- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

Carbon fiber is transforming industries like automotive, aerospace, and sports equipment. Its strength-to-weight ratio makes it an essential material in high-performance applications. But what exactly is carbon fiber, and what is it made of?

In this guide, we’ll explore the entire carbon fiber production process. From the raw materials to its final form, we’ll cover everything you need to know. Let’s dive into how carbon fiber is made and its diverse applications.

Table of Contents

ToggleCarbon fiber is a lightweight, high-strength material made from carbon atoms bonded together in a crystalline structure. It’s known for its exceptional strength-to-weight ratio, making it a go-to choice for high-performance applications in industries like aerospace, automotive, and sports equipment.

Carbon fiber was invented in the late 1950s by researchers at the Union Carbide Corporation, with commercial production beginning in the 1970s. Since then, its use has expanded, revolutionizing many fields due to its durability and lightness.

Despite its name, carbon fiber is not a metal. It’s a polymer fiber reinforced with carbon atoms, giving it its incredible strength. This misconception is common but easily clarified when you understand its composition and properties.

Carbon fiber comes from a few essential raw materials, mainly polyacrylonitrile (PAN) fibers and pitch. PAN fibers are the most common precursor, while pitch-based fibers are used in specific cases. These materials are chosen for their ability to withstand the high temperatures needed for the carbonization process.

So, what happens during carbonization? In simple terms, the fibers are heated to extreme temperatures—up to 3,000°C—without oxygen. This removes everything but the carbon, creating a super-strong, lightweight fiber. It’s the key to carbon fiber’s remarkable strength.

You might be wondering, “Can carbon fiber come from oil?” Well, yes! Some types of carbon fiber are made from oil-based products. The process is the same, but the end result is still a high-performance material that’s used in everything from cars to sports equipment.

Making carbon fiber is an intricate process that involves several stages, each crucial in transforming raw materials into a lightweight yet incredibly strong fiber. Let’s dive deeper into each step:

The journey starts with the precursor material, typically polyacrylonitrile (PAN), a synthetic polymer, or pitch, derived from petroleum or coal tar. PAN fibers are more commonly used because they produce higher-quality carbon fiber. During this stage, the raw material is stretched into long, thin fibers to enhance its strength. The precursor fibers are then washed to remove impurities and treated with an oxidizing agent to prepare them for the next step.

Why it matters: The quality and consistency of the precursor material play a huge role in the strength and properties of the final carbon fiber.

In this step, the fibers undergo stabilization at 200-300°C in an air environment. The process lasts several hours and is critical for preventing the fibers from melting in the next stage. The heat causes the fibers to form a more stable, heat-resistant structure.

Why it matters: Stabilization ensures the fibers won’t burn or deform when exposed to the extreme temperatures in carbonization.

The heart of the carbon fiber process is carbonization. During this stage, the fibers are heated in a furnace (often called a carburization furnace) at temperatures ranging from 1,000°C to 3,000°C in an oxygen-free atmosphere (typically nitrogen or argon). The high heat removes non-carbon elements, like hydrogen and oxygen, leaving behind pure carbon atoms.

Why it matters: Carbonization is what gives carbon fiber its remarkable strength-to-weight ratio. This step transforms the fibers into the pure carbon material that’s so widely sought after in advanced industries.

After carbonization, the carbon fibers undergo surface treatment to prepare them for bonding with resins. This step typically involves oxidizing the surface and applying chemical treatments that roughen the surface, making it more reactive. The fibers may also be coated with an adherence promoter, a chemical substance that enhances the bonding between the fiber and the resin during the next stages of processing.

Why it matters: Without proper surface treatment, carbon fibers wouldn’t bond effectively with other materials, such as resin, which is essential for forming composite materials used in various applications.

In the sizing step, carbon fibers are coated with a resin or sizing agent to improve handling and prevent them from sticking together. This resin can be an epoxy or a thermoplastic material, depending on the intended application. The resin coating also helps preserve the fiber’s structural integrity and makes it easier to work with during further fabrication, like weaving it into fabrics or molding it into specific shapes.

Why it matters: The sizing step is crucial for ensuring the fibers maintain their strength and durability while being handled, especially in manufacturing processes like carbon fiber cloth production or carbon fiber molding.

