Custom Fiberglass Cloth Manufacturer & Supplier in China

- 20+ years of fiberglass fabric manufacturing experience

- CE, ISO, ROHS, SGS and other certifications

- Customize fiberglass fabric with different gram weight, width, length, and colors,etc

- Custom fiberglass spun yarn, non-twist roving, unidirectional, multi-axial, warp knitting and other reinforced fabrics

- OEM & ODM service, door-to-door service

years

Manufacturing Experience

Projects

We had finished

Clients

Over the world

Satisfaction

Top Fiberglass Cloth Manufacturer & Supplier in China

NQ Fiberglass is a leading manufacturer of high-quality fiberglass cloth, dedicated to providing durable, versatile, and cost-effective solutions for construction, marine, automotive, and industrial applications worldwide.

We specialize in producing premium-grade fiberglass fabrics from 100g-1200g, We engineered to deliver superior strength, heat resistance, and dimensional stability—perfect for reinforcing, insulation, and composite applications etc.

Looking for reliable fiberglass cloth supply at competitive prices? Our fiberglass fabric is supplied directly from our factory, with customizable weight (100–1200 g/m²), weave patterns (plain, twill,etc), thickness (0.05–0.40 mm), and colors (natural white, black, or custom). — including natural white, black, and custom finishes — plus single or multi-layer lamination for different customers’ needs.

Contact us today for bulk orders, OEM customization, or tailored solutions. Let NQ Fiberglass be your trusted partner in advanced fiberglass materials.

Professional

20 years of advanced manufacturing technology

High Quality

High quality CE, ASTM, SGS, ISO, BSCI certification

Cost Effective

Direct factory price

Customized

Different sizes, colors, designs, OEM/ODM

Delivery

delivery time of about 15 days

Hot Selling Fiberglass Cloth Series

We produce high-quality, versatile fiberglass fabrics with excellent physical properties, including high strength, corrosion resistance, sound insulation, and intense heat resistance. These properties make it widely used in the construction, aerospace, and electronics industries. We are committed to providing customized fiberglass fabric solutions to meet the diverse needs of different industries and applications.

Fiber Glass Cloth Specifications

Choose from our wide range of fiberglass fabric specifications, designed for durability, heat resistance, and versatile applications. NQ Fiberglass offers customizable sizes, weaves, and finishes to meet your project needs.

Place of Origin | China |

Brand Name | NQ fiberglass |

Model Number | Glass Fiber Twisted Fabric Glass Fiber Woven Roving Glass Fiber Unidirectional Fabric Glass Fiber Axial Fabric Glass Fiber Multiaxial Fabric |

Weight (g/m²) | 100 g/m², 200 g/m², 260 g/m², 430 g/m², 600 g/m² (varies by model) |

Surface Treatment | Silicon ,Aluminized,PU,PVC,Acrylic,Ceramic ,PTFE,Hypalon,Silica Coated |

Thickness / Width | Thickness: 0.03–0.90 ± 0.10 mm (varies by model) |

Mesh Size (mm) | 13 × 16 mm (7628); other sizes vary by model |

Weave Type | Plain, Twill, Satin, etc. |

Yarn Type | E-glass, C-glass, etc. |

Alkali Content | Alkali Free |

Maximum Operating Temperature | 550 °C |

Color | White, Grey, Black, customizable |

Quality Control | 1. On-site inspection |

Material | E-Glass / C-glass/ Fiber Yarn |

Roll Length | 1–50 m, customizable |

Key Features | Excellent insulation, heat resistance, corrosion resistance, high strength, good mechanical properties |

Applications | Aerospace, automotive manufacturing, construction, electronics, sports equipment, shipbuilding, new energy, and other industries |

Delivery Time | 15–20 days after sample confirmation |

Types of Fiberglass Cloth Weaves

Our fiberglass fabrics are available in multiple weave types, each engineered to optimize mechanical properties, thermal resistance, and surface quality. Ideal for demanding projects in construction, automotive, aerospace, and marine industries, etc.

