Professional Cellulose Ether Manufacturer in China

✅️ 16 years of global production and sales experience

✅️ Cellulose Ether Factory in China, complete supply chain system

✅️ Cellulose ether annual production capacity of 50,000, to provide a stable supply, fast delivery

✅️ 98.2% customer satisfaction, NQ professional team do our best to meet your needs

Your Reliable Cellulose Products Manufacturer

NQ is an influential cellulose ether manufacturer in China. We are committed to the research, development, production and sales of hpmc, hemc and hec. High-quality products and first-class services make us do better!

√ Production base

Our company has 2 production bases with an annual capacity of 70,000 tons each.

√ Quality Control

We strictly control the quality of products at every production stage from procurement to export.

√ Innovation

We have at least three technical research laboratories, and we also have a team of technology advisors from the top domestic research centers.

Warehouse & Factory

Total Annual Revenue

Skilled Worker

Choose Your Cellulose Products

Our cellulose products perform all kinds of different functions in the various fields of applications. Our additives have been widely used in a variety of industries such as building and construction, home and personal care.

Cellulose Packaging Information

We offer customized packaging solutions tailored to your specific needs, ensuring that your products are delivered securely and efficiently. Contact us now to discuss your customized needs!

HPMC: 25 kg/bag

MHEC: 25 kg/bag

HEMC: 25 kg/bag

HEC: 25 kg/bag

CMC: 25 kg/bag

HPS: 25 kg/bag

VAE: 25 kg/bag

PVA: 25 kg/bag

Industry-Tailored Cellulose Ether Innovations

Cellulose for File

Cellulose ethers (e.g., HPMC, MHEC) and Redispersible Polymer Powder (RDP) are part of the tile adhesive formulation to improve product efficiency and performance.

Cellulose for Wall

Cement based render ensures top quality and high efficiencies when applied to projects sites in terms of tensil strength, crack resistance,workability, sag resistence and more.

Cellulose for Detergent

Widely used in daily care chemicals and detergents. They can provide good dispersion, thickening effect, good compatibility and highly transparent.

Cellulose for Pharma

It can be used in various applications, including tablets, capsules, oral liquids, and ophthalmic preparations.

Cellulose for Paint

It has excellent biostability and high pigment compatibility so to improve the stability of viscosity and dissolution of water based paints.

Cellulose for Food

Used in baking, dairy substitutes, beverages, and frozen foods.

Cellulose Spectification

| Brand Name | NQ |

| Product Name | Cellulose |

| Material | Refined Cotton |

| Type | Powder |

| Classification | Chemical Auxiliary Agent |

| Storage | In The Shade |

| Function | Thickening Agent |

| Application | Construction industrial, food grade, daily chemicals |

| Moisture | 5% Max |

| MP | 274 °C (dec.) |

| PH | 6.0-8.0 |

| Heavy Metal | 10PPM |

| Viscosity | 400-200000 Mpa.s |

| Appearance | White Powder |

| Usage | Electronics Chemicals, Paper Chemicals, Rubber Auxiliary Agents, Textile Auxiliary Agents, Chemical Auxiliary Agentr |

