- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

Looking for a powerful and versatile material? Fiberglass fabric, known for its exceptional durability and wide range of applications, has become the material of choice across many industries. Whether in construction, marine, or automotive manufacturing, selecting the right fiberglass fabric can significantly enhance the quality and performance of your project.

In this article, we will delve into the different types of fiberglass fabric and their applications, while also comparing fiberglass fabric to fiberglass mat. Let’s explore how to make the best choice based on your specific needs.

Table of Contents

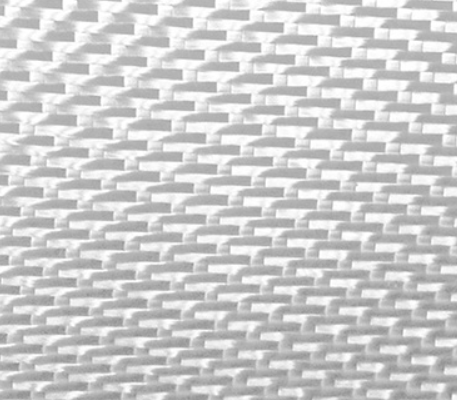

ToggleFiberglass cloth is made from woven glass fibers, known for its strength and versatility. You’ll find it commonly used in composites, coatings, and laminates, offering a lightweight yet durable solution for various applications. Whether you’re working on a boat repair or reinforcing a structure, fiberglass cloth provides the reliability you need for strong, long-lasting results.

