- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

When you think of snowboarding, you probably imagine carving through powder or launching tricks in the park. But behind every smooth turn and controlled landing is a careful blend of materials — and one of the most important is fiberglass.

In this guide, you’ll learn how fiberglass works inside a snowboard, what makes it essential to performance, how it compares to carbon fiber, and why it continues to be the industry standard.

Table of Contents

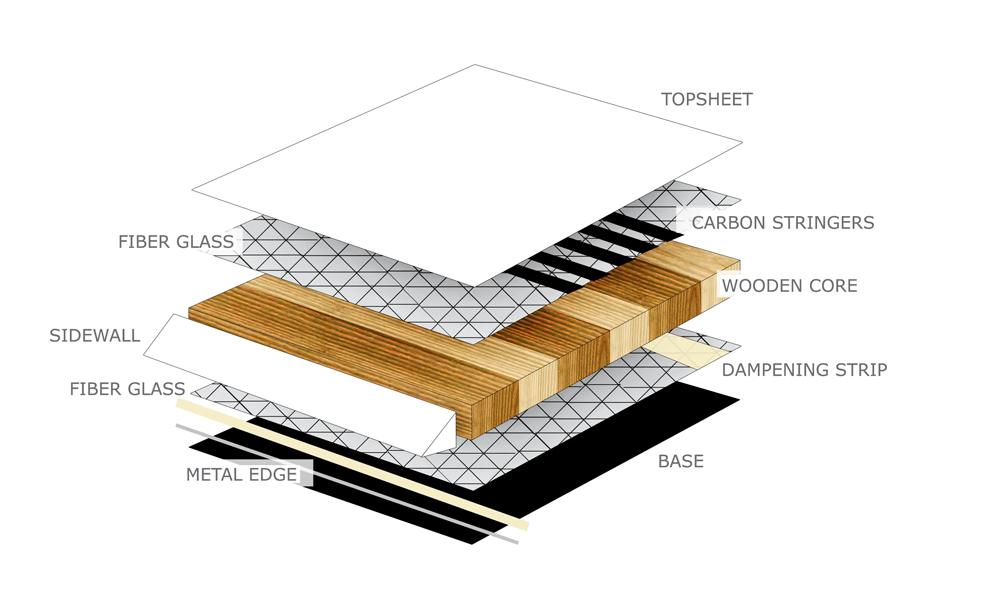

ToggleBefore you can understand the role of fiberglass, it helps to know what a snowboard is made of. Snowboards consist of several core components, each affecting how your board rides:

The core is the heart of your snowboard—it drives the board’s flex, rebound, and response. Most are made from lightweight woods like poplar, bamboo, or aspen. Softer cores (common in freestyle snowboards) offer playful flex, while stiffer ones (used in freeride snowboards) provide more stability. The core also absorbs vibration and affects overall board weight and control.

Fiberglass sits above and below the core, adding strength, torsional stiffness, and flex control. By changing the number of layers or weave patterns (like biaxial or triaxial), manufacturers fine-tune how your board handles different terrain. Fiberglass is key to snowboard performance—impacting how well your board carves, pops, and adapts to conditions.

The topsheet isn’t just for graphics—it protects against UV rays, scratches, and moisture. In some boards, it also adds torsional stiffness for better edge control. While it’s a subtle layer, it plays a role in durability and lateral flex, especially for aggressive riders.

This is the part that touches the snow. Sintered bases are faster and absorb wax better but need more maintenance. Extruded bases are slower but tougher and easier to repair. Your snowboard base influences your glide, speed, and upkeep needs on the mountain.

Steel edges give you grip on hardpack and ice, while sidewalls protect the core and help with energy transfer. Together, they improve edge control, boost durability, and give you confidence at speed or in tough conditions.

ed edge and sidewall systems in all high-end types of snowboards.

Fiberglass is a composite material made from extremely fine strands of glass woven into a fabric, which is then combined with resin to form a strong, lightweight, and flexible layer. In the world of snowboard materials, fiberglass plays a crucial role in enhancing the board’s performance.

Here’s why it’s so widely used in snowboards:

Fiberglass is one of the most essential snowboard materials—and for good reason. Whether you’re cruising groomers or riding deep powder, fiberglass gives your board the strength, flex, and response needed for a smooth and controlled experience. Let’s break down the key benefits you’ll notice on the slopes.