Model | Weave | Thickness (mm) | Warp Density (ends/cm) | Weft Density (ends/cm) | Weight (g/m²) | Tensile Strength Warp (N/25mm) | Tensile Strength Weft (N/25mm) | Warp Yarn Count (Tex) | Weft Yarn Count (Tex) | Filament Diameter (μm) |

EW25 | Plain | 0.03 | 20±2 | 18±2 | 25±2 | ≥160 | ≥70 | 8 | 4 | 4.5 |

EW50 | Plain | 0.05 | 20±2 | 20±2 | 48±4 | ≥260 | ≥260 | 12.5 | 12.5 | 5.5 |

EWT80 | Twill | 0.09 | 12±2 | 12±2 | 80±8 | ≥300 | ≥300 | 33 | 33 | 9 |

EW100 | Plain | 0.10 | 16±1 | 15±1 | 100±10 | ≥400 | ≥400 | 33 | 33 | 9 |

EW130 | Plain | 0.12 | 10±1 | 10±1 | 130±10 | ≥600 | ≥600 | 66 | 66 | 9 |

EW160 | Plain | 0.16 | 12±1 | 12±1 | 160±12 | ≥700 | ≥650 | 66 | 66 | 9 |

EWT160 | Twill | 0.16 | 12±1 | 12±1 | 160±12 | ≥700 | ≥650 | 66 | 66 | 9 |

EW200 | Plain | 0.20 | 8±0.5 | 7±0.5 | 200±14 | ≥700 | ≥650 | 132 | 132 | 9 |

EWT200 | Twill | 0.20 | 16±1 | 13±1 | 200±20 | ≥900 | ≥700 | 66 | 66 | 9 |

EWT400 | Twill | 0.40 | 8±0.5 | 7±0.5 | 400±32 | ≥1200 | ≥1100 | 264 | 264 | 13 |

WR400 | Plain | 0.40 | 3.4±0.3 | 3.2±0.3 | 400±32 | ≥1200 | ≥1100 | 600 | 600 | 17 |

