Products Categories

Featured Products

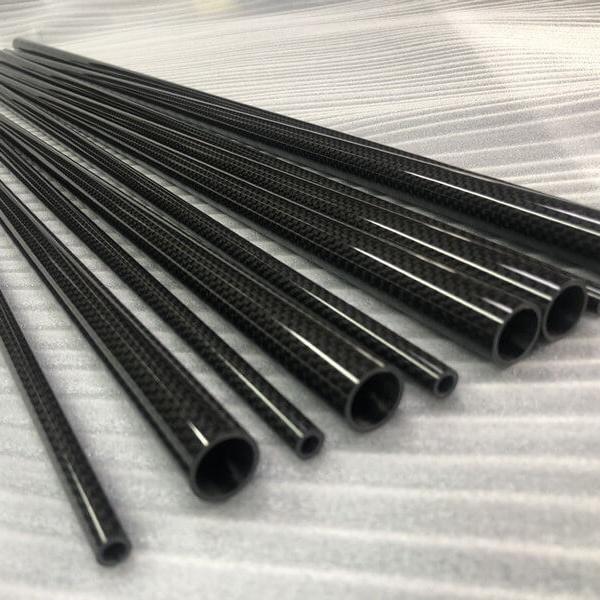

Tapered Carbon Fiber Tube

A Tapered Carbon Fiber Tube is a lightweight, high-strength composite tube with a gradually changing diameter along its length. Typically made using prepreg carbon fiber, it offers excellent mechanical performance and structural efficiency.

- Lightweight Design: Carbon fiber has low density, and the tapered shape reduces unnecessary material, minimizing weight.

- High Strength & Stiffness: Fiber orientation can be optimized for superior axial and bending performance.

- Stress Distribution: The tapered geometry reduces stress concentrations, improving structural integrity.

- Vibration Damping: Carbon fiber naturally absorbs vibrations, enhancing dynamic stability.

- Corrosion & Weather Resistance: With excellent environmental durability, it resists moisture, UV, and chemicals.

- Customizable: Tube diameter, taper ratio, wall thickness, and length can be tailored to specific design needs.

Product MOQ

Please note our minimum order quantity of Carbon Fiber Tube. For the conventional Carbon Fiber Tube in stock, there is no MOQ. For customized Carbon Fiber Tube, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

