Products Categories

Featured Products

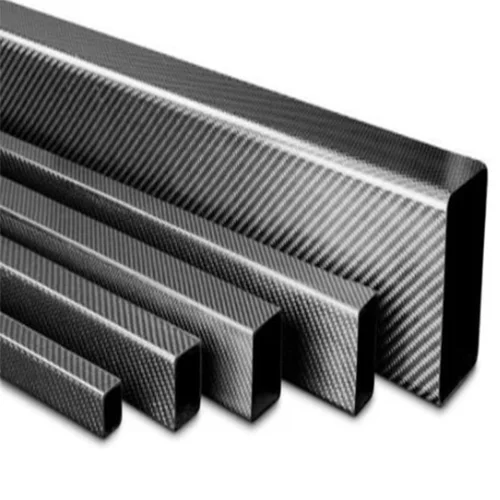

Carbon Fiber Rectangular Tube

Carbon fiber rectangular tubes are manufactured from high-strength carbon fiber prepregs using precise fabrication processes. They offer exceptional mechanical properties and minimal thermal expansion. The rectangular cross-section ensures directional stiffness and dimensional stability, while the surface finish options provide consistent quality. These tubes deliver outstanding strength and corrosion resistance, meeting stringent engineering standards.

Product MOQ

Please note our minimum order quantity of Carbon Fiber Tube. For the conventional Carbon Fiber Tube in stock, there is no MOQ. For customized Carbon Fiber Tube, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

- Carbon Fiber Rectangular Tube, a tubular product crafted from high-performance carbon fiber composite material, features a rectangular cross-section design. This type of tubing possesses significant potential value in various industries due to its unique material properties and shape.

- Carbon Fiber Rectangular Tube stands out for its exceptional characteristics, including high strength, lightweight, corrosion resistance, and thermal stability. Its high strength endows the rectangular tube with superior load-bearing capacity and stability. Meanwhile, its lightweight characteristic significantly reduces the burden on equipment or structures, enhancing overall performance. Furthermore, the tube’s excellent corrosion resistance allows it to operate stably in harsh environments, unaffected by corrosive media such as acids, alkalis, and salts.

- When it comes to the customization capabilities of Carbon Fiber Rectangular Tube, they demonstrate the high flexibility and professionalism of modern industrial manufacturing. Factories are able to provide personalized customization services based on specific customer needs. Whether it’s the tube’s dimensions, shape, or performance parameters, factories can achieve precise control by adjusting the production process and material mix ratio, ensuring that the product perfectly meets customers’ expectations.

- Additionally, factories possess the ability to respond quickly and flexibly to production. In the face of urgent customer demands or market changes, factories can promptly adjust production plans to ensure timely delivery of products. This high level of flexibility and responsiveness provides significant convenience and assurance for customers.

- In summary, Carbon Fiber Rectangular Tube boasts not only remarkable material properties and shape design but also strong customization capabilities from factories, enabling it to satisfy customers’ individual needs. This makes Carbon Fiber Rectangular Tube a promising choice for various applications across industries.

Specification

- Size Range: Width 10mm to 100mm, wall thickness 1mm to 5mm, customizable lengths (commonly 500mm, 1000mm, 1500mm)

- Cross-Section: Standard rectangular profile; corners customizable as rounded or sharp

- Wall Thickness Tolerance: ±0.1mm for consistent structural integrity

- Length Tolerance: ±1mm to meet assembly precision

- Material: Aerospace-grade carbon fiber prepreg (e.g., Toray T700) with epoxy resin matrix

- Weave Pattern: 3K plain or twill weave; surface finish options include matte or glossy

- Density: Approximately 1.5 g/cm³ for lightweight design

- Coefficient of Thermal Expansion: Less than 2 × 10⁻⁶ /°C ensuring dimensional stability

- Tensile Strength: Over 700 MPa for high-strength performance

- Compressive Strength: Over 600 MPa providing excellent load-bearing capacity

Main applications

Aerospace Industry

- Missiles, Space Platforms, and Launch Vehicles: Carbon Fiber Rectangular Tube is extensively used in aerospace applications such as missile weapons, space platforms, and launch vehicles due to its high strength, lightweight, and excellent corrosion resistance. It is utilized in the manufacturing of critical components like missile domes, composite brackets, and instrument compartments, ensuring minimal structural deformation, good load-bearing capacity, and resistance to radiation, aging, and space environments.

Automotive Industry

- Body Panels, Chassis, and Seats: Carbon Fiber Rectangular Tube is increasingly being used in the automotive industry for the manufacture of body panels, chassis, and seats. Its lightweight properties significantly improve the vehicle’s fuel efficiency while enhancing impact resistance and corrosion resistance.

- Compressed Natural Gas Tanks (CNG Tanks): Carbon Fiber Rectangular Tube is also used in the manufacturing of compressed natural gas tanks (CNG tanks) for environmentally friendly and energy-efficient automotive power solutions.

Rail Transportation

- Train Car Bodies and Wheels: Carbon Fiber Rectangular Tube finds application in the rail transportation sector for the production of train car bodies and wheels. This helps reduce the weight of trains, leading to increased speed and improved energy efficiency.