| Purity | 99.90% |

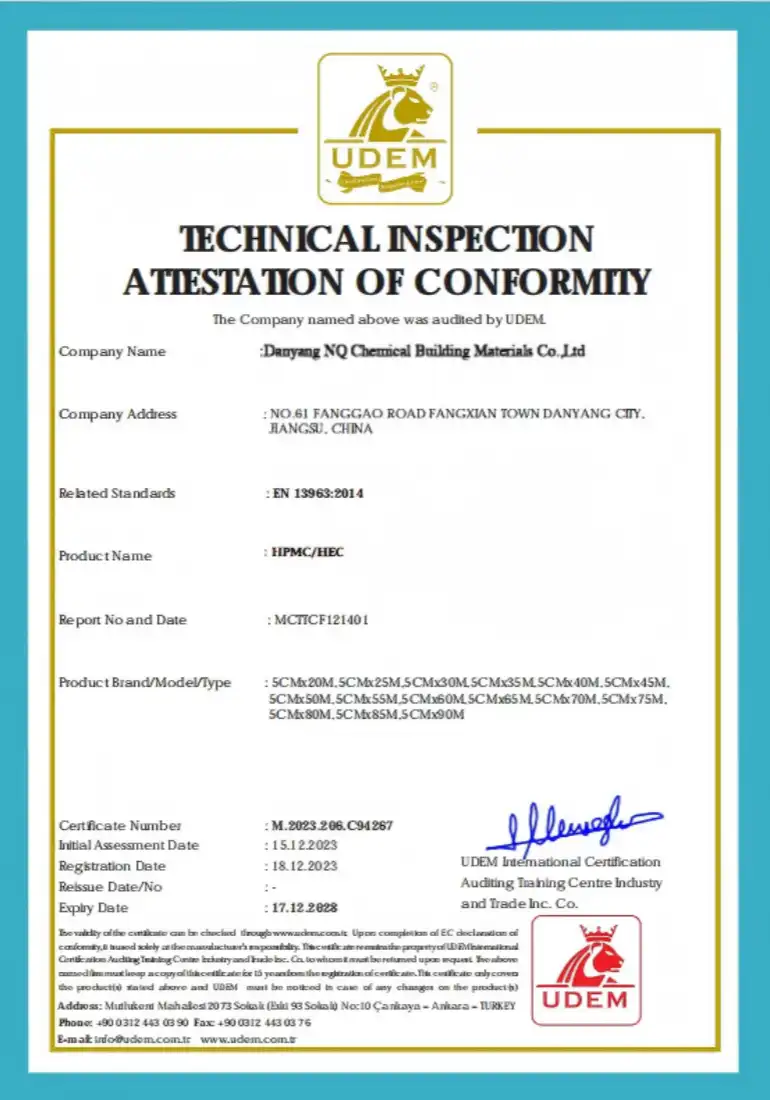

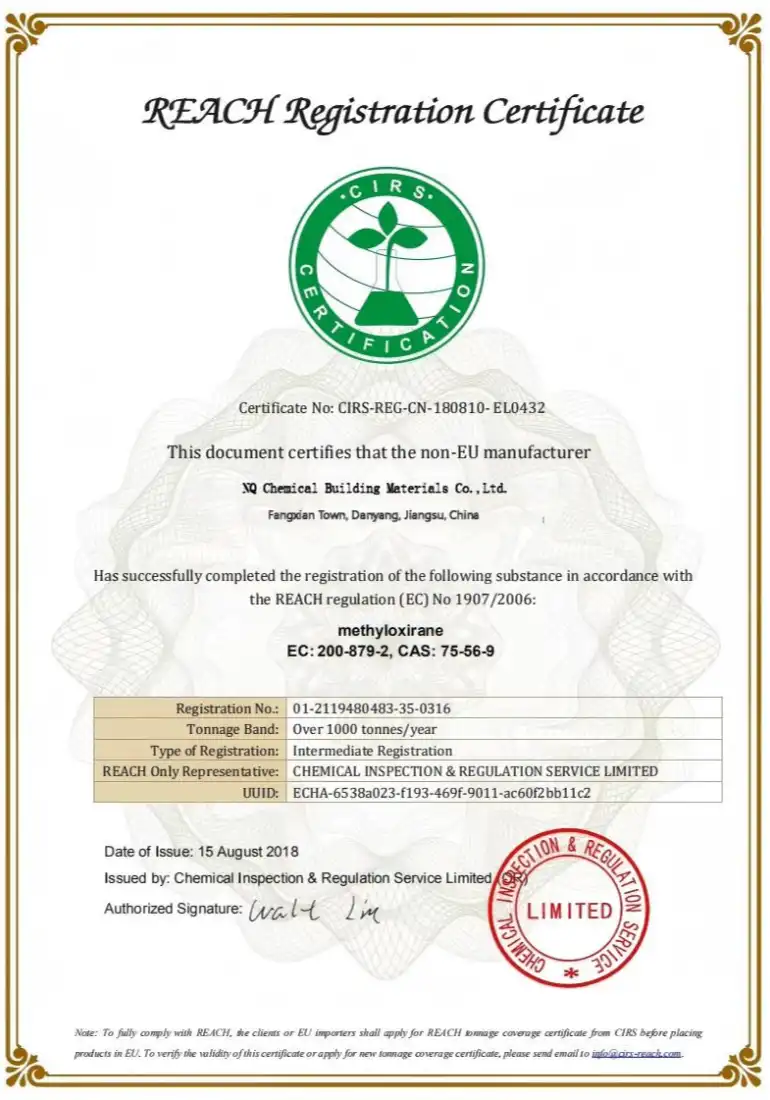

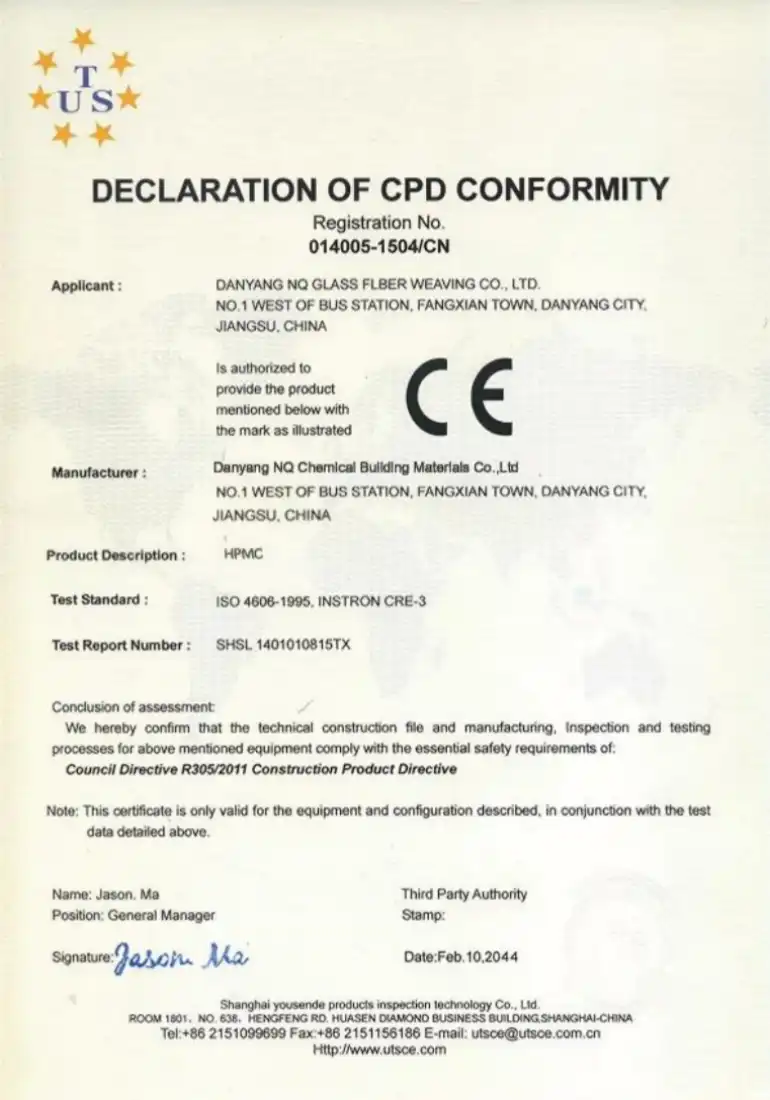

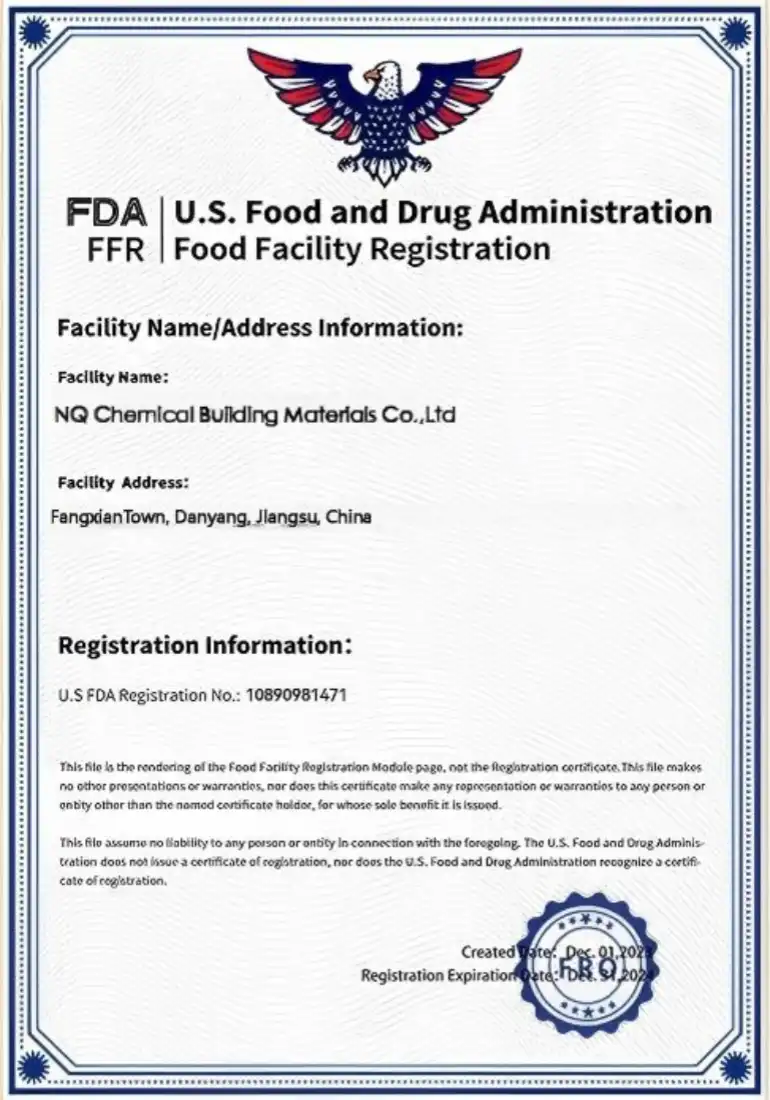

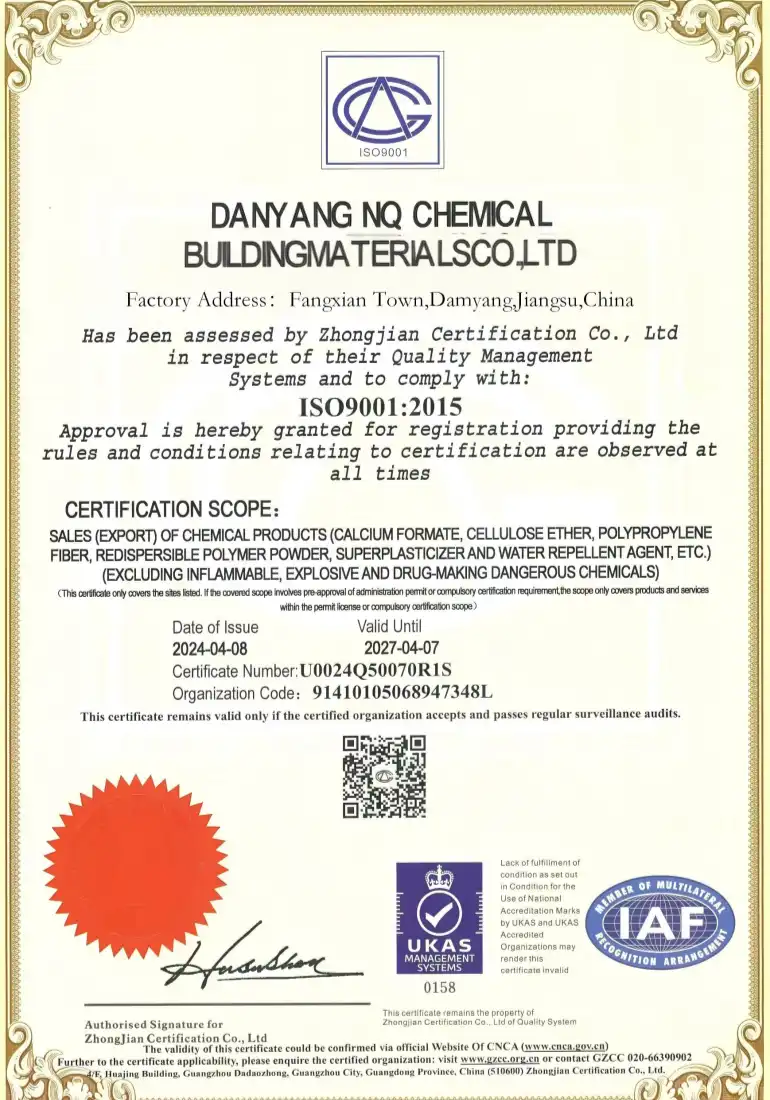

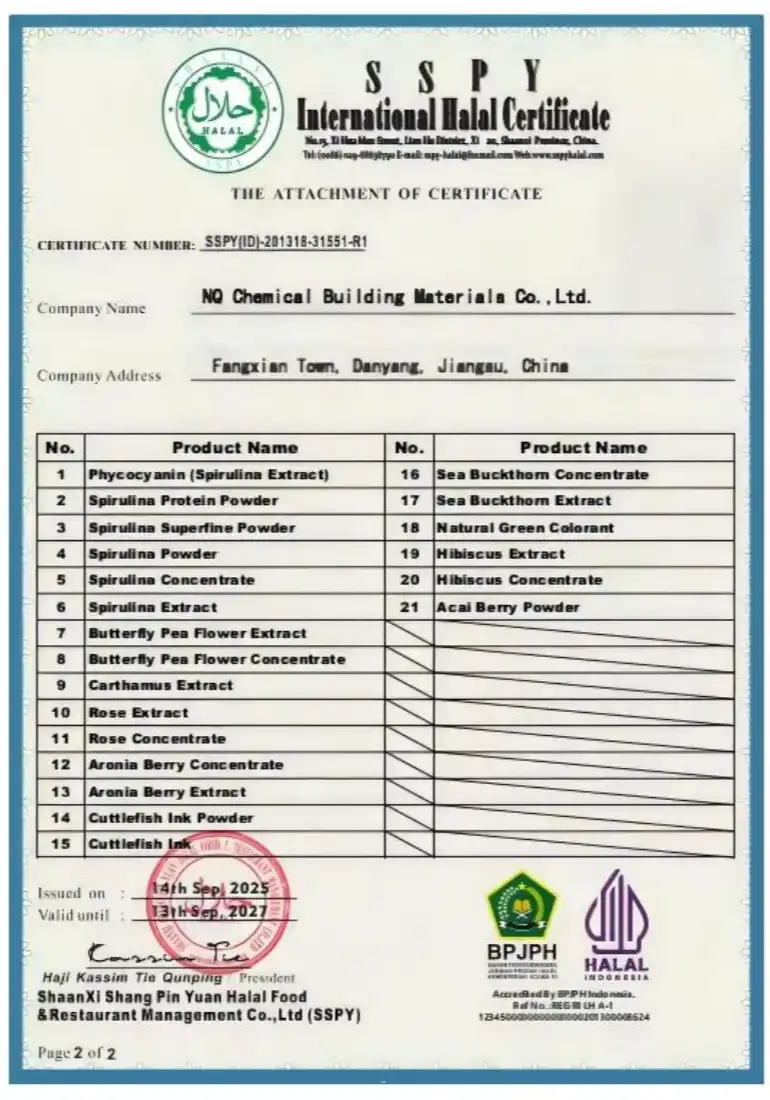

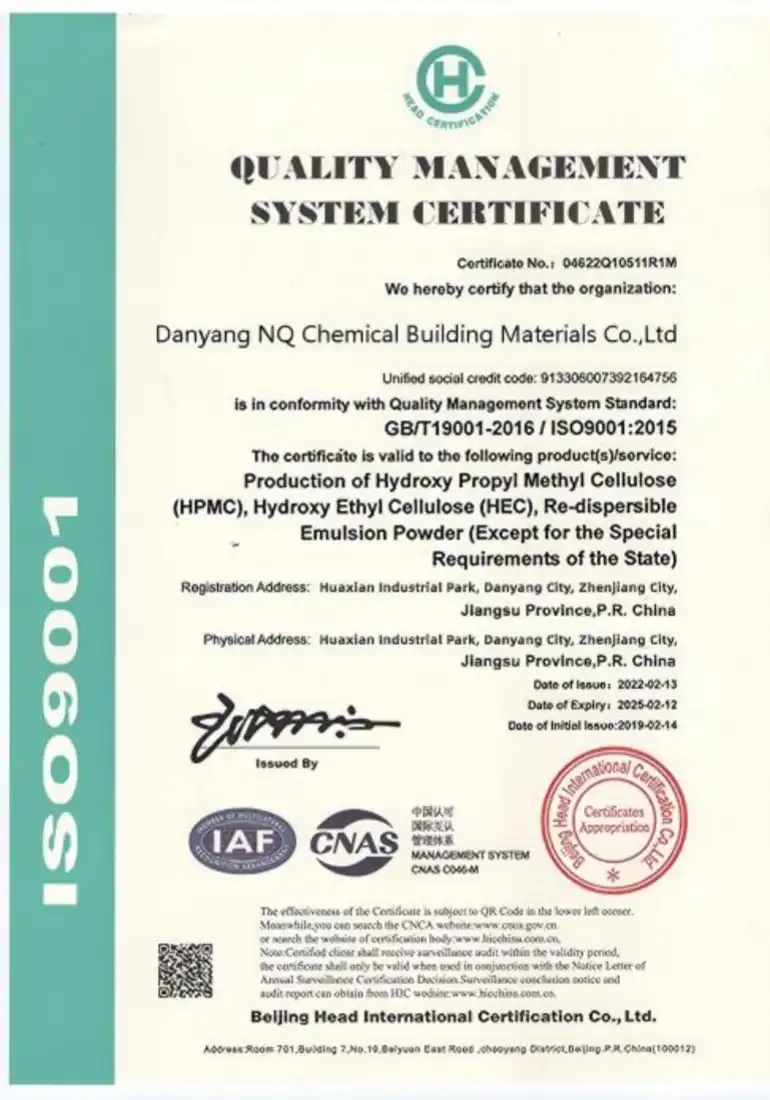

| Certification | CE, ASTM, SGS, ISO, BSCI |

| Sample | Availiable |

| Place of Origin | Jiangsu, China |

Cellulose Production Process

1

Raw Material Selection

We select high-quality cellulose raw materials like wood, cotton, and bamboo, and perform pre-treatment to enhance purity and efficiency. This reduces impurities, improving product