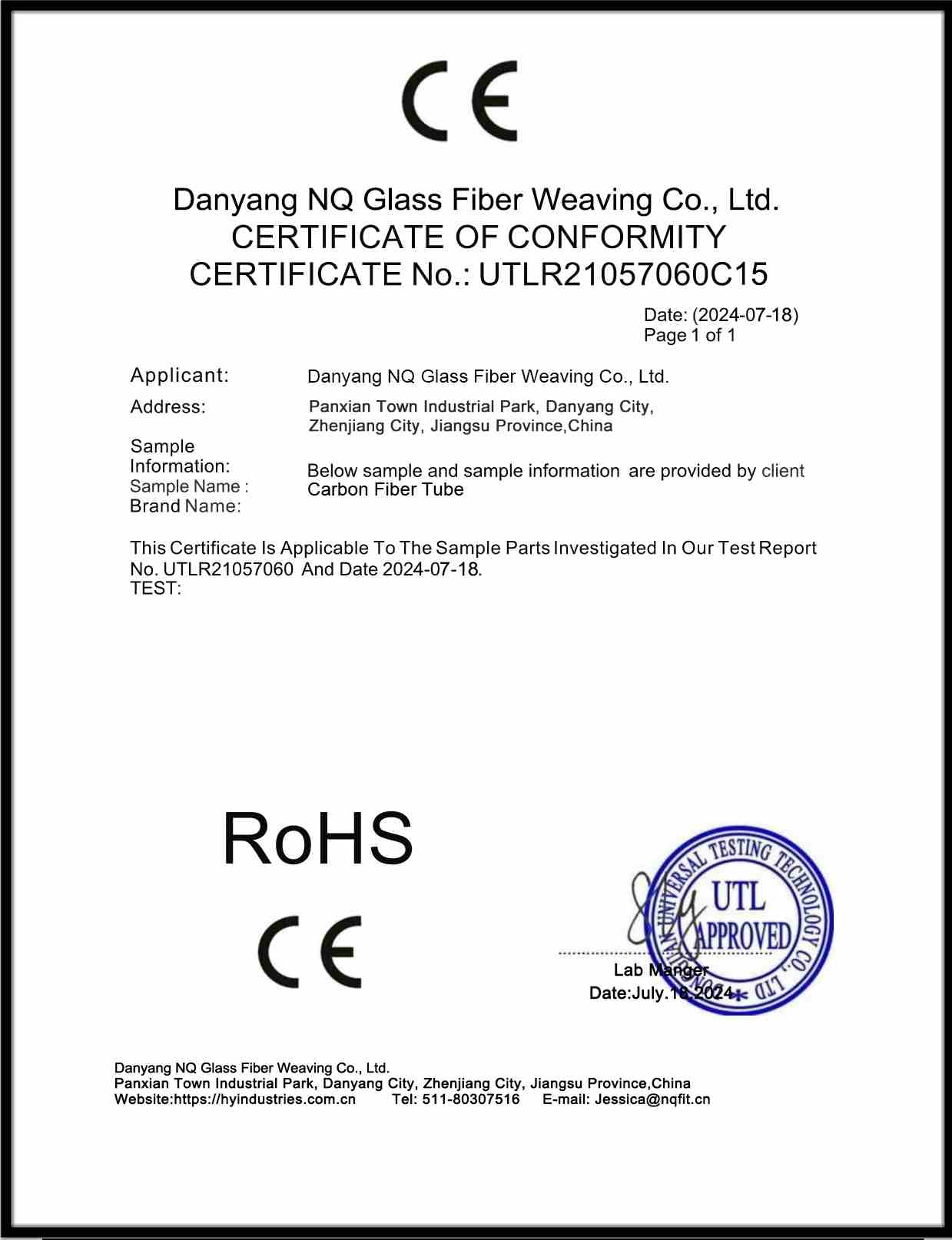

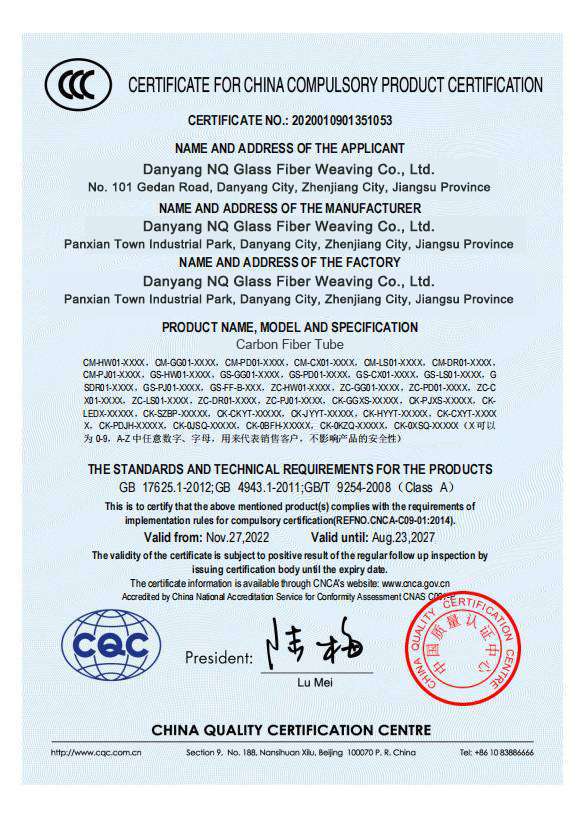

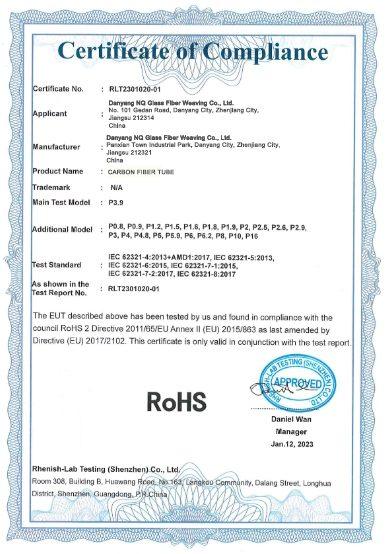

- Certified by CE, ASTM, SGS, ISO, BSCI.

