Products Categories

Featured Products

Forged Carbon Fiber Tube

Color customization

Carbon Fiber tubes come in a variety of colors, including the usual black, white, blue, red, yellow, color, and a variety of other color options. Customers can customize unique colors according to specific needs to match specific application scenarios or brand styles. The factory will use advanced technology and high-quality materials to ensure the stability and durability of customized colors, and provide customers with personalized carbon fiber square tube products.

Product MOQ

Please note our minimum order quantity of Carbon Fiber Tube. For the conventional Carbon Fiber Tube in stock, there is no MOQ. For customized Carbon Fiber Tube, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

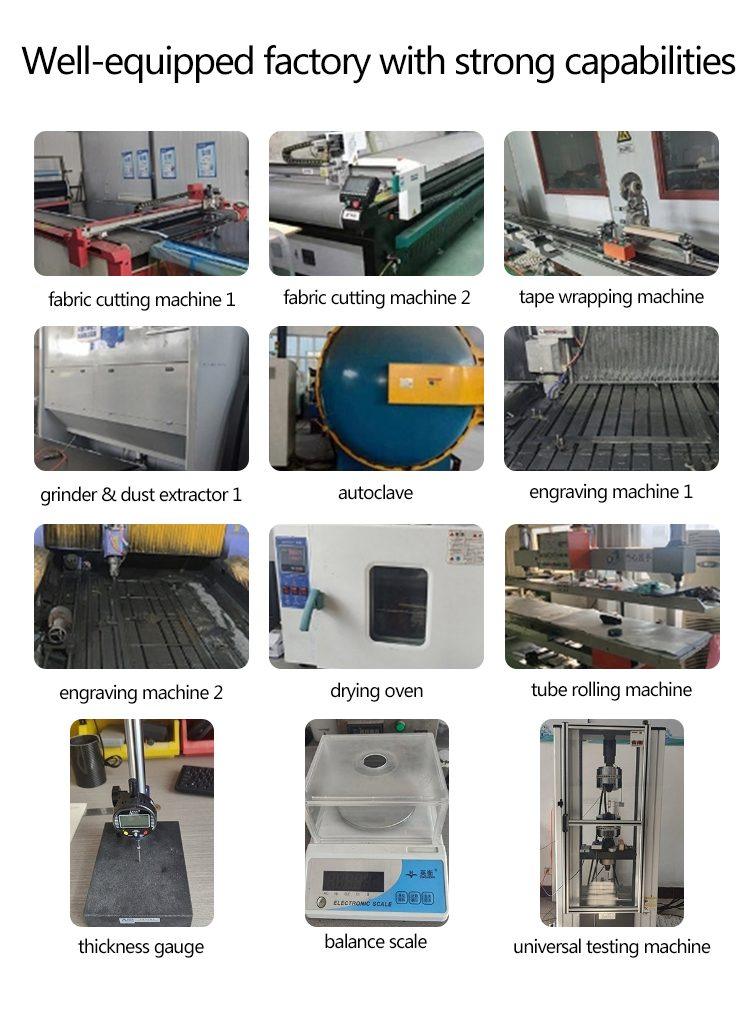

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

Forged Carbon Fiber Tube, a tubular product processed from carbon fiber material through advanced techniques, inherits the numerous advantages of carbon fiber itself, including extreme strength, lightness, and exceptional corrosion resistance.

In terms of customization, modern factories often possess high flexibility and robust manufacturing capabilities, enabling them to customize Forged Carbon Fiber Tubes based on clients’ specific needs in terms of specifications, dimensions, and performance. These factories are typically equipped with advanced production equipment and professional technical teams, capable of precisely controlling every detail of the products to ensure they meet the clients’ specific requirements.

Through customized services, clients can obtain Forged Carbon Fiber Tubes that cater to their unique application scenarios, whether it’s for strength, weight, or other performance parameters. This customized manufacturing approach not only improves the applicability and performance of the products but also delivers greater value to clients.