Heat-Resistant Coated Fiberglass Cloth

High-Performance Fiberglass Prepreg

- 300 g/m² high-strength fiberglass prepreg

- Excellent durability, heat resistance, and mechanical properties

- Custom thickness options available

- Supplied in long rolls for efficient processing

- Certified for international quality and safety standards

PTFE Non-Stick Fiberglass Fabric

- Non-stick surface、easy to clean

- High temperature resistance up to 260 °C

- Excellent chemical and corrosion resistance

- Superior dimensional stability and strength

- Available in various thicknesses and widths

Hypalon Coated Fiberglass Cloth

- Excellent weathering and UV resistance

- Strong chemical and corrosion resistance

- High mechanical strength and tear resistance

- Flame-retardant and waterproof surface

- Long service life in outdoor and industrial use

Tough Acrylic-Coated Fiberglass Fabric

- High tensile strength and durability

- Resistant to chemicals、 UV、 and corrosion

- Flexible yet strong for long-term industrial use

- Flame retardant and waterproof surface

- Available in various thicknesses and widths

Aluminum Foil Laminated Fiberglass Fabric

- Reflects up to 95% radiant heat

- High temperature and flame resistance

- Strong mechanical and tensile strength

- Corrosion、moisture、and chemical resistance

- Available in various thicknesses and roll sizes

High-Temperature Silica Fiber Fabric

- Exceptional heat resistance up to 1,000 °C

- Excellent thermal insulation properties

- Superior chemical and corrosion resistance

- Lightweight and flexible for easy handling

- High tensile strength and durability

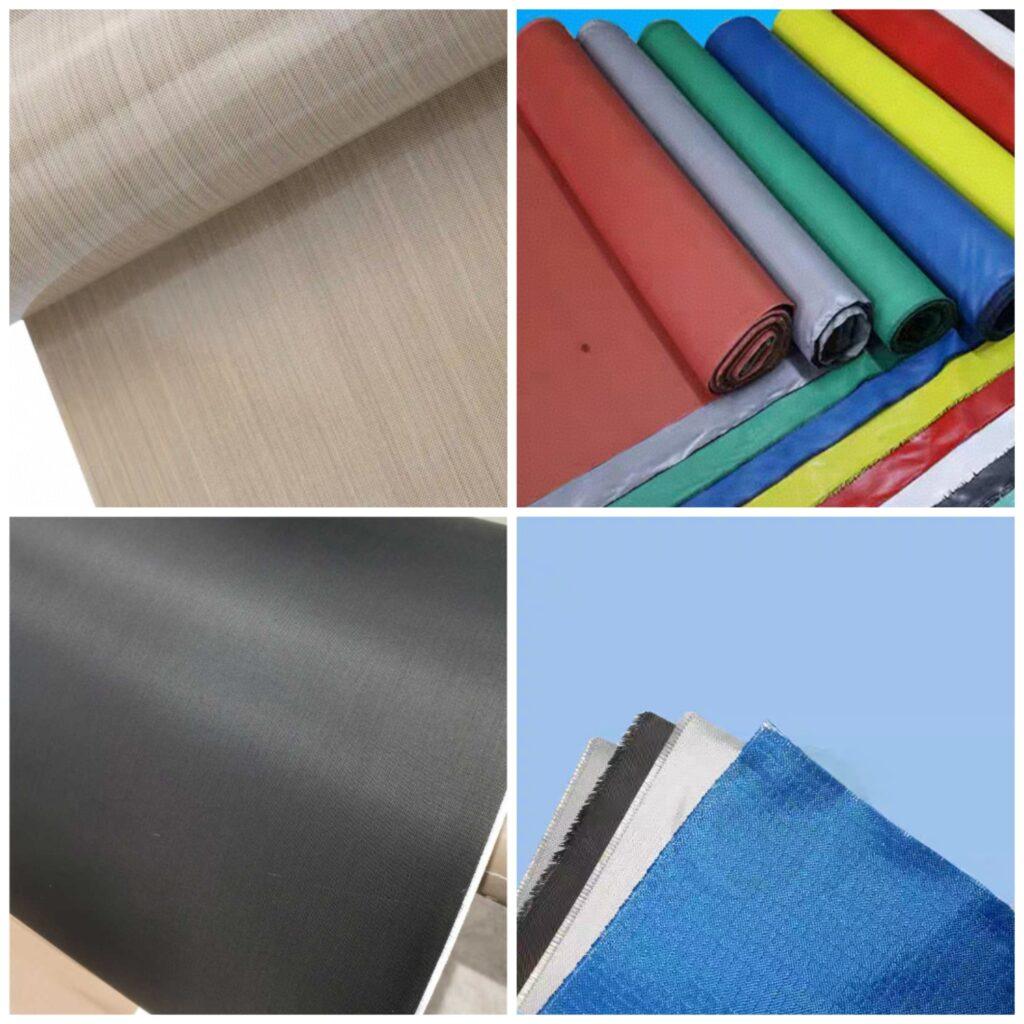

PVC Coated Fiberglass Reinforced Fabric

- High tensile strength and tear resistance

- Waterproof, UV, and corrosion resistant

- Flame retardant and chemical resistant

- Flexible and durable for long-term use

- Available in various thicknesses and widths

Industrial Ceramic Fiber Cloth

- Exceptional heat resistance up to 1,260 °C

- Excellent thermal insulation and energy saving

- Lightweight, flexible, and durable

- Resistant to chemicals and corrosion

- High tensile strength and dimensional stability

Why Choose Us?

100% Premium Raw Materials

Crafted from 100% high-density platinum fiberglass yarn, our products offer superior strength, outstanding durability, and reliable long-term performance.

100% Quality Inspection

Every roll of fabric undergoes strict quality control during the weaving and rolling process to guarantee defect-free products.

Advanced Tech & Safety

Our knitting machines feature automatic stop switches, which halt production in case of knitting errors, ensuring consistent product quality.