- Customizable shapes: square, round, oval, and more.

years

Manufacturing Experience

Projects

We had finished

Clients

Over the world

Satisfaction

Carbon Tube Manufacturers And Suppliers

You are partnering with NQ, a leading carbon tube manufacturer and supplier, offering you high-quality, durable carbon fiber tubes for a wide range of industries. With advanced manufacturing techniques and customizable solutions, NQ ensures you get precision, strength, and lightweight performance tailored to meet all your needs.

Precision-designed carbon fiber tube manufacturing machine

By adopting CNC precision processing technology and automatic detection systems and integrating automated winding, curing, and cutting processes, the production speed is increased by 20% to 30%. Multi-station collaborative operation reduces manual intervention and reduces the error rate.

- Compatible with carbon fiber prepregs such as T300, T700, T800

- Supports a variety of resin systems such as epoxy and phenolic

- ISO 9001, CE, SGS, and ASTM standards

- 40 automated production lines to ensure on-time delivery

- In-house Strictly Testing Lab for 6-step internal inspection

Professional

Advanced manufacturing technology

High Quality

High quality CE, ASTM, SGS, ISO, BSCI certification

Cost Effective

Direct factory price

Customized

Different sizes, colors, designs, OEM/ODM

Service

Excellent customer service

Hot Selling Carbon Fiber Tube Series

Standard

Glossy finish with a unidirectional spiral-wound appearance or a woven/twill-weave texture.

Clearcoat

Clearcoat carbon fiber tube with a smooth, transparent, and glossy woven or unidirectional finish.

Sanded

Sanded carbon fiber with a smooth finish, ideal for painting or bonding, available in woven or unidirectional options.

Peel-ply

Peel-ply carbon fiber with a textured finish, specifically designed for bonding. Ideal for creating a glue-ready surface inside tubes where sanding is difficult, it also enhances grip on both woven and unidirectional tubes.

Painted

Sanded and painted for a high-gloss finish with superior UV protection. We offer a premium-quality coating in any commercially available spray paint color.

Our carbon fiber tubes come in a wide variety of colors, including black, yellow, blue, red, green, white, purple, pink, and a variety of color mixes, etc. We also provide customizable designs so that you can create a unique color that matches your brand image.