Specification

- Material Composition

Made from chopped carbon fiber mixed with epoxy resin through high-pressure compression molding. Unlike woven tubes, it features a random fiber orientation and a unique marble-like forged pattern, offering isotropic mechanical properties. - Outer Diameter Range

Common sizes range from 10 mm to 60 mm. Custom diameters from 6 mm up to 100 mm are available upon request. - Wall Thickness Options

Standard wall thickness ranges from 1.0 mm to 4.0 mm. Thicker options can be customized for high-load structural use. - Standard Length

Typically supplied in 1000 mm (1 meter) lengths. Custom cut lengths such as 500 mm, 1500 mm, or others are available. - Surface Finish

Available in high gloss, matte, or semi-gloss finishes. The forged carbon fiber surface provides a premium and visually distinctive appearance. - Weight

Varies by size. For example, a Ø30 mm tube with 3 mm wall thickness and 1000 mm length weighs approximately 400–500 grams. - Dimensional Tolerances

Precise tolerances of ±0.1 mm for outer diameter and wall thickness ensure high compatibility in precision assemblies. - Color and Texture

Standard in black with a forged carbon fiber texture. Custom colors and surface coatings (e.g., UV coating, sanding, painting) are available. - Machinability

Compatible with CNC machining, drilling, trimming, and bonding. Ideal for integration into complex components or finished assemblies.

Main applications

Aerospace Industry

- Carbon fiber composite materials play a crucial role in the aerospace industry, and Forged Carbon Fiber Tube, as one of its important forms, is widely used in critical parts of missiles, space platforms, and launch vehicles.

- Its high strength and lightweight properties enable a significant reduction in the structural weight of missiles and other aerospace vehicles, thus improving their range and strike capability.

- For instance, the third-stage shells of intercontinental missiles developed in the 1980s in the United States were all made of carbon fiber and epoxy resin composites, which may have included the application of Forged Carbon Fiber Tube.

Rail Transportation

- In the rail transportation sector, Forged Carbon Fiber Tube is a key material for the new generation of high-speed rail vehicle bodies.

- The application of carbon fiber composite materials to train bodies can reduce the overall weight by 30%, improving high-speed running performance, reducing energy consumption, mitigating environmental pollution, and enhancing safety.

- The use of carbon fiber composite materials in rail transportation has become a trend, and Forged Carbon Fiber Tube, as one of its forms, will play an important role.

Sports and Recreation

- Forged Carbon Fiber Tube has a wide range of applications in the sports and recreation industry, particularly in the manufacture of sports equipment.

- It is commonly seen in items such as baseball bats, tennis racket frames, fishing rods, bicycles, windsurfing spars, and sailing hulls.

- It is estimated that a significant number of baseball bats and tennis racket frames are made of carbon fiber, which may include the use of Forged Carbon Fiber Tube.

Automotive Industry

- In the automotive industry, Forged Carbon Fiber Tube is used to manufacture high-performance automotive components such as body frames and suspension systems.

- The application of carbon fiber can significantly reduce the weight of automobiles, thereby improving fuel efficiency and dynamic performance.

- Compared to traditional materials, carbon fiber can reduce weight by over 40%, providing a significant advantage for automakers.

Other Industries

- In addition to the above-mentioned major industries, Forged Carbon Fiber Tube is also used in wind power generation, energy, chemical engineering, construction, and other sectors.

- In the wind power generation industry, carbon fiber composite materials are the primary material for turbine blades, and Forged Carbon Fiber Tube may play an important role in their manufacture.

- In the construction industry, carbon fiber composite materials are also used to create lightweight and high-strength structural materials such as bridges and roofs, and the application of Forged Carbon Fiber Tube will help improve the performance and durability of these structures.

Features

- Lightweight with Exceptional Strength

Offers an outstanding strength-to-weight ratio, making it ideal for weight-sensitive applications without sacrificing structural performance. - Balanced Performance in All Directions

The non-woven, randomly oriented fiber structure provides consistent mechanical strength across multiple directions, ideal for complex load conditions. - High Impact and Crack Resistance

Excellent ability to absorb shocks and resist fracture, ensuring longer life in demanding environments. - Unique and Premium Appearance

The forged carbon texture delivers a sleek, marble-like visual that stands out in high-end product designs, such as electronics, automotive, and sporting goods. - Precision-Friendly and Customizable

Easily machinable and adaptable for drilling, cutting, or bonding, making it suitable for precise engineering applications.

