- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

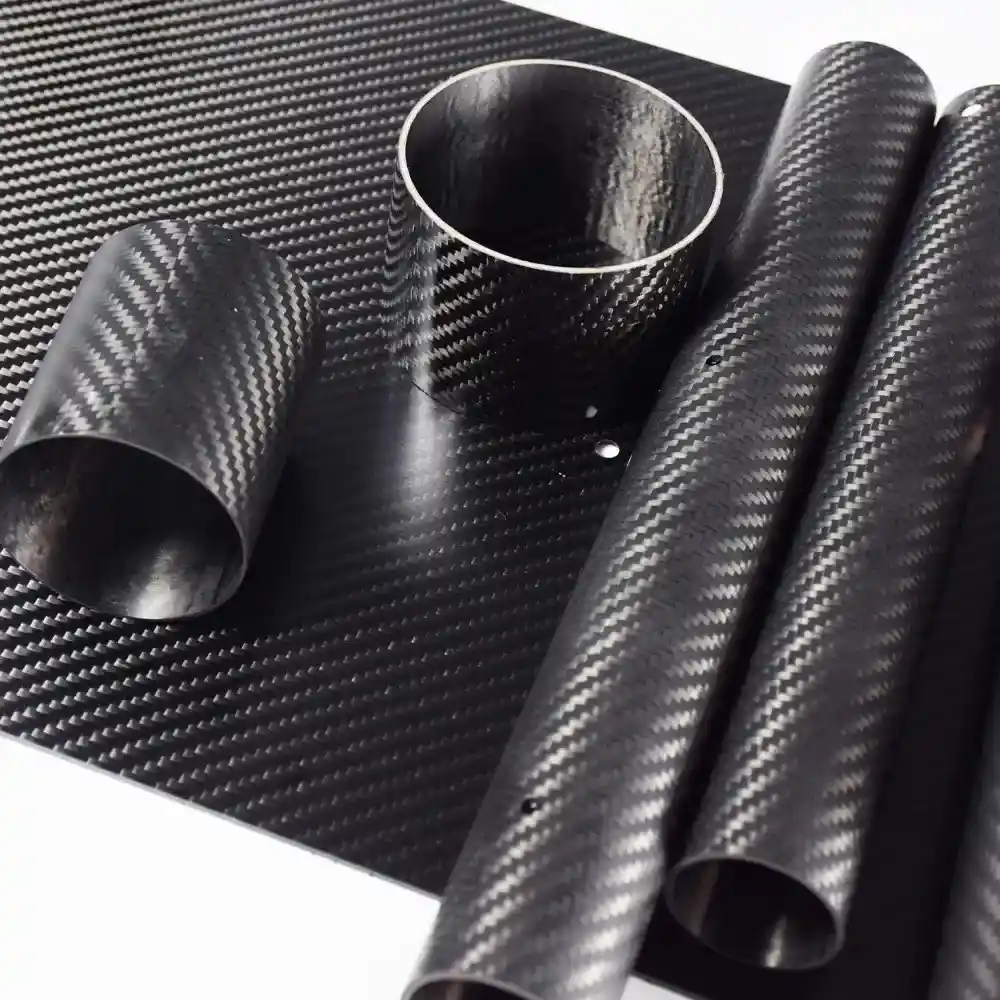

A carbon fiber tube is a hollow rod made from carbon fiber reinforced polymer, known for high strength-to-weight ratio and low thermal expansion. It fights corrosion, stands up to heavy stress, and maintains stiffness under load. Typical applications include drones, camera rigs, sports equipment, medical devices, and light frames.

Carbon fiber tubes are precisely what you’d expect — carbon fibers set in a resin matrix and formed into a hollow cylinder. They are composite parts engineered for performance — high strength and stiffness at extremely low weight. That’s why you see them in aerospace, cars, bikes, drones, robots, and factory tools — they accomplish more with less mass.

Understanding what they are, how they’re made, and what your options are helps you select the proper tube for load paths, vibration limitations, and longevity. Low weight helps reduce inertia, so components start and stop quickly, which conserves energy and enhances your command.

Each ply is thin, approximately 0.006 inches (approximately 0.15 mm). A 0.060-inch (approximately 1.52 mm) wall typically contains 9 to 10 layers. Makers set angles and sequences to tune behavior. Suppose you need axial stiffness for a mast. With more 0° layers, you can achieve this.

Carbon fiber tubes provide strength-to-weight ratios that blow away steel and aluminum, and they really shine if stiffness and fatigue life are important. Unidirectional fibers bear axial loads, and woven layers provide hoop strength to resist crush and torsion.

Two common types exist: pultruded and roll-wrapped, each with clear trade-offs for cost, performance, and loading direction.

Roll-wrapped tubes sacrifice mass in order to maintain strength, frequently providing stiffness comparable to metals at a fraction of the weight. This weight drop aids in endurance, handling, and safety of mobile equipment.

UAV arms fly longer on the same battery as lighter arms mean less load on the motors. Camera rigs equilibrate more quickly and ease your operator’s back, which counts on long shoots. Window washing poles go farther with less sway and less strain for workers.

These tubes are harder and more costly to produce than pultruded ones because they layer multiple fiber angles to provide hoop and torsional strength. Still, they found parts that experience intricate loads. Sort product weights, diameters, and wall thickness side by side in a table to select the right tube for your duty cycle and budget.

Pultruded tubes provide extremely high axial rigidity with near-zero flex, ideal when loads are applied along the tube’s length. Fibers are unidirectional, usually 0° to the axis. That alignment, combined with an appropriate resin matrix and cure, generates tensile stiffness and straight-beam behavior.

Since all the fibers run in that same direction, pultruded tubes bear load only along that direction. This makes them perfect for beams or rods, such as a fishing rod blank, a linear actuator push rod, or a straight truss member with minimal torsion.