Flexible Packaging Options

Our fiberglass cloth is available in large rolls or small packages, shipped by carton or pallet, making it easy to meet the needs of both industrial customers and e-commerce businesses.

Fast & Reliable Delivery

We guarantee fast and reliable delivery, with a standard lead time of 15–20 days. Backed by strong production capacity and efficient logistics, we ensure every order arrives on time and meets your expectations.

Customization Solutions

For professional wholesalers and importers of fiberglass, we provide customized packaging solutions tailored for platforms such as building material markets and brands like Knauf, helping you reach customers more efficiently.

Explore our selection of custom solutions to find the right one for your needs

Glass Fiber Twisted Fabric,Glass Fiber Woven Roving,Glass Fiber Unidirectional Fabric,Glass Fiber Axial Fabric,

Glass Fiber Multiaxial Fabric

NQ Fiberglass Fabric Manufacturing Process

1. Raw Materials

We source our material from the world’s largest producer, china Jushi Group. 20% stronger than standard fiberglass yarn.

2. Twisting Process

The high speed automatic twisting machine combines tension and yarn guide devices to ensure uniform tension during the twisting process.

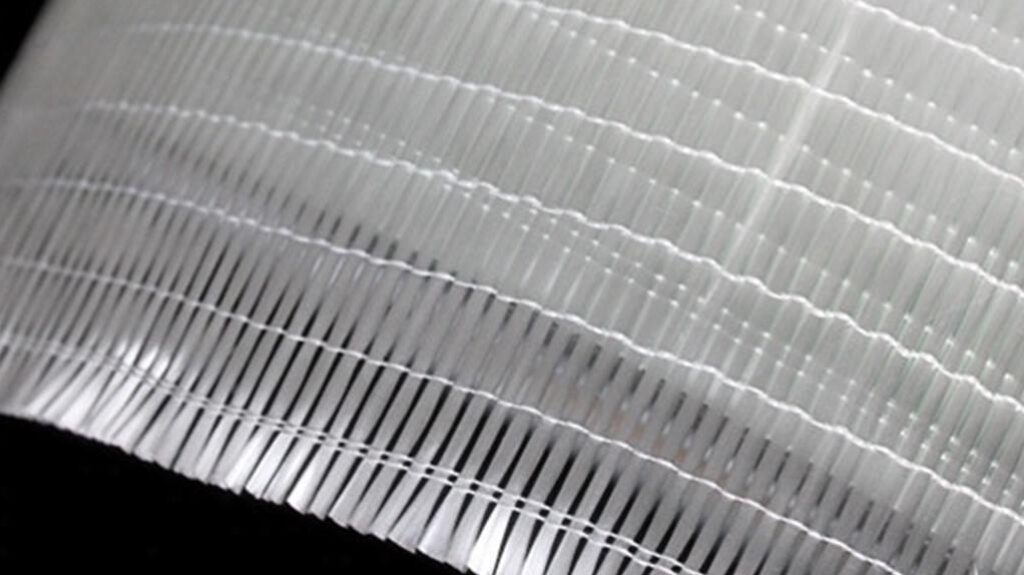

3. Weaving Process

The fiberglass yarn is woven on a high-speed rapier loom and uses tension magnetic separators to alleviate distortion, resulting in a strong and flexible cloth.

4. Coating Process

Pretreatment is performed by applying one or more intermediate layers on the primer. Common types include acrylic, PU,Silicon, PTFE and fluorocarbon paints,etc.

5. Drying And Curing

Different curing methods are used with different materials to ensure that the resin or coatings fully hardens and forms a durable protective layer.

6. Cutting Process

Mechanical cutting uses automated or laser cutting machines programmed for precision, delivering fast and accurate cuts. This makes it ideal for mass production with customizable sizes such as 10 cm, 30 cm, 50 cm, and more.

7. Quality Inspection

8. Packing

We provide multiple packaging options, such as shrink film with pallet, ensuring full product protection during delivery at no additional cost. All packaging is designed to be safe and reliable for ocean shipping.

