China Drywall Fiberglass Tape Manufacturer

- 16+ years of factory manufacturing experience.

- CE, ASTM, SGS, ISO, BSCI certifications.

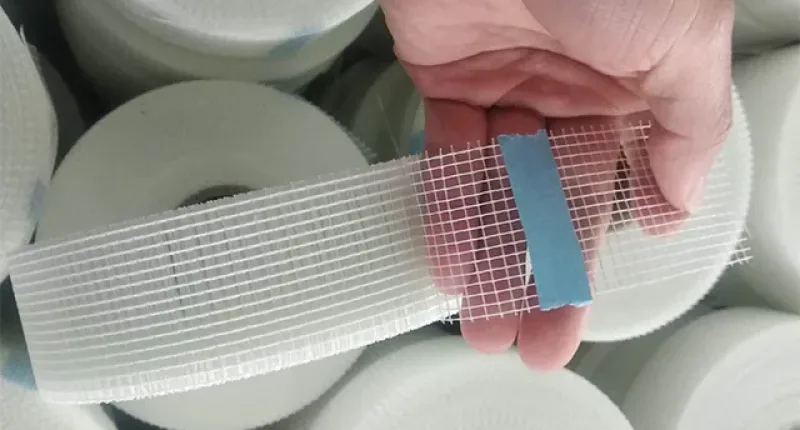

- Custom colors:Black, transparent, red, white, blue, color, gray, orange, etc.

- OEM&ODM service

- Perfect after-sales service system.

years

Manufacturing Experience

Projects

We had finished

Clients

Over the world

Satisfaction

Drywall Fiberglass Tape Manufacturers

As a professional fiberglass tape manufacturer and supplier in China, we have more than 16 years of industry experience. And with a number of international well-known brands, large retailers such as Walmart, home depot, delta lite, empire, KUANF, USG and so on to establish a long-term and stable cooperative relationship.

High-End Automatic Gluing Machine

Our glue machine delivers excellent performance with precise accuracy, ensuring an even application of adhesives like latex and acrylic. This results in superior coating quality and curing effects. Additionally, the stable performance of our warp and weft textile machine facilitates mass production and customization of various shapes, sizes, and colors.

- 50 automated weaving production lines to ensure on-time delivery

- In-house strict testing laboratory with 6-step internal inspection

- ISO 9001, CE, SGS, ASTM certification

- Strong adhesion and high tensile strength, with excellent holding effect and excellent tensile strength

Professional

Advanced manufacturing technology

High Quality

High quality CE, ASTM, SGS, ISO, BSCI certification

Cost Effective

Direct factory price

Customized

Different sizes, colors, designs, OEM/ODM

Service

Excellent customer service

Fiberglass Mesh Tape Series

Fiberglass tape is a versatile strip material made from fiberglass, known for its exceptional properties such as heat resistance, corrosion resistance, insulation, and tensile strength. It finds widespread application across various industries.In the electrical and electronics sector, it serves as an insulating packaging material, ensuring the stability and safety of current transmission. In construction, it is utilized for anti-corrosion, waterproofing, and sealing of pipelines and storage tanks, as well as for reinforcing building structures to enhance safety and stability.In the chemical and petroleum industries, its corrosion resistance effectively protects equipment from damage caused by chemical media and is ideal for sealing and repairing oil pipelines. Additionally, fiberglass tape is commonly used in boat repairs, reinforcing concrete slabs, fixing wall cracks, strengthening roofs, and producing parts for model rockets and motorcycles.

Improve Your Business With Custom Manufactured Fiberglass Tape

NQ is widely recognized in the fiberglass tape industry for its exceptional custom service and packaging capabilities. We offer fiberglass tape in a variety of colors and specifications, and we can tailor our products to meet your specific needs—whether it’s width, length, or mesh size.Our efficient supply chain allows us to deliver up to 100,000 rolls per day, ensuring that you receive your products promptly. When it comes to packaging, we pay close attention to detail, customizing conventional methods to meet customer requirements and ensuring the safe transport of our products.

Color Customization

We provide a variety of standard fiberglass tape colors, including white, blue, orange, green, black, and more, to meet the diverse needs of our customers. Additionally, we accept custom color requests. Just send us a color sample or number, and we will work to match or develop the perfect shade for you.

Size Customization

We offer fiberglass tape in a wide range of lengths, widths, and mesh sizes, and we support customization for both small kits and large bulk orders. Our conventional sizes include 1 inch, 2 inch, 3 inch, 4 inch, 6 inch, 3m, 6m, and more.