Energy Industry

- Wind Turbine Blades: As wind turbine generators increase in rated power, the corresponding blade sizes also grow. Carbon Fiber Rectangular Tube is used in wind turbine blades to reduce weight while meeting strength and stiffness requirements.

Sports Equipment

- Golf Clubs, Bicycle Frames: Carbon Fiber Rectangular Tube is utilized in sports equipment, including golf clubs and bicycle frames, to meet the demands for lightweight and high strength by athletes.

Construction Industry

- Reinforcement and Strengthening: Carbon Fiber Rectangular Tube is also employed for reinforcement and strengthening in industrial and civil buildings, such as railway and highway bridges, tunnels, chimneys, and tower structures.

Medical Device Industry

- Artificial Joints, Dental Braces: Carbon Fiber Rectangular Tube finds applications in medical devices like artificial joints and dental braces, offering better biocompatibility and mechanical properties.

Features

- High Strength-to-Weight Ratio

Provides exceptional mechanical strength while significantly reducing overall weight compared to metals. - Excellent Directional Stiffness

Rectangular cross-section offers superior bending rigidity and structural stability in key load directions. - Dimensional Stability

Low thermal expansion ensures consistent shape and size under temperature variations. - Corrosion and Chemical Resistance

Inherently resistant to rust, moisture, and most chemicals, ensuring long-term durability. - Fatigue Resistance

Superior performance under cyclic loading, reducing risk of structural failure over time. - Precision Manufacturing

Tight tolerances and quality control guarantee reliable fit and integration into complex assemblies. - Customizable Surface Finish

Matte or glossy finishes with visible weave patterns provide both functional and aesthetic benefits.

For more product specifications, please contact our professionals!

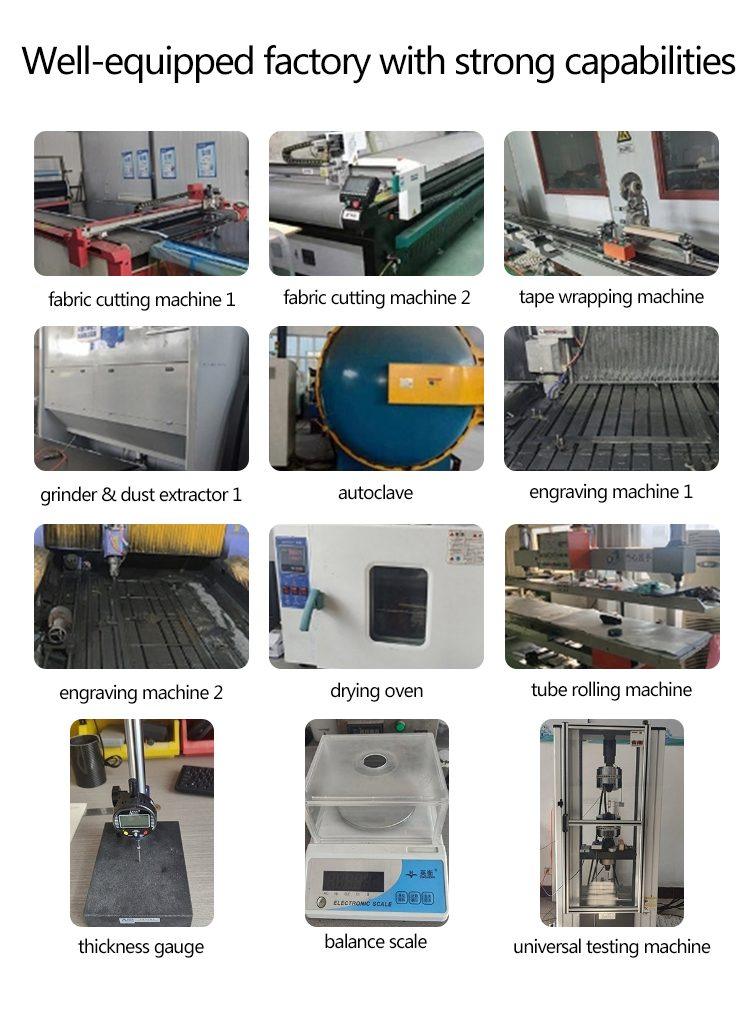

By adopting CNC precision processing technology and automatic detection systems and integrating automated winding, curing, and cutting processes, the production speed is increased by 20% to 30%. Multi-station collaborative operation reduces manual intervention and reduces the error rate.

- Compatible with carbon fiber prepregs such as T300, T700, T800

- Supports a variety of resin systems such as epoxy and phenolic

- ISO 9001, CE, SGS, and ASTM standards

- 40 automated production lines to ensure on-time delivery

- In-house Strictly Testing Lab for 6-step internal inspection

Enhance Performance, Simplify Processing, Reduce Costs

Experience the power of Carbon Fiber Tubes—lightweight, ultra-strong, and corrosion-resistant. Perfect for industries demanding high performance and durability. Elevate your products with precision-engineered tubes that combine advanced materials with cutting-edge manufacturing. Choose carbon fiber tubes for unmatched strength, reduced weight, and superior reliability.