The biggest advantage of fiberglass is how it balances flexibility and strength. It allows your board to bend naturally when you carve or land a trick, yet it’s strong enough to keep the board stable at high speeds. This is crucial across all types of snowboards, from playful freestyle decks to all-mountain and freeride models.

One of the hidden benefits of fiberglass is how lightweight it is. Compared to some other materials, fiberglass adds strength without increasing the board’s weight. That makes your board easier to maneuver—especially when navigating tight terrain or hitting the park.

Better performance for tricks, turns, and quick edge changes

Fiberglass allows the board to flex and rebound naturally, it enhances your overall maneuverability. You’ll feel more in control whether you’re weaving through trees, carving hard on ice, or adjusting your stance mid-air.

Snowboarding exposes your gear to freezing temps, wet snow, and repeated impact. Fiberglass adds a protective layer that keeps your board performing over time.

No matter your preferred terrain, fiberglass is engineered to adapt. That’s why it’s a core material in beginner boards, expert-level setups, and even hybrid designs like the carbon fiber snowboard.

sed in performance boards: blends with other fibers for race-ready control

Not all fiberglass is the same. Depending on your riding style, manufacturers use different weave patterns to control the ride.

Weave Type | Flexibility | Stiffness | Best For |

Biaxial | High | Low | Freestyle, beginners |

Triaxial | Medium | Medium-High | All-mountain, carving |

Quadraxial | Low | Very High | Racing, carbon fiber boards |

Whether you’re floating through powder, carving on hardpack, or sending jumps in the park, fiberglass helps your snowboard adapt to changing terrain. Thanks to its blend of flexibility, torsional strength, and durability, fiberglass remains one of the most versatile and trusted snowboard materials across all riding conditions.

In soft, deep snow, flex matters. Fiberglass allows the board to flex naturally, helping the nose rise and stay afloat. This is especially important in freeride and all-mountain snowboards, where smooth control is essential.

When the snow is firm or icy, control becomes critical. Triaxial or quadraxial fiberglass adds torsional stiffness, which helps your edges dig in and maintain grip even at higher speeds.

Keeps response predictable on slick surfaces

Freestyle riding demands both resilience and rebound. Whether you’re hitting kickers or rails, fiberglass construction offers the pop needed for tricks while absorbing repeated impacts.

Withstands heavy use in jumps and rail slides

Backcountry riding often involves varied and unpredictable snow conditions. Fiberglass gives your board the versatility and structure it needs to perform across crust, slush, powder, and everything in between.

Now that you understand how fiberglass affects flexibility, strength, durability, and ride feel, you’re better equipped to choose a snowboard that matches your riding style and performance needs.

So the next time you pick up a board, don’t just admire the graphics—look deeper into the materials. It’s the fiberglass layers and core construction that truly define how your snowboard feels on the slopes.

Want to learn more about why fiberglass remains the industry standard? Check out our full guide:

Why Fiberglass Remains a Top Choice in Snowboard Construction

If you have any questions or want to discuss your snowboard project, feel free to reach out!

WhatsApp: +86-13775339109

WeChat: 13775339100

Email: fiberglassmesh@hotmail.com

We’re here to help!

It depends on your riding style. Fiberglass is more flexible and forgiving, ideal for beginners and freestyle. Carbon fiber is stiffer and better for speed and carving.

Most snowboards use fiberglass because it provides an excellent balance of flex, strength, and affordability. Some high-performance models also include carbon fiber or other composites.

Yes. Fiberglass is moisture-resistant and impact-tolerant, which increases the durability and lifespan of the snowboard.

Absolutely. Biaxial fiberglass is flexible and responsive, making it a great choice for freestyle riders who need smooth flex and control for tricks.

Efficiency – Another reason for fiberglass’ continued popularity is its effectiveness as an insulator. Fiberglass insulation has been shown to reduce heating and cooling bills by 40 to 50 percent.

“S” Fiberglass Cloth (also known as S-Cloth or S-Glass) is sometimes used on the deck of surfboards for more impact resistance against heel dents and caving in the deck. In very basic terms, it has a tighter weave with more fibers per square inch.

Connect with an NQ expert to discuss your product needs and get started on your project.