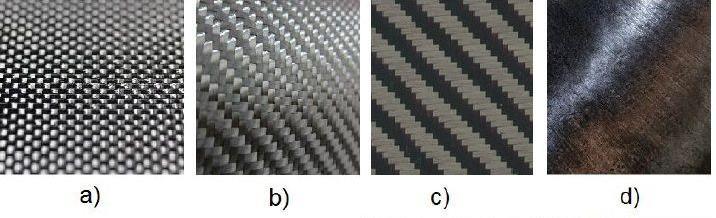

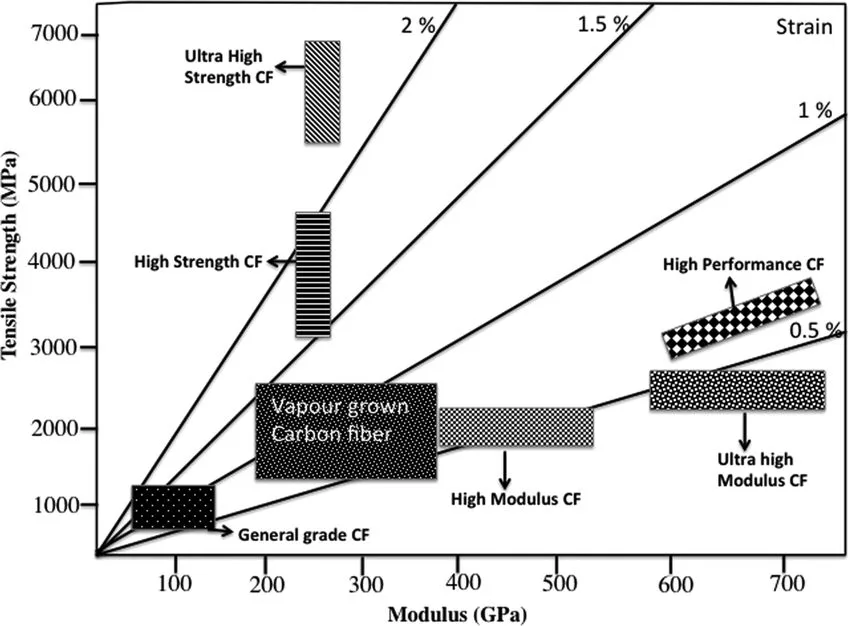

Carbon fiber comes in different grades, each designed for specific needs. Depending on your project’s requirements—whether it’s strength, stiffness, or lightweight properties—understanding the types of carbon fiber will help you make the best choice.

Standard modulus carbon fiber is the most common and affordable type, making it widely used in everyday applications. It provides a strong, lightweight material ideal for automotive parts, sports equipment, and general manufacturing. If you’re looking for carbon fiber properties that offer durability without breaking the bank, this is the go-to option.

When your project requires higher strength, intermediate modulus carbon fiber is the next step up. It’s used in applications where a balance of strength and flexibility is needed. Industries like aerospace and construction rely on this type of carbon fiber to ensure components can withstand higher stress levels while maintaining flexibility.

In applications where stiffness is critical, high modulus carbon fiber is the ideal choice. This type is highly resistant to deformation under stress, making it perfect for use in aerospace components and high-performance sporting goods. If your design needs to maintain rigidity under intense conditions, this type provides the carbon fiber properties you need.

For specialized, high-performance uses, ultra high modulus carbon fiber takes carbon fiber to the next level. This type is designed for extreme applications that demand maximum stiffness and strength under the most challenging conditions. It’s often found in the military, aerospace, and high-tech industries, where performance is non-negotiable.

Carbon fiber is a cutting-edge material used in a wide range of applications due to its exceptional properties. Let’s dive into the strength, durability, and corrosion resistance of carbon fiber, backed by data that showcases why it’s a preferred choice in many industries.

One of the standout features of carbon fiber is its strength-to-weight ratio. Carbon fiber is 5 times stronger than steel but only one-fourth of the weight, making it ideal for industries like aerospace, automotive, and sports equipment.

In terms of durability, carbon fiber outshines many other materials. It’s highly resistant to abrasion and fatigue, which makes it perfect for high-stress applications.

Unlike steel, which is prone to rusting and degradation over time, carbon fiber is naturally resistant to corrosion. This makes it highly desirable for industries that deal with moisture and harsh environmental conditions.

When compared to steel and aluminum, carbon fiber offers superior performance in various key metrics, especially in weight reduction and strength:

Property | Carbon Fiber | Steel | Aluminum |

Weight | 4 times lighter than steel | Heavy | |

Tensile Strength | 1,000 MPa | 400 MPa to 600 MPa | 350 MPa to 550 MPa |

Fatigue Resistance | Higher durability, more stress cycles | Lower fatigue resistance | Moderate fatigue resistance |

Strength-to-Weight Ratio | Superior, ideal for weight-critical applications | Lower compared to carbon fiber | High, but less than carbon fiber |

Applications | Aerospace, automotive, sports gear | Structural frameworks, construction | Aerospace, automotive, packaging |

Carbon fiber is making a significant impact across various industries, thanks to its unique properties. Let’s dive into how it’s being used in different fields and which types of carbon fiber are most commonly applied.

In the aerospace industry, carbon fiber helps reduce weight while maintaining strength. It’s often used in aircraft wings and satellites, with unidirectional carbon fiber and woven carbon fabrics being the go-to choices. These materials offer high rigidity and strength, which is crucial for high-stress aerospace applications.

When it comes to the automotive industry, carbon fiber is a game-changer. It’s used to lighten high-performance cars and electric vehicles, improving fuel efficiency and handling. Common types used include carbon fiber sheets for body panels and woven fabrics for structural components, ensuring both durability and performance.

In sports equipment, carbon fiber is popular for its strength and lightness. It’s used in bicycles, tennis rackets, and golf clubs, helping athletes enhance their performance. Carbon fiber fabrics and tubes are often found in these products, providing the perfect balance of strength and flexibility.

Handling carbon fiber requires care. Follow these steps for safe and effective use.

Now that you’ve learned how to work with carbon fiber safely and effectively, it’s time to put these techniques to use in your projects. Whether you’re handling carbon fiber fabric or working on more complex fabrications, following these steps will ensure high-quality results.

Want to take it further? Explore our advanced carbon fiber fabrication techniques guide for expert tips to enhance your skills.

Connect with an NQ expert to discuss your product needs and get started on your project.

Carbon fiber is produced through these key steps:

This process results in carbon fiber with high strength and low weight.

Yes, carbon fiber can be molded. It is typically combined with resin and molded into shapes using processes like compression molding, vacuum bagging, or RTM (Resin Transfer Molding). These methods allow carbon fiber composites to take complex forms while maintaining their strength and lightweight properties.

Carbon fiber was invented in 1958 by Roger Bacon at Union Carbide. He developed the first carbon filament by heating rayon fibers to high temperatures, creating a material with high strength and heat resistance.