- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

In the field of modern advanced composite materials, carbon fiber has become the core pillar of aerospace, high-end automotive, and sports equipment due to its exceptional specific strength and specific modulus. Carbon fiber is not a single, homogeneous material; its physical performance, processing characteristics, and economic cost depend largely on the number of filaments in a single bundle, commonly referred to as the “K” count. The K count (e.g., 1K, 3K, 6K, 12K) defines not only the thickness of the fiber tow but also directly influences fabric thickness, resin wettability, and the mechanical properties of the final structure.

Carbon fiber is composed of thousands of extremely thin filaments bundled together. The diameter of these individual filaments typically ranges between 5 and 10 microns, roughly one-twentieth the thickness of a human hair. Because single filaments are extremely fragile and difficult to process independently, they are gathered into bundles called “tows” during industrial production.

The “K” stands for “thousand,” representing the number of individual filaments contained in a single bundle. For instance, 1K represents 1,000 filaments, 3K represents 3,000 filaments, and so on. An increase in the K-count directly leads to an expansion of the tow’s cross-sectional area and an increase in weight. In engineering calculations, this is measured via linear density (Linear Density), with units of grams per kilometer (g/1000m or Tex).

The table below provides a detailed comparison of common K-grade physical indicators:

| Specification | Filament Count | Linear Density (g/1000m) | Fabric Thickness Range (mm) | Typical Weight (GSM) |

|---|---|---|---|---|

| 1K | 1,000 | ~66 | 0.07 – 0.14 | 50 – 120 |

| 3K | 3,000 | ~198 | 0.20 – 0.32 | 160 – 280 |

| 6K | 6,000 | ~396 | 0.38 – 0.42 | 300 – 400 |

| 12K | 12,000 | ~800 | 0.46 – 0.62 | 400 – 600 |

| 24K/48K | 24,000+ | 1,600+ | 0.80+ | 600 – 1200+ |

Data indicates that the larger the K-count, the thicker the individual tow, resulting in thicker and heavier woven fabrics. While the strength of the filaments themselves does not change with the K-count, the increased tow size alters the fabric’s topological structure, affecting manufacturing efficiency and stress distribution in laminates.

In industry practice, specifications of 24K and below are referred to as “Small Tow,” while specifications above 24K are known as “Large Tow”. Small tow carbon fiber is primarily used in aerospace and high-end sporting goods because it provides finer weaving results and better processing stability. In contrast, large tow (e.g., 48K) is considered industrial-grade carbon fiber, widely used in wind turbine blades and shipbuilding where rapid thickness buildup is required.

1K carbon fiber is one of the rarest and most expensive specifications on the market. Containing only 1,000 filaments per tow, its weaving process is extremely slow and prone to defects, requiring high-precision looms. 1K fabric is ultra-thin and primarily used for surface decoration or high-end luxury goods where a refined visual texture is prioritized over structural thickness.

The 3K specification is the most widely used and balanced carbon fiber standard globally. It is recognized as the “workhorse” of composite engineering. 3K fabric balances classic visual aesthetics with excellent processability, offering easy resin saturation and good drapability for complex shapes. Most automotive parts and bicycle frames prioritize 3K for their surface layers.

6K carbon fiber offers higher stiffness than 3K and allows for a reduced number of layers in large structures, accelerating production speed. 12K carbon fiber leans entirely toward manufacturing efficiency. Due to its thick bundles, it is significantly cheaper to produce and has a major advantage in large flat structural components, such as racing chassis reinforcements or architectural retrofitting plates. Its surface texture is coarse, providing a bold and “rugged” visual impact.

A common misconception in the consumer market is that “a higher K-count equals higher strength.” In reality, the mechanical performance of carbon fiber depends primarily on its material grade (e.g., T300, T700, T1000), not the number of filaments per tow.

The standards set by Toray (Japan) have become the global benchmark. T300 is the industry baseline, while T700 and T1000 represent much higher tensile strengths.

| Fiber Model | Tensile Strength (MPa) | Tensile Modulus (GPa) | Performance Positioning |

|---|---|---|---|

| T300 | 3,530 | 230 | Standard modulus, mature and stable |

| T700S | 4,900 | 230 | High strength, cost-effective choice |

| T800H | 5,490 | 294 | Intermediate modulus, aerospace grade |

| T1000G | 6,370 | 294 | Top-tier strength, extreme loads |

A 3K T700 part is far stronger than a 12K T300 part. In engineering design, choosing the correct T-grade determines the structure’s load-bearing capacity, while selecting the K-count is more about optimizing the layup process and surface appearance.