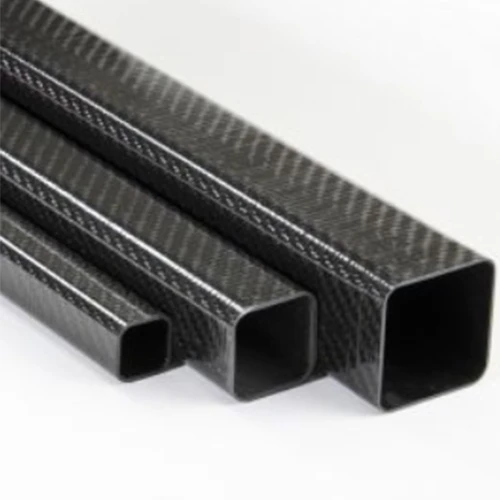

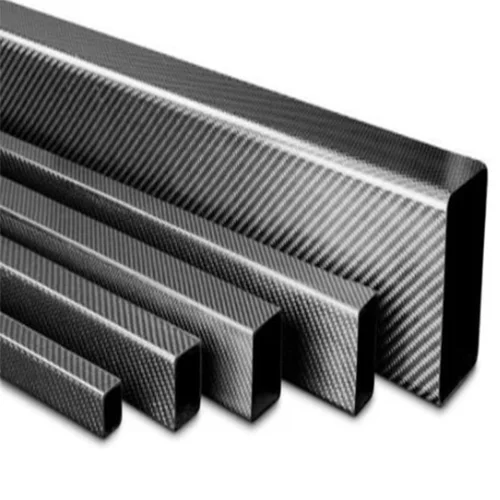

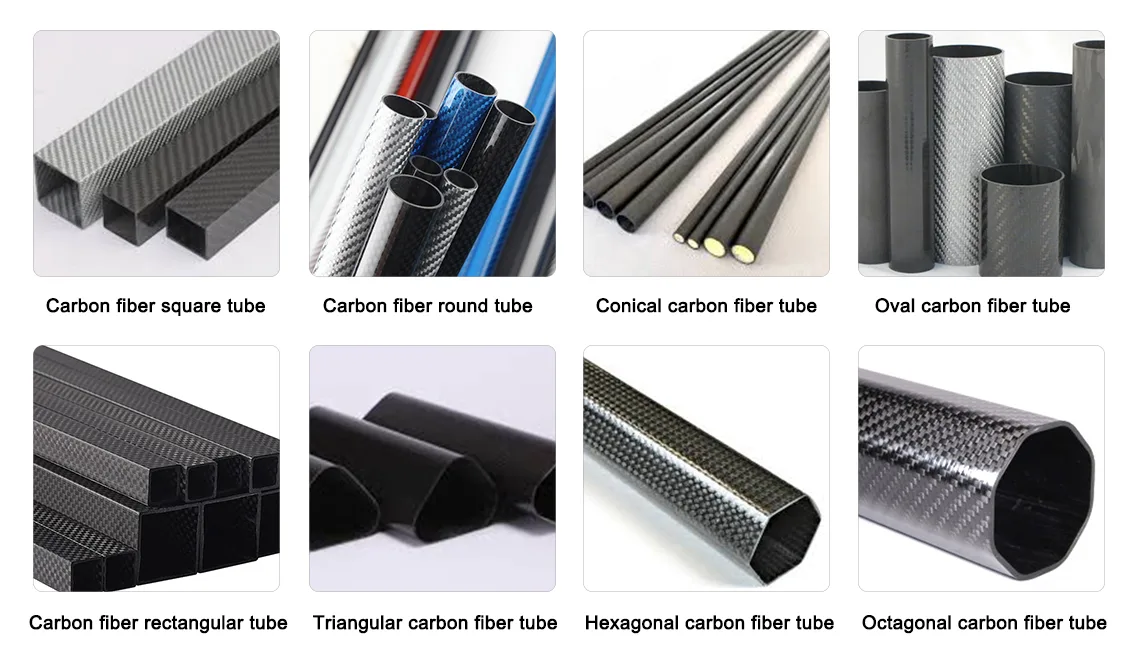

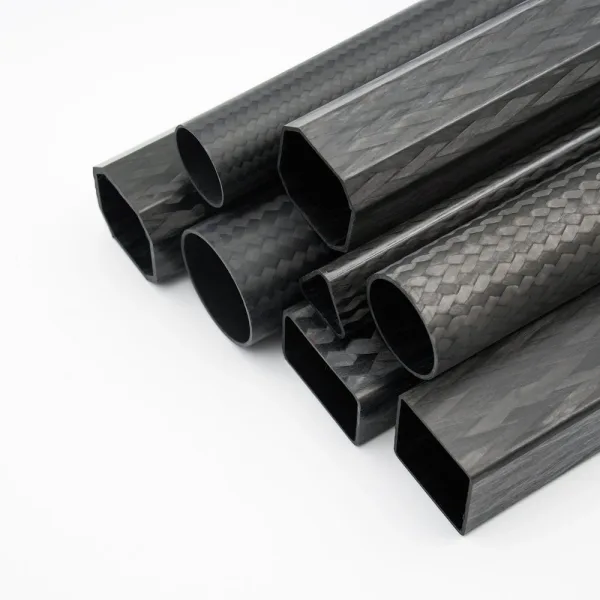

Our carbon fiber tubes are available in various shapes to meet your shape requirements and target markets. Among them, carbon fiber square tubes, conical carbon fiber tubes, carbon fiber round tubes, elliptical carbon fiber tubes, carbon fiber rectangular tubes, triangle carbon fiber tubes, hexagonal carbon fiber tubes, and octagonal carbon fiber tubes are more common, and we can ship quickly.

Boost Your Business With Custom Carbon Fiber Tubes

Size Customization

Our carbon fiber tube customization service includes a variety of diameters, lengths, and shapes for specialized applications. Common sizes range from 6mm, 8mm, 10mm, 1 inch, 1.5 inch, up to 14 inches in diameter, with lengths up to 2000mm or more. We offer customizable shapes, including square, round, oval, and more, to meet your exact specifications and project needs.

Customized Color Options

We offer various color options for our carbon fiber tubes, including classic shades like black, red, white, yellow, orange, blue, transparent, and charcoal gray. No matter your project requirements, we can tailor the colors to suit your needs and preferences. For customized packaging and color requests, please feel free to contact us.

Customized Shapes

At NQ, our carbon fiber tube customization service extends to various shapes to suit your unique applications. We can manufacture tubes in round, square, oval, and tapered designs, ensuring they meet your specific project requirements. Whether you need specialized profiles for structural applications or unique configurations for mechanical systems, our team is equipped to deliver precision-engineered shapes that enhance performance and functionality. Contact us to discuss your customized shape needs and how we can bring your vision to life.

Packaging Customization

At NQ, we understand the importance of packaging for safely delivering and presenting our carbon fiber tubes. We offer customizable solutions, including protective materials like bubble wrap, foam inserts, and branded boxes that enhance your brand identity. For eco-conscious businesses, we provide sustainable packaging options and tailor sizes for a secure fit, minimizing damage during transport. Our team collaborates with you to create packaging that reflects your brand while ensuring product protection.

Carbon Fiber Tubes Specifications

Brand Name | NQ |

application | Automobile and machinery parts (such as intake pipes, buffers, suspension pipes and rocket tubes). |

Shape | Square, rectangle, cone, circle, oval, arc, triangle, hexagon, octagon. |

Product Type | Carbon Fiber |

Operating temperature | 150 degrees |

Volatile | 0.001% |

Material | 100% Carbon Fiber |

color | Black, blue, red, yellow, orange, green, purple, etc., customizable |

surface | Glossy/Matte/50% Glossy |

feature | Light |

size | Custom length |

Weaving | 3K Twill/Twill Logo |

Logo | Customized Logo |

work | Winding |

Unit (mm) ID*Length) | |||

3.2*650 | 8*1000 | 10*1200 | 12*1200 |

3.2*600 | 8*1000 | 10*1300 | 12*1400 |

4*1000 | 8. 1*1000 | 10. 1*1000 | 12*1600 |

4*1100 | 8.3*1000 | 10.3*1200 | 12.5*1100 |

5*1000 | 8.5*720 | 10.5*1200 | 12.7*1000 |

6*1000 | 8.5*1000 | 10.5*1000 | 12.7*1100 |

6*1300 | 9*1000 | 11*1000 | 13*1000 |

6. 1*1000 | 9*1200 | 11*1200 | 13*1100 |

7*1300 | 9.3*1200 | 11.5*1100 | 13.5*1100 |

7.2*1000 | 9.75*1200 | 11.8*1200 | 14*1200 |

86*1100 | 200*1100 | 31*950 | 9.5*1500 |

99.3*1100 | 40.8*1100 | 22*1450 | 94*1300 |

155*900 | 44.7*1200 | 47.8*1000 | 54*1200 |

If we don’t have your size, we can customize your size, please contact us | |||

Product Name | High strength carbon fiber tube |

Surface | Glossy,matte,woven textureBlack or colorful, etc. Custom-madeis welcome |

Specification Length | Various styles are welcome to customize |

Service | Various specifications can be customized according to yourneedsSelection of high quality materialsProvide professional and attentive serviceFine workmanship well-made products more practical |

Advantage | Corrosion resistance, light weight, high strength, not easyto wearand tear, strong designability, good thermal and electrical |

Tube Manufacturing Processes & Fabrication Techniques

The manufacturing of NQ’s carbon fiber tube is a meticulous and highly efficient process that ensures the highest quality standards. This process is broken down into six critical steps:

1.Prepare the Carbon Fiber Prepreg

Cut sheets of carbon fiber prepreg (resin-infused fiber layers) to the desired length and angle, ensuring the fiber direction matches the required strength specifications for the tube.