They are cheaper than roll-wrapped tubes when your design requires strength in just one orientation. High stiffness is important in precision builds, such as aerospace linkages, test fixtures, and robotics, where even small deflection will break tolerances.

Define the job first, then match tube specs to the loads, weight limits and environment. Compare dimensions, fiber, weave, resin, wall thickness and finish. Check data sheets, pricing, warranties and return policies before you buy.

Pay attention to static versus dynamic duty, cycle counts, and safety factors. Tailor tensile strength and modulus of elasticity to that load case. For bending-dominant parts such as camera booms, a higher modulus layup assists. For torque shafts, bias toward plus or minus 45-degree plies for shear. If risking buckling, increase wall or change diameter.

Use manufacturer specs and point bend or three-point test data for apples-to-apples comparison. Check tube ID and OD tolerances, wall uniformity, and void content. Thermal effects: Modulus shifts with temperature. Factor in fatigue if loads fluctuate. PAN-based fibers fit general high strength. Pitch-based fibers can provide very high modulus for stiffness-critical tubes.

UD fibers provide premium axial strength to weight for spars. Woven fabrics provide drape and superior damage tolerance, with a pretty cosmetic layer. Hybrids, such as carbon and aramid, exchange a minor weight penalty for impact resistance.

Fiber and weave affect stiffness, strength, and the appearance of the face you see. Weaves: a 2×2 twill is typical for cosmetic parts, plain weave is stable, and UD appears negligible but rules when matched with load.

Choose resin to match the occasion. Epoxy supplies powerful bonds, has very high durability, and offers large thermal stability. Vinyl ester delivers nice chemical resistance at a mid price. Polyester is economical for light duty and mild heat.

The matrix directs chemical resistance, toughness, and temperature thresholds. Verify service temperature, glass transition (Tg), fuel or salt exposure, and UV requirements. The epoxy cure cross-links polymers, locking fibers in place for a rigid, durable structure.

Fiber angles tune behavior: 0° for axial strength and low stretch, 90° for hoop strength and crush resistance, ±45° for torsional rigidity. Angle balance achieves combined loads without extra weight.

Check the specs of some typical angle stacks and weave options. Define custom layups when torque spikes, high heat, or conductivity targets require. Price per meter, minimum orders, lead times, and policy terms.

Tube longevity depends on how carbon fiber tubes encounter real-world loads and environments over time. Material selection, manufacturing process, fit-up, and maintenance all affect it. Regular checkups and minor preventative efforts frequently provide additional years of service life.

UV, moisture, chemicals and temperature swings are the primary enemies. High humidity greater than 80% relative humidity can force water into micro-voids in the resin, loosening the fiber-resin bond and increasing the risk of delamination.

About: The hidden variables in tube life High Tg epoxies (around 120 to 180 °C) maintain stiffness better near heat sources, while a poor cure or low Tg will invite softening in warm environments or near motors. Post-cured systems in 120 to 180 °C limits seem to maintain properties longer.

Carbon fiber doesn’t like cyclic loads. Not all tubes are created equal. Fiber type (standard vs intermediate modulus), resin toughness and cure quality do shift the curve. Manufacturing process matters. Helical winding improves torsion fatigue. Axial winding favors axial cycles. Hybrid layups balance both.

Design for margin. Keep local stresses low in the vicinity of joints, include generous radii and don’t put drill holes near peak strain lines. A slight increase in wall thickness or a sleeve at interfaces can reduce strain ranges and increase life by several orders of magnitude.

Impact performance is a function of fiber layout, resin ductility, and tube thickness. Woven or braided sleeves prevent crack growth across directions, while harder epoxies inhibit brittle shatter from tool drops or rock hits.

Map impact risks by use case. Drone spars have bird strikes. Camera booms suffer clamp crush. Marine poles endure dropped weights. Select layups accordingly. Thicker walls at contact zones, sacrificial wrap layers, and edge protectors all reduce real-world dents.

Carbon fiber tube tech appears transparent now. You’ve got the base, the types, and the key specs down. Weight, wall thickness, layup, and fit shape lead to actual gains in actual builds. Minor adjustments come back tenfold.

To pick like a pro, pair tube grade to load and vibe. Replace frayed straps. Torque them to the right specification. For next steps, provide your use case and budget. Find a quick specs, vendors, and sample cuts list of tubes.

Connect with an NQ expert to discuss your product needs and get started on your project.

Contact NowWhat is a carbon fiber tube and why is it used?

Carbon fiber tube A carbon fiber tube is a lightweight, strong and stiff composite consisting of carbon fibers and resin. It’s for high strength-to-weight applications. Typical applications include drones, robotics, sports gear, cameras, and automotive parts.

How do unidirectional, woven, and roll-wrapped tubes differ?

Unidirectional tubes maximize stiffness in one direction. Woven tubes provide balanced strength and impact resistance. Roll wrapped tubes combine layers for custom performance. Select depending on load direction, torsion requirements, and durability.

How do I choose the right carbon fiber tube for my project?

Match the tube to your loads: axial, bending, or torsion. Verify outer diameter, wall thickness, and length. Let’s talk fiber direction, resin choice, and finish. Check tolerances and quality from the supplier.

Are carbon fiber tubes stronger than aluminum tubes?

Generally, yes for stiffness-to-weight and tensile strength. Carbon fiber is lighter and can be stiffer by design. Aluminum is more ductile and has better impact resistance. Select according to use case, load type, and budget.

What impacts the lifespan of a carbon fiber tube?

The culprits are UV exposure, moisture ingress, impact damage, overload, and poor bonding at joints. A clear coat for protection, sealed ends with appropriate fittings, and routine inspection increase service life.