Cellulosic Used For Textiles

Features

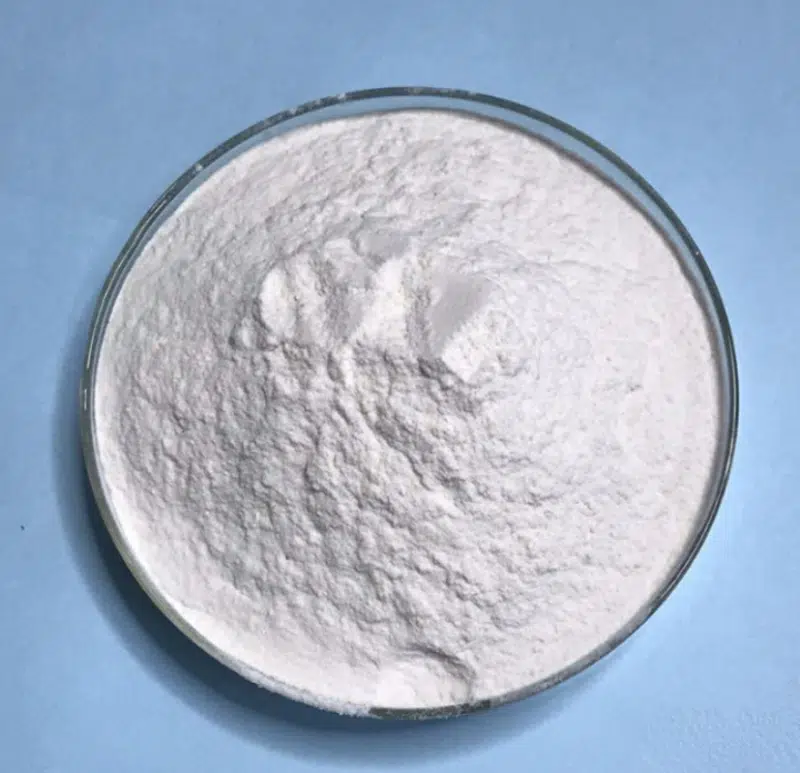

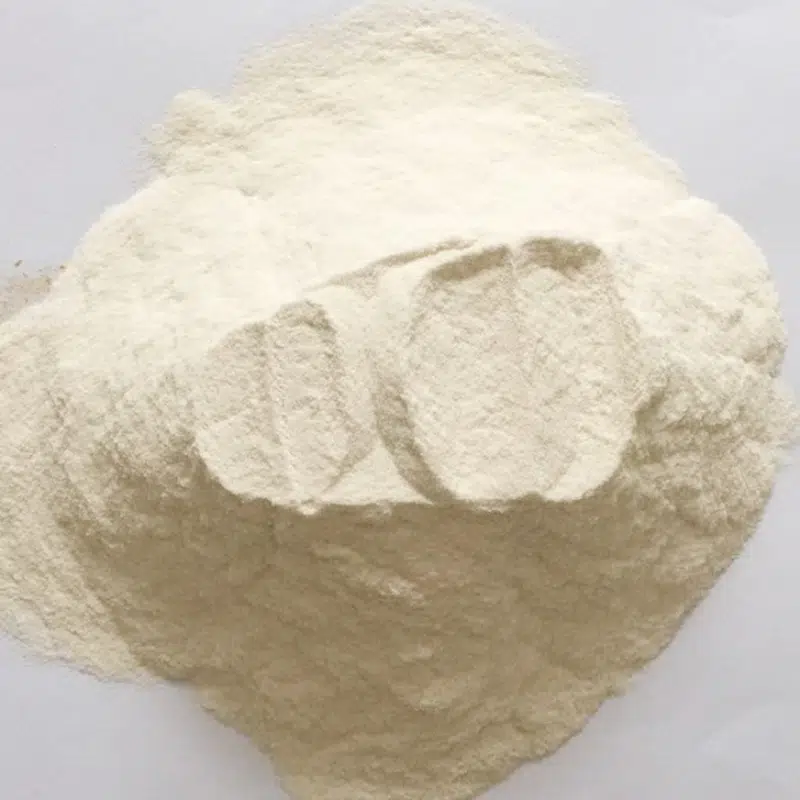

Textile cellulose, as a high-quality textile material derived from nature, presents a natural and pure white or light yellow appearance. The fibers are slender and uniform, with a warm and non glaring luster. Textile cellulose exhibits excellent strength and toughness, capable of withstanding high tensile forces, while also possessing good moisture absorption and breathability, keeping textiles dry and comfortable. Textile cellulose has stable alkali resistance, is easy to accept various dyeing treatments, and has bright and long-lasting colors that are not easily faded, adding rich color choices to textiles.

Market Prospects

With the increasing global emphasis on sustainable development and green consumption, textile cellulose, as an important alternative to traditional chemical fiber materials, continues to grow in demand in various fields such as clothing, home furnishings, healthcare, and environmental protection. Especially in the high-end textile market, textile cellulose has won the favor of more and more consumers with its unique texture, excellent comfort, and biodegradability.

Hydroxypropyl Methyl Cellulose Manufacturing Process

As one of the professional cellulose manufacturers,we select raw materials that are subjected to pre-treatment such as crushing and impurity removal to ensure their purity and suitability. Through advanced chemical or mechanical methods, we efficiently extract cellulose components while removing non target substances such as lignin and hemicellulose. Fine filtration, washing, and drying treatment are carried out on the extracted cellulose solution to obtain high-purity cellulose products. According to your needs, we may further crush, screen or modify cellulose to meet the requirements of different specifications and application scenarios, and carefully package textile cellulose that has undergone strict quality control and testing.

