- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

Table of Contents

ToggleWhen it comes to reinforced materials, fiberglass cloth stands out as one of the most versatile and widely used options. Whether you’re repairing a boat hull, restoring a car panel, or tackling a DIY project, fiberglass fabric offers an excellent balance of strength, flexibility, and affordability. But like any material, it comes with both advantages and limitations.

In this guide, you’ll explore the strengths and weaknesses of fiberglass cloth, understand the differences between the main types of fiberglass fabrics

When choosing a fiberglass fabric, the weight (measured in ounces per square yard) and weave style are key factors.

Perfect for model airplanes, drones, surfboards, or small DIY projects. Thin layers provide smooth reinforcement without adding bulk.

The most popular choice for boat repairs and small structures. They balance strength, flexibility, and ease of handling.

7781 fiberglass: widely used in aerospace and industry for its high strength and thermal stability.

If your project requires structural reinforcement—such as boat hulls or industrial parts—1708 biaxial cloth is ideal. Its weave gives exceptional durability.

Best used as a finishing or insulation layer. Provides a smooth surface and is common in lamination finishing.

Cloth Type | Weight (oz) | Weave | Best For | Strength |

2 oz | Lightweight | Plain | Models, DIY | Low |

4 oz | Light-medium | Plain/Twill | Surfboards, light repairs | Moderate |

6 oz | Medium | Plain/Twill | Boats, panels | Strong |

7.5 oz / 7781 | Medium-heavy | Satin | Aerospace, industrial | Very strong |

1708 biaxial | Heavy | Biaxial + mat | Hulls, structures | Extremely strong |

Fleece cloth | N/A | Non-woven | Finishing, insulation | N/A |

Fiberglass has become a go-to reinforcement material in many industries because it’s strong, lightweight, and durable. You’ll find it everywhere – from building sites and car factories to shipyards and chemical plants. It gets the job done without breaking the bank.

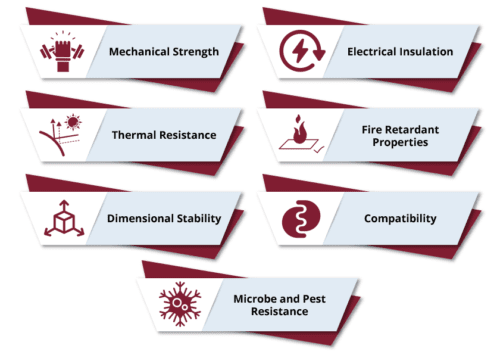

You may wonder, how strong is fiberglass? According to ASTM D638 standards, E-glass fibers exhibit tensile strengths up to 3.4 GPa (around 500,000 psi), while their density is only 2.6 g/cm³, roughly 75% lighter than steel (density ~7.85 g/cm³). This characteristic makes fiberglass ideal for structural applications that require strength without the added weight.

Its lightweight nature facilitates easier transportation, quicker installation, and reduced labor expenses. Fiberglass composites are widely used in aviation for their lightweight and fuel-saving properties. The FAA has officially recognized these advantages. the same benefits make fiberglass equally valuable for designing cars and building boats.

Fiberglass doesn’t rust like metal and holds up well against chemicals, saltwater, and moisture. According to the U.S. Army Corps of Engineers, fiberglass-reinforced plastics (FRPs) maintain their strength even in harsh, corrosive conditions.

That’s why fiberglass is a great choice for wastewater systems, chemical tanks, and marine structures—where long-term durability is key. With little maintenance, fiberglass parts can last over 25 years, making them a cost-effective option in the long run.

Another significant advantage of fiberglass is its ability to be molded into intricate shapes without the need for expensive tooling modifications. This allows engineers to create custom components tailored to specific requirements.

Industries frequently choose fiberglass-reinforced plastic tanks for their design flexibility, chemical resistance, and mechanical strength. Whether in round, rectangular, or specialized shapes, fiberglass provides design options at a competitive price.

Fiberglass has become a go-to reinforcement material in many industries because it’s strong, lightweight, and durable. You’ll find it everywhere – from building sites and car factories to shipyards and chemical plants. It gets the job done without breaking the bank.

You may wonder, how strong is fiberglass? According to ASTM D638 standards, E-glass fibers exhibit tensile strengths up to 3.4 GPa (around 500,000 psi), while their density is only 2.6 g/cm³, roughly 75% lighter than steel (density ~7.85 g/cm³). This characteristic makes fiberglass ideal for structural applications that require strength without the added weight.

Its lightweight nature facilitates easier transportation, quicker installation, and reduced labor expenses. Fiberglass composites are widely used in aviation for their lightweight and fuel-saving properties. The FAA has officially recognized these advantages. the same benefits make fiberglass equally valuable for designing cars and building boats.

Fiberglass is recognized for its outstanding electrical insulation capabilities. It has dielectric strengths ranging from 15 to 30 kV/mm (according to IEEE standards), making it suitable for electrical enclosures, circuit boards, and insulating components.