Custom Self-Adhesive Layer

We utilize a composite layer process that employs adhesives produced by BASF in Germany. The first layer features alkali-resistant glue and acrylic emulsion containing zirconia, which provides structural support. The second layer incorporates materials like Teflon and resin to create a self-adhesive effect. Customers have the option to customize the adhesive to achieve their desired results.

Label Customization

Labels are essential for product identification and information. We offer comprehensive label customization services, including printing product names, specifications, brand logos, production dates, and other content. To ensure the durability and clarity of our labels, we utilize high-quality materials and cutting-edge printing technology.

Packaging Customization

We use heat shrink film for packaging to protect against moisture and provide antioxidant benefits. Additionally, we offer personalized packaging customization services, allowing customers to choose their preferred materials, design styles, and printed content to showcase their unique brand image.

Color Box Customization

We offer professional color box customization services that encompass design, material selection, and printing. Customers can create unique color boxes tailored to their brand image and market positioning.

Fiberglass Tape Specification

Fiberglass Tape | Density Count/25mm | Unit Weight | Tensile Strength N/5CM X20CM | Tensile Strength N/5CM X20CM | Woven Structure | Content of Resin % | |

Warp | Weft | g/m2 | Warp | Weft | |||

RD55-8**8 | 8 | 8 | 55 | 550 | 450 | leno | 28±2 |

RD60-8*8 | 8 | 8 | 60 | 550 | 450 | leno | 28±2 |

RD60-9*9 | 9 | 9 | 60 | 550 | 500 | leno | 28±2 |

RD65-9*9 | 9 | 9 | 65 | 550 | 550 | leno | 28±2 |

RD70-9*9 | 9 | 9 | 70 | 550 | 600 | leno | 28±2 |

RD75-9*9 | 9 | 9 | 75 | 550 | 650 | leno | 28±2 |

RD110-5*5 | 5 | 5 | 110 | 1000 | 1000 | leno | 28±2 |

Mesh size | 5×5 MM, 4×4 MM, 3×3 MM |

Weight/square meter | 60g-300g,customize |

Width | 0.5m-2m,customize |

Application | Construction, packaging, electronics and automotive industries for wall enhancement, waterproofing, insulation and fixing. |

Length | 50m-300m,customize |

fiberglass sample | free sample |

packing | Plastic Bag , PE Bag , Woven Bag |

colors | White Blue Orange Yellow etc |

Customer Logo | customize |

Brand Name | NQ Fiberglass Tape |

Model Number | 8×8 counts; 9*9 counts,etc |

Weight | 55g/m2; 65g/m2; 75g/m2,etc |

Width | 35mm;50mm;100mm;etc |

Mesh Size | 2.82×2.82mm;3.1×3.1mm,etc |

Color | White, yellow, blue,black,support customization |

Size | 50mmx90m/45m/20m; 35mmx90m/45m/20m; 100mm wide;etc |

Application Fields | Construction, automotive, electronic appliances, aerospace and packaging industries. |

Fiberglass sample | Free sample |

Packing | Heat shrink film, carton, custom color box, etc., support customization |

Packaging Details | Shrink-wrapped each roll with label; Details see arrangement |

Material & Process | Woven fiberglass alkali-resistant fabric coated with adhesive acrylic compound; cut fabric into tapes and pack . |

Properties | Good performance of alkaline-resistance; |

Usage | Construction industry, drywall repair and joint treatment, gypsum board joint reinforcement and caulking treatment, thermal insulation, pipe insulation fixed and sealed, waterproof wall, roof and other parts of the repair and reinforcement. Car and boat body restoration. Electronics and electrical industry, pipe repair and insulation, aerospace, cement and tile industry. Let’s wait. |

NQ Fiberglass Mesh Tape Production Process

1. Raw Materials

Using premium fiberglass yarns from Monolith Group, the world’s largest producer, our materials are 20% stronger than standard options, ensuring superior durability and performance.

2. Twisting Process

We use tension devices and yarn guides to maintain consistent tension and path stability throughout the twisting process.

3.Weaving Process

We use a warp tension magnetic separator to prevent warp yarn distortion due to tension variations, resulting in a strong yet flexible mesh.

4. Coating Process

We use BASF Germany adhesives: a strong alkali-resistant first layer with zirconium oxide acrylic emulsion and a self-adhesive second layer for enhanced performance.

