Aramid Tire Cord Reinforcement Fabric

Features

Color:

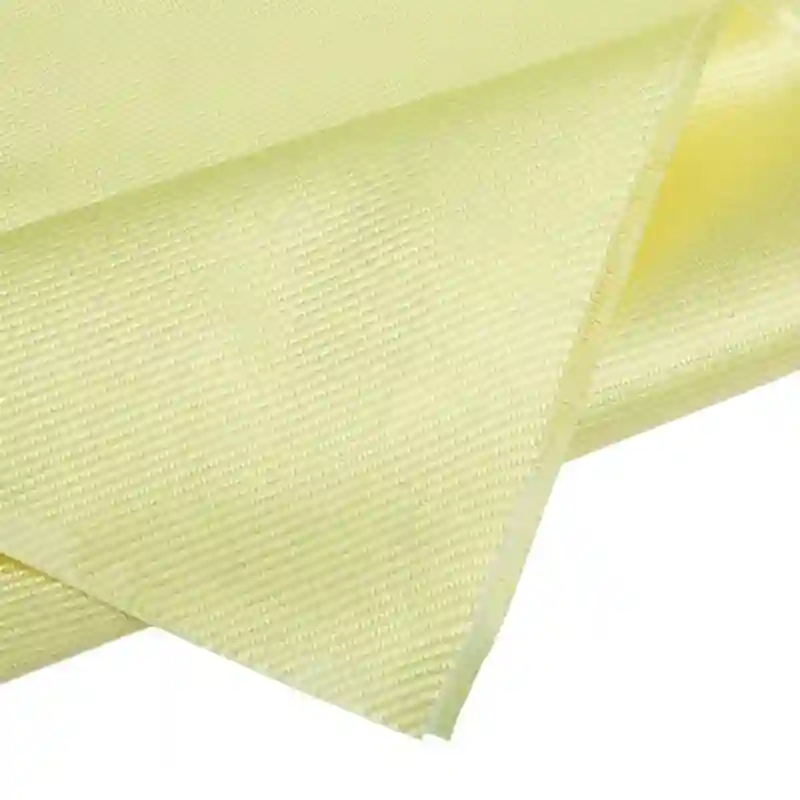

Aramid Tire Cord Reinforcement Fabric (ATCRF) is available in a variety of colors to meet the specific needs of different tire manufacturers and users. Although its main function is to enhance the strength and durability of the tire, in order to meet specific aesthetic or identification needs, ATCRF color choice is also very important. Common colors include black, gray, white, etc., which are determined based on the dyes and additives in the raw material or processing process. Factories often have flexible dyeing and color matching capabilities, and can customize ATCRF in a specific color based on a customer’s sample or color card.

Weaving method

The weaving method of ATCRF not only affects its appearance, but also directly relates to its mechanical properties and the overall performance of the tire. The factory has a wide range of weaving technologies to meet the needs of different applications. Common knitting methods include:

Plain weave: This weave has the largest number of warp and weft interweaving points, high fabric density, and provides uniform tensile strength for applications requiring high stability.

Twill braid: compared with plain braid, twill braid has fewer interweaving points, and the fabric density is lower, but the elasticity is better, and it is suitable for tires that need a certain amount of elasticity.

Satin weaving: This weaving method has the least points of warp and weft interweaving, high gloss, soft feel, and is often used for high-end tires or occasions that require special appearance effects.

According to the requirements of customers, the factory can choose or combine different weaving methods to achieve the best mechanical properties and appearance.

Product MOQ

Please note our minimum order quantity of Aramid Fabric. For the conventionalAramid Fabric in stock, there is no MOQ. For customized Aramid Fabric, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

●FREE SAMPLE ●FREE RETURNS

*Customization is always available, please mark down your need in cart or just contact us.

Project Monitoring

Shipping Order Track

Instructions for Use

VIP Customer Service

Intact Guarantee

Description

Aramid Tire Cord Reinforcement Fabric (ATCRF) is a high-performance tire reinforcement material made from Aramid Fiber. Renowned for its high strength, high modulus, heat resistance, wear resistance, and corrosion resistance, ATCRF offers significant advantages in the tire manufacturing industry.

ATCRF significantly enhances the load-bearing capacity and impact resistance of tires while maintaining stable mechanical properties in high-temperature environments. Its wear and corrosion resistance further prolong the lifespan of tires, improving their durability and safety. Moreover, compared to traditional materials, ATCRF boasts a lighter weight, contributing to the lightweight design of tires and reducing energy consumption and carbon emissions.

Our factory demonstrates a high level of customization capability in the production of ATCRF. We can adjust parameters such as fiber thickness, density, and strength based on specific customer needs, and select or combine different weaving methods to achieve optimal mechanical properties and visual effects. Additionally, we offer customized sizes and shapes to fit the design requirements of various tires. Through close cooperation with customers, we ensure that the ATCRF produced meets their exact expectations and requirements.

Main Function

High-Performance Tires:

ATCRF is widely used in the reinforcement of high-performance tires, such as those for racing cars, sports cars, and luxury vehicles. The high strength and modulus of Aramid Fiber allow ATCRF to significantly increase the load-bearing capacity and impact resistance of these tires, ensuring superior handling and safety at high speeds.