Its non-conductive properties reduce the risk of electrical failures and eliminate the need for additional insulation layers, enhancing system safety and performance.

Fiberglass has low thermal conductivity, approximately 0.035 W/m·K (ISO 8302), making it an excellent choice for thermal insulation in buildings and industrial equipment.

The U.S. Department of Energy states that fiberglass insulation can reduce heating and cooling energy consumption by up to 30%. It is commonly utilized in HVAC systems, industrial ovens, and process enclosures to improve energy efficiency and maintain consistent temperatures.

Understanding these drawbacks can help you make better choices when selecting materials. These weaknesses also reveal the optimal usage scenarios for fiberglass panels, especially in demanding and complex environments.

Fiberglass is known for its strength and versatility, but it does have limitations. One of the biggest issues is its poor resistance to sharp impacts. While some materials might bend or deform when struck, fiberglass often cracks or even breaks because of its stiff structure. The tightly bonded glass fibers and resin don’t offer much flexibility, which makes it unsuitable for areas exposed to frequent heavy blows—like some automotive or industrial parts.

Sunlight is also another challenge for fiberglass. Long term exposure to ultraviolet radiation can cause glass fibers to gradually fade, decrease in strength, and even deform. Although this damage can be delayed by adding UV resistant coatings or improving formulations, it cannot be completely prevented. Therefore, although glass fiber has many advantages, there are still some limitations.

In applications that require extremely high weight and strength, such as aerospace, sports equipment, and automobiles, carbon fiber is the preferred material. However, its high cost has deterred many applications. In contrast, fiberglass provides a more cost-effective solution, although it falls short in terms of durability and performance.

Glass fiber is a widely used reinforcement material known for its high strength-to-weight ratio, corrosion resistance, and versatility. It is commonly integrated into composites and construction materials to enhance mechanical properties and durability. Below are key applications of glass fiber in reinforcement:

Fiberglass Reinforced Plastic(FRP) Rebars: Used as a corrosion-resistant alternative to steel rebar in concrete structures, improving longevity in harsh environments such as bridges, marine structures, and chemical plants.

Drywall Joint Tapes: Glass fiber mesh tape is used for reinforcing drywall joints to prevent cracking and improve surface durability.

Insulation Materials: Glass fiber mats and blankets provide thermal insulation in buildings, reducing heat transfer and improving energy efficiency.

Panels and Roofing: Glass fiber reinforced panels offer lightweight, durable, and weather-resistant cladding or roofing solutions.

Body Panels and Structural Parts: Glass fiber reinforced composites are used in car and truck body panels to reduce weight while maintaining structural integrity, improving fuel efficiency.

Boat Hulls and Marine Applications: Due to excellent corrosion resistance and strength, glass fiber composites are popular in boat hulls, decks, and other marine components.

Aerospace Components: Lightweight glass fiber composites are used in aircraft interiors and secondary structures to reduce overall weight and improve fuel economy.

Pressure Vessels and Tanks: Glass fiber reinforced plastic (FRP) tanks and pipes resist corrosion from chemicals and environmental exposure, making them ideal for storage of aggressive fluids.

Electrical Insulation: Glass fiber tapes and fabrics are used as insulators in electrical motors, transformers, and circuit boards due to their excellent dielectric properties.

Filtration: Glass fiber filters are employed in air and liquid filtration systems for their durability and chemical resistance.

Sports Gear: Glass fiber reinforcement is used in equipment like fishing rods, tennis rackets, skis, and helmets to provide a balance of strength and flexibility.

Recreational Vehicles: Components of bicycles, snowboards, and kayaks often utilize.glass fiber composites for enhanced performance.

Wind Turbine Blades: Glass fiber reinforced composites are widely used in the manufacturing of wind turbine blades due to their high strength, lightweight, and fatigue resistance.

Fiberglass cloth is a versatile, affordable, and strong reinforcement material, but it’s important to choose the right type for your project. Whether you need a lightweight 2 oz cloth for DIY models, a 6 oz roll for boat building, or a 1708 biaxial fabric for structural reinforcement, there’s a fiberglass fabric designed to fit your needs.

By understanding the strengths and weaknesses, you’ll make smarter choices and achieve professional-quality results.

Connect with an NQ expert to discuss your product needs and get started on your project.

Fiberglass cloth is used in boat building, automotive repairs, aerospace, and DIY reinforcement projects.

Cloth is woven for strength, while mat is non-woven for bulk and shape-building.

2 oz, 4 oz, 6 oz, 7.5 oz, 7781, 1708 biaxial, fleece, and epoxy fiberglass cloths.

Consider your application, required strength, and resin compatibility.

Yes, but use sharp scissors and wear protective gloves.

Yes, but always use gloves, goggles, and a mask to avoid irritation.