Why You Should Choose Aramid for Chemical-Resistant Tapes

Explore why aramid is a top choice for chemical-resistant tapes with insights from NQ fiber. Learn about the key benefits and uses.

Glass fiber check cloth is a non-twist roving plain fabric, is an important base material for hand paste glass fiber reinforced plastic. The strength of the plaid cloth is mainly in the warp and weft direction of the fabric, for the occasion of requiring high warp or weft strength, it can also be woven into one-way cloth, which can be arranged in the warp or weft more untwisted roving, single warp cloth, single weft cloth. Untwisted roving is made by bunching parallel strands or parallel monofilaments. Untwisted roving can be divided into E-GLASS untwisted roving and C-GLASS untwisted roving. The diameter of the glass fiber used to produce glass roving ranges from 12 to 23μm. The number of untwisted roving is from 150 to 9600 (tex). Untwisted roving can be directly used in some composite process forming methods, such as wrap entanglement, pultrusion process, because of its average tension, it can also be woven into untwisted roving fabric, and in some applications, the untwisted roving can be further shortened.

The quality requirements of the gingerbread are as follows:

① The fabric is average, the cloth edge is flat and straight, the cloth surface is flat and match-like, without stains, fuzziness, creases, wrinkles, etc.;

② Warp and weft density, area weight, fabric and roll length are in line with the scale;

③ Winding on a firm paper core, winding neatly;④ Rapid and good resin permeability;

⑤ The dry and wet mechanical strength of the laminate material made of fabric should meet the requirements.

The composite material coated with plaid cloth is characterized by low interlayer shear strength, poor compression and fatigue strength.

(1) Cut the glass filament (sometimes also with untwisted roving) into 50mm long, which is randomly but evenly spread on the mesh belt, and then apply emulsion binder or sprinkle powder binder after heating and curing to bond into short cut filament felt. Chopped felt is mainly used in hand paste, continuous plate making and die pressing and SMC process. The quality requirements of chopped strands are as follows:

1.The area mass is equal along the width direction;

2. The cut strands are evenly distributed in the felt surface, no large holes are formed, and the binder is evenly distributed;

3. with moderate dry felt strength;

4. Excellent resin infiltration and penetration.

(2) Continuous filament felt the glass filament formed in the process of wire drawing or the continuous filament retreated from the cylinder in a figure-8 spread on the continuous moving mesh belt, and the powder binder bonding is formed. The fiber of continuous glass fiber filament felt is continuous, so its strengthening effect on composite material is better than that of short cut felt. It is mainly used in pultruding, RTM, pressure bag and glass felt reinforced hot plastic (GMT) process.

(3) Surface felt glass fiber reinforced plastic products usually need to form a rich resin layer, which is generally achieved with alkali glass surface felt. This kind of felt is made of medium alkali glass (C), so it gives the glass steel chemical resistance, especially acid resistance, and because the felt is thin and the glass fiber diameter is small, it can also absorb more resin to form a rich resin layer, which covers the glass fiber reinforcement material (such as check cloth), and plays the role of surface polishing.

(4) Needle felt Needle felt or divided into short fiber needle felt and continuous raw thread needle felt. Staple fiber needle felt is a glass fiber roving cut into 50mm pieces, randomly laid on the substrate pre-placed on the conveyor belt, and then needled with a barb needle, the needle stabbed the staple fiber into the substrate, and the crochet needle brought up some of the fibers to form a three-dimensional structure. The base material used can be thin fabric of glass fiber or other fibers, and this kind of needle felt has a fuzzy feeling. Its main uses include thermal insulation materials, lining heat materials, filter materials, and can also be used in the production of FRP, but the strength of the FRP is low and the use range is limited. Another kind of continuous primary thread needled felt is the three-dimensional structure of the felt in which the continuous glass primary thread is randomly thrown on the continuous mesh belt by a wire throwing device and then needled by a needle plate. This kind of felt is mainly used for the production of glass fiber reinforced thermoplastic laminates.

(5) stitched felt cut glass fiber from 50mm or even 60cm long can be stitched into short fiber or long fiber felt, the former can replace the traditional binder bonded short felt in several uses, the latter to a certain extent instead of continuous filament felt. Their common advantage is that they do not contain binders, avoid the pollution of the production process, and have good penetration function and low price.

