Products Categories

Featured Products

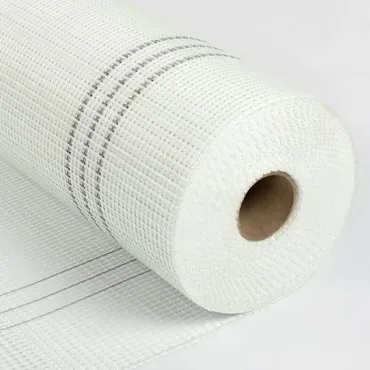

Adhesive-Backed Fiberglass Mesh

Adhesive-Backed Fiberglass Mesh is a woven fiberglass fabric coated with a pressure-sensitive adhesive on one side. It features uniform mesh structure, stable dimensions, and strong adhesive bonding. Available in various mesh sizes, widths, and roll lengths to suit different technical requirements. Custom cutting, labeling, and packaging options are also supported.

Product MOQ

Please note our minimum order quantity of Fiberglass mesh. For the conventional Fiberglass mesh in stock, there is no MOQ. For customized Fiberglass mesh, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Fiberglass manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

As a professional manufacturer of adhesive-backed fiberglass mesh, we specialize in producing high-quality mesh rolls using E-glass yarns and advanced coating technology. Our self-adhesive fiberglass mesh is engineered with a pressure-sensitive adhesive backing, ensuring consistent tack and dimensional stability during use.

We offer a wide range of mesh specifications, including various mesh sizes, roll widths, and basis weights. Whether you require fiberglass mesh tape with adhesive for precise applications or bulk rolls for industrial processing, we support full OEM and ODM customization.

All fiberglass mesh with adhesive backing is manufactured under strict quality control and ISO-compliant systems. Customized packaging, logo printing, and private label services are available to meet the demands of distributors and brand owners worldwide.

Specification

- Base Material

Made from E-glass fiberglass yarns, typically 75 tex in both warp and weft, plain weave structure. - Mesh Size

Standard mesh openings include:

– 2.85 × 2.85 mm

– 4 × 4 mm

– 5 × 5 mm

Other mesh sizes available based on project or regional standards. - Fabric Weight (Before Coating)

– 60 g/m²

– 75 g/m²

– 90 g/m²

Frequently requested by customers needing custom fiberglass mesh rolls. - Adhesive Type

We offer pressure-sensitive coatings including:

– Acrylic adhesive (standard)

– Rubber-based or hot melt adhesive upon request

All adhesives are selected to ensure clean, sticky fiberglass mesh rolls with stable bonding. - Total Weight (After Adhesive Coating)

Ranges between 70–120 g/m² depending on base fabric and glue loading. - Roll Width

Available in:

– 50 mm, 100 mm, 200 mm, 1000 mm

Maximum width up to 1000 mm for bulk processing or cutting. - Roll Length Options

Common roll lengths:

– 20 m, 45 m, 90 m, 100 m, or customer-specified.

Suitable for both large-scale users and OEM buyers. - Color Options

Standard: White and Yellow

Optional: Blue, Green, or Black (with MOQ) - Core & Packaging

– Core ID: 50 mm (paper), 76 mm (paper/plastic)

– Each roll packed in PE wrap

– Cartons: 24–72 rolls per carton depending on size

– Export palletized packaging available for container orders - Tolerances

– Width: ±1.0 mm

– Weight: ±5%

– Mesh opening: ±0.2 mm

Strict QC ensures every fiberglass mesh with adhesive meets international standards. - Production Capacity

– Output: Over 30,000 m² per day

– Lead time: 7–15 working days based on order size

We serve global B2B clients with consistent lead time and stable supply for custom adhesive fiberglass mesh. - Color customization

We offer blue, white, yellow, orange, green and many other regular colors. For customers with special color needs, customers can provide specific color samples or color values, the factory through professional color technology and equipment to ensure the accuracy and consistency of customized colors.

Special color customization services usually require more information and requirements from the customer, and the factory will communicate closely with the customer to ensure that the final product meets the customer’s expectations.

Main applications

- Drywall and Interior Wall Reinforcement

In the construction and renovation industry, adhesive-backed fiberglass mesh is widely used for reinforcing gypsum board joints and internal plaster layers. Contractors prefer self-adhesive fiberglass mesh for its clean application and reduced labor time—helping them meet deadlines with less mess. - Waterproofing and Crack Isolation Systems

Waterproofing system installers use fiberglass mesh with adhesive in bathrooms, balconies, and wet areas to enhance flexibility and control substrate movement. The sticky fiberglass mesh roll allows for fast placement over corners and seams, a key concern for waterproofing professionals. - EIFS and Thermal Insulation Finishing

In external insulation finishing systems (EIFS), custom fiberglass mesh rolls are bonded onto insulation boards to improve mechanical strength and durability. Builders appreciate the adhesive-backed design that simplifies mesh alignment and reduces installation errors. - Precast Panel and Concrete Surface Layering

Manufacturers of precast concrete panels often integrate adhesive fiberglass mesh into surface coatings or overlays to improve tensile strength and avoid delamination. The mesh’s adhesive backing prevents shifting during casting or spraying operations—important for consistent surface quality. - Industrial Fabric Lamination and Composite Layers

In industries such as HVAC, filter production, and soundproofing materials, self-adhesive fiberglass mesh rolls are laminated with foams or fabrics to create multi-layer structures. The adhesive eases automated processing and reduces glue consumption—an important cost-saving point for OEM buyers.

