Products Categories

Featured Products

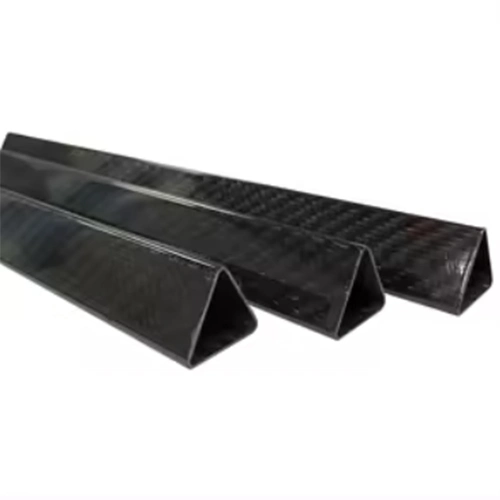

Carbon Fiber Triangle Tube

Carbon fiber triangle tube is a high-performance composite tube made from premium carbon fiber and epoxy resin, featuring a unique triangular cross-section. It offers lightweight construction, high strength, excellent rigidity, and superior dimensional stability, along with strong corrosion and aging resistance. The triangular profile enhances overall structural stability and mechanical performance.

Product MOQ

Please note our minimum order quantity of Carbon Fiber Tube. For the conventional Carbon Fiber Tube in stock, there is no MOQ. For customized Carbon Fiber Tube, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

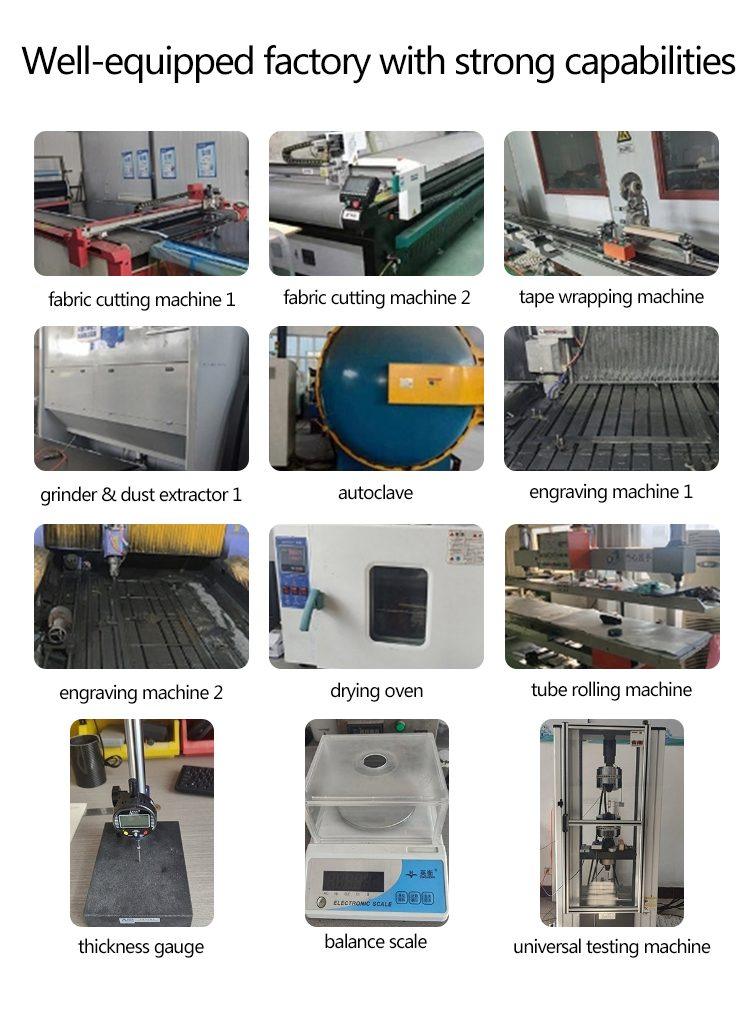

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

Carbon Fiber Triangle Tube, a tubular structure with a triangular cross-section made from carbon fiber composite materials, possesses numerous exceptional properties. Carbon fiber, as a high-performance fiber material, is renowned for its remarkable strength, low density, corrosion resistance, and high-temperature tolerance. The triangular cross-section design of the Carbon Fiber Triangle Tube further enhances its structural advantages.

Firstly, the Carbon Fiber Triangle Tube boasts significant strength, enabling it to maintain structural stability and integrity under heavy pressure or loads. Its strength can reach 6 to 12 times that of steel, depending on the fiber arrangement and manufacturing process.

Secondly, the low density of the Carbon Fiber Triangle Tube contributes to its lightweight advantage. With a density approximately one-quarter of steel, it ensures that for the same volume, the tube weighs significantly less, improving the efficiency of the overall structure.