Heavy-Duty Applications:

In the construction, mining, and agricultural sectors, tires need to be able to withstand heavy loads and harsh conditions. ATCRF provides the necessary reinforcement to ensure durability and longevity in these demanding applications.

Passenger Car Tires:

Even in everyday passenger cars, ATCRF can be used to improve tire performance. It can enhance the durability of the tire, reduce wear and tear, and improve fuel efficiency by reducing the overall weight of the tire.

Low Rolling Resistance Tires:

ATCRF’s lightweight nature contributes to the development of low rolling resistance tires. These tires have less friction when rolling, which results in lower fuel consumption and reduced emissions.

Improved Safety:

The increased strength and stability provided by ATCRF help improve the safety of tires. This is especially important in emergency situations, such as sudden braking or evasive maneuvers, where the tires need to perform optimally.

Temperature Resistance:

ATCRF’s excellent heat resistance allows it to maintain stable performance even in high-temperature conditions. This is crucial for tires used in hot climates or in applications where high temperatures are generated, such as braking systems.

Specification

Model | Surface | weight/gsm | Thickness/mm | Density |

ZF-200P-60 | PPlain | 60 | 0.1 | 15*15 |

ZF-400P-80 | Plain | 80 | 0.11 | 9*9 |

ZF-400P-90 | Plain | 90 | 0.12 | 10*10 |

ZF-400P-110 | Plain | 110 | 0.13 | 12*12 |

ZF-400P-120 | Plain | 120 | 0.14 | 13*13 |

ZF-1000P-120 | Plain | 120 | 0.2 | 5*5 |

ZF-1000P-135 | Plain | 135 | 0.22 | 6*6 |

ZF-1000P-155 | Plain | 155 | 0.24 | 7*7 |

ZF-1000P-180 | Plain | 180 | 0.25 | 8*8 |

ZF-1000T-180 | Twill | 180 | 0.25 | 8*8 |

ZF-1000P-200 | Plain | 200 | 0.26 | 9*9 |

ZF-1000T-200 | Twill | 200 | 0.26 | 9*9 |

ZF-1000T-220 | Twill | 220 | 0.28 | 10*10 |

ZF-1500P-170 | Plain | 170 | 0.22 | 5*5 |

ZF-1500P-185 | Plain | 185 | 0.24 | 5.5*5.5 |

ZF-1500T-185 | Twill | 185 | 0.24 | 5.5*5.5 |

ZF-1500P-200 | Plain | 200 | 0.26 | 6*6 |

ZF-1500T-200 | Twill | 200 | 0.26 | 6*6 |

ZF-1500P-250 | Plain | 250 | 0.32 | 7.5*7.5 |

ZF-1500T-250 | Twill | 250 | 0.32 | 7.5*7.5 |

ZF-3000P-400 | Plain | 400 | 0.45 | 6*6 |

ZF-3000P-450 | Twill | 450*450 | 0.58 | 7*7 |

Model | Surface | weight/gsm | Thickness/mm | Density |

ZF-200P-60 | Plain | 60 | 0.1 | 15*15 |

ZF-400P-80 | Plain | 80 | 0.11 | 9*9 |

ZF-400P-90 | Plain | 90 | 0.12 | 10*10 |

ZF-400P-110 | Plain | 110 | 0.13 | 12*12 |

ZF-400P-120 | Plain | 120 | 0.14 | 13*13 |

ZF-1000P-120 | Plain | 120 | 0.2 | 5*5 |

ZF-1000P-135 | Plain | 135 | 0.22 | 6*6 |

ZF-1000P-155 | Plain | 155 | 0.24 | 7*7 |

ZF-1000P-180 | Plain | 180 | 0.25 | 8*8 |

ZF-1000T-180 | Twill | 180 | 0.25 | 8*8 |

ZF-1000P-200 | Plain | 200 | 0.26 | 9*9 |

ZF-1000T-200 | Twill | 200 | 0.26 | 9*9 |

ZF-1000T-220 | Twill | 220 | 0.28 | 10*10 |

ZF-1500P-170 | Plain | 170 | 0.22 | 5*5 |

ZF-1500P-185 | Plain | 185 | 0.24 | 5.5*5.5 |

ZF-1500T-185 | Twill | 185 | 0.24 | 5.5*5.5 |

ZF-1500P-200 | Plain | 200 | 0.26 | 6*6 |

ZF-1500T-200 | Twill | 200 | 0.26 | 6*6 |

ZF-1500P-250 | Plain | 250 | 0.32 | 7.5*7.5 |

ZF-1500T-250 | Twill | 250 | 0.32 | 7.5*7.5 |

ZF-3000P-400 | Plain | 400 | 0.45 | 6*6 |

ZF-3000P-450 | Twill | 450*450 | 0.58 | 7*7 |

Consult Your NQ Aramid Fabric Wholesale And Packaging Specialist

We help you avoid pitfalls and deliver the quality and value you need for aramid fabric on time and on budget.