Products Categories

Featured Products

Thick Wall Carbon Fiber Tube

Color customization

Carbon Fiber tubes come in a variety of colors, including the usual black, white, blue, red, yellow, color, and a variety of other color options. Customers can customize unique colors according to specific needs to match specific application scenarios or brand styles. The factory will use advanced technology and high-quality materials to ensure the stability and durability of customized colors, and provide customers with personalized carbon fiber square tube products.

Product MOQ

Please note our minimum order quantity of Carbon Fiber Tube. For the conventional Carbon Fiber Tube in stock, there is no MOQ. For customized Carbon Fiber Tube, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

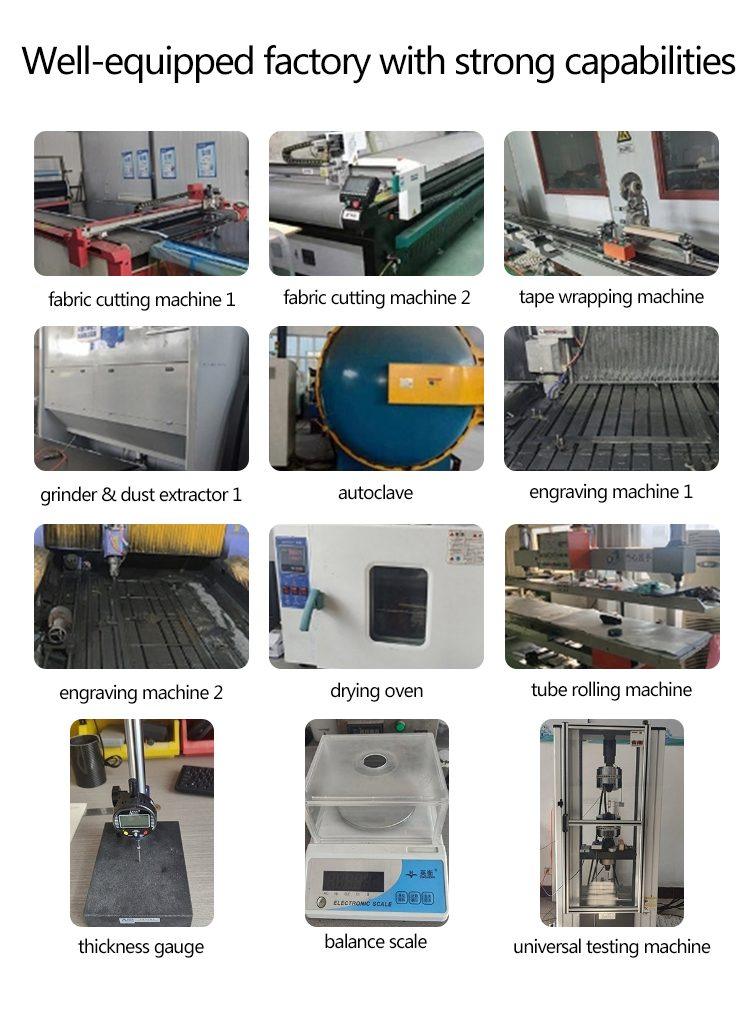

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

Thick Wall Carbon Fiber Tube, or simply referred to as a thick-walled carbon fiber tube, is a tubular structure primarily made of carbon fiber, characterized by its thicker wall thickness. Carbon fiber, as a new type of high-strength and high-modulus fiber material, is formed by stacking organic fibers such as graphite microcrystals along the fiber axis. Through carbonization and graphitization processes, this material not only maintains the inherent characteristics of carbon materials but also possesses the flexibility and processability of textile fibers.

With its unique structural design and material selection, thick-walled carbon fiber tubes typically exhibit higher compressive strength and stability. During the manufacturing process, factories can customize the tubes according to customers’ needs, including flexibly adjusting parameters such as tube diameter, length, and wall thickness to meet different application requirements. NQ Manufacturer, for instance, possesses the capability to produce thick-walled carbon fiber tubes and can customize them based on customers’ specific demands.

While maintaining the lightweight properties of carbon fiber materials, thick-walled carbon fiber tubes enhance their overall structural strength by increasing wall thickness. This characteristic赋予them significant advantages in scenarios that require high pressure and impact resistance, such as aerospace, automobile manufacturing, and sports equipment. In addition, thick-walled carbon fiber tubes possess excellent corrosion resistance and wear resistance, enabling them to maintain a long service life in harsh environments.

In summary, Thick Wall Carbon Fiber Tube is a high-performance, customizable tubular structural material that boasts excellent compressive strength and stability. It is widely used in various fields that require high-strength and lightweight materials.

Specification

- Material Composition

Manufactured from high-strength carbon fiber prepreg materials using precise filament winding or roll wrapping techniques, ensuring structural consistency. - Outer Diameter Range

Typically available from 10 mm up to 100 mm or customized to specific project requirements, catering to diverse industrial needs. - Wall Thickness Range

Thick wall design ranging from 2.0 mm to 10 mm, providing enhanced durability and strength for demanding applications. - Standard Length

Standard cut lengths of 1000 mm (1 meter) with custom length options available upon request. - Weight

Varies between approximately 100 grams to 1500 grams per meter depending on diameter and wall thickness specifications. - Surface Finish

Available in matte or glossy finishes, with options for additional surface treatments such as UV protection or anti-scratch coatings. - Dimensional Tolerance

Tight manufacturing tolerances maintained, typically ±0.1 mm for both outer diameter and wall thickness, ensuring precise fit and reliable assembly. - Color Options

Standard black carbon fiber appearance, with customization available to meet specific aesthetic or branding requirements.