Boost Your Business with High-Quality Fiberglass Cloth

NQ provides comprehensive fiberglass cloth solutions for global buyers. Our premium fiberglass cloth is manufactured with strict quality control from raw materials to final shipment, ensuring consistency and reliability. With customizable options in weight, width, weave, and finish, our professional-grade fiberglass cloth helps distributors, wholesalers, and manufacturers enhance product value and strengthen their brand in competitive markets.

Customized weaving method

We support various fabric structures, including plain, twill, and satin, as well as customization for different braiding options, such as single strands and twisted plies. You can also customize the weight (50 g/m²、80 g/m²、100 g/m² to 1200 g/m²), color (any RAL or Pantone color), and size (width: 50–2500 mm, length: such as 50m、100m、etc ) according to your project needs for the best results.

Color Customization

We support various fiberglass fabric colors, including red, green, blue, black, grey, orange, white, and more, as well as full customization for any special shades based on RAL or Pantone standards. With advanced dyeing and coating technologies, we ensure vibrant, uniform, and long-lasting colors that remain stable even under heat, UV exposure, or harsh environments.

Customized weaving method

We support various fiberglass fabric coatings, including silicone, PTFE, acrylic, PVC, and polyurethane, as well as customization for different surface finishes such as glossy, matte, or textured. You can also customize the coating thickness (20–200 μm), color (any RAL or Pantone shade), and performance features (heat resistance up to 600 °C, waterproofing, chemical resistance, etc.) according to your project needs for the best results.

Packaging Customization

We use various packaging methods for different sizes of fiberglass fabric, including polyethylene bags, cartons, cardboard boxes, wooden crates, and roll packaging. The choice of packaging depends on the fabric’s type, specifications, and intended use. You can also request specific packaging to ensure your product is well-protected.

Monthly Output

Total annual revenue

Skilled worker

NQ Fiberglass Company Overview

Premium Quality Fiberglass – With 25 advanced production lines and state-of-the-art fiberglass textile technology, we guarantee superior fiberglass materials through rigorous quality control.

Affordable & Competitive Pricing – Choose our custom fiberglass fabric for high-quality products, cost-effective pricing, and reliable on-time delivery—saving you cost and avoiding delays.

Fully Customizable Fiberglass – As a leading fiberglass fabric manufacturer, we offer tailor-made solutions including custom weight, texture, length, and packaging to meet your exact needs.

NQ Factory production pictures

NQ Company Certificate

Trade Shows & Exhibitions

NQ Fiberglass showcases cutting-edge production, strict quality control, and customized fiberglass solutions. At every exhibition, we prove our strength as a trusted global supplier with innovation, reliability, and strong manufacturing power.

Fiberglass Fabric Applications & Industry Uses

Construction Industry

Type of fiber: E/ECR-GLASS

Linear density( tex):300-9600

Compatible resin: UP,VE

Electronic And Electrical Industry

Type of fiber: E-GLASS

Linear density ( tex ):300-2400

Compatible resin: PP, PA

Transportation Industry

Type of fiber: E/ECR-GLASS

Linear density( tex ):300-9600

Compatible resin:UP, VE,PF

New Energy Industry

Type of fiber: E/ECR-GLASS

Linear density( tex ):300-4800

Compatible resin: UP,VE, PF

FRP Product

Type of fiber: E-GLASS

Linear density( tex ):2400/4800

Compatible resin:UP, VE

Structural Product

Type of fiber: E/ECR-GLASS

Linear density ( tex ):2400/4800

Chopping Roving For Headliner

Type of fiber: E/ECR-GLASS

Linear density( tex ):2400/4800

Compatibie resin:UP,VE,PU

Assembled Roving For Pultrusion

Type of fiber: E/ECR-GLASS

Linear density( tex ):2400/4800

Filament diameter:13-14

Compatible resin: UP,VE

What Buyers Say About NQ Fiberglass

“Working with NQ fiberglass fabric has always been a smooth experience. The quality of their products is consistently stable, ensuring that each batch meets our high standards and significantly reducing our quality control costs. Additionally, their delivery times are always reliable, supporting our production schedule. Overall, NQ is undoubtedly one of our most trusted partners.”