stability and reliability, ultimately providing you with superior cellulose products tailored to your needs.

2

Crushing & Classification

Use a hammer mill to crush the impurity-free raw materials into 0.5 – 2 cm fragments. Through multiple layers of vibrating screens, perform particle size classification; large fragments are returned for re-grinding, while small debris is collected separately to ensure that the particle size deviation is ≤ 0.3 cm.

3

Pre-treatment

Pre-dry the sorted materials with hot air at low temperature, precisely adjust the moisture content, industrial grade controlled at 12% – 14%, food grade at 10% – 12%; the materials are conveyed by a closed belt conveyor, reducing dust loss and secondary pollution.

4

Steaming & degumming

The materials are put into the cooking tank, with a ratio of alkali solution or neutral sulfite solution according to the grade, liquid-to-solid ratio 3:1 – 4:1; cook at 130 – 150℃, 0.3 – 0.5 MPa for 2.5 – 3.5 hours, after dissociating cellulose, depressurize and cool down, the waste liquid is collected and reused.

5

Filtration & Washing

The thick slurry is washed 3 – 4 times in counter-flow with clean water by a continuous washing machine, until the corresponding pH value is reached, then undergo solid-liquid separation by a vacuum coarse filter to obtain a wet coarse cellulose filter cake with a moisture content of 65% – 70%.

6

Bleaching & Purification

Use chlorine dioxide or hydrogen peroxide with no residual bleaching process, stir and react at a constant temperature and pH value; after bleaching, rinse with clean water 3 times, filtered through a plate and frame fine filter machine, the finished cellulose has a whiteness of ≥ 88% and purity of ≥ 95%.

7

Drying & Dust Removal

Industrial-grade drum dryers and food-grade vacuum dryers both operate at low temperatures to avoid damaging the fiber structure. After drying, they undergo pulse bag dust removal. For food-grade models, additional sterile air dust removal is also provided to completely remove dust from the materials.

8

Packing for storage

The packaged cellulose is sent to a constant temperature and humidity warehouse (temperature 20~25℃, humidity ≤60%), and is stored in sections by grade and specification. An warehousing ledger is established to facilitate traceability.

Why Choose Us As Your Partner?

Numerous Customers

Serving 2,000 customers in China, NQ will be registered as a new brand in August 2022 and promoted to the world.

Abundant Products

In order to meet the different application needs of customers around the world, our products are divided into twelve series.