The following introduces a variety of glass fiber cloth woven with glass fiber yarn, glass fiber fabric.

(1) Glass cloth The glass cloth produced in our country is divided into two categories: alkali-free and alkali, and most of the foreign countries are E-GLASS alkali-free glass cloth. Glass cloth is mainly used in the production of various electrical insulation laminates, printed circuit boards, various vehicle bodies, storage tanks, boats, molds and so on. Medium alkali glass cloth is mainly used for the production of plastic coated packaging cloth, and for corrosion resistance occasions. The properties of fabric are determined by fiber function, warp and weft density, yarn structure and weave. The warp and weft density is determined by the fabric structure and weave. The warp and weft density, together with the yarn structure, determines the physical properties of the fabric, such as weight, thickness and breaking strength. There are five basic weaves: plain plan(similar to plaid), twill(generally +-45 degrees), satin statin(similar to one-way fabric), ribbed leno(mainly glass mesh fabric) and matts(similar to Oxford fabric).

(2) The glass fiber strip is divided into woven side strips (light edge strips) and non-woven side strips (raw edge strips). Alkali-free glass fiber tape is often used in the manufacture of high-strength, good dielectric function of electrical equipment parts.

(3) Glass fiber unidirectional fabric, unidirectional fabric in which the single warp fabric is a coarse warp and fine weft woven into four broken satin or long axis satin fabric, which is characterized by high strength in the warp main direction of 0 degrees. There are also glass fiber single weft cloth, there are two kinds of warp knitting and machine weaving, characterized by thick weft yarn, fine warp yarn, glass fiber yarn are fed in the weft, at 90 degrees latitude with high strength.

(4) glass fiber three-dimensional fabric Three-dimensional fabric is relative to flat fabric, its structural characteristics from one-dimensional two-dimensional development to three-dimensional, so that the composite material as the reinforcement has good integrity and shape copying, greatly improving the interlayer shear strength and damage tolerance of the composite material. It is developed with the special needs of aerospace, aviation, swords, ships and other parts, and its application has been expanded to automobiles, sports equipment, medical equipment and other parts. There are five main categories: woven 3D fabrics, knitted 3D fabrics, orthogonal and non-orthogonal non-woven 3D fabrics, 3D woven fabrics and other forms of 3D fabrics. The shape of three-dimensional fabric includes block, column, tube, hollow truncated cone and variable thickness shaped section.

The shape of the special-shaped fabric is very similar to the shape of the product it is intended to enhance, and must be woven on a special loom. Symmetrical shape of the special-shaped fabric are: cap, cone, cap, dumbbell fabric, etc., can also be made into boxes, hull and other different miscalled shape.

(6) Glass fiber channel core fabric Channel core fabric is composed of two layers of parallel fabric, connected by vertical vertical bars of fabric, its cross-section shape can be triangular, rectangular, honeycomb structure.

(7) Glass fiber stitched fabric is also known as knitted felt or woven felt, it is different from ordinary fabric, but also different from the usual sense of felt. The most typical stitched fabric is a layer of warp and a layer of weft overlapping, by sewing the warp and weft woven together into fabric. The advantages of stitch-knitted fabrics are as follows:

1.It can increase the ultimate tensile strength, delamination strength and bending strength of FRP laminates under tension;

2.Reduce the weight of FRP products;

3. The surface is smooth so that the surface of FRP is smooth;

4.Simplify hand paste manipulation and improve labor productivity. This reinforced material can be used in pultrusion FRP and RTM instead of continuous filament felt, and can also be used in centrifugal glass tube production instead of plaid cloth.