Features

- Strong Adhesion and Easy Application

Our adhesive-backed fiberglass mesh features a uniform, pressure-sensitive adhesive layer that provides excellent tackiness for immediate bonding without additional glue. This self-adhesive fiberglass mesh reduces installation time and labor costs, highly valued by contractors and manufacturers. - Dimensional Stability and Mesh Integrity

Woven from high-quality E-glass yarns, this fiberglass mesh with adhesive maintains consistent mesh size and shape during handling and application. Buyers appreciate the stable grid structure that prevents deformation or shrinkage after installation. - High Tensile Strength and Tear Resistance

The mesh delivers superior mechanical strength, crucial for reinforcing drywall joints or composite layers. The sticky fiberglass mesh roll withstands tension and abrasion, ensuring long-lasting durability in demanding environments. - Moisture and Chemical Resistance

The adhesive coating and fiberglass substrate resist moisture, alkalis, and common construction chemicals. This performance feature assures buyers that the custom adhesive fiberglass mesh will maintain integrity in humid or harsh conditions. - Clean and Residue-Free Removal

Unlike traditional tapes or meshes, our self-adhesive fiberglass mesh can be repositioned during installation and removed cleanly if necessary, minimizing waste and rework costs—an important consideration for quality-focused buyers. - Consistent Quality from OEM Production

As a reliable fiberglass mesh manufacturer, we guarantee tight quality control, ensuring every adhesive-backed fiberglass mesh roll meets specified adhesion, weight, and mesh opening tolerances for consistent performance.

Item Number | Yarn(Tex) | Mesh size(mm) | Density Count/25mm | Finished weight(g/m2) | Tensile StrengthX20cm | Woven Structure | Content of resin%(≥) | ||||

Warp | Weft | Warp | Weft | Warp | Weft | Warp | Weft | ||||

NQ 5X5-70 | 45X2 | 200 | 5 | 5 | 5 | 5 | 70 | 550 | 850 | Leno | 18 |

NQ 5X5-80 | 67X2 | 200 | 5 | 5 | 5 | 5 | 80 | 700 | 850 | Leno | 18 |

NQ 5X5-90 | 67X2 | 250 | 5 | 5 | 5 | 5 | 90 | 700 | 1050 | Leno | 18 |

NQ 5X5-110 | 100X2 | 250 | 5 | 5 | 5 | 5 | 110 | 800 | 1050 | Leno | 18 |

NQ 5X5-125 | 134X2 | 250 | 5 | 5 | 5 | 5 | 125 | 1200 | 1300 | Leno | 18 |

NQ 5X5-135 | 134X2 | 300 | 5 | 5 | 5 | 5 | 135 | 1300 | 1400 | Leno | 18 |

NQ 4X4-135 | 100X2 | 250 | 4 | 4 | 6 | 6 | 135 | 1000 | 1300 | Leno | 18 |

NQ 5X5-145 | 134X2 | 360 | 5 | 5 | 5 | 5 | 145 | 1200 | 1300 | Leno | 18 |

NQ 4X5-150 | 134X2 | 300 | 4 | 5 | 6 | 5 | 150 | 1300 | 1300 | Leno | 18 |

NQ SX5-160 | 134X2 | 400 | 5 | 5 | 5 | 5 | 160 | 1450 | 1600 | Leno | 18 |

NQ 4X4-160 | 134X2 | 300 | 4 | 4 | 6 | 6 | 160 | 1550 | 1650 | Leno | 18 |

NQ 4X5-165 | 134X2 | 350 | 4 | 5 | 6 | 5 | 165 | 1300 | 1300 | Leno | 18 |

For more product specifications, please contact our professionals!

Premium quality: Our production process and products are certified by ISO, CE, SGS, etc., to meet your high standards.

Competitive price: By choosing our fiberglass mesh, you can purchase high-quality products at a lower cost and reduce the overall project budget while maintaining construction quality.

Fully Customize: As a fiberglass mesh manufacturer, we provide various customized solutions in specifications, meshes, and weights to meet your different applications.

Effortless Reinforcement with Premium Adhesive-Backed Fiberglass Mesh

Maximize project efficiency with our high-strength self-adhesive fiberglass mesh. Engineered for quick application and superior durability, this fiberglass mesh with adhesive reduces labor costs and material waste, ensuring consistent, long-lasting reinforcement across various substrates. Choose reliability and speed — choose our sticky fiberglass mesh roll.