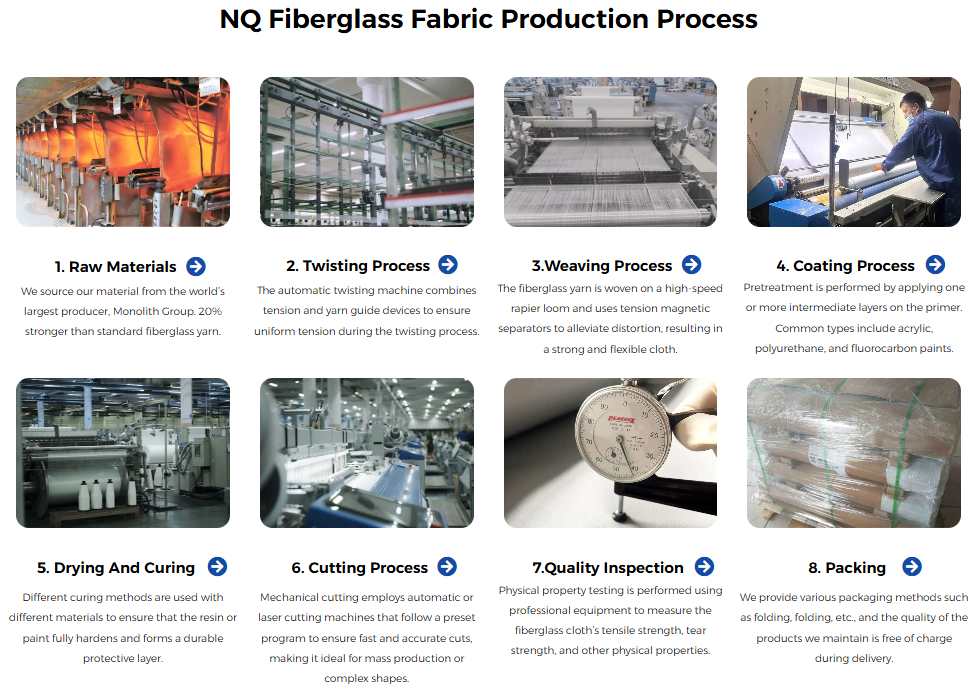

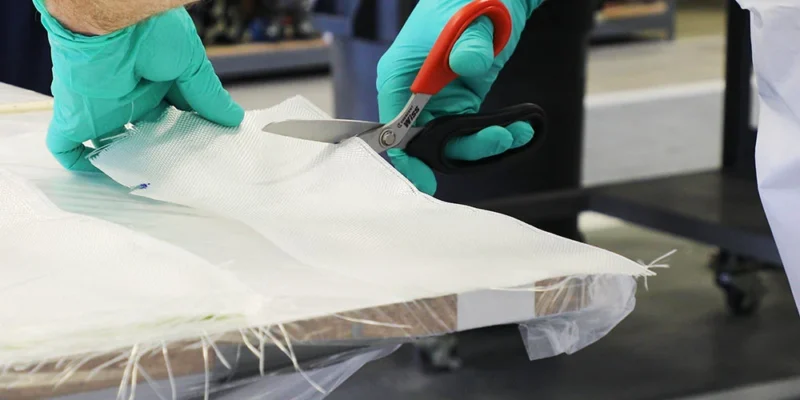

Fiberglass cloth is produced by weaving fine glass fibers, which are drawn from molten glass. These fibers are then woven together to form a flexible, durable fabric. Once woven, the fiberglass cloth can be coated with resin, making it ideal for fiberglass resin and polyester cloth applications or for use in composite materials that require extra strength and durability.

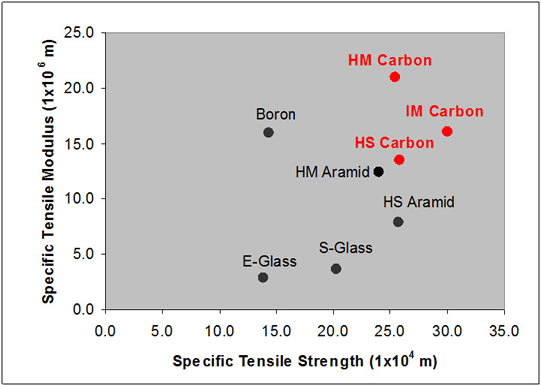

Fiberglass is known for its high tensile strength, making it a popular choice for a variety of structural applications. Whether you’re working on boat repairs, reinforcing a building, or crafting custom parts, fiberglass offers a great balance of strength and lightweight properties. Compared to materials like steel or carbon fiber, fiberglass stands out for its impressive strength-to-weight ratio, making it ideal for situations where reducing weight is important without compromising durability.

Type of Glass Fiber: The most common types are E-glass and S-glass. S-glass offers higher strength and heat resistance than E-glass, which makes it suitable for high-performance applications.

Resin Used for Bonding: The type of resin used for bonding the fibers plays a huge role in strength. For example, epoxy resin provides a stronger, more durable bond compared to other resins, which increases the overall strength of the composite material.

Thickness of the Cloth or Mat: Generally, the thicker the fiberglass cloth or fiberglass mat, the stronger the material. Thicker layers provide better reinforcement and more durability, which is why they’re often used in heavy-duty applications like boat hulls or structural components.

Fiberglass is a powerful material, and understanding its strength is key to choosing the right type for your project. If you’re interested in learning more about how fiberglass works in different applications, check out our full guide on All About Fiberglass for a deeper dive into the material’s versatility and uses.