2. Roll-Wrapping

Wrap the carbon fiber prepreg around a mandrel (a cylindrical mold) using advanced roll-wrapping machinery. This ensures a precise fiber alignment and the tube’s desired thickness and dimensions.

3.Vacuum Bagging

Place the wrapped mandrel into a vacuum bag to remove any air pockets or excess resin. This step ensures an even distribution of resin and prevents defects in the final product.

4. Curing

Place the vacuum-sealed tube into an autoclave or curing oven, where controlled heat and pressure solidify the resin. This process enhances the strength and durability of the carbon fiber tube.

5. Mandrel Removal

Once cured, remove the carbon fiber tube from the mandrel. This process can include cooling the tube and applying force or mechanical means to release the tube without damaging its structure.

6.Finishing and Quality Control

Trim any excess material, sand the surface for a seamless finish, and run the tube through strict quality control checks, including dimensional analysis and strength testing, to ensure it meets performance standards.

NQ Premium Carbon Fiber Tube Advantages

Lightweight & High Strength

You’ll benefit from the exceptional strength-to-weight ratio of our carbon fiber tubes. They are significantly lighter than metal alternatives while offering superior strength and durability, perfect when you need to reduce weight without compromising performance.

Superior Stiffness

When you need stiffness and minimal deflection under heavy loads, our carbon fiber tubes are the solution. You can rely on them for your structural and high-performance projects, ensuring top-notch reliability.

Corrosion Resistance

You won’t have to worry about rust or corrosion over time. Our carbon fiber tubes resist moisture, chemicals, and saltwater, giving you long-lasting performance even in the harshest environments.

Thermal Stability

No matter the temperature, hot or cold, you can trust our carbon fiber tubes to maintain stability and performance. Whether you’re working in aerospace, automotive, or industrial settings, these tubes won’t let you down.

Customization Options

Get exactly what you need with our customizable carbon fiber tubes. You can specify the length, diameter, and shape—whether round or rectangular—to perfectly fit your project requirements.

Electrical Conductivity

If your application demands it, you can take advantage of carbon fiber tubes engineered for electrical conductivity, perfect for static dissipation or EMI shielding needs.

SF

Warehouse and factory

Total annual revenue

Skilled worker

Partner With NQ To Elevate Your Project To Success

Superior Quality: Made from high-strength carbon fiber, our tubes offer exceptional tensile strength, fatigue resistance, and durability against corrosion and harsh weather. They ensure reliability in extreme conditions while maintaining a lightweight structure.

Wide Selection: Our carbon fiber tubes serve aerospace, automotive, and industrial needs and are available in diameters from 6mm to 14 inches and lengths up to 2000mm. Choose from round, square, oval, or tapered shapes with customizable wall thickness, surface finishes, and colors.

Competitive Price: With a streamlined supply chain and automated production, we offer high-quality carbon fiber tubes at cost-effective prices. Bulk orders receive even more significant pricing advantages, delivering premium performance at an unbeatable value.

Certificate

What Peoples Say About Us

“As a building materials wholesaler, adding NQ carbon fiber tubes has been a game-changer. Their superior quality and versatility make them a customer favorite. NQ’s expert support and fast, reliable service simplify my operations and give me complete confidence in recommending their products.”

Alexander Smith

Entrepreneur

“I recently purchased NQ carbon fiber tubes, and their high tensile strength, corrosion resistance, and structural stability make them ideal for various engineering applications. Whether for reinforcement, lightweight alternatives, or durability in harsh environments, NQ’s tubes offer exceptional versatility and performance. Their superior quality has given my business a competitive edge, and I look forward to continuing my partnership with NQ for future projects.”

Michael Brown

Entrepreneur

“Their carbon fiber tubes have become a cornerstone of my wholesale business through my collaboration with NQ. These products have earned customer trust and enhanced my market competitiveness by offering competitive pricing and exceptional quality. I’m excited to continue strengthening this successful partnership.

James Williams

Entrepreneur

Application Of Carbon Fiber Tube

As a leading manufacturer of carbon fiber tubes, we are dedicated to supplying you with premium, high-strength carbon fiber tube products. Whether it’s for structural reinforcement, aerospace applications, automotive upgrades, or sports equipment, carbon fiber tubes are the ultimate solution. From residential DIY projects to commercial constructions, industrial machinery, and even high-performance racing vehicles, carbon fiber tubes offer unparalleled durability and a sleek, modern aesthetic.

Aerospace

At NQ, we provide carbon fiber tubes essential for reducing aircraft weight while maintaining strength. Whether you’re building drones or satellites, we recommend our high-strength, low-weight carbon fiber tubes with optimized fiber alignment for increased rigidity and durability.

For aerospace applications, tubes with a diameter range of 10-100mm and a wall thickness of 0.5-2mm are ideal to ensure superior performance in critical conditions.

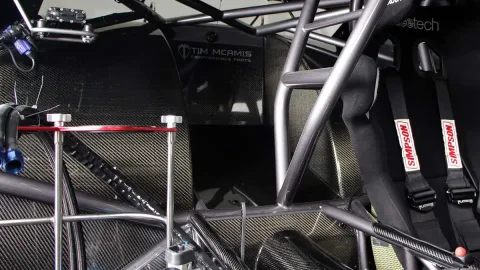

Automotive

We manufacture carbon fiber tubes that enhance vehicle performance by reducing weight without sacrificing strength.

For drive shafts and roll cages, we recommend using tubes with a diameter range of 20-120mm and a wall thickness of 1-3mm. These specifications provide the balance needed for better acceleration, handling, and safety in automotive projects.

Sports Equipment

Our carbon fiber tubes are perfect for high-performance sports equipment. Whether you’re designing lightweight bicycle frames or flexible fishing rods, we recommend tubes with a diameter of 15-50mm and a wall thickness of 0.8-1.5mm. These specifications ensure durability, flexibility, and precision for superior athletic performance.