Daniel Parker

Entrepreneur

“My first experience using NQ fiberglass fabric was highly satisfying. The entire process was efficient and professional, from the initial sample testing to subsequent bulk orders. I especially appreciated their customer service team, who were very patient and offered valuable advice and assistance to our new customers with specific product requirements. I look forward to more collaboration opportunities in the future.”

James Rodriguez

Entrepreneur

“Since choosing NQ fiberglass fabric as our supplier, I have noticed increased cost-effectiveness. Their competitive pricing, flexible batch customization services, and commitment to quality have helped us effectively reduce inventory pressure and production costs. The NQ team is a valuable partner that responds quickly to market needs and consistently provides the best cost optimization solutions at critical moments.”

Mark Wilson

Entrepreneur

Fiberglass Cloth Factory

Below you can find some frequently asked questions about shipment and MOQ. If you have any further questions, please feel free to contact us.

We produce a wide range of fiberglass cloth, including plain weave, twill weave, chopped strand mat, unidirectional, and multi-axial fabrics. We can customize the fabric based on weight, weave pattern, and resin compatibility to suit your needs.

Our fiberglass cloth is compatible with various resins, including unsaturated polyester (UP), vinyl ester (VE), epoxy (EP), and phenolic resins. This makes it suitable for a variety of applications, such as automotive, construction, and marine industries.

Fiberglass cloth is commonly used in construction for reinforcement, waterproofing, and insulation. It is also widely used in automotive parts, boat hulls, wind turbine blades, electrical insulation, and more.

Yes, we offer customizable fiberglass cloth options, including custom gram weight, width, length, and weave. We work closely with clients to ensure the fabric meets specific project requirements.

Our standard lead time is typically between 15-20 days depending on the order volume and customization. We offer expedited shipping options if needed.

Yes, we provide both OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services. You can rely on us for high-quality, customized solutions tailored to your specific needs.

We follow stringent quality control processes throughout production. From raw material selection to final shipment, each batch of fiberglass cloth undergoes thorough testing to ensure it meets industry standards like ISO and SGS certifications.

Yes, we accept both small and large orders. Whether you need a small sample or bulk orders, we are happy to accommodate your requirements.

Our minimum order quantity varies depending on the type and customization of the fiberglass cloth. Please contact us directly for a specific quote based on your needs.

You can place an order by contacting our sales team via email or phone. We will guide you through the order process, including material selection, specifications, pricing, and delivery.

Fiberglass Cloth FAQ

Have questions about fiberglass cloth? Here, we’ve compiled answers to the most common inquiries about its uses, benefits, and applications. Whether you’re exploring how it works or its suitability for your project, you’ll find all the information you need right here.

Fiberglass cloth is used for reinforcing composites, waterproofing, insulation, boat building, surfboards, automotive repairs, and strengthening structures.

It refers to using heavy canvas drop cloth with exterior paint (often latex or oil-based) as a cheap alternative to fiberglass cloth for waterproofing surfaces like wooden boats or trailers.It refers to using heavy canvas drop cloth with exterior paint (often latex or oil-based) as a cheap alternative to fiberglass cloth for waterproofing surfaces like wooden boats or trailers.

For small boats, 4 oz to 6 oz cloth is common. For larger boats or higher strength areas, 8 oz, 10 oz, or heavier biaxial/1708 cloth is recommended.

- Plain Weave – balanced, easy to handle.

- Twill Weave – stronger and more flexible.

- Satin Weave – highest strength, conforms well to curves.

Fiberglass is not globally banned. Some countries restrict fiberglass in consumer items like mattresses or insulation because loose fibers can irritate skin, eyes, and lungs.

Yes, but it can cause itching and skin irritation. Gloves and protective clothing are recommended.