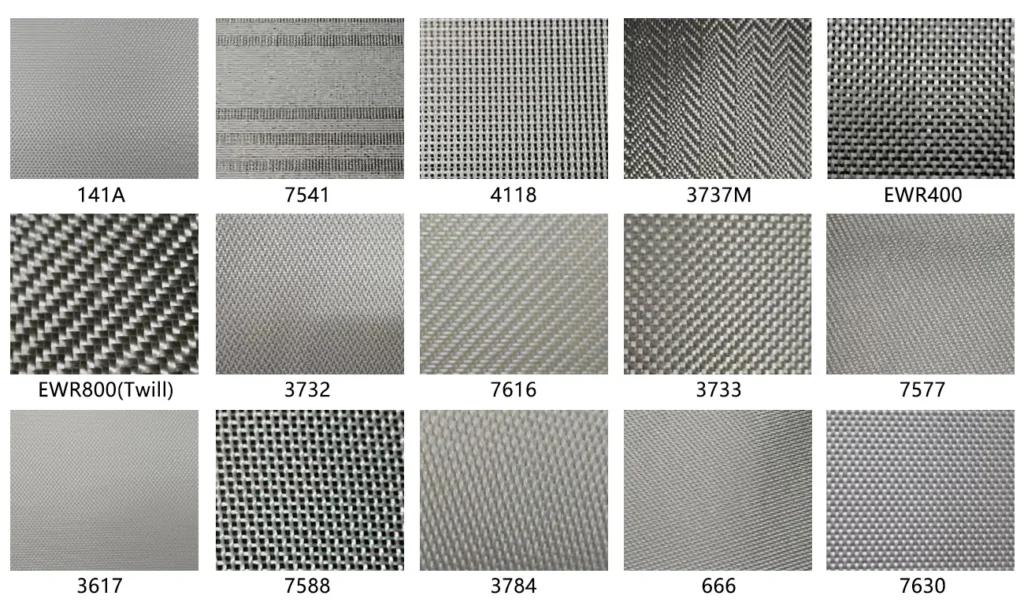

Plain weave fiberglass cloth is the most common and versatile type. It’s created by weaving glass fibers in a simple over-under pattern, making it flexible yet strong. Fiberglass cloth and resin are commonly used together to form a strong bond for a variety of applications, including boat repairs and structural reinforcement. This type of fabric is excellent for a wide range of applications, from woven fiberglass fabric for DIY repairs to more complex projects in construction and manufacturing.

Advantages: Versatile, easy to work with, suitable for various projects.

Disadvantages: Slightly less flexible than other weaves, especially in more complex shapes.

Twill weave fiberglass cloth has a distinctive diagonal weave pattern, giving it more flexibility compared to plain weave. It’s ideal for fiberglass resin and polyester cloth applications, such as creating molds or working with complex curves. This fabric’s intricate weave pattern makes it a bit more expensive but well-suited for high-performance applications like aerospace or marine industries.

Advantages: More flexibility, ideal for curved surfaces and molds.

Disadvantages: More expensive due to the detailed weave process.

Satin weave fiberglass cloth offers a smooth, shiny finish, making it perfect for high-end products or applications where appearance is important. It’s often used in products like boats, automotive parts, or other items that require both strength and aesthetic appeal. This type of fabric is popular when the visual quality of the surface is as crucial as its structural strength.

Advantages: Smooth, shiny finish; perfect for aesthetic or high-end applications.

Disadvantages: Generally less durable than other fabrics in extreme conditions.

Chopped Strand Mat is made from randomly oriented glass fibers, making it ideal for bulk applications like boat building or automotive parts. It is easier to work with than woven fabrics, but it is less strong and durable, making it more suitable for applications where strength is not as critical. It’s commonly used with fiberglass resin to create a durable composite.

Advantages: Easy to work with, good for bulk applications.

Disadvantages: Not as strong as woven cloth; not ideal for high-performance projects.

PTFE-coated fiberglass fabric is known for its high chemical and heat resistance, which makes it perfect for industrial applications where extreme conditions are present, like heat sealing or conveyor belts. This fabric is also used in industrial insulation and fireproofing.

Advantages: Excellent heat and chemical resistance.

Disadvantages: More expensive than standard fiberglass cloth, less flexible.

Silicone fiberglass fabric is treated to enhance its heat resistance and flexibility, making it ideal for products like gaskets, fire blankets, and industrial insulation. It is used in applications that require high heat resistance, especially in extreme industrial conditions.

Advantages: Excellent heat resistance, flexible, ideal for fireproof applications.

Disadvantages: Can be costlier than untreated fiberglass cloth.