Use Precautions

Textile cellulose should be kept dry and ventilated during storage, avoiding moisture and high temperatures to ensure its stable performance. During the processing, please adjust the proportion and process parameters of textile cellulose reasonably according to your specific application scenario to achieve the best textile effect. Please pay attention to the compatibility of textile cellulose with other chemicals and avoid direct contact with harmful substances such as strong acids and bases to prevent damage to cellulose. To maintain the durability and aesthetics of textiles, it is recommended that you follow relevant guidelines during washing and maintenance, avoiding excessive scrubbing and high-temperature ironing.

●FREE SAMPLE

*Customization is always available, please mark down your need in cart or just contact us.

Project Monitoring

Shipping Order Track

Instructions for Use

VIP Customer Service

Intact Guarantee

Characteristics

- Natural And Glossy Appearance: Textile cellulose comes from plants in nature, such as cotton, hemp, bamboo, etc. These plant fibers are nourished by sunlight, rain, and dew during their growth process, forming a natural and pure appearance. Meanwhile, due to the ordered arrangement of the microstructure of cellulose, light undergoes diffuse reflection on the fiber surface, presenting a warm and glossy appearance. This appearance not only conforms to modern people’s pursuit of nature and environmental protection, but also adds unique charm to textiles.

- High Strength And Good Toughness: The high strength of textile cellulose is mainly due to the hydrogen bonding in its molecular structure of cellulose. Cellulose molecular chains are connected to each other through hydrogen bonds, forming a tight network structure. This structure enables fibers to uniformly disperse stress when subjected to external forces, thereby exhibiting high strength. Meanwhile, cellulose has good toughness and can resist deformation and fracture to a certain extent, ensuring the durability and stability of textiles.

- Excellent Moisture Absorption And Breathability: The moisture absorption and breathability of textile cellulose mainly come from the microporous structure inside its fibers. These micropores can quickly absorb and store moisture, allowing textiles to remain dry even in humid environments. At the same time, the presence of micropores also promotes the circulation of air between fibers, improves the breathability of textiles, and allows the human body to feel a more comfortable environment when wearing.

- Stable Chemical Properties And Easy Dyeability: Textile cellulose has stable chemical properties and can resist the erosion of chemicals such as acids and bases, mainly due to the hydroxyl (- OH) functional groups in its structure of cellulose. These functional cellulose can react chemically with dye molecules to form stable covalent bonds, allowing the dye to firmly adhere to the fiber and exhibit good dyeing performance. Meanwhile, the chemical stability of textile cellulose also ensures that textiles are not easily faded, deformed, or damaged during use.

Main Function

- Clothing And Textile Industry

- In the clothing and textile industry, textile cellulose is an indispensable core raw material. It has become the preferred material for making various high-end clothing due to its excellent moisture absorption, breathability, and comfort. From casual wear to formal wear, from children’s clothing to adult clothing, textile cellulose brings consumers the ultimate wearing experience with its natural luster and soft touch.

- Home Decoration Industry

- In the home decoration industry, textile cellulose has also demonstrated its unique charm. Whether it’s bedding, curtains, carpets, sofa covers, pillows, etc., textile cellulose can add warmth and elegance to the home environment with its rich colors, diverse patterns, and excellent durability. At the same time, its good breathability and moisture absorption also ensure the comfort and health of household products.

- Medical And Healthcare Industry

- In the medical and health industry, textile cellulose is widely used in the manufacturing of medical supplies such as medical dressings, surgical gowns, masks, etc. due to its sterile, non-toxic, and easy to disinfect characteristics. The excellent moisture absorption and breathability of textile cellulose help to keep wounds dry and clean, promote wound healing, and provide strong support for the healthy development of the medical industry.

- Environmental Protection And Sustainable Development Industry

- In the field of environmental protection and sustainable development, textile cellulose, as a biodegradable material, is gradually becoming an important choice to replace traditional plastics. It can be used to make shopping bags, packaging materials, agricultural coverings, etc., which not only reduces environmental pollution but also promotes the recycling of resources. The characteristic of textile cellulose fully meets the urgent global demand for environmental protection and sustainable development.

- Industrial and construction industry

- Textile cellulose also plays an important role in the industrial and construction industries. It can be used as a reinforcement material in the manufacturing of building materials such as concrete and gypsum board, improving the strength and durability of the materials. Meanwhile, textile cellulose can also be used to make filtering materials, sound insulation materials, thermal insulation cellulose, etc., providing strong guarantees for industrial production and building safety.

Appearance | White or yellowish powder |

Molar substitution degree M.S | 1.5-2.5 |

Fineness /% | 80 mesh sieve residue≤8.0 |

Purity | 100% |

Dry weight loss rate /% | ≤6.0 |

Ash/% | ≤10.0 |

Viscosity /MPa·S | 100.0 – 5500.0 (annotated value±20%) |

PH value | 5.0-9.0 |

Grade | Industrail Grade |

Classification | Chemical Auxiliary Agent |

Place of origin | Jiangsu |

Sample | Availiable |

Light transmittance /% | ≥80 |