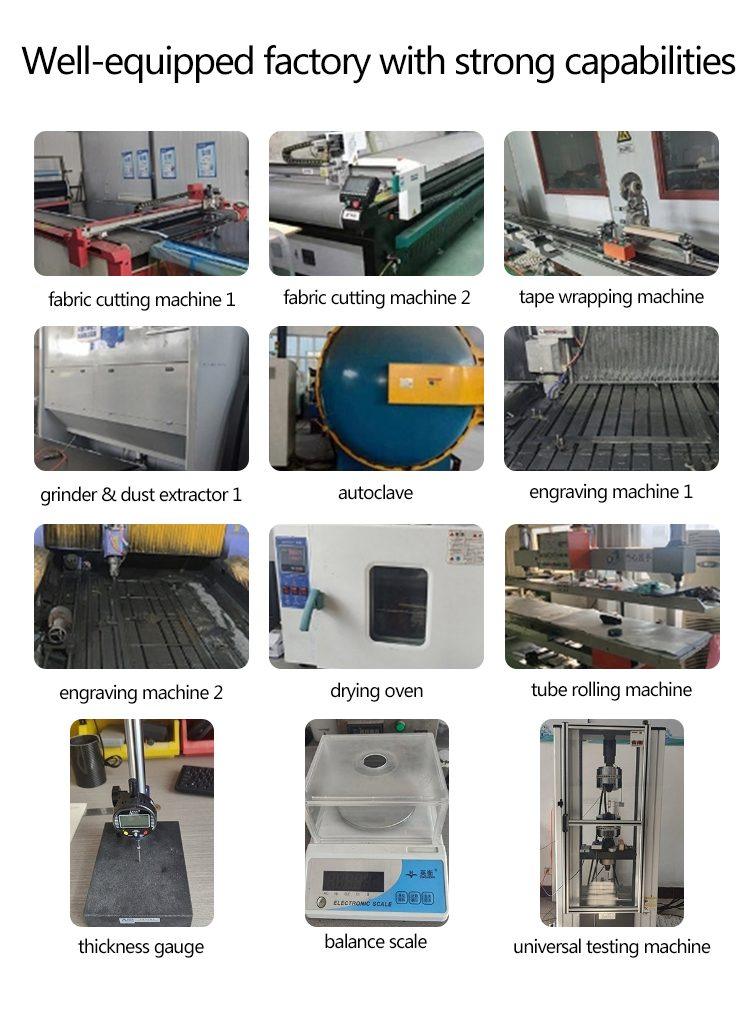

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

- The Tapered Carbon Fiber Tube, a tubular structure crafted from carbon fiber composite and featuring a gradually changing diameter, offers specific mechanical properties and broad application potential.

- When showcasing our factory’s customization capabilities, the precision in controlling the specifications and dimensions of the tapered carbon fiber tube stands out. We can produce tubes with diameters ranging from 0.5mm to 600mm, lengths from 2mm to 5500mm, and wall thicknesses varying from 0.2mm to 50mm, all tailored to meet the individual needs of our customers. This flexibility ensures we can satisfy the diverse demands across various industries and applications.

- Beyond specifications and dimensions, our factory excels in customizing materials and processes. We utilize premium carbon fiber materials and advanced production techniques to guarantee the exceptional mechanical properties and stability of the tapered carbon fiber tube. Furthermore, we can adjust the carbon fiber content, resin type, and other factors to meet specific performance requirements in diverse environments.

- In terms of design and functionality, our factory boasts significant customization capabilities. Our professional design team and advanced production equipment enable us to create personalized designs based on customer needs. For instance, in the aerospace industry, we can design tapered carbon fiber tubes with specific taper ratios, lightweight construction, and high strength to suit complex operating conditions. In the sports equipment sector, we can customize tubes with shock absorption and impact resistance features to enhance athletes’ performance.

- Through our factory’s customization capabilities, we address various challenges for our customers. Firstly, we meet their individualized demands for tapered carbon fiber tubes’ specifications, dimensions, and performance, ensuring products fulfill specific application requirements. Secondly, our premium materials and advanced production techniques guarantee product stability and reliability, reducing risks for customers during use. Lastly, our quick response and efficient production capabilities ensure timely delivery of the required products, shortening product development and production cycles.

Specification

- Large End Outer Diameter

- Typical range: 20mm – 100mm

- Larger sizes available upon request

- Small End Outer Diameter

- Typical range: 5mm – 60mm

- Proportional to large end diameter

- Length

- Standard range: 500mm – 2000mm

- Customizable from 100mm up to 3000mm or more

- Taper Ratio / Taper Angle

- Usually linear taper

- Example: 1mm diameter change per 100mm length (1:100)

- Wall Thickness

- Range: 0.5mm – 3mm

- Uniform or variable wall thickness optional

- Fiber Orientation

- Common layups: 0° / ±45° / 90°

- Optimized based on structural load requirements

- Surface Finish

- Options: Matte, Glossy, Visible Weave

- UV clear coating available for protection

- Material Type

- High-strength carbon fibers (e.g., T300, T700, T800)

- Resin systems: Epoxy (standard), high-temperature resins available

- Manufacturing Process

- Common methods: Roll wrapping, filament winding, compression molding

Main applications

Aerospace Industry

- Airframe Components: Due to their high strength, lightweight, and high-temperature resistance, tapered carbon fiber tubes are used in the manufacturing of specific components of aircraft, such as brackets and load-bearing structures. These components significantly reduce the overall weight of the aircraft, improving flight performance.

- Engine Parts: Carbon fiber materials are also suitable for making engine parts, such as using tapered carbon fiber tubes as pipelines or structural parts of engines. This lightens the weight of the engine while improving its high-temperature resistance.