Model | | Outer Dimensions (mm) | Wall Thickness (mm) | Length (mm) | Fiber Type | Fiber Specification |

NQ-20×20-T3 | 20 × 20 | 26 × 26 | 3 | 300 | T700 | 3K |

NQ-30×30-T4 | 30 × 30 | 36 × 36 | 4 | 400 | T700 | 3K |

NQ-40×40-T5 | 40 × 40 | 46 × 46 | 5 | 500 | T700 | 3K |

NQ-50×50-T6 | 50 × 50 | 56 × 56 | 6 | 600 | T700 | 3K |

For more product specifications, please contact our professionals!

By adopting CNC precision processing technology and automatic detection systems and integrating automated winding, curing, and cutting processes, the production speed is increased by 20% to 30%. Multi-station collaborative operation reduces manual intervention and reduces the error rate.

- Compatible with carbon fiber prepregs such as T300, T700, T800

- Supports a variety of resin systems such as epoxy and phenolic

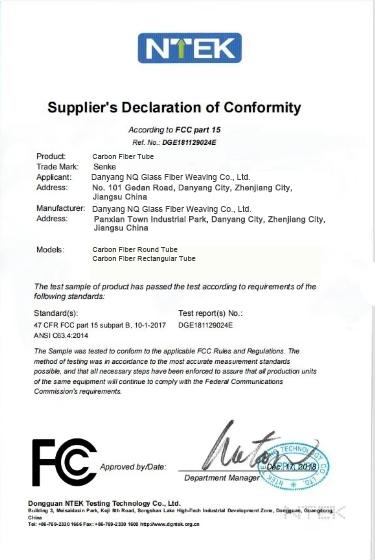

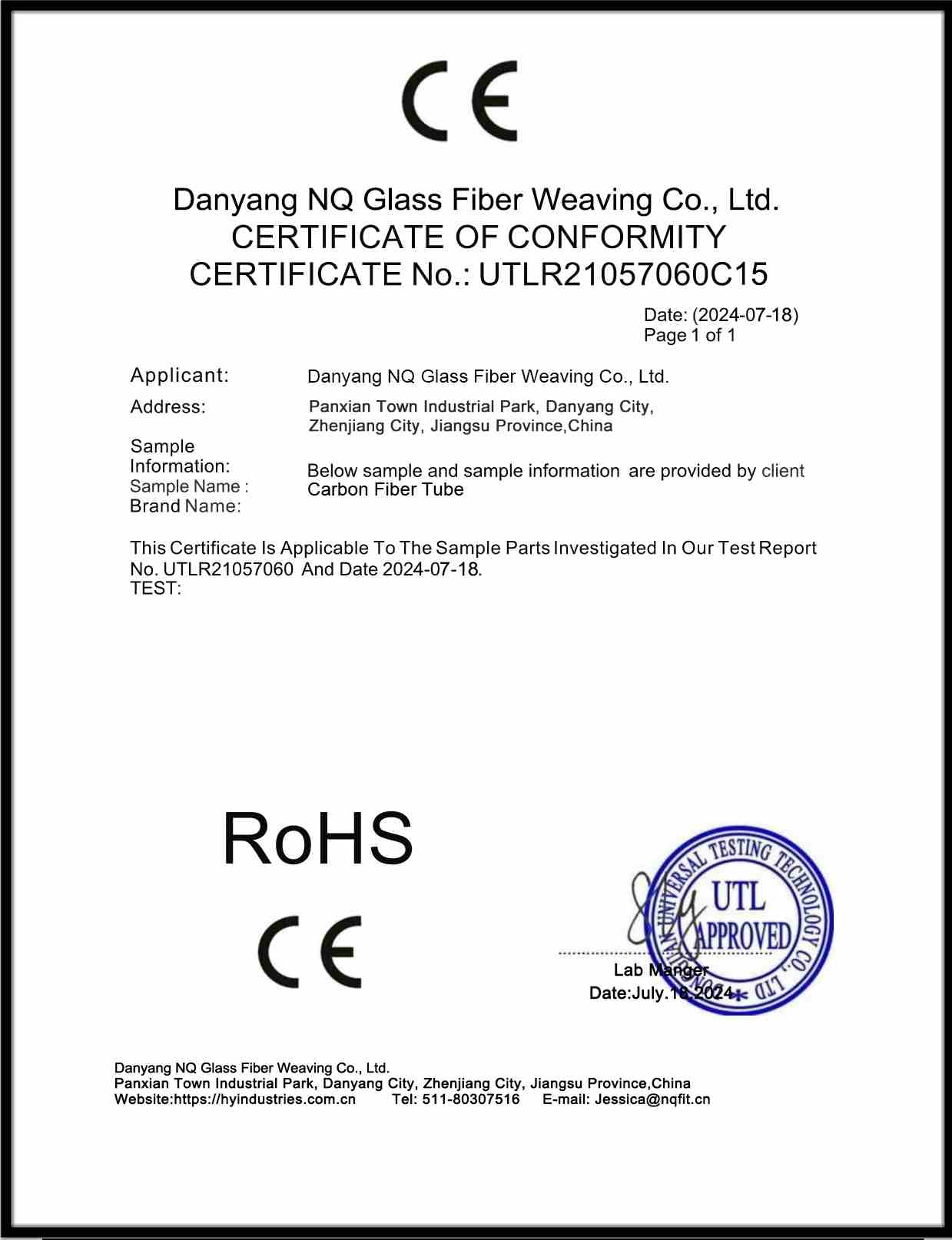

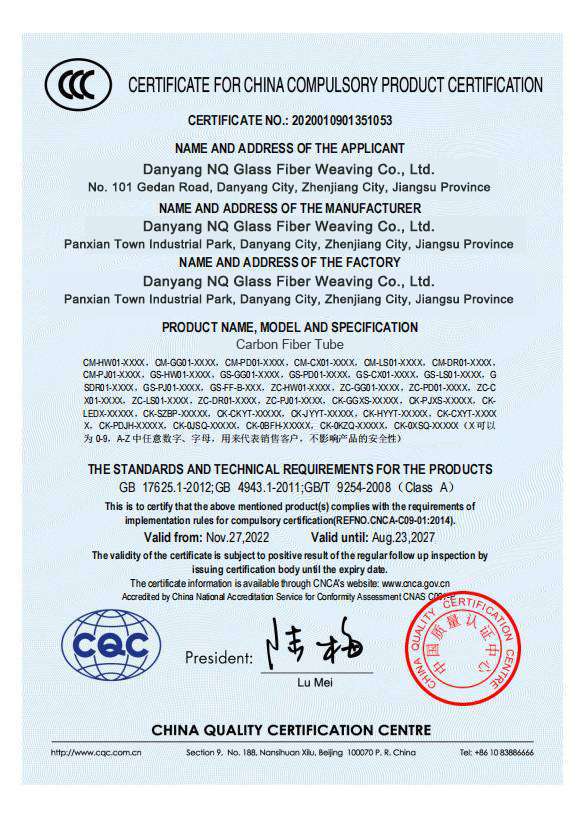

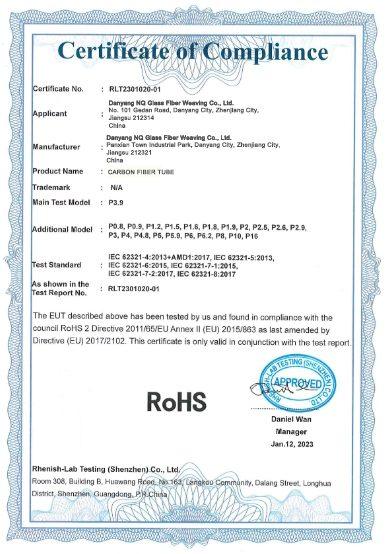

- ISO 9001, CE, SGS, and ASTM standards

- 40 automated production lines to ensure on-time delivery

- In-house Strictly Testing Lab for 6-step internal inspection

Enhance Performance, Simplify Processing, Reduce Costs

Experience the power of Carbon Fiber Tubes—lightweight, ultra-strong, and corrosion-resistant. Perfect for industries demanding high performance and durability. Elevate your products with precision-engineered tubes that combine advanced materials with cutting-edge manufacturing. Choose carbon fiber tubes for unmatched strength, reduced weight, and superior reliability.