- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

Table of Contents

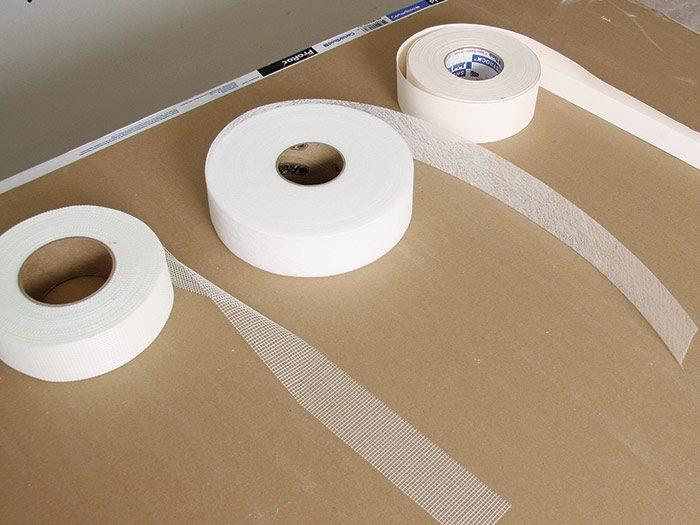

ToggleWhen finishing drywall, choosing the right tape is one of the most important decisions you’ll make. The debate often comes down to paper tape vs fiberglass tape—two essential materials that can dramatically affect the strength, durability, and appearance of your walls and ceilings.

If you’ve ever wondered which tape is better for walls, ceilings, or long-term crack prevention, this guide will give you the clear answers you need.

Material & Structure

Paper tape: Dense cellulose paper with a center crease that folds cleanly for inside corners. No adhesive—designed to be embedded in joint compound.

Fiberglass (mesh) tape: Woven glass-fiber self-adhesive mesh that sticks to the board before mudding; great visibility of the seam through the grid.

Strength & Crack Resistance

Paper tape: High tensile strength when fully embedded; distributes stress across the seam and resists hairline cracking, especially on ceilings and long tapered joints.

Fiberglass tape: Strong in its fibers but more prone to micro-cracks if you use only all-purpose drying compound. Performs best when paired with setting-type (hot mud).

Ease of Use (Beginner vs Pro)

Paper tape: Requires an initial mud bed and proper pressure to avoid bubbles, blisters, and wrinkles. Slightly steeper learning curve but yields a flatter, cleaner finish.

Mesh tape: Self-adhesive—stick it, then mud over it. Faster for DIY and production work; fewer placement errors on flats.

Cost & Availability

Paper tape: Generally lower cost per linear foot; ideal for whole-room installs and long seams.

Fiberglass/mesh tape: Slightly higher unit cost, but can reduce labor time on spot repairs and small jobs.

1.5 Joint Compound Compatibility

Paper tape: Works with all joint compounds—lightweight, all-purpose, and setting-type.

Fiberglass/mesh tape: For best results, pair with setting-type compounds (hot mud, e.g., 20/45/90 minute). Using only drying-type mud can lead to weaker joints.

Moisture & Mold Resistance

Paper tape: Cellulose can absorb moisture if not sealed; fine in normal interiors when properly primed and painted.

Fiberglass/mesh tape: Inorganic and mold-resistant, a smart pick for bathrooms, basements, and other humid zones—still rely on correct ventilation and coatings.

1.7 Finish Quality & Sanding

Paper tape: Embeds thin, helping you achieve a flatter profile with fewer high spots on long seams; typically less sanding to correct telegraphing.

Mesh tape: The grid can telegraph through if coverage is light; plan on careful fill and finish coats to hide the mesh texture.

Best Use Cases (Quick Selector)

Choose paper tape for:

• Ceilings, long tapered joints, high-movement areas

• Inside corners (use the center crease)

• Top-tier finishes where flatness matters

Choose fiberglass/mesh tape for:

• Patches and small repairs

• Butt joints you want to align quickly

Humid rooms (with setting-type compound)

Choosing between paper drywall tape and fiberglass mesh drywall tape is only half the battle—your application technique is what ensures a smooth finish and crack-free drywall surfaces. Below are step-by-step instructions and pro tips for using paper tape and mesh tape, written for you so that you can avoid common mistakes and achieve the best results.

Applying Paper Tape

Paper tape requires a little more skill but rewards you with a clean, strong, and durable finish—especially on ceilings and long seams.

Step-by-Step:

• Prepare the joint – Make sure the drywall seam is dust-free and slightly beveled.

