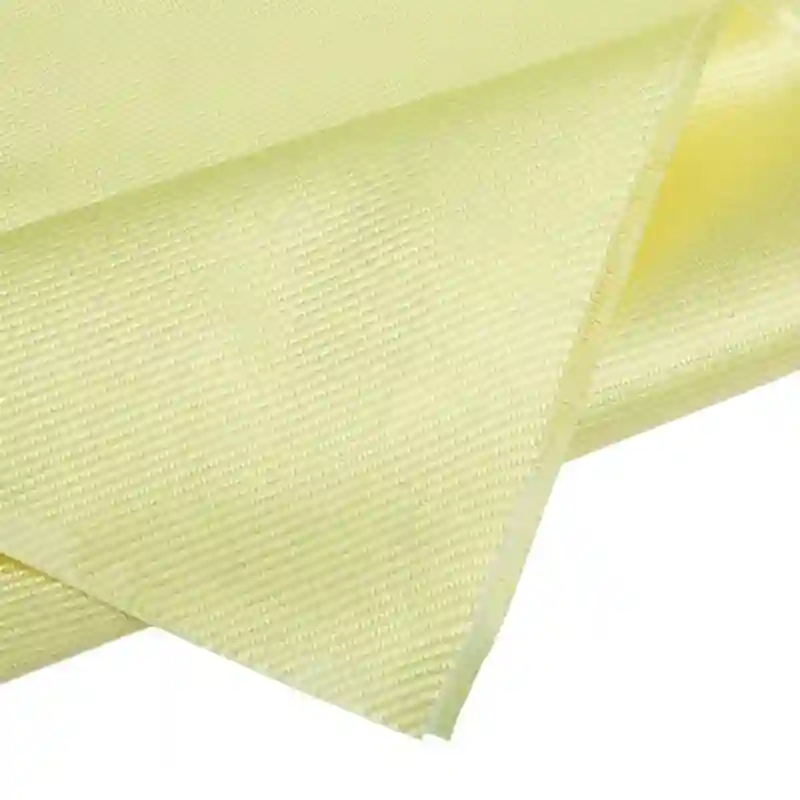

Glass-Aramid Fibre Fabric

Features

Color Options:

Basic Tones: Including neutral shades like black, white, gray, and beige, these colors are often used for applications requiring a subdued and stable appearance.

Vivid Hues: Bright and vivid colors such as red, blue, yellow, and green are suitable for applications that need to stand out or express vitality.

Multi-Color Mixes: Different colors can be blended together to create unique multi-color effects, such as gradients, speckles, and stripes, adding visual layers and appeal to the fabric.

Customized Tones: Factories can also provide customized color options based on specific customer requirements. This includes matching brand standard colors, fulfilling project-specific needs, or catering to individual preferences.

Weave Texture Options

Plain Weave: The most common weave texture, with warp and weft yarns interlacing evenly to form a smooth and uniform surface. Plain weave fabrics have stable structures and excellent strength and durability.

Twill Weave: In twill weave fabrics, the warp or weft yarns are woven at a certain angle, creating a diagonal texture. Twill weave fabrics exhibit good elasticity and tear resistance.

Satin Weave: Satin weave fabrics have a smooth and silky surface resembling silk. In satin weave, there is less interlacing of warp and weft yarns, resulting in a glossy appearance on one side and a relatively rough appearance on the other.

Mesh Weave: Mesh weave fabrics are composed of small cells, creating a breathable and lightweight texture. This texture is often used in applications requiring good ventilation and air permeability.

Multi-Layer Weaves: By layering different textures or colored yarn layers, complex and multi-layered weave textures can be created. This design approach adds thickness, strength, and aesthetic appeal to the fabric.

Customized Textures: Factories can also provide customized texture designs based on specific customer needs. This includes customizing textures according to project requirements, creative ideas, or brand styles to meet personalized demands.

Product MOQ

Please note our minimum order quantity of Aramid Fabric. For the conventionalAramid Fabric in stock, there is no MOQ. For customized Aramid Fabric, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

●FREE SAMPLE ●FREE RETURNS

*Customization is always available, please mark down your need in cart or just contact us.

Project Monitoring

Shipping Order Track

Instructions for Use

VIP Customer Service

Intact Guarantee

Description

Glass-Aramid Fibre Fabric is a high-performance composite material woven from a blend of glass fibers and aramid fibers (also known as poly(p-phenylene terephthalamide) fibers). This fabric combines the advantages of both fiber types to provide a unique combination of properties.

Glass fibers are renowned for their high strength, high modulus, heat resistance, corrosion resistance, and electrical insulation properties, giving the fabric excellent mechanical performance and stability. On the other hand, aramid fibers are known for their high temperature resistance, high strength, high modulus, exceptional chemical stability, and wear resistance, adding additional heat and chemical resistance to the fabric.

Glass-Aramid Fibre Fabric is widely used in various industries, including aerospace, automotive, marine, construction, and protective equipment. In the aerospace industry, it is utilized in manufacturing structural components of aircraft and rockets, such as fuselages, wings, and tail fins. In the automotive industry, it is used to reinforce vehicle bodies and chassis, enhancing collision safety and durability. In marine applications, it is employed to strengthen hulls and decks, improving the strength and corrosion resistance of ships. Additionally, it is utilized in the production of protective equipment, such as bulletproof vests and fire-resistant suits, to provide extra protection and safety.

Overall, Glass-Aramid Fibre Fabric is a high-performance composite material with excellent properties such as high strength, high modulus, heat resistance, corrosion resistance, and wear resistance. It finds widespread applications in various industries, providing reliable and efficient solutions for various industrial applications.