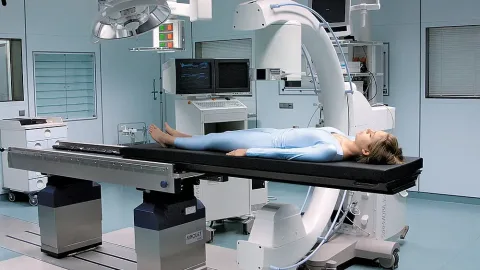

Medical Devices

NQ’s carbon fiber tubes are ideal for lightweight and durable medical devices. For applications such as surgical instruments or rehabilitation equipment, we recommend using tubes with a smaller diameter range of 5-20mm and a wall thickness of 0.5-1mm. These specifications provide the strength and biocompatibility needed for patient care.

Robotics

For robotics, our carbon fiber tubes provide the rigidity and lightweight properties necessary for precise movements and increased load-bearing capabilities. We recommend tubes with a diameter range of 10-80mm and a wall thickness of 0.5-2mm, ensuring your robotic arms or drone frames have the precision and strength needed for optimal performance.

Marine

In the marine industry, our carbon fiber tubes offer corrosion resistance and high strength. For masts, rudders, and other marine components, we recommend tubes with a diameter of 20-150mm and a wall thickness of 1-4mm. These specifications guarantee long-lasting performance even in harsh saltwater environments.

Frequently Asked Questions

Below you can find some frequently asked questions about shipment and MOQ. If you have any further questions, please feel free to contact us.

What is your MOQ?

Our MOQ is usually a 1x20ft container. But we accept lower quantities for your trial order. Please inform us of your purchasing plan; we will offer the price corresponding to your quantity. We hope you will increase your order qty after you check our

product quality and know our services.

What is the shipping port?

We ship the goods via Shanghai port.

How many colors are available?

We can do custom color when reach our MOQ qty.

Our regular colors are white, yellow, green, blue, orange, red etc.

What format of the file do you need if I want to do my own design?

For printing label design, we need AI or PDF file for set up the print-plate.

What is your delivery time?

The time of delivery is about 20~30days after we receive the deposit.

What is your sample time?

Usually we will take 7-10 days to make the samples.

Which Shipment way is available?

By sea to your designated port.

Which Payment way is workable?

1. Irrevocable L/C, Cash, PayPal, Credit card and T/T money transfers.

2.30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo.

3.L/C ( Irrevocable LC at sight)

If you need custom size such as gram weight and mesh size etc or private logo pls feel free inquiry us!

Carbon Fiber Tube FAQ

What Are Carbon Fiber Tubes Used For?

Carbon fiber tubes are utilized across various industries due to their exceptional strength-to-weight ratio, rigidity, and resistance to corrosion. Their applications include:

Civil Engineering: In structural engineering, carbon fiber-reinforced polymers (CFRPs) are employed to strengthen existing structures such as bridges, beams, and columns. They enhance load capacity and seismic resistance, offering a cost-effective alternative to traditional retrofitting methods.

Sports Equipment: Beyond bicycle frames, carbon fiber tubes are used in various sports equipment, including fishing rods, ski poles, and golf clubs, owing to their lightness and strength.

Medical Applications: In dentistry, carbon fibers are used for splinting teeth and in endodontic procedures, providing strength and durability in dental restorations.

These diverse applications highlight the versatility and importance of carbon fiber tubes in modern engineering and manufacturing.

Can You Cut Carbon Fiber Tubes?

- Diamond-Coated Abrasive Cut-Off Blade: Utilizing a diamond-coated abrasive blade is highly effective for cutting carbon fiber tubes. This type of blade minimizes the risk of fraying and ensures a clean cut. It’s advisable to avoid toothed blades, as they may cause splintering.

- Rotational Cutting Technique: When using power tools like a Dremel or a jigsaw, employing a rotational cutting technique can yield precise results. This method involves rotating the tube during the cutting process to achieve a uniform and clean edge.

- Water Jet Cutting: Water jet cutting uses a high-pressure water stream to cut the material. It’s crucial to note that the tube wall should not be too thick, and operators should have adequate skill to handle the equipment effectively.

How To Cut Carbon Fiber Tube?

- Diamond-Coated Abrasive Cut-Off Blade: Ideal for cutting carbon fiber, these blades minimize fraying and provide clean cuts.

- Rotational Cutting Tools: Tools like a Dremel or jigsaw, when used with appropriate blades and a rotational cutting technique, can achieve precise cuts.

- Rotational Cutting Method: Rotate the tube while cutting to ensure a uniform and clean edge. This technique is effective with both handheld and power tools.

- Personal Protective Equipment (PPE): Always wear safety glasses, gloves, and a dust mask to protect against fine carbon fiber particles.

- Ventilation: Ensure the workspace is well-ventilated or equipped with a dust extraction system to minimize inhalation risks.

How Do You Fasten Carbon Fiber Tubes?

Fastening carbon fiber tubes requires careful consideration to maintain their structural integrity and performance. The primary methods for connecting these tubes are adhesive bonding and mechanical fastening.

Adhesive Bonding:

This method involves joining carbon fiber tubes using specialized adhesives, providing a seamless connection that preserves the material’s strength. Key points include:

Surface Preparation: Proper cleaning and surface treatment of the bonding areas are crucial to ensure strong adhesion.

Adhesive Selection: Choosing adhesives with suitable curing processes, environmental resistance, and temperature stability is essential.

Application: Apply the adhesive evenly, align the tubes accurately, and allow sufficient curing time as per the adhesive manufacturer’s guidelines.

Mechanical Fastening:

Mechanical methods involve using fasteners such as bolts, screws, or clamps to connect carbon fiber tubes. Considerations include:

Avoid Drilling: Drilling into carbon fiber tubes can compromise their structural integrity. It’s advisable to use clamps or external fittings instead of drilling.

Use of Clamps and Fittings: Employ clamps or external connectors that encircle the tubes, distributing loads evenly without penetrating the tube walls.