5. Drying Process

The coated tape enters a hot air circulation oven, where controlled heat and airflow dry the adhesive, remove moisture or solvents, and enhance strength and stability.

6. Cutting Process

Measure the fiberglass tape precisely with tools like calipers, then steadily cut along the marked line to ensure quality.

7.Quality Inspection

We inspect fiberglass tape for a smooth, defect-free surface and neat edges. Physical tests ensure strength, adhesion, and durability meet high-quality standards.

8. Packing

We choose packaging like PE film, cardboard, and bubble wrap based on product needs, ensuring moisture, dust, and shock protection during transport and storage.

SF

Warehouse and factory

Total annual revenue

Skilled worker

Partner With NQ To Elevate Your Project To Success

Premium quality: With 50 production lines, we use high-quality raw materials with a strength retention rate of more than 90% and an elongation of less than 1%, ensuring the production of high-quality fiberglass tapes.

Competitive price: Our efficient production process is supported by eight dedicated production lines, allowing us to complete bulk orders in a timely manner, helping you minimize wholesale costs and gain a competitive advantage.

Fully Customize: We offer a variety of specifications, including lengths of 50m, 100m, 150m, and 200m, as well as mesh sizes such as 4mm x 4mm, 5mm x 5mm, and 6mm x 6mm. Additionally, we provide custom solutions to meet the specific size requirements of our customers.

Certificate

NQ Glass Fiber Tape Unique Features And Advantages

Our fiberglass tapes can meet the unique needs of different industry or project target audiences.

Dimensional Stability

The fiberglass tape boasts excellent dimensional stability, maintaining its shape and size even under significant temperature fluctuations, humidity, or mechanical stress. This makes it an ideal choice for applications where accuracy and consistency are crucial.

Corrosion Resistance

Fiberglass tape exhibits inherent corrosion resistance, ensuring it will not rust, corrode, or deteriorate when exposed to moisture, chemicals, or harsh environmental conditions. This provides long-term durability and reliability, particularly in outdoor or corrosive environments.

Light And Flexible

Fiberglass tape is lightweight, highly flexible, and easy to handle, transport, and install. The flexibility of the fiberglass mesh allows it to adapt to irregular surfaces, making it suitable for curved or contoured structures.

Enhanced Durability

NQ fiberglass tape undergoes rigorous testing and quality control measures to ensure exceptional durability and longevity. This enables the mesh to withstand harsh conditions, including extreme temperatures, ultraviolet radiation, and chemical exposure.

Excellent Adhesion

NQ fiberglass tape features enhanced bonding properties, designed to promote a strong and reliable bond to a variety of substrates. This superior adhesion minimizes the risk of delamination or peeling, ensuring long-lasting performance.

Optimal Grid Structure

NQ fiberglass tape features an optimized mesh structure designed to provide excellent reinforcement. The nets are carefully woven with evenly distributed fibers that enhance load-bearing capacity and prevent the propagation of cracks.

Experience The Power Of Fiberglass Tape To Enhance Structure

Whether you are using it for the construction industry, plastering, waterproofing, electronic cloth or wire and cable coating, electrical insulation, pipe repair, etc., NQ can provide products to meet your specific needs.

Building Material

Improve construction quality

Extended service life

Improve security

Construction convenience

EIFS Stucco System

Excellent durability

Strong adhesion and sealing

Easy to construct and maintain

Aesthetic and decorative

Marble Backing

Using NQ fiberglass tape strengthens the bond between the marble and the backboard, improving stability and reducing the risk of cracks and deformation during installation.

Increase support

Tightly fit waterproof and moisture-proof

Easy cutting and pasting efficiency

Hide reinforcement

Waterproofing System

NQ fiberglass tape is utilized in waterproofing systems as a reinforcement layer alongside a waterproofing film or asphalt. This combination adds strength and dimensional stability, significantly improving overall water resistance.

Excellent waterproof sealing

Strong bond and tensile strength

Weather resistance and chemical stability

Construction convenience and flexibility

FAQ'S

What is your MOQ?

Our MOQ is usually 1x20ft container.But we accept lower quantity for your trial order. Please feel free to inform us your plan for purchasing, we will offer the price correspond to your qty. And we hope your would increase your order qty after you check our product quality and know our services.

What is the shipping port?

We ship the goods via Shanghai port.

How many colors are available?

We can do custom color when reach our MOQ qty.

