- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

Table of Contents

ToggleCarbon fiber has become a go-to material in industries like aerospace, automotive, marine, and sports. Its appeal comes from a unique balance of lightweight strength, rigidity, and durability. Unlike metals that add weight and are prone to corrosion, carbon fiber enables the creation of stronger, lighter, and more efficient structures. This guide explains what carbon fiber is, how it’s made, how it compares to fiberglass and metals, and where it’s most effectively used.

Carbon fiber is a high-performance composite material composed of thin crystalline filaments of carbon atoms. These filaments, each about 5–10 microns in diameter, are bonded together in a parallel alignment that gives them extraordinary strength and stiffness. When combined with a polymer matrix, typically epoxy or polyester resin, carbon fiber composites provide mechanical performance that surpasses most metals while remaining significantly lighter.

The exceptional performance of carbon fiber materials is the result of a complex and energy-intensive carbon fiber manufacturing process, where each step contributes to the final material properties.

Most high-performance carbon fibers originate from polyacrylonitrile (PAN), while pitch- and rayon-based precursors serve more specialized needs. PAN-based carbon fiber materials dominate the industry due to their superior balance of strength, flexibility, and cost-efficiency.

The precursor fibers, including high performance carbon fibers, undergo chemical treatment in air at temperatures up to 300°C, ensuring they are thermally stable and resistant to melting.

During the carbon fiber manufacturing process, fibers are heated in an inert, oxygen-free atmosphere at 1000–3000°C, expelling non-carbon atoms and resulting in strong, high-performance carbon fibers.

At the highest grades, additional heat treatment aligns the carbon atoms into crystalline structures, enhancing the mechanical properties of high performance carbon fibers. Surface treatments improve adhesion to resins, ensuring the carbon fiber material bonds effectively when incorporated into composite parts.

Carbon filaments, including high performance carbon fibers, are woven into cloths or formed into unidirectional tapes. These are then impregnated with resin systems to create advanced carbon fiber composites used in structural applications.

The table below highlights the performance of high performance carbon fibers compared to traditional engineering metals.

Feature | Carbon Fiber | Steel | Aluminum | Titanium |

Strength | Very High | High | Medium | Very High |

Weight | Very Low | High | Low | Low |

Corrosion Resistance | Excellent | Poor | Moderate | Excellent |

Cost | High | Low | Low | Very High |

Fiberglass is often considered the entry-level composite material, while high performance carbon fibers offer significant performance differences for more demanding applications.

Feature | Carbon Fiber | Fiberglass |

Strength | Very High | Moderate |

Weight | Very Low | Low |

Stiffness | Very High | Moderate |

Durability | Excellent | Good |

Cost | High | Low |

Budget-driven projects

Non-critical components

Applications where weight reduction is less critical

Aerospace or advanced automotive components

Structural applications demanding a high strength-to-weight ratio

Long-term use in harsh operating environments

Carbon fiber’s versatility enables its integration across diverse sectors, particularly in high performance carbon fibers and advanced carbon fiber materials.

Aircraft fuselages, wings, and interior components

Unmanned aerial vehicle (UAV) structures

Satellite components requiring lightweight durability

Performance car chassis, body panels, and crash structures

Electric vehicle structural elements to offset heavy battery packs

Motorsport components where speed and weight reduction are critical

Racing bicycles, tennis rackets, golf clubs

Surfboards, skis, and snowboards

Protective sports equipment

Yacht masts and hull reinforcements

Lightweight racing boats

Paddleboards and kayaks

Prosthetics with enhanced mobility

Surgical instruments requiring precision and strength

Imaging equipment housings where non-magnetic materials are essential

Reinforced pipelines and pressure vessels

Robotics arms and automation systems

Wind turbine blades for renewable energy

Fiberglass cloth, while less advanced than high performance carbon fibers, remains one of the most widely used reinforcement materials in construction, automotive repair, and industrial applications due to its excellent balance of affordability and mechanical properties.

Strong and durable at a fraction of the cost of carbon fiber

Simple to cut, shape, and layer, making it DIY- and industry-friendly

Resistant to corrosion, moisture, and heat exposure

Available in multiple weaves, densities, and finishes for different applications

Boat hull and automotive panel repairs

Roofing reinforcement and insulation support

Pipe, tank, and general construction reinforcement

Pro Tip

For maximum performance