Design Considerations: Ensure that the fastening system does not induce stress concentrations that could lead to failure.

Each method has its advantages and is suitable for different applications. Adhesive bonding offers a clean and seamless connection, ideal for applications where aesthetics and weight savings are important. Mechanical fastening provides a detachable connection, useful for assemblies requiring maintenance or adjustment. It’s essential to assess the specific requirements of your project, including load conditions, environmental factors, and design constraints, to choose the most appropriate fastening method for carbon fiber tubes.

How to connect carbon fiber tubes

- Surface Preparation: Proper cleaning and preparation of the tube ends are essential for ensuring strong adhesive bonds.

- Connector Selection: Choosing appropriate connectors is vital for achieving the desired balance between strength and adjustability.

- Stress Distribution: Ensure that connectors distribute stresses evenly to prevent localized weaknesses.

How to bend carbon fiber tube?

Bending carbon fiber tubes requires careful consideration to maintain their structural integrity and performance. Unlike metals, carbon fiber reinforced polymers (CFRP) are anisotropic, meaning their properties vary depending on the fiber orientation and the manufacturing process. Here’s how you can approach bending carbon fiber tubes:

1. Understanding Carbon Fiber Tubes:

Carbon fiber tubes are typically manufactured using processes like pultrusion, filament winding, or roll-wrapping. These methods influence the tube’s fiber orientation and mechanical properties. It’s essential to know the manufacturing process and fiber alignment of your specific tube, as these factors dictate its flexibility and the feasibility of bending.

2. Bending During Manufacturing:

Ideally, carbon fiber tubes should be molded into their final shape during the manufacturing process. This approach ensures that the fiber orientation and structural integrity are optimized for the intended application. Attempting to bend fully cured carbon fiber tubes can lead to issues such as delamination or reduced strength.

3. Post-Manufacturing Bending:

If bending after manufacturing is necessary, it must be done carefully to avoid damaging the tube:

- Heating: Applying heat can increase the resin’s flexibility, making the tube more pliable for bending. However, this process requires precise temperature control to prevent degradation of the material.

- Using an Internal Mandrel: Employing an internal mandrel during the bending process helps maintain the tube’s shape and prevents collapse. Research has shown that using a rigid internal mandrel is effective in supporting the tube walls during bending.

- Avoiding Over-Bending: Exceeding the material’s bending limits can cause permanent deformation or failure. It’s crucial to stay within the manufacturer’s recommended bending radii and angles.

4. Consulting Manufacturers:

Before attempting to bend carbon fiber tubes, consult with the manufacturer or supplier. They can provide specific guidelines based on the tube’s design, fiber orientation, and intended application.

5. Visual Guide:

For a practical demonstration and further insights into bending carbon fiber, you might find the following video helpful:

In summary, while bending carbon fiber tubes post-manufacturing is possible, it requires careful consideration of the material’s properties, the use of appropriate techniques, and consultation with manufacturers to ensure the structural integrity and performance of the tube are maintained.

How to drill carbon fiber tube

Drilling carbon fiber tubes requires precision and care to avoid damaging the material. Here are some steps to follow when drilling carbon fiber tubes:

1. Choose the Right Drill Bit

- Carbide-tipped drill bits are the best choice for drilling carbon fiber tubes. They are hard and durable enough to handle the abrasive nature of carbon fiber without causing damage.

- Cobalt drill bits are also effective for this task and can withstand the stresses of drilling into tough materials like carbon fiber.

2. Preparation

- Mark the Drilling Point: Use a fine-tip marker or tape to mark the exact spot where you want to drill.

- Clamp the Tube Securely: It’s important to hold the tube in place to prevent any movement while drilling. Use soft clamps or padding to avoid damaging the tube’s surface.

- Use a Backing Material: Place a piece of scrap wood or other backing material behind the carbon fiber tube to prevent the hole from splintering as you drill through.

3. Drilling Process

- Start Slowly: Begin drilling at a low speed. High-speed drilling can cause heat buildup, leading to delamination or damage to the carbon fibers.

- Drill with Light Pressure: Apply light, steady pressure. Don’t force the drill bit through the material as this can cause cracking.

- Use Coolant or Lubricant: Applying cutting fluid or coolant will help reduce heat and friction. A light spray of water or a specialized cutting fluid for composites is recommended.

4. Drill in Stages

- If the hole needs to be larger, it’s better to use a series of progressively larger drill bits rather than trying to drill directly with a large bit. This helps reduce the stress on the material.

5. Finishing the Hole

- Deburr the Edges: After drilling, use a file or deburring tool to smooth out any rough edges around the hole to prevent the tube from splintering or cracking further.

- Clean Up: Carbon fiber dust is hazardous, so make sure to clean up properly and avoid inhaling the particles. Wear a dust mask and gloves while drilling.

By following these guidelines, you can safely and effectively drill into carbon fiber tubes without damaging them.

What is carbon fiber tube?

A carbon fiber tube is a cylindrical structure composed of carbon fibers embedded in a polymer matrix, resulting in a lightweight yet exceptionally strong material. These tubes are manufactured by weaving carbon fibers and bonding them together with resin, creating a composite material that offers impressive strength-to-weight ratios.

Key Characteristics:

Lightweight: Carbon fiber tubes are significantly lighter than metals like steel and aluminum, making them ideal for applications where weight reduction is crucial.

High Strength: Despite their lightness, these tubes possess high tensile strength, allowing them to withstand substantial loads without deformation.

Durability: Carbon fiber is resistant to corrosion, ensuring a longer lifespan even in harsh environments.

Manufacturing Process:

The production of carbon fiber tubes involves wrapping carbon fiber sheets around a mandrel (a rod or form) and curing them with resin. Once hardened, the mandrel is removed, leaving behind a hollow, cylindrical tube. This process allows for customization in terms of tube dimensions and fiber orientation, tailoring the mechanical properties to specific applications.

Applications:

Due to their unique properties, carbon fiber tubes are utilized in various fields, including:

Aerospace and Automotive Industries: For components that require high strength while minimizing weight.