Our regular colors are white, yellow, green, blue, orange, red etc.

What format of the file do you need if I want to do my own design?

For printing label design, we need AI or PDF file for set up the print-plate.

What is your delivery time?

The time of delivery is about 20~30days after we receive the deposit.

What is your sample time?

Usually we will take 7-10 days to make the samples.

Which Shipment way is available?

By sea to your designated port.

Which Payment way is workable?

1. Irrevocable L/C, Cash, PayPal, Credit card and T/T money transfers.

2.30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo.

3.L/C ( Irrevocable LC at sight)

If you need custom size such as gram weight and mesh size etc or private logo pls feel free inquiry us!

What is fiberglass tape used for?

Fiberglass mesh tape is a strong, tear-resistant material primarily used for reinforcing and repairing drywall seams. Its main uses include:

Drywall Joint Reinforcement: Fiberglass mesh tape is applied to drywall seams to prevent cracks and provide a solid base for further repairs. It helps ensure a smooth, durable finish.

Drywall Hole Repair: For small holes in drywall, fiberglass mesh tape serves as a repair material, enhancing the strength and stability of the patched area.

Structural Reinforcement: Fiberglass mesh tape, with its high tensile strength, is used to repair and reinforce structures like pipes, tanks, and ducts, ensuring long-term durability.

Filtration and Protection: Fiberglass mesh tape can also be used in water filtration systems, capturing fine particles. Additionally, it is utilized in protective clothing to shield users from heat and chemicals.

Fiberglass mesh tape is excellent for repairing damaged drywall. Because it is self-adhesive, it can be installed quickly and easily without the need to mud the joints first. When combined with a setting compound, it creates a strong bond in a short amount of time, providing a reliable, durable repair solution.

Is fibreglass tape strong?

- Drywall Joint Reinforcement: Applied over drywall seams, it prevents cracks from reoccurring and provides a stable base for further repair work.

- Drywall Hole Repair: Ideal for repairing holes in drywall, it enhances the strength and stability of the patched area.

- Structural Reinforcement: With its high tensile strength, it is used to repair and reinforce structures like pipes, tanks, and ductwork, ensuring long-term durability.

- Filtration and Protection: Utilized in water filtration systems to capture fine particles and in protective clothing to shield users from heat and chemicals.

Is fiberglass tape safe?

Here’s a detailed answer in points regarding the safety of fiberglass tape:

Chemical Safety:

- Fiberglass mesh tape does not contain chemicals that pose significant hazards. It is safe to handle in most situations without special chemical precautions.

Physical Hazards:

- The tape itself is not likely to cause harm, as it does not rot, tear, or wear easily. It is a durable material suitable for long-term use.

Respiratory and Eye Irritation:

- While fiberglass mesh tape itself is safe, exposure to fiberglass dust may cause irritation to the eyes, skin, and respiratory system if inhaled.

- This can occur if the material is cut or disturbed, but it’s not common with normal use.

Safety Measures:

- When working with fiberglass mesh tape, it’s advisable to wear protective gloves and safety glasses to avoid irritation from the dust.

- Ensure proper ventilation in the workspace to minimize the buildup of dust in the air.

First Aid:

- If fiberglass dust comes into contact with your skin, wash the area thoroughly with soap and water.

- If the dust gets into your eyes, rinse immediately with water for several minutes.

- If inhaled and irritation persists, move to fresh air and seek medical attention.

In conclusion, fiberglass mesh tape is safe to use with proper handling and safety precautions, especially to avoid respiratory or eye irritation from dust.

Is fiberglass tape a good insulator?

Here’s the answer in points regarding whether fiberglass tape is a good insulator:

Thermal Resistance:

- Fiberglass mesh tape offers low thermal conductivity, which means it has some degree of thermal resistance. However, it is not specifically designed as an insulation material.

Temperature Rating:

- Woven fiberglass tape can handle temperatures up to 1000°F (537°C) without breaking down, making it suitable for high-temperature applications.

Primary Use:

- The main purpose of fiberglass tape is for reinforcing and strengthening surfaces, such as drywall, in construction. It is also useful for gasketing, sealing, packing, and encapsulation projects.

Suitability for Insulation:

- While it offers some thermal resistance, fiberglass tape is not primarily designed for thermal insulation. Other insulation materials specifically intended for thermal insulation are better choices for insulation purposes.