Moreover, the Carbon Fiber Triangle Tube’s corrosion resistance and high-temperature tolerance enable it to maintain stable performance in harsh environments. These properties make it a promising material for applications in aerospace, automotive, sports equipment, and other industries.

In terms of factories’ customization capabilities, Carbon Fiber Triangle Tubes can be custom-processed according to customers’ specific requirements. By utilizing advanced manufacturing techniques and processes, factories can produce Carbon Fiber Triangle Tubes with varying sizes, shapes, and performance. Additionally, factories can also provide surface treatment and aesthetic enhancements to the tubes, fulfilling the diverse application needs of different industries.

Specification

- Side Length:

Typically ranges from 5 mm to 40 mm, customizable upon request. - Wall Thickness:

Standard options include 0.5 mm, 1.0 mm, 1.5 mm, and 2.0 mm, with multi-layer designs available. - Length:

Standard lengths are 1000 mm and 2000 mm, with custom lengths up to 3000 mm+. - Material:

- Carbon fiber types: T300, T700, T800 high-strength carbon fabrics

- Resin system: Primarily epoxy resin, offering excellent mechanical properties and corrosion resistance

- Surface Finish:

- Glossy

- Matte

- Visible weave patterns (3K Twill, Plain weave)

- Manufacturing Process:

- Roll-wrapping

- Compression molding

Main applications

Aerospace Industry

- Carbon Fiber Triangle Tube is widely used in the aerospace industry due to its high strength and lightweight properties. For instance, it can be employed as structural components for aircraft and rockets, reducing overall weight and improving flight efficiency.

- The use of carbon fiber in the Intercontinental Ballistic Missiles (ICBM) shells developed in the 1980s in the United States demonstrates the significance of carbon fiber in aerospace technology.

Sports and Recreation

- In sports equipment, Carbon Fiber Triangle Tube is commonly used to manufacture high-performance bats, racket frames, bicycles, sailing masts, and more. For instance, it is estimated that 40% of all bats worldwide are made from carbon fiber.

- The high strength and low weight of Carbon Fiber Triangle Tube provide sports equipment with lighter weight and durability, enhancing the athlete’s user experience.

Industrial Machinery

- Carbon Fiber Triangle Tube also finds applications in industrial machinery, such as roll shafts for textile machinery, aluminum foil machinery, plastic film machinery, and more. These applications showcase the durability of carbon fiber tubes while highlighting their weight reduction and energy efficiency benefits.

- Take the roll shaft for non-woven fabric machinery as an example. Carbon fiber tubes provide significant weight advantages, meeting the need for wider production widths and reducing operator fatigue.

Other Applications

- Carbon Fiber Triangle Tube is also used in the automotive industry, wind power generation, energy, chemical engineering, construction, and other sectors. For instance, in new energy vehicles, carbon fiber tubes can be utilized for vehicle bodies and chassis systems, achieving lightweighting and enhancing safety.

Features

- High Strength-to-Weight Ratio

Offers exceptional mechanical strength while maintaining a lightweight structure, ideal for weight-sensitive applications. - Enhanced Rigidity

The triangular cross-section provides superior stiffness and resistance to bending and torsion compared to circular tubes of similar size. - Excellent Dimensional Stability

Low thermal expansion and high structural integrity ensure consistent performance under varying environmental conditions. - Improved Load Distribution

Three flat surfaces facilitate even load transfer and easier integration with other structural components. - Corrosion and Chemical Resistance

Made from advanced carbon fiber and epoxy resin, the tube exhibits strong resistance to moisture, chemicals, and UV degradation. - Precision Alignment and Assembly

The flat edges of the triangular profile allow precise positioning and anti-rotation assembly in modular structures. - Customizable Design

Available in various sizes, wall thicknesses, fiber orientations, and surface finishes to meet specific engineering requirements.

For more product specifications, please contact our professionals!

By adopting CNC precision processing technology and automatic detection systems and integrating automated winding, curing, and cutting processes, the production speed is increased by 20% to 30%. Multi-station collaborative operation reduces manual intervention and reduces the error rate.

- Compatible with carbon fiber prepregs such as T300, T700, T800

- Supports a variety of resin systems such as epoxy and phenolic

- ISO 9001, CE, SGS, and ASTM standards

- 40 automated production lines to ensure on-time delivery

- In-house Strictly Testing Lab for 6-step internal inspection

Enhance Performance, Simplify Processing, Reduce Costs

Experience the power of Carbon Fiber Tubes—lightweight, ultra-strong, and corrosion-resistant. Perfect for industries demanding high performance and durability. Elevate your products with precision-engineered tubes that combine advanced materials with cutting-edge manufacturing. Choose carbon fiber tubes for unmatched strength, reduced weight, and superior reliability.