Products Categories

Featured Products

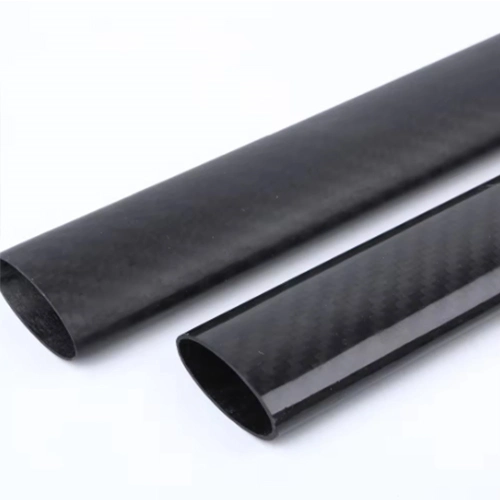

Oval Carbon Fiber Tube

Oval carbon fiber tubes are precision-engineered composite components designed with a non-circular cross-section to optimize mechanical performance in weight-sensitive and structurally demanding systems. Manufactured using high-strength carbon fiber prepreg and cured under controlled temperature and pressure, these tubes provide superior stiffness, low density, and consistent dimensional stability.

- Stronger Rigidity

- Lightweight Structure

- Precise Dimensions

- Premium Appearance

- Corrosion Resistant

- Customizable Specs

Product MOQ

Please note our minimum order quantity of Carbon Fiber Tube. For the conventional Carbon Fiber Tube in stock, there is no MOQ. For customized Carbon Fiber Tube, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

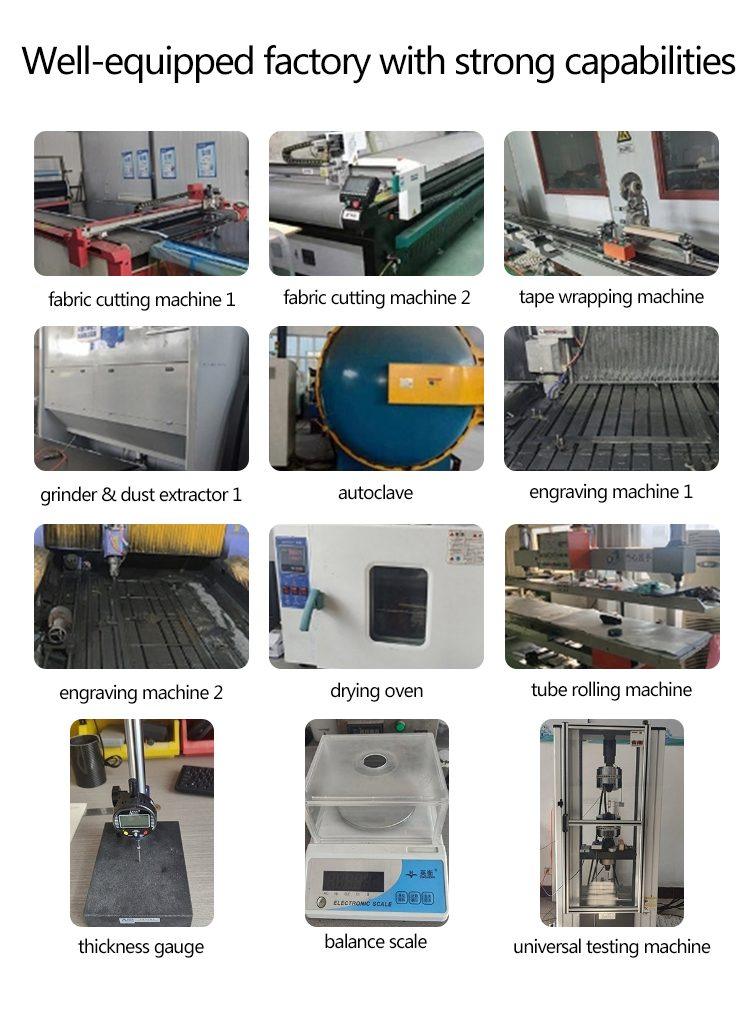

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

- Oval Carbon Fiber Tube, a type of tubing made of carbon fiber composite material with an elliptical cross-section, incorporates numerous advantages of carbon fiber, including high strength, lightweight, excellent fatigue resistance, thermal stability, and corrosion resistance.