Summary:

- Fiberglass mesh tape is not a primary insulator but can provide some degree of thermal resistance in certain applications. For optimal insulation performance, materials specifically designed for insulation should be used.

What is the advantage of fiberglass tape?

Fiberglass tape offers several advantages that make it a preferred choice in various applications:

High Durability: Fiberglass tapes are rust-resistant, even to saltwater, and tear-resistant, ensuring longevity and reliability in demanding environments.

High Temperature Resistance: They can withstand temperatures up to 1000°F (537°C), making them suitable for high-temperature applications.

Corrosion Resistance: Fiberglass mesh tape serves as a protective layer against corrosion, extending the lifespan of structures and equipment.

Cost-Effectiveness: Compared to steel tape, fiberglass tapes are more economical, offering a cost-effective solution without compromising performance.

Ease of Application: Their flexibility allows for easy handling and application, even in hard-to-reach areas, making them ideal for various wrapping tape scenarios.

In summary, fiberglass tape combines durability, high-temperature resistance, corrosion protection, cost-effectiveness, and ease of application, making it a versatile and reliable choice for numerous industrial and construction applications.

Why is fiberglass the best insulator?

Fiberglass is considered an excellent insulator due to its unique structure and properties:

Structure and Air Trapping: The glass fibers in fiberglass insulation trap millions of tiny air pockets between them. These air pockets significantly reduce heat transfer, enhancing the material’s insulating properties.

Thermal Conductivity: Fiberglass insulation has low thermal conductivity, meaning it resists the flow of heat effectively. This property makes it one of the most efficient materials for thermal insulation.

R-Value: The effectiveness of fiberglass insulation is measured by its R-value, which indicates its resistance to heat flow. Fiberglass insulation typically ranges from R-11 to R-38, depending on its thickness and application.

Cost-Effectiveness: Fiberglass insulation is one of the most popular insulating materials for residential and commercial applications because of its effectiveness and affordability.

In summary, the combination of its structure, low thermal conductivity, high R-value, and cost-effectiveness makes fiberglass an excellent choice for insulation in various applications.

Paper vs fiberglass drywall tape

Paper vs Fiberglass Drywall Tape:

Both paper and fiberglass mesh tapes are commonly used for drywall joint treatment, each with its own advantages and disadvantages suited to different application needs.

Paper Tape:

Adhesion: Paper tape requires embedding in a layer of joint compound to adhere to the drywall surface. If the compound isn’t applied evenly, bubbles may form under the tape.

Strength: Paper tape provides strong adhesion, enhancing the overall strength of the joint. This makes it ideal for areas that will experience higher stress.

Applicability: Paper tape is suitable for standard drywall joints, especially in areas requiring more strength and durability. However, its installation process may require more skill and experience.

Fiberglass Mesh Tape:

Adhesion: Fiberglass mesh tape is self-adhesive, allowing it to stick directly to the drywall surface, simplifying the application process.

Flexibility and Durability: Due to its thin, open weave structure, fiberglass mesh tape offers superior flexibility and durability, reducing the likelihood of tearing, cracking, or bubbling.

Applicability: Fiberglass mesh tape is suitable for quick repairs and high-moisture areas due to its moisture-resistant properties. However, its strength may not be as high as paper tape, and cracking at the joints could occur.

Summary:

Choosing between paper tape and fiberglass mesh tape depends on the specific application and preference. If stronger adhesion and durability are needed, paper tape might be a better option. For easier application and moisture resistance, fiberglass mesh tape may be the preferred choice.

Fiberglass drywall tape vs paper tape

When choosing between fiberglass mesh tape and paper tape for drywall applications, it’s important to consider their respective advantages:

Paper Tape:

Strength: Paper tape’s inelastic nature makes it a stronger choice for seaming sheets of drywall together.

Ease of Use in Corners: Due to its middle crease, paper tape is easy to fold into inside corners, facilitating precise corner joints.

Fiberglass Mesh Tape:

Adhesion: Fiberglass mesh tape is self-adhesive, allowing it to stick directly to the drywall surface, simplifying the application process.

Flexibility and Durability: Due to its thin, open-weave structure, fiberglass mesh tape offers superior flexibility and durability, reducing the likelihood of tearing, cracking, or bubbling.

Moisture Resistance: Fiberglass mesh tape is moisture-resistant, making it suitable for high-humidity areas.

In summary, if you prioritize strength and ease of use in corners, paper tape may be the better choice. However, if you value ease of application, flexibility, and moisture resistance, fiberglass mesh tape could be more suitable.