Another key factor is resin penetration. Smaller K-counts (1K and 3K) allow resin to penetrate the tow center more easily, ensuring every filament is encapsulated. Large tows (12K and above) often develop “dry zones” at the center due to long penetration paths, which can reduce the laminate’s shear strength unless advanced processes like autoclaving or vacuum infusion are used.

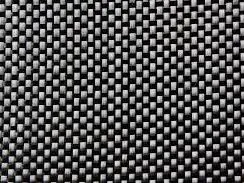

Plain weave uses a “one-over, one-under” pattern, resembling a checkerboard.

High Stability: Fibers are less likely to slide, making it ideal for flat surfaces.

Low Flexibility: Frequent intersections make the fabric stiff and difficult to drape over complex 3D surfaces.

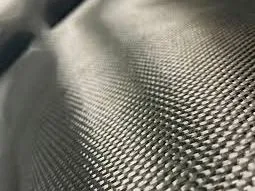

Twill weave typically uses a “two-over, two-under” pattern, creating a distinct diagonal texture.

Superior Drapability: The structure is looser, allowing it to easily cover complex curves and corners.

Visual Appeal: Twill has a three-dimensional depth, making it the mainstream choice for automotive modifications and sports gear.

Satin weave (e.g., 4HS, 8HS) allows fibers to cross over several tows before passing under one. This creates an extremely smooth surface and top-tier drapability for complex shapes.

The K-grade classification of carbon fiber is more than just an aesthetic choice; it serves as a lever in composite design to balance weight, process, aesthetics, and cost.

Connect with an NQ expert to discuss your product needs and get started on your project.

Contact NowWhat does the “K” in carbon fiber stand for?

The “K” stands for “thousand,” representing the number of individual filaments contained in a single bundle (tow). For example, 3K means there are 3,000 filaments in a single bundle, while 12K contains 12,000 filaments. These filaments are extremely thin, with a diameter of about 5 to 10 microns—roughly one-twentieth the thickness of a human hair.

Does a higher K-count mean the carbon fiber is stronger?

This is a common misconception; K-count does not directly represent strength. The strength of carbon fiber is determined by its material grade (e.g., T300, T700, or T1000) rather than the size of the bundle. A 3K component made of high-grade T700 fiber can be significantly stronger than a 12K component made of standard T300 fiber. K-count primarily affects the thickness, appearance, and manufacturing efficiency of the material.

Why are 1K and 3K fibers more expensive than 12K fibers?

It is mainly due to production efficiency and manufacturing difficulty. Producing fine bundles like 1K or 3K is a much slower process that requires more precision and results in lower output per hour compared to larger tows. 12K fibers allow for faster material buildup and are more economical to manufacture, making them the preferred choice for large-scale industrial use where cost-efficiency is a priority.

What is the difference in feel between 3K and 12K in padel rackets?

In sports equipment like padel rackets, K-count is used to fine-tune the “hitting sensation” :

3K Carbon Fiber: Provides a “crisp” and rigid feel with direct power feedback, ideal for players who want maximum speed and explosiveness.

12K Carbon Fiber: Despite having thicker tows, the structure is often more flexible, providing a “softer” touch and better ball control, making it suitable for versatile or defensive players.

How do You choose between Plain and Twill weave?

The choice depends on the shape of your part and the desired look :

Plain Weave (1×1): Resembles a checkerboard. It is highly stable and does not distort easily, making it perfect for flat surfaces, tubes, or simple structural parts.

Twill Weave (2×2): Features a diagonal pattern. It is much more pliable and “drapable,” allowing it to conform to complex 3D curves and corners without wrinkling, while also providing the iconic “carbon fiber look”.

Can You mix different K-counts in a single product?

Yes, this is very common in advanced manufacturing. Manufacturers often use hybrid layups to balance aesthetics, performance, and cost. For instance, they may use a 3K layer on the surface for its refined, luxury finish, while using 12K or unidirectional (UD) layers internally to build thickness and strength more cost-effectively.