Technical Strength

The technicians are the first batch of scientific research personnel of state-owned enterprises in China, a strong R & D team.

Productive Capacity

Manufacturing factory has an annual production capacity of 50,000MT of MC (HPMC/HEMC) plus 4,000MT of HEc.

Quality Control

NQ cellulose is ISO 9001:2000 certified and has its laboratory for quality control.We strictly guarantee the quality of our products.

Export Standard

The most advanced horizontal reactor and quality testing equipment have reached the EU factory standard.

Hear From Our Clients

Our clients love working with us, just read what they have to say!

Get Brochures of NQ Chemical

You ask, we answer

Some questions that customers often ask about our company

Our MOQ is usually 1x20ft container.But we accept lower quantity for your trial order. Please feel free to inform us your plan for purchasing, we will offer the price correspond to your qty. And we hope your would increase your order qty after you check ourproduct quality and know our services.

We ship the goods via Shanghai port.

The time of delivery is about 20~30days after we receive the deposit.

Usually we will take 7-10 days to make the samples.

By sea to your designated port.

1. Irrevocable L/C, Cash, PayPal, Credit card and T/T money transfers.

2.30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo.

3.L/C ( Irrevocable LC at sight)

If you need custom size such as gram weight and mesh size etc or private logo pls feel free inquiry us!

FAQ

What is cellulose powder?

Cellulose powder is a fine, white, odorless powder made from cellulose, which is a natural polymer found in the cell walls of plants. It is often derived from wood pulp or cotton. Cellulose powder is used in various applications, including:

- Food Industry: As a food additive, it acts as a thickener, stabilizer, or anti-caking agent.

- Pharmaceuticals: Used as a filler or binder in tablets and capsules.

- Cosmetics: Serves as a thickening agent or bulking agent in lotions and creams.

- Industrial Uses: Utilized in the production of paper, textiles, and as a component in some biodegradable plastics.

Cellulose powder is non-digestible by humans, making it a source of dietary fiber when consumed in foods.

Is cellulose a carbohydrate?

Yes, cellulose is a carbohydrate. Specifically, it is a polysaccharide made up of long chains of glucose molecules linked together. Unlike other carbohydrates, humans cannot digest cellulose, which is why it acts as a source of dietary fiber.

What is cellulose used for?

Cellulose is used in various applications, including:

- Food Industry: As a thickener, stabilizer, and anti-caking agent.

- Pharmaceuticals: In tablet and capsule production as a binder or filler.

- Cosmetics: As a thickening agent in creams and lotions.

- Paper and Textiles: In the production of paper products and fabrics.

- Biofuels: As a raw material for producing renewable energy sources.

- Building Materials: In insulation and other construction applications.

These uses highlight cellulose’s versatility across different industries.

What is cellulose insulation?

Cellulose insulation is a type of thermal and acoustic insulation made from recycled paper products, primarily newsprint, which is treated with fire-retardant chemicals. It is typically used in buildings to improve energy efficiency and reduce noise.

- Key features of cellulose insulation include:

- Sustainability: Made from recycled materials, making it an environmentally friendly option.

- Effective Insulation: Offers good thermal resistance (R-value), helping to maintain consistent indoor temperatures.

- Air Quality: Can help improve indoor air quality by reducing drafts and air leaks.

- Soundproofing: Provides good acoustic insulation, reducing noise transfer between rooms.

Cellulose insulation can be installed in attics, walls, and floors, often using blown-in or dense-pack techniques.

Is cellulose a polymer?

Yes, cellulose is a polymer. It is a polysaccharide, which means it is made up of long chains of repeating units (monomers) of glucose. These chains are linked together by β-1,4-glycosidic bonds, forming a rigid and structural component in the cell walls of plants. Cellulose is the most abundant organic polymer on Earth and plays a crucial role in providing structural support to plants.

Is cellulose insulation safe?

Yes, cellulose insulation is generally considered safe when properly installed. It is made from recycled paper and treated with fire-retardant chemicals to reduce flammability. However, like any insulation material, safety depends on proper installation and adherence to building codes.

- Key safety aspects include:

- Fire Resistance: Treated with fire-retardants, it is less likely to ignite.

- Non-Toxic: Made from natural materials, it poses minimal health risks.

- Dust Control: During installation, proper precautions should be taken to limit dust exposure.