Main applications

Aerospace Industry

- Missiles, Space Platforms, and Launch Vehicles: Due to its high strength, high modulus, and lightweight properties, carbon fiber composite materials (CFRP) are extensively used in critical components of missiles, space platforms, and launch vehicles in the aerospace industry. Thick Wall Carbon Fiber Tubes provide sufficient strength and stability while reducing the overall structural weight.

- Helicopter Blades: Thick Wall Carbon Fiber Tubes play a crucial role in the manufacturing of helicopter blades due to their fatigue resistance. This material can withstand the fatigue caused by long-term rotation and vibration, ensuring the stability and safety of the blades.

Automotive Manufacturing

- Electric Vehicles and Trucks: With the development of electric vehicles and trucks, the demand for lightweight materials is increasing. Thick Wall Carbon Fiber Tubes, with their high strength and lightweight characteristics, have become an ideal material for electric vehicles and trucks. They can be used in body structures, chassis, and transmission systems to improve vehicle performance and energy efficiency.

- Fuel Cells: In automotive manufacturing, fuel cells are an essential energy system. Thick Wall Carbon Fiber Tubes are used in the stacking and support structure of fuel cells, providing sufficient strength and stability while reducing system weight.

Sports Equipment

- Golf Practice Nets, Arrow Shafts, and Batons: Thick Wall Carbon Fiber Tubes are an excellent material for golf practice nets, arrow shafts, and batons due to their high strength, anti-aging, and good mechanical properties. These sports equipment require frequent use and impact resistance, and carbon fiber tubes ensure their durability and stability.

- Water Sports Equipment: In the field of water sports, such as windsurfing boards and surfboards, Thick Wall Carbon Fiber Tubes are used in structural frames and support components. This material can withstand corrosion from seawater and frequent collisions, ensuring the safety and stability of water sports equipment.

Construction and Infrastructure

- Public Infrastructure: In the field of construction and infrastructure, Thick Wall Carbon Fiber Tubes are used in the support structures and reinforcement components of bridges, tunnels, stadiums, and other public facilities. They provide sufficient strength and stiffness while reducing material usage and construction costs.

- Building Materials: In the field of building materials, carbon fiber tubes are used to manufacture lightweight wall panels, beams, and columns. These structural components have high strength and lightweight characteristics, improving the overall performance and energy efficiency of buildings.

Other Applications

- Audio Equipment: Utilizing its vibration damping properties, Thick Wall Carbon Fiber Tubes are applied in audio equipment such as loudspeakers and speaker cabinets. This material reduces the transmission of vibration and noise, enhancing the sound quality and performance of audio equipment.

- Customized Needs: Additionally, Thick Wall Carbon Fiber Tubes can be customized according to specific customer requirements, such as manufacturing tubes with unique shapes, sizes, and performance specifications to meet various special application scenarios.

Features

- Superior Load-Bearing Capacity

Thick wall carbon fiber tubes deliver high tensile strength, enabling them to withstand heavy mechanical loads and stresses. - Increased Rigidity and Structural Stability

Enhanced wall thickness significantly improves bending resistance and overall stiffness, ensuring reliable performance. - Excellent Impact and Damage Resistance

Robust thick walls provide superior protection against impact, reducing the risk of cracks and structural failure. - Lightweight Advantage Over Metals

Despite thicker walls, these tubes remain much lighter than steel or aluminum, contributing to weight reduction in applications. - Outstanding Corrosion and Chemical Resistance

Resistant to moisture, acids, alkalis, and other corrosive substances, lowering maintenance costs and extending service life. - Precision Manufacturing with Tight Tolerances

Ensures consistent dimensions (typically ±0.1 mm), facilitating seamless integration into assemblies. - Thermal Stability for Harsh Environments

Maintains mechanical integrity across wide temperature ranges, suitable for diverse industrial uses.

Model | | Outer Dimensions (mm) | Wall Thickness (mm) | Length (mm) | Fiber Type | Fiber Specification |

NQ-20×20-T3 | 20 × 20 | 26 × 26 | 3 | 300 | T700 | 3K |

NQ-30×30-T4 | 30 × 30 | 36 × 36 | 4 | 400 | T700 | 3K |

NQ-40×40-T5 | 40 × 40 | 46 × 46 | 5 | 500 | T700 | 3K |

NQ-50×50-T6 | 50 × 50 | 56 × 56 | 6 | 600 | T700 | 3K |

For more product specifications, please contact our professionals!

By adopting CNC precision processing technology and automatic detection systems and integrating automated winding, curing, and cutting processes, the production speed is increased by 20% to 30%. Multi-station collaborative operation reduces manual intervention and reduces the error rate.

- Compatible with carbon fiber prepregs such as T300, T700, T800

- Supports a variety of resin systems such as epoxy and phenolic

- ISO 9001, CE, SGS, and ASTM standards

- 40 automated production lines to ensure on-time delivery

- In-house Strictly Testing Lab for 6-step internal inspection

Enhance Performance, Simplify Processing, Reduce Costs

Experience the power of Carbon Fiber Tubes—lightweight, ultra-strong, and corrosion-resistant. Perfect for industries demanding high performance and durability. Elevate your products with precision-engineered tubes that combine advanced materials with cutting-edge manufacturing. Choose carbon fiber tubes for unmatched strength, reduced weight, and superior reliability.