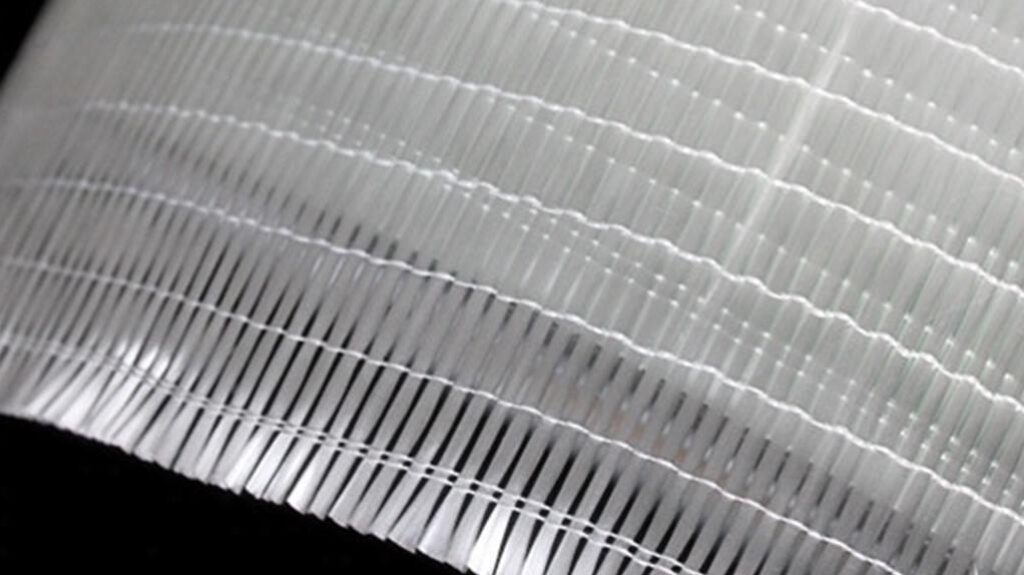

Biaxial fiberglass cloth features fibers arranged in two directions, offering more strength and durability compared to unidirectional fabrics. It’s typically used for composite materials that require high strength in both directions. This fabric is commonly used in marine applications and structural reinforcement.

Advantages: High strength in multiple directions, ideal for demanding projects.

Disadvantages: Stiffer than other fabrics, may be difficult to manipulate in certain applications.

EW160 fiberglass insulation fabric is a type of fabric designed specifically for high-temperature insulation. It is used in industrial settings where heat resistance is critical, such as in furnace linings and high-temperature ducts.

Advantages: Excellent heat resistance and insulation properties.

Disadvantages: Mainly suited for insulation applications, not for structural use.

Silicone-impregnated fiberglass fabric is designed for applications requiring both heat resistance and fireproofing. It’s commonly used in fireproof blankets, gaskets, and other high-heat industrial applications.

Advantages: Excellent fire resistance and heat durability.

Disadvantages: Less flexible and can be more expensive than untreated fiberglass cloth.

Triaxial fiberglass fabric features fibers arranged in three directions, making it stronger and more stable than biaxial or unidirectional fabrics. It’s used in high-performance composite materials for marine applications and other demanding industries.

Advantages: Stronger and more stable than other fabrics, ideal for high-stress applications.

Disadvantages: More expensive and harder to handle due to thickness.

Unidirectional fiberglass fabric has fibers aligned in a single direction, providing maximum strength along that axis. It is commonly used for reinforcement where the stress is primarily applied in one direction, like in structural components.

Advantages: Maximum strength in one direction, great for reinforcement.

Disadvantages: Limited flexibility in non-aligned directions.

Vermiculite-coated fiberglass fabric is used for its thermal insulation and fire-resistant properties, making it ideal for high-heat applications like fire protection and thermal insulation.

Advantages: Excellent thermal insulation and fire resistance.

Disadvantages: Less flexible than stand

Fiberglass materials come in various forms, each serving a unique purpose in different industries. When it comes to fiberglass mat and fiberglass cloth, understanding the differences is key to selecting the right material for your project. Here’s a breakdown of their key characteristics:

Aspect | Fiberglass Cloth | Fiberglass Mat |

Material Structure | Woven fibers for flexibility and durability. | Randomly laid fibers for thicker, stiffer structure. |

Strength & Durability | High tensile strength for high-stress applications. | Strong but lower tensile strength, better for coverage. |

Cost | More expensive due to weaving process. | More cost-effective due to simpler production. |

Weight | Lightweight, ideal for weight-sensitive applications. | Heavier, better for large surface areas. |

Flexibility | More flexible, suitable for complex shapes and molds. | Less flexible, better for bulk applications. |

Ideal Uses | High-performance applications (automotive, aerospace, marine). | Heavy-duty, structural applications (boats, construction). |

Fiberglass fabric is a versatile material with a wide range of applications across industries. Its unique combination of strength, lightweight properties, and durability makes it an excellent choice for both high-performance and bulk applications. Let’s explore how fiberglass fabric is used in different industries, from construction to automotive and marine.

Fiberglass fabric plays a crucial role in construction, where it is primarily used for reinforcement and strengthening materials.

Reinforcement Bars: Fiberglass reinforced bars (rebars) are used to replace traditional steel in concrete applications. These rebars are more corrosion-resistant, making them ideal for bridges, foundations, and facade repairs, especially in harsh environments.