Alternatives include carbon fiber, Kevlar, natural fibers (like hemp or flax composites), or “poor man’s fiberglass” (painted canvas).

Fiberglass is classified as a skin and respiratory irritant, not a carcinogen. Long-term exposure without protection may cause chronic irritation, coughing, or dermatitis.

Because it can be itchy, messy, hard to clean, and uncomfortable to work with.

Depends on strength needed:

- Small repairs: 2–3 layers.

- Boats or structural projects: 4–10+ layers.

Satin weave (e.g., 8-harness) is the strongest per weight. For heavy-duty use, biaxial or 1708 cloth provides maximum strength.

About 0.005–0.006 inches (0.13–0.15 mm) thick.

Sharp scissors, a rotary cutter, or specialized shears designed for composites.

About 0.008 inches (0.2 mm) thick.

A biaxial fiberglass (17 oz) stitched at ±45°, backed with 8 oz mat for strength and bulk — widely used in boats.

Some lawsuits exist if fiberglass escaped from the cover and caused damage or injury. It depends on jurisdiction and product disclosure.

Yes, most inhaled fibers are trapped by mucus and expelled, but repeated heavy exposure may cause irritation or scarring.

Fiberglass is a composite material: glass fibers reinforced with a plastic resin (polyester, epoxy, or vinyl ester).

No. Fiberglass can slow bullets and is used in ballistic panels, but by itself it’s not bulletproof like Kevlar.

Tiny fibers may stay for days if not washed out, but the body pushes them out over time.

When you need strength with low weight, waterproofing, reinforcement of resin, or smooth finishing surfaces.

Yes, touching or cutting it releases fine fibers that irritate the skin.

Lay the cloth on the surface, saturate with resin, smooth out bubbles, let cure, and repeat for multiple layers if needed.

- Cloth = stronger, smoother, uses less resin.

- Mat = bulk, conforms to curves, bonds layers. Often used together.

No. Fiberglass is an irritant, but unlike asbestos, it does not cause cancers such as mesothelioma.

Yes if kept intact. Loose fibers may irritate skin and lungs if handled carelessly.

Because molten glass is spun into thin fibers, giving a fluffy, sugar-like appearance.

Yes, but wash separately. Small fibers may remain and cause itching.

Some cheaper couches (and especially mattresses) use fiberglass as a flame retardant layer.

Yes, but plywood must be clean, dry, and often sealed first for proper bonding.

Typically 24–48 hours for full curing, depending on resin and temperature.

- Fiberglass: cheaper, flexible, corrosion resistant.

- Carbon fiber: lighter, stiffer, stronger, but more expensive.

Resins (epoxy, polyester, vinyl ester), hardener, and sometimes gelcoat for finishing.

It can crack under impact, degrade under UV light, and is less stiff than carbon fiber.

Yes, when sealed with resin. The cloth alone absorbs water but resin makes it waterproof.

Dry cloth will absorb water, but once laminated with resin, fiberglass becomes waterproof.

No. The fibers are glass, but the finished material includes resin (plastic).

It is strong under tension but brittle under sharp impact.

- Skin and lung irritation.

- Brittle under impact.

- UV degradation.

- Not as strong as carbon fiber.

Fiberglass itself is non-flammable, but the resin can burn.

- Lightweight and strong.

- Corrosion and water resistant.

- Cost-effective compared to carbon fiber.

Yes, widely used in construction, boats, vehicles, insulation, and consumer goods.

Carbon fiber and Kevlar are both stronger, though more expensive.

UV exposure, strong impact, certain chemicals, and repeated stress can weaken it.

Roofing shingles, bathtubs, shower stalls, ladders, surfboards, boats, insulation, and some mattresses.

Yes, fiberglass is much cheaper than carbon fiber or Kevlar, making it popular for mass applications.

Contact

- Phone: +86-13775339109

- Whatsapp: 0086-13775339109

- mail: fiberglassmesh@hotmail.com

- Address: Fangxian Town, Danyang, Jiangsu, China, 212333

.jpg)