Where to buy fiberglass casting tape

To purchase fiberglass casting tape, you can consider the following options:

Online Retailers: Platforms like Amazon offer a variety of fiberglass casting tapes in different colors and sizes. For instance, TrelaCo provides a 10-pack of black fiberglass casting tape, measuring 2″ x 4 yards.

Medical Supply Stores: Specialized medical supply retailers, such as OrthoTape, offer fiberglass cast tapes in multiple colors, including camouflage green, pink, and blue.

Wholesale Suppliers: Websites like Alibaba list numerous suppliers offering fiberglass casting tapes, allowing you to compare prices and options.

When selecting a supplier, consider factors such as product quality, shipping options, and customer reviews to ensure a satisfactory purchase experience.

How to tape drywall with fiberglass mesh

- Prepare the Surface: Ensure that the drywall seams are clean and dry. Apply a layer of joint compound (mud) to the drywall seams where the tape will be placed.

- Apply the Tape: Unroll the fiberglass mesh tape and press it gently into the wet joint compound. The mesh tape can be applied directly over the seams or cracks. It should be embedded in the compound, ensuring there are no air pockets underneath the tape.

- Smooth and Embed the Tape: Use a drywall knife to smooth the tape into the joint compound and ensure it’s well adhered. This also removes any excess compound and ensures a flat, even surface.

- Apply Additional Layers of Joint Compound: After the tape is applied and smoothed, apply additional layers of joint compound over the tape. Allow each layer to dry completely before applying the next. Sanding between layers will help achieve a smooth finish.

How to use fiberglass mesh drywall tape

- Prepare the Surface: Ensure that the drywall seams are clean and dry. Apply a layer of joint compound (mud) to the drywall seams where the tape will be placed.

- Apply the Tape: Unroll the fiberglass mesh tape and press it gently into the wet joint compound. The mesh tape can be applied directly over the seams or cracks. It should be embedded in the compound, ensuring there are no air pockets underneath the tape.

- Smooth and Embed the Tape: Use a drywall knife to smooth the tape into the joint compound and ensure it’s well adhered. This also removes any excess compound and ensures a flat, even surface.

- Apply Additional Layers of Joint Compound: After the tape is applied and smoothed, apply additional layers of joint compound over the tape. Allow each layer to dry completely before applying the next. Sanding between layers will help achieve a smooth finish.

Can i use fiberglass tape on drywall

Yes, you can use fiberglass mesh tape on drywall, but it’s important to understand its proper application and limitations to ensure a durable finish.

✅ Advantages of Fiberglass Mesh Tape

- Self-Adhesive: Fiberglass mesh tape is self-adhesive, making it quicker and easier to apply compared to paper tape.

- Ideal for Patches: It’s particularly useful for patching small holes and cracks in drywall and plaster interiors .

⚠️ Limitations and Considerations

- Requires Setting-Type Compound: When using fiberglass mesh tape, it’s crucial to embed it with a setting-type joint compound (often referred to as “hot mud”). Using regular pre-mixed joint compound can lead to cracks over time .

- Not Ideal for Inside Corners: Mesh tape doesn’t fold easily, making it less suitable for inside corners. Paper tape, which has a crease for folding, is better suited for these areas .

- Potential for Cracking: If not applied correctly, especially without the appropriate compound, mesh tape can lead to joint cracks .

🛠️ Best Practices for Using Fiberglass Mesh Tape

- Surface Preparation: Ensure the drywall surface is clean and free of dust.

- Apply Mesh Tape: Place the self-adhesive mesh tape over the joints or cracks.

- Use Setting-Type Compound: Apply a setting-type joint compound over the tape, pressing it through the mesh to ensure proper adhesion.

- Finish with Regular Compound: Once the setting compound has dried, you can apply regular joint compound for the final coats, sanding between layers for a smooth finish.

🧰 Alternative: FibaFuse Tape

For those seeking a middle ground, FibaFuse tape is a non-woven fiberglass tape that combines the strength of fiberglass with the ease of paper tape. It can be used with both setting-type and regular joint compounds, offering flexibility and reduced risk of cracking .

In summary, while fiberglass mesh tape is suitable for certain drywall applications, especially quick patches, it’s essential to use it correctly with the appropriate compounds to prevent future issues. For comprehensive drywall projects, many professionals prefer paper tape or alternatives like FibaFuse for their reliability and finish quality.