Polymer Concrete: Fiberglass mat is often incorporated into polymer concrete to provide enhanced strength and load-bearing capacity. This combination is highly effective for structural applications that need to withstand heavy pressure.

If you’re involved in large-scale construction projects, fiberglass fabric helps reduce weight while ensuring structural integrity in environments where traditional materials may fail.

2. In Automotive:

In the automotive industry, fiberglass fabric is widely used to create lightweight yet strong parts for vehicles.

Car Body Panels: Fiberglass cloth combined with resin creates lightweight car body panels that reduce overall vehicle weight without sacrificing strength. This helps improve fuel efficiency and performance.

Underbody Insulation: Fiberglass mats are used in automotive underbody insulation to protect against heat and sound. These mats provide a durable and cost-effective solution for noise reduction.

Whether you’re manufacturing or repairing vehicles, fiberglass offers the strength-to-weight ratio needed to improve both safety and efficiency.

Fiberglass fabric is indispensable in the marine industry, where it is used to construct and repair boats and marine parts.

Boat Hulls: The combination of fiberglass resin and fiberglass cloth provides the ideal material for boat hulls, offering corrosion resistance and lightweight strength to withstand the challenges of saltwater environments.

Surfboards: Fiberglass cloth is also used in the manufacture of surfboards, where it reinforces the foam core and provides the flexibility and strength needed for high-impact surfing activities.

If you’re in boat building or marine repairs, fiberglass fabric provides the ideal balance of strength, lightness, and durability, even in the harshest marine conditions.

When working on RC vehicles or surfacing applications, fiberglass fabric offers a great balance of strength-to-weight ratio:

RC Cars & Drones: Lightweight fiberglass fabric is perfect for RC car bodies, drones, and other remote-controlled vehicles. It provides the impact resistance needed for high-speed movements while keeping the overall weight low for better performance.

Surface Coatings: If you’re applying fiberglass for surface coatings, such as aerospace models or RC planes, the fabric provides the necessary strength and flexibility to handle high-stress conditions.

For lightweight, high-performance applications like RC car parts or model aircraft, fiberglass fabric ensures durability without compromising speed.

For medium-weight applications like surfboards and sailboats, fiberglass fabric offers a perfect balance between strength and lightweight characteristics.

Surfboards: Fiberglass cloth is applied over the foam core to enhance rigidity and durability while keeping the board lightweight for easy handling in the water.

Sailboats: Fiberglass fabric is commonly used for sailboat hulls and deck panels. It provides the necessary strength to withstand wind pressure and water resistance, while still being lightweight enough for speed.

Whether you’re building sailboats or surfboards, fiberglass fabric ensures optimal performance on the water, combining strength with flexibility.

In the aerospace industry, fiberglass fabric is essential for creating lightweight, strong parts that meet stringent performance standards.

Aircraft Components: Fiberglass cloth is used in manufacturing aircraft panels, fuselages, and wing reinforcements. Its strength-to-weight ratio is ideal for reducing fuel consumption without compromising structural integrity.

High-Performance Components: For high-stress aerospace applications, fiberglass fabric combined with epoxy resin provides the strength and impact resistance needed for critical parts.

In aerospace, fiberglass fabric is a trusted material for high-performance, lightweight components that meet the rigorous standards of the industry.

For heavy-duty applications in marine or general-purpose construction, heavier fiberglass fabrics like fiberglass mats are commonly used.

Large Boats & Marine Vessels: Heavier fiberglass fabrics are ideal for large boat hulls and offshore vessels that require high strength to withstand the pressures of deep water and harsh conditions.

Construction Applications: Fiberglass mats are widely used in reinforcing concrete and industrial projects where large surface areas need to be covered efficiently and effectively.

In marine applications and large construction projects, heavier fiberglass fabrics provide the resilience and durability needed for long-lasting results.

Now that you have a deeper understanding of the different types of fiberglass fabric, its strength, and how it compares to fiberglass mat, it’s time to take the next step. Whether you’re working on automotive manufacturing, marine construction, or high-performance projects, choosing the right fiberglass material can significantly impact your success.

If you’re looking to dive deeper into fiberglass and explore its definition, uses, and properties, check out our comprehensive article on All About Fiberglass: Definition, Uses, Properties, and More.