- Tools and Equipment: In aerospace exploration, tapered carbon fiber tubes are also used in the manufacture of components such as spacecraft cabins, satellites, and other supports or connectors to ensure structural stability and reliability.

Automotive Industry

- Body Structure: Tapered carbon fiber tubes are used in the automotive industry to manufacture body structure components like frames and chassis, reducing the overall weight of the vehicle, improving fuel efficiency, and enhancing rigidity and safety.

- Engine and Suspension Systems: Carbon fiber tubes are also used to make parts for automotive engines and suspension systems, such as exhaust pipes and suspension arms, to enhance vehicle performance and durability.

Sports Equipment and Recreational Products

- Golf Clubs, Tennis Rackets, etc.: Due to their lightweight and high strength, tapered carbon fiber tubes are suitable for manufacturing sports equipment such as golf club shafts and tennis racket frames, providing excellent mechanical properties and feel.

- Bicycle Frames: Carbon fiber tubes are also commonly used in the manufacture of high-performance bicycle frames to achieve lightweight and improve riding performance.

Machinery and Infrastructure

- Robots and Automation Equipment: Tapered carbon fiber tubes are used in the robotics and automation industry to make components like robotic arms and brackets, leveraging their lightweight and high-strength properties to improve equipment efficiency and longevity.

- Bridges and Buildings: In infrastructure construction, carbon fiber tubes can be used to reinforce bridges, buildings, and other structures, providing additional support and stability.

Medical and Industrial Equipment

- Surgical Instruments and Prostheses: Carbon fiber tubes are used in the medical field to make surgical instruments and prostheses, providing comfort and convenience for patients due to their lightweight and high-strength characteristics.

- Precision Instruments: In the industrial equipment sector, tapered carbon fiber tubes are used to make parts for various precision instruments, such as optical instruments and measuring instruments, to ensure equipment stability and accuracy.

Features

- High Strength-to-Weight Ratio

- Carbon fiber offers exceptional tensile strength while remaining ultra-lightweight—ideal for structural efficiency.

- Optimized Load Transfer

- Tapered geometry provides a smooth transition of forces, minimizing stress concentrations at connection points.

- Superior Bending and Axial Stiffness

- Custom fiber layups allow high rigidity in both bending and compression directions, ensuring stability under load.

- Excellent Vibration Damping

- Carbon fiber naturally absorbs shocks and vibrations, improving performance in dynamic environments.

- Corrosion and Chemical Resistance

- Unlike metals, carbon fiber does not corrode or degrade in harsh chemical or marine environments.

- Thermal Stability

- Maintains dimensional and mechanical integrity over a wide temperature range, especially with high-temp resin systems.

- Fatigue Resistance

- Outstanding durability under repeated loading cycles, far exceeding most metals in fatigue performance.

- Customizable Mechanical Properties

- Fiber orientation, taper angle, and wall thickness can be tuned to meet specific structural and performance goals.

- Low Thermal Expansion

- Minimal expansion or contraction with temperature changes, ideal for precision applications.

- Aesthetic Appeal

- The woven carbon fiber finish and tapered shape offer a sleek, high-tech look for visible components.

For more product specifications, please contact our professionals!

By adopting CNC precision processing technology and automatic detection systems and integrating automated winding, curing, and cutting processes, the production speed is increased by 20% to 30%. Multi-station collaborative operation reduces manual intervention and reduces the error rate.

- Compatible with carbon fiber prepregs such as T300, T700, T800

- Supports a variety of resin systems such as epoxy and phenolic

- ISO 9001, CE, SGS, and ASTM standards

- 40 automated production lines to ensure on-time delivery

- In-house Strictly Testing Lab for 6-step internal inspection

Enhance Performance, Simplify Processing, Reduce Costs

Experience the power of Carbon Fiber Tubes—lightweight, ultra-strong, and corrosion-resistant. Perfect for industries demanding high performance and durability. Elevate your products with precision-engineered tubes that combine advanced materials with cutting-edge manufacturing. Choose carbon fiber tubes for unmatched strength, reduced weight, and superior reliability.