Main Function

Aerospace Industry:

- Aircraft Structures: Used in the construction of aircraft fuselages, wings, and tail fins due to its high strength, stiffness, and heat resistance.

- Engine Components: Provides thermal and mechanical protection for critical engine parts.

- Spacecraft and Satellites: Lightweight yet durable, it is suitable for space-bound applications.

Automotive Industry:

- Body Panels: Reinforces car bodies, improving collision safety and durability.

- Underbody Shields: Protects vehicles from road debris and damage.

- Engine Compartments: Resists high temperatures and chemicals in engine bays.

Marine Industry:

- Ship Hulls and Decks: Strengthens hulls and decks, improving durability and corrosion resistance.

- Yacht and Boat Construction: Lightweight yet strong, it is ideal for high-performance watercraft.

Protective Equipment:

- Bulletproof Vests: Provides superior ballistic protection for law enforcement and military personnel.

- Fire-Resistant Clothing: Used in firefighting and other high-temperature environments.

- Helmets and Shields: Reinforces protective gear for various applications.

Industrial Applications:

- Chemical Processing: Resists harsh chemicals and solvents in industrial processes.

- Oil and Gas: Used in piping, tanks, and other equipment in oil and gas exploration and production.

- Electrical and Electronics: Provides insulation and reinforcement for electrical components.

Construction and Architecture:

- Reinforcement of Concrete Structures: Adds strength and durability to concrete beams, columns, and slabs.

- Exterior Cladding: Provides thermal insulation and fire resistance for building envelopes.

Sports and Recreation:

- High-Performance Boats and Kayaks: Lightweight yet strong, it is used in the construction of sports boats and kayaks.

- Protective Gear for Athletes: Used in the production of protective gear for extreme sports and motorsports.

Specification

Model | Surface | weight/gsm | Thickness/mm | Density |

ZF-200P-60 | PPlain | 60 | 0.1 | 15*15 |

ZF-400P-80 | Plain | 80 | 0.11 | 9*9 |

ZF-400P-90 | Plain | 90 | 0.12 | 10*10 |

ZF-400P-110 | Plain | 110 | 0.13 | 12*12 |

ZF-400P-120 | Plain | 120 | 0.14 | 13*13 |

ZF-1000P-120 | Plain | 120 | 0.2 | 5*5 |

ZF-1000P-135 | Plain | 135 | 0.22 | 6*6 |

ZF-1000P-155 | Plain | 155 | 0.24 | 7*7 |

ZF-1000P-180 | Plain | 180 | 0.25 | 8*8 |

ZF-1000T-180 | Twill | 180 | 0.25 | 8*8 |

ZF-1000P-200 | Plain | 200 | 0.26 | 9*9 |

ZF-1000T-200 | Twill | 200 | 0.26 | 9*9 |

ZF-1000T-220 | Twill | 220 | 0.28 | 10*10 |

ZF-1500P-170 | Plain | 170 | 0.22 | 5*5 |

ZF-1500P-185 | Plain | 185 | 0.24 | 5.5*5.5 |

ZF-1500T-185 | Twill | 185 | 0.24 | 5.5*5.5 |

ZF-1500P-200 | Plain | 200 | 0.26 | 6*6 |

ZF-1500T-200 | Twill | 200 | 0.26 | 6*6 |

ZF-1500P-250 | Plain | 250 | 0.32 | 7.5*7.5 |

ZF-1500T-250 | Twill | 250 | 0.32 | 7.5*7.5 |

ZF-3000P-400 | Plain | 400 | 0.45 | 6*6 |

ZF-3000P-450 | Twill | 450*450 | 0.58 | 7*7 |

Model | Surface | weight/gsm | Thickness/mm | Density |

ZF-200P-60 | Plain | 60 | 0.1 | 15*15 |

ZF-400P-80 | Plain | 80 | 0.11 | 9*9 |

ZF-400P-90 | Plain | 90 | 0.12 | 10*10 |

ZF-400P-110 | Plain | 110 | 0.13 | 12*12 |

ZF-400P-120 | Plain | 120 | 0.14 | 13*13 |

ZF-1000P-120 | Plain | 120 | 0.2 | 5*5 |

ZF-1000P-135 | Plain | 135 | 0.22 | 6*6 |

ZF-1000P-155 | Plain | 155 | 0.24 | 7*7 |

ZF-1000P-180 | Plain | 180 | 0.25 | 8*8 |

ZF-1000T-180 | Twill | 180 | 0.25 | 8*8 |

ZF-1000P-200 | Plain | 200 | 0.26 | 9*9 |

ZF-1000T-200 | Twill | 200 | 0.26 | 9*9 |

ZF-1000T-220 | Twill | 220 | 0.28 | 10*10 |

ZF-1500P-170 | Plain | 170 | 0.22 | 5*5 |

ZF-1500P-185 | Plain | 185 | 0.24 | 5.5*5.5 |

ZF-1500T-185 | Twill | 185 | 0.24 | 5.5*5.5 |

ZF-1500P-200 | Plain | 200 | 0.26 | 6*6 |

ZF-1500T-200 | Twill | 200 | 0.26 | 6*6 |

ZF-1500P-250 | Plain | 250 | 0.32 | 7.5*7.5 |

ZF-1500T-250 | Twill | 250 | 0.32 | 7.5*7.5 |

ZF-3000P-400 | Plain | 400 | 0.45 | 6*6 |

ZF-3000P-450 | Twill | 450*450 | 0.58 | 7*7 |

Consult Your NQ Aramid Fabric Wholesale And Packaging Specialist

We help you avoid pitfalls and deliver the quality and value you need for aramid fabric on time and on budget.