The glass fiber cloth, cut yarn felt, continuous yarn felt, untwisted roving fabric and untwisted roving, etc. are generally combined in a certain order of reinforcement materials, as follows:

(1) Cut raw silk felt + non-twist roving fabric

(2) Cut yarn felt + untwisted roving cloth + cut yarn felt

(3) Cut raw silk felt + continuous raw silk felt + cut raw silk felt

(4) Cut raw felt + random untwisted roving

(5) Cut raw silk felt or cloth + one-way untwisted roving

(6) Cut raw silk + surface felt

(7) Glass fiber cloth + one-way non-twist roving or glass rod + glass fiber cloth

(1) For low temperature -196 ° C, high temperature between 300 ° C, with climate resistance

(2) Non-adhesive, not easy to adhere to any substance

(3) Chemical corrosion resistance, capable of strong acid, strong alkali, and various organic solvent decay

(4) Low friction coefficient, is the best choice for oil-free self-lubrication

(5) Light transmittance of 6~ 13%

(6) With high isolation properties, anti-ultraviolet, anti-static

(7) High strength. It has good mechanical properties

(8) Drug resistance

But glass doesn’t burn. The combustion we can see is actually to change the properties of the glass fiber cloth, and the resin material coated on the surface of the glass fiber cloth, or the adhesion of impurities. Pure glass fiber cloth or coated with some high-temperature paint, it is possible to make refractory clothing, refractory gloves, refractory blankets and other products. But if it is directly against the skin, the broken fiber will stimulate the skin more than the other, and it will be very itchy.

Table 1: Alkali free and twist free roving specifications

Code | Thickness (mm) | Width (cm) | Weight (g/m2) | Remarks |

EWR200-100 | 0.2 | 100 | 210 |

|

EWR220-90 | 0.22 | 90 | 190 |

|

EWR300-100 | 0.3 | 100 | 290 |

|

EWR400-100 | 0.4 | 100 | 420 |

|

EWR500-100 | 0.5 | 100 | 480 |

|

EWR750-100 | 0.75 | 100 | 580 |

|

EWR-100 | – | 100 | 810 |

|

EWR1300-100 | 1.3 | 100 | 830 |

|

Table 2: Medium alkali untwisted roving specifications

Code | Thickness (mm) | Width (cm) | Weight (g/m2) | Remarks |

CWR200-90 | 0.2 | 90 | 175 |

|

CWR240-90 | 0.24 | 90 | 195 |

|

CWR300-90 | 0.3 | 90 | 290 |

|

CWR340-100 | 0.34 | 100 | 350 |

|

CWR370-90 | 0.4 | 90 | 370 |

|

CWR380-90 | 0.4 | 90 | 380 |

|

CWR400-90 | 0.4 | 100 | 340 |

|

CWR400-100 | 0.4 | 100 | 400 |

|

CWR400-100 | 0.4 | 100 | 400 |

|

Table 3: Specifications of cut yarn felt

Code | Resin Content (%) | Width (cm) | Weight (g/m2) | Remarks |

EM230 | <10 | 186 | 230 | Use “C” in lay-up |

EM300 | <10 | 186 | 300 |

|

EM360 | <10 | 186 | 360 |

|

EM400 | <10 | 186 | 400 |

|

EM450 | 12-15 | 125 | 450 | Use “M” in lay-up |

EM450 | 3-4 | 125 | 450 |

|

EM600 | <10 | 186 | 600 |

|

EM900 | <10 | 186 | 900 |

|

Surface | – | – | 30 | Use “S” in lay-up |

Notes:

Explore why aramid is a top choice for chemical-resistant tapes with insights from NQ fiber. Learn about the key benefits and uses.

Compare aramid fiber vs. fiberglass in strength, weight, heat resistance, and cost. Learn which material suits your project, from aerospace parts to cost-effective construction.

Aramid fiber and carbon fiber have different molecular structures and properties. Because of its remarkable impact resistance and flexibility, aramid fiber is ideal for protective gear and other applications that require toughness.

Aramid fiber and carbon fiber have different molecular structures and properties. Because of its remarkable impact resistance and flexibility, aramid fiber is ideal for protective gear and other applications that require toughness.

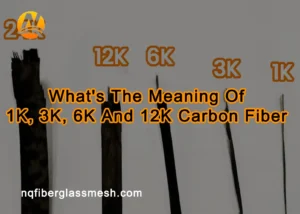

K means the amount of carbon fiber finaments one bundle. 1K means one bundle has 1000 carbon fiber filaments, 3K means one bundle has 3000 carbon fiber filaments,6K means one bundle has 6000 carbon fiber filaments and so on.

Carbon fiber is an advanced material that has gained widespread popularity due to its strength and lightweight properties.