Sports Equipment: Such as golf club shafts, bicycle frames, and fishing rods, where performance and durability are essential.

Structural Supports: In construction and robotics, providing rigid yet lightweight support structures.

In summary, carbon fiber tubes are advanced composite materials that combine the lightweight nature of carbon fibers with the versatility of tubular forms, making them indispensable in applications demanding high performance and efficiency.

Is Carbon Fiber Tube Strong?

- High Tensile Strength: Carbon fiber tubes are known for their impressive tensile strength, which means they can withstand a lot of pulling or stretching forces without breaking. This makes them ideal for high-stress applications like aerospace, automotive, and sporting goods.

- Lightweight: Despite their strength, carbon fiber tubes are much lighter than materials like steel or aluminum. This strength-to-weight ratio makes them perfect for industries that require both strength and weight efficiency, such as in aerospace, racing, and high-performance sports.

- Stiffness and Rigidity: Carbon fiber tubes are also highly rigid, meaning they maintain their shape under pressure without bending or flexing. This is crucial in applications where precision and structural integrity are important.

- Durability: Carbon fiber is resistant to corrosion, fatigue, and wear. It can withstand extreme environmental conditions, making it durable and long-lasting in demanding situations.

- Unidirectional Strength: For unidirectional carbon fiber tubes, the strength is even more concentrated along the length of the tube, offering maximum resistance to forces in that direction. This makes them ideal for structural applications that experience stress along a single axis.

Is Carbon Fibre Tube Flexible?

- Fiber Orientation: Aligning fibers in specific directions affects the tube’s stiffness. For instance, unidirectional fibers aligned along the tube’s length provide maximum strength and stiffness in that direction. Incorporating woven or braided patterns introduces crisscrossing fibers, which can add controlled flexibility, allowing the tube to twist or bend as needed.

- Layering Techniques: The arrangement and number of layers in a carbon fiber tube influence its mechanical properties. Combining different layer types, such as unidirectional and woven fibers, enables the customization of both strength and flexibility. Woven layers, for example, can enhance flexibility compared to unidirectional layers.

- Manufacturing Processes: Techniques like filament winding allow for precise control over fiber orientation, enabling the creation of tubes with specific directional strengths and flexural properties. This process offers greater flexibility in tailoring the tube’s characteristics to meet specific requirements.

What Are The Carbon Fiber Tube Sizes Strength Density?

Carbon fiber tubes are engineered products, and their mechanical properties—including strength and density—are primarily determined by their design, manufacturing process, and the specific carbon fiber materials used. Unlike uniform materials, carbon fiber tubes can be customized in various ways, leading to a range of properties.

Key Factors Influencing Carbon Fiber Tube Properties:

Fiber Orientation and Layup: The arrangement of carbon fibers within the tube affects its stiffness and strength. Unidirectional layups provide strength in one direction, while woven patterns offer multi-directional strength.

Fiber Type: Different carbon fiber grades offer varying tensile strengths and moduli. For example, standard modulus fibers typically exhibit a tensile modulus of 33-34 Msi, whereas intermediate modulus fibers can reach up to 42 Msi.

Resin System: The type of resin used to bond the fibers influences the tube’s overall mechanical properties, including its density and strength.

Manufacturing Process: Techniques such as pultrusion or filament winding can affect the tube’s density and structural integrity.

Typical Properties:

Density: Carbon fiber tubes generally have densities ranging from approximately 1.6 to 1.9 g/cm³, depending on the fiber and resin combination.

Tensile Strength: The ultimate tensile strength of carbon fiber can reach up to 4000 MPa, though this varies based on fiber grade and construction.

Modulus of Elasticity: This property indicates the stiffness of the material. Carbon fibers typically have a modulus of elasticity around 500 MPa, but this value can vary with different fiber types and orientations.

Selecting Tube Sizes:

The dimensions of carbon fiber tubes (outer diameter and wall thickness) are chosen based on the specific application requirements, balancing factors like weight, strength, and flexibility. It’s essential to consult with manufacturers or refer to technical datasheets to obtain precise information tailored to your application’s needs.

In summary, carbon fiber tubes are highly customizable, and their mechanical properties are influenced by several design and manufacturing factors. For detailed specifications, it’s recommended to consult technical datasheets from manufacturers or engage with materials engineers to select the appropriate tube configuration for your specific application.

How Stiff Is Carbon Fiber Tubing?

Carbon fiber tubes are renowned for their exceptional stiffness, which is primarily determined by their Modulus of Elasticity, commonly known as Young’s Modulus. This property measures a material’s resistance to elastic deformation under stress. The stiffness of carbon fiber tubes surpasses that of many traditional materials, making them ideal for applications requiring high precision and stability.

Stiffness Comparison:

Carbon Fiber: Approximately 4 times stiffer than fiberglass and over twice as stiff as aluminum.

Standard Modulus Carbon Fiber: Offers excellent strength and stiffness, being 1.5 times stiffer than aluminum.

Intermediate Modulus Carbon Fiber: Provides enhanced stiffness, about twice as stiff as aluminum tubing.

High Modulus Carbon Fiber: At three times stiffer than aluminum (or equivalent to steel stiffness), this grade maintains similar strength to standard modulus carbon fiber tubing.

Tailoring Stiffness:

The stiffness of carbon fiber tubes can be customized by adjusting several factors during their design and manufacturing:

Fiber Orientation: Aligning fibers in specific directions affects the tube’s stiffness. Unidirectional fibers provide maximum stiffness along their length, while woven patterns offer multi-directional stiffness.

Layering Techniques: Combining different fiber orientations and layering sequences allows for precise control over the tube’s stiffness properties.

Resin Systems: The choice of resin influences the overall stiffness. Selecting resins with appropriate curing processes and temperature stability is crucial for achieving desired stiffness levels.

By manipulating these design parameters, manufacturers can produce carbon fiber tubes with stiffness tailored to meet the specific requirements of various applications, from aerospace components to sporting equipment.

How to join carbon fiber tubes

- Surface Preparation: Proper cleaning and preparation of the tube ends are essential for ensuring strong adhesive bonds.