For any further questions or to discuss your project needs, feel free to contact us via:

WhatsApp: +86-13775339109

WeChat: 13775339100

Email: fiberglassmesh@hotmail.com

We’re here to help you find the best fiberglass solutions for your needs!

Contact us now to get the latest drywall tape brochure and start choosing the right drywall tape for your project.

Fiberglass looks like thin, shiny filaments or strands, often resembling fine glass or silk fibers. It typically appears off-white or transparent and has a smooth, woven texture when used as fabric. When in mat form, it has a coarse, felt-like texture due to the randomly arranged fibers. The material is often translucent, with a glass-like sheen that gives it strength and flexibility in various applications.

Foam and layers of fiberglass are generally better than nylon for insulation purposes. Foam provides excellent thermal resistance, while fiberglass offers added strength and durability. Nylon is more flexible and lightweight but doesn’t offer the same level of insulation or structural support as fiberglass, making it less suitable for applications that require thermal or impact resistance.

Yes, you can use polyester cloth with fiberglass resin. The combination of polyester cloth and fiberglass resin creates a strong, durable composite, commonly used in marine applications, automotive repairs, and construction. This pairing provides excellent strength and flexibility while being cost-effective compared to other resin types.

Yes, fiberglass fabric is generally considered safe when handled properly. However, it can cause skin irritation or respiratory issues if the fibers are inhaled or come into direct contact with the skin. It’s important to wear protective gear, such as gloves, masks, and goggles, when working with fiberglass to minimize any potential risks.

Fiberglass cloth can cause skin irritation or itchiness due to the tiny, sharp glass fibers it contains. These fibers can embed in the skin, leading to discomfort. While the material itself is safe when handled correctly, it is important to wear appropriate protective gear, such as gloves, long sleeves, and safety goggles, to prevent direct contact with the fibers. Inhaling the dust or particles can also irritate the respiratory system, so working in a well-ventilated area or wearing a mask is recommended. Proper handling minimizes the risk of irritation and ensures safe use of fiberglass fabric.

Fiberglass cloth is not bulletproof by itself. While it provides strength and durability, it lacks the necessary density and tensile strength required to stop bullets. However, fiberglass can be used as a component in composite materials, often layered with other materials like Kevlar or carbon fiber, to create bulletproof or ballistic-resistant panels. In these applications, the fiberglass cloth helps provide structural support, but the overall effectiveness in stopping bullets depends on the combination of materials and the thickness of the layers.

No, fiberglass is not like cotton. While both materials are used in fabrics, fiberglass is made from woven glass fibers, which are strong, durable, and heat-resistant. Cotton, on the other hand, is a natural fiber derived from plants, known for its softness and breathability. Fiberglass is much stiffer and abrasive, while cotton is soft, flexible, and comfortable to wear. The two materials serve very different purposes—fiberglass is used in composites, insulation, and reinforcement, while cotton is primarily used in textiles for clothing and household items.

Fiberglass fabric is highly strong due to its high tensile strength and durability. It is resistant to stretching and tearing and can withstand significant stress without failing. When combined with resin, it forms a composite material that is stronger than steel in terms of weight-to-strength ratio, making it ideal for applications in aerospace, automotive, marine, and construction. However, its strength depends on the type of glass fiber used (e.g., E-glass or S-glass) and the resin bonding the fabric.

Fiberglass can be harmful to health if not handled properly. The tiny glass fibers can cause skin irritation, respiratory issues, and eye irritation if inhaled or if they come into contact with the skin. Prolonged exposure to fiberglass dust or fibers may lead to chronic respiratory problems. It’s important to wear protective clothing, gloves, masks, and goggles when working with fiberglass to reduce the risk of exposure. In well-controlled environments, and with the proper safety measures in place, fiberglass is generally safe to use.

Fiberglass cloth itself is not inherently waterproof, but it can be made water-resistant when combined with resin or coatings. When fiberglass cloth is saturated with a waterproof resin (such as epoxy or polyester resin), it forms a strong, waterproof composite material. This combination is commonly used in boat hulls, pools, and other marine applications, where water resistance is essential. Without resin or a protective coating, fiberglass cloth will absorb water and may lose its strength over time.