Overall, when handled and installed correctly, cellulose insulation is a safe and effective choice.

What is the function of cellulose?

Cellulose serves several essential functions, particularly in plants:

- Structural Support: It provides rigidity and strength to plant cell walls, helping maintain their shape and integrity.

- Protection: Cellulose helps protect plants from pathogens and physical damage.

- Water Regulation: It plays a role in regulating water uptake and retention within plant cells.

- Dietary Fiber: In human diets, cellulose acts as a source of dietary fiber, promoting digestive health.

Overall, cellulose is crucial for plant structure and function, as well as having significant benefits in human nutrition.

What is vegetable cellulose?

Vegetable cellulose refers to cellulose derived specifically from plant sources, typically from fruits, vegetables, or other plant materials. It is a natural, plant-based fiber that is often used in food products, pharmaceuticals, and cosmetics.

- Key features include:

- Food Additive: Used as a thickener, stabilizer, or bulking agent in various food products.

- Dietary Fiber: Contributes to dietary fiber intake, aiding digestion.

- Plant Source: It can be extracted from a variety of vegetables, such as carrots, or from wood pulp.

Vegetable cellulose is valued for its versatility and natural origins, making it a popular ingredient in health-conscious products.

What category is cellulose?

Cellulose is classified as a polysaccharide, which is a type of carbohydrate. Specifically, it is a structural polysaccharide found in the cell walls of plants. As a polymer made up of glucose monomers linked by β-1,4-glycosidic bonds, it plays a crucial role in providing strength and rigidity to plant structures.

What is the basic difference between starch and cellulose?

The main difference between starch and cellulose is in their linkage because the glucose units in starch are connected by α- linkages, and that the glucose units in cellulose are connected by β- linkages.

Is microcrystalline cellulose a natural ingredient?

Yes, microcrystalline cellulose (MCC) is considered a natural ingredient. It is derived from cellulose, which is extracted from plant materials, primarily wood pulp or cotton. MCC is processed to create a fine, white powder that is commonly used as a bulking agent, stabilizer, or thickener in food, pharmaceuticals, and cosmetics.

Is fiber cellulose?

Cellulose is a type of fiber that makes up the cell walls of plants. When you consume plant foods, you are eating cellulose. Many other foods, ranging from shredded cheese to low calorie or diet foods, have added cellulose to help with different properties. Cellulose also exists in supplement form.

Is cellulose a starch or not?

There is one major difference between Starch and Cellulose. For starch, glucose repeat units are located in the same direction, and each successive glucose unit is rotated 180 degrees in cellulose. Cellulose is thicker than sugar, which is water-insoluble.

What is the source of cellulose?

Although the primary occurrence of cellulose is the existing material in forests with wood as the most important source, cellulose-containing materials include agricultural residues, water plants, grasses, and other plant substances.

Is cellulose a complex carbohydrate?

Cellulose is classified as a complex carbohydrate since it has more than two units of sugar linked together. Cellulose is a polysaccharide. This suggests it’s made up of smaller, interconnected units.

Is it healthy to eat cellulose?

Cellulose is a safe and inexpensive carbohydrate that comprises the woody parts and cell walls of plants. It is a type of dietary fiber found naturally in fruits, vegetables, and cereals.

Is methyl cellulose safe in food?

While methyl cellulose is generally considered safe, there are some potential risks associated with its use in food products. One of the most significant risks is that it can cause digestive issues such as bloating, gas, and diarrhea in some individuals.

What is a cellulose fiber?

Cellulose or cellulosic fibers are fibers structured from cellulose, a starch-like carbohydrate. They are created by dissolving natural materials such as cellulose or wood pulp, which are then regenerated by extrusion and precipitation.

Get Your Quote

What delivery did you have in mind? Fill in the details below to receive a quote.

Welcome to Danyang NQ Chemical Building Materials Co. Ltd! We are a professional manufacturer and exporter with over 16 years of experience. Our main products include cellulose ethers like HPMC/HEMC/HEC and so on.

Contact Us

- Phone: +86-13775339109

- Whatsapp: 0086-13775339109

- mail: txybbf@gmail.com

- Address: Fangxian Town, Danyang, Jiangsu, China

Join Us

Get updates on special events and receive your up-to-date information on us!