- Connector Selection: Choosing appropriate connectors is vital for achieving the desired balance between strength and adjustability.

- Stress Distribution: Ensure that connectors distribute stresses evenly to prevent localized weaknesses.

How strong is carbon fiber tube?

Carbon fiber tubes are renowned for their exceptional strength-to-weight ratio, making them ideal for applications requiring both lightweight and high-strength materials. The strength of a carbon fiber tube is influenced by several factors, including the type of carbon fiber used, fiber orientation, resin system, and manufacturing process.

Tensile Strength:

Carbon Fiber Filaments: Individual carbon fibers exhibit high tensile strengths, typically ranging from 3 to 7 GPa (gigapascals).

Carbon Fiber Tubes: The tensile strength of carbon fiber tubes depends on their design and construction. For instance, pultruded composite tubes can have tensile strengths up to 1,200 MPa (megapascals), while roll-wrapped tubes may reach higher strengths due to their manufacturing process.

Flexural and Compressive Strength:

Flexural Strength: Carbon fiber tubes exhibit significant bending strength, which is influenced by fiber orientation and wall thickness. Proper design can optimize flexural properties for specific applications.

Compressive Strength: The compressive strength of carbon fiber tubes is typically lower than their tensile strength, ranging from 1 to 3 GPa. This property is crucial for applications subjected to axial loads.

Design Considerations:

Fiber Orientation: Aligning fibers in the direction of expected loads enhances the tube’s strength. Conversely, cross-ply orientations can improve resistance to transverse loads.

Resin System: The choice of resin affects the tube’s mechanical properties. Epoxy resins are commonly used for their favorable strength characteristics.

Manufacturing Process: Techniques such as pultrusion and roll-wrapping influence the fiber alignment and resin distribution, thereby affecting the tube’s overall strength.

Applications:

Due to their high strength and low weight, carbon fiber tubes are widely used in aerospace, automotive, sporting goods, and structural applications. However, it’s essential to note that while carbon fiber tubes offer high tensile and flexural strengths, they may be more susceptible to impact damage compared to metals.

Conclusion:

The strength of carbon fiber tubes is a function of their material composition, design, and manufacturing process. By optimizing these factors, manufacturers can produce tubes tailored to meet the specific requirements of various applications, balancing strength, weight, and cost considerations.

How to cut carbon fiber tube with dremel

Cutting carbon fiber tubes with a Dremel rotary tool can be effective for small, precise cuts, but it requires careful technique to avoid damaging the material. Here’s a step-by-step guide:

1. Select the Appropriate Cutting Wheel:

- Diamond-Grit Cutting Wheel: Opt for a diamond-coated cutting wheel designed for tile or masonry. These wheels are more durable and less likely to cause fraying compared to standard abrasive wheels.

2. Secure the Carbon Fiber Tube:

- Clamping: Use clamps or a soft-jaw vise to hold the tube firmly in place, preventing movement during cutting. Ensure the tube is well-supported to avoid flexing or deformation.

3. Mark the Cutting Area:

- Clearly mark the desired cut line on the tube using a fine-tip marker or masking tape. This provides a visual guide and helps maintain cutting accuracy.

4. Set the Dremel to Appropriate Speed:

- Operate the Dremel at a high speed to facilitate efficient cutting.

5. Cutting Technique:

- Light Pressure: Apply minimal pressure, allowing the cutting wheel to do the work. Excessive force can lead to binding or splintering.

- Cooling the Cutting Area: Periodically apply a cooling agent, such as oil or WD-40, to the cut area to reduce heat buildup and prevent material degradation.

- Rotational Cutting: Rotate the tube slowly while cutting to ensure an even and clean cut. This technique helps in achieving a smooth edge and reduces the risk of delamination.

6. Finishing the Cut:

- Deburring: After cutting, use a fine-grit sandpaper or file to smooth any rough edges or burrs, ensuring a clean finish.

- Cleaning: Remove any residual dust or debris from the cutting process to maintain the tube’s integrity.

Safety Precautions:

- Personal Protective Equipment (PPE): Wear safety glasses, a dust mask, and gloves to protect against flying debris and inhalation of carbon fiber dust.

- Ventilation: Ensure the work area is well-ventilated to disperse any airborne particles.

By following these steps and precautions, you can effectively cut carbon fiber tubes with a Dremel tool while minimizing the risk of damage.

Where to buy carbon fiber tube?

If you’re looking to purchase carbon fiber tubes in the United States, here are some reputable suppliers:

Clearwater Composites, LLC: They offer a wide range of carbon fiber tubes, including round, standard modulus, and ferrule options, all with high fatigue resistance and low to zero coefficient of thermal expansion.

DragonPlate: A leading innovator in high-performance carbon fiber-reinforced composites, DragonPlate provides custom carbon fiber shapes, as well as products like tubes, sheets, and plates.

Forte Carbon Fiber Tubing: Specializing in marine and aerospace quality carbon fibers, Forte manufactures custom carbon fiber tubes and composite tubular structures for various industries, including marine, defense, and automotive.

TipTop Composites: They offer customized carbon fiber tubes and pipes, catering to industries such as agriculture, marine, UAVs, medical equipment, and industrial machinery.

National Plastics & Seals, Inc.: This company distributes carbon fiber tubes suitable for structural applications across various industries, including aerospace, automotive, and medical.

In addition, you can also contact NQ directly to find out how to purchase its carbon fiber tube products. NQ is a carbon fiber tube manufacturer located in Danyang, Jiangsu Province, China, providing high-strength, lightweight carbon fiber tubes, which are widely used in structural reinforcement, aerospace, automotive modification and sports equipment.

NQFIBERGLASSMESH

Contact information:

- Tel: +86-13775339109

- Email: Jessica@nq-fiberglass.cn

- Whatsapp: 0086-13775339109

- Wechat: 13775339109

- Email: fiberglassmesh@hotmail.com

It is recommended that you contact NQ directly to inquire about their sales channels or agent information in Singapore, so as to make it easier to purchase and obtain after-sales service.