• Apply a mud bed – Spread a thin, even layer of all-purpose or setting-type joint compound across the seam with a 4–6 inch drywall knife.

• Embed the tape – Place the paper tape over the wet compound and press it firmly into place, smoothing out excess mud.

• Remove air bubbles – Use the knife to press outward from the center. Any trapped air will cause blistering after painting.

• Apply a cover coat – Once the tape sets, apply a wider layer of compound, feathering edges to blend into the drywall.

Dry, sand, repeat – Let dry completely, sand lightly, and apply at least 2 more finish coats.

Common Mistakes to Avoid:

Dry spots under the tape – causes tape to lift.

Too much mud – leads to ridges that require heavy sanding.

Not creasing corners – paper tape has a center crease; use it for perfect inside corners.

Applying Fiberglass (Mesh) Tape

Fiberglass tape is faster to use and self-adhesive, making it a favorite for DIY projects and quick repairs. When considering drywall installations, fiberglass mesh drywall tape offers great adhesion properties.

Step-by-Step:

Clean the surface – Remove dust so the adhesive grips properly

Apply the tape – Stick the fiberglass tape directly over the seam, ensuring it’s centered.

Cover with compound – Apply setting-type joint compound (hot mud) over the tape. Spread firmly to press compound into the mesh.

Feather edges – Use a wider knife (8–10 inch) for smoother transitions.

Build up coats – After drying, add 1–2 more thin coats to fully cover the mesh pattern.

Sand carefully – Lightly sand between coats to achieve a smooth finish.

Common Mistakes to Avoid:

Using drying-type compound only – can lead to cracks because it shrinks.

Thin coverage – if you don’t bury the mesh fully, it can show through paint.

Over-sanding – can expose the mesh grid.

Tools You’ll Need

Drywall Knives (4, 6, 8, 12 inches)

You’ll need different sizes of knives. Small knives are perfect for the first coat, while larger knives help with finishing for a smoother wall.

Mud Pan or Hawk

Keep your joint compound handy in a mud pan so you don’t have to keep running back and forth. It makes the job much easier.

Corner Trowel

This tool is made for corners. Use it with paper tape to get clean, straight inside angles.

Sanding Block or Sponge

Use it to lightly sand off extra compound. This step makes your walls smooth and paint-ready.

Drywall Tape

•Paper Tape: Great for flat seams and corners, leaves a smooth finish.

•Mesh Tape: More moisture-resistant, perfect for kitchens, bathrooms, or other damp areas.

Utility Knife Handy for cutting tape cleanly without tearing it.

Handy Tips for DIYers

Clean the surface first: Dust and debris will weaken adhesion, so start with a clean area.

Don’t apply mud too thick: Thin layers are better and less likely to crack.

Sand gently: Too much pressure can leave dents.

Choose tape by environment: Paper tape works best in dry areas, mesh tape is better for humid spaces.

Both paper tape and fiberglass tape have their strengths—paper tape is ideal for ceilings and smooth seams, while fiberglass tape is perfect for quick repairs and humid areas. For the best finish, use them where they perform best.

Need help choosing or sourcing the right drywall tape? Contact us today for expert guidance and quality products.

Connect with an NQ expert to discuss your product needs and get started on your project.

Paper tape is a drywall joint tape made from durable cellulose paper. It has a crease for easy folding in corners and must be embedded in joint compound since it has no adhesive backing. It’s best for long seams, ceilings, and corners because it provides strong reinforcement and a smooth finish.

Can you use fiberglass tape on ceilings?

It depends on your project.

Paper tape is stronger, better for ceilings and inside corners, and gives a smoother finish.

Mesh (fiberglass) tape is easier for beginners, faster to apply, and more mold-resistant in humid areas.

No. Fiberglass tape should only be used with setting-type joint compounds (hot mud), which harden chemically and secure the mesh. If you use it with all-purpose drying compound only, cracks are more likely. Paper tape, however, works with both drying and setting-type compounds.

For Sheetrock seams, paper tape is best for full-length joints and ceilings, while fiberglass tape is useful for small patches or quick butt joint repairs. For long-term durability, especially in entire rooms, paper tape is the better choice.

Yes. “Fiber tap” is usually just a misspelling of fiberglass tape. Both refer to the same woven glass fiber mesh used to reinforce drywall seams.

• Paper tape – strong and foldable for seams and corners

• Fiberglass (mesh) tape – self-adhesive, quick for flat joints

• Metal-reinforced paper tape – best for outside corners

• Flexible corner tape – for angled or curved walls