- In terms of customization capabilities in factories, the production of Oval Carbon Fiber Tube can be tailored to specific requirements. Factories are typically able to precisely adjust the production process based on customer specifications, such as length, diameter, and wall thickness, to ensure the product meets the specific needs. Furthermore, factories can select different carbon fiber materials and resin matrices based on the application environment and usage conditions, thereby customizing the Oval Carbon Fiber Tube to have specific strength, stiffness, and temperature resistance.

- Additionally, factories can utilize advanced surface treatment technologies, such as applying corrosion-resistant coatings or wear-resistant layers, to enhance the durability and service life of the Oval Carbon Fiber Tube. These customized services make the Oval Carbon Fiber Tube a versatile solution with broad application prospects in industries such as aerospace, automotive, rail transportation, and energy.

- In summary, the Oval Carbon Fiber Tube boasts remarkable physical and chemical properties, and factories possess strong customization capabilities to produce personalized products that meet various special application scenarios.

Specification

- Major Axis (Width): 10 mm – 100 mm (customizable)

- Minor Axis (Height): 5 mm – 50 mm (customizable)

- Wall Thickness: 0.3 mm – 5 mm, adjustable for strength/weight balance

- Length: Standard 1 m or 2 m; custom lengths on request

- Material: High-strength carbon fiber prepreg with epoxy resin matrix, cured under controlled heat and pressure

- Weave Patterns: Unidirectional (UD), plain weave, twill weave, satin weave

- Surface Finish: Matte or glossy; smooth finish with clear fiber texture

- Dimensional Tolerance: ±0.1 mm for both axes and wall thickness

- Mechanical Properties:

- Tensile strength > 5000 MPa

- Modulus > 200 GPa

- Excellent fatigue resistance

- Environmental Resistance: Corrosion-proof, UV stable, wide thermal range (–60 °C to +120 °C)

- Color: Standard carbon black; optional surface coatings or paint for color/UV protection

- Customization Options: Any combination of major/minor axis, wall thickness, weave pattern, finish, and length to meet specific project requirements.

Main applications

Aerospace Industry

- Aircraft Structural Components: Oval Carbon Fiber Tube is widely used in aircraft frames, wing beams, and other structural components due to its lightweight and high strength properties, improving flight performance by reducing the overall weight of the aircraft.

- Missiles and Space Platforms: In the aerospace field, including missiles, space platforms, and carrier rockets, Oval Carbon Fiber Tube serves as a crucial material for manufacturing missile bodies, main structures, and other components, meeting the strict requirements for strength and stiffness.

Automotive Industry

- Body and Chassis: Vehicle lightweighting is essential for improving fuel efficiency and reducing emissions. Oval Carbon Fiber Tube is used in manufacturing automotive bodies and chassis to reduce weight and enhance vehicle performance.

- Seats and Interior Trim: Oval Carbon Fiber Tube also plays a vital role in seat frames and interior trim pieces, providing excellent support and durability.

Sports Equipment Industry

- Golf Clubs and Bicycle Frames: Oval Carbon Fiber Tube is an ideal material for manufacturing golf clubs and bicycle frames, as it requires both lightweight and high strength characteristics to provide better handling and performance for athletes.

- Fishing Rods and Skis: Oval Carbon Fiber Tube is also favored in these sports equipment due to its unique properties, enhancing the user’s experience.

Construction Industry

- Reinforcement Material for Reinforced Concrete: In the construction field, Oval Carbon Fiber Tube serves as a reinforcement material for reinforced concrete, enhancing the strength and durability of buildings while maintaining lightweight.

- Bridge Support Material and Earthquake Disaster Prevention Material: Its excellent creep resistance and seismic performance make Oval Carbon Fiber Tube an ideal choice for bridge support material and earthquake disaster prevention material.

Other Fields

- Medical Devices: Such as artificial joints and dental braces, Oval Carbon Fiber Tube is widely used in medical devices due to its biocompatibility and high strength properties.

- Energy and Environmental Protection: Oval Carbon Fiber Tube also finds applications in wind turbine blades, solar panel brackets, environmental monitoring equipment, pollution treatment equipment, and other areas, owing to its excellent corrosion resistance and mechanical properties.

Features

- High Strength-to-Weight Ratio

Delivers exceptional structural strength while significantly reducing overall weight — ideal for UAVs, aerospace components, bicycles, and any weight-sensitive applications. - Aerodynamically Efficient Profile

The oval cross-section minimizes air and fluid resistance compared to round tubes, enhancing aerodynamic performance in drones, racing bikes, wind tunnel setups, and automotive designs. - Superior Bending and Torsional Stiffness

Provides enhanced rigidity in the vertical axis and better load distribution, making it optimal for structures under dynamic stress, vibration, or long-span conditions. - Corrosion and Chemical Resistance

Carbon fiber composites are inherently rust-proof and chemically stable, making them suitable for harsh environments including marine, coastal, or industrial applications — with minimal maintenance. - Excellent Fatigue and Impact Resistance

Laminated structure ensures high resistance to cyclic loading and absorbs shock effectively, crucial for robotic arms, dynamic joints, sports equipment, and mechanical linkages. - Tight Dimensional Tolerances

Precision molding and controlled curing deliver consistent tolerances (±0.1 mm), ensuring reliable fitment in high-precision systems such as medical devices and engineering assemblies. - Technical and Aesthetic Surface Finish

Available in visible UD, plain, or twill weave, with matte or glossy finishes — ideal for exposed applications where clean appearance and perceived value are important (e.g., e-bikes, high-end consumer products). - Fully Customizable for Engineering Requirements

Buyers can specify major/minor axis dimensions, wall thickness, fiber orientation, resin type, and finish to meet mechanical, aesthetic, and installation-specific needs — supporting both prototyping and mass production.

- Material Composition: 100% Toray carbon fiber with epoxy resin

- Manufacturing Process: Roll-wrapped using prepreg technology

- Fiber Orientation: Outer layer: 3K weave; Inner layers: Unidirectional (UD)

- Tensile Strength (0° direction):

- 750 MPa

- Compressive Strength (0° direction):

- 600 MPa

- Elastic Modulus (0° direction): 90–120 GPa

- Shear Modulus: Approximately 4.6 GPa

- Thermal Conductivity: 0.1–0.3 W/m·K

- Operating Temperature Range: -30°C to +120°C

- Carbon Content: ≥90%

- Ash Content: 0.8–1.0%

For more product specifications, please contact our professionals!

By adopting CNC precision processing technology and automatic detection systems and integrating automated winding, curing, and cutting processes, the production speed is increased by 20% to 30%. Multi-station collaborative operation reduces manual intervention and reduces the error rate.

- Compatible with carbon fiber prepregs such as T300, T700, T800

- Supports a variety of resin systems such as epoxy and phenolic

- ISO 9001, CE, SGS, and ASTM standards

- 40 automated production lines to ensure on-time delivery

- In-house Strictly Testing Lab for 6-step internal inspection

Enhance Performance, Simplify Processing, Reduce Costs

Experience the power of Carbon Fiber Tubes—lightweight, ultra-strong, and corrosion-resistant. Perfect for industries demanding high performance and durability. Elevate your products with precision-engineered tubes that combine advanced materials with cutting-edge manufacturing. Choose carbon fiber tubes for unmatched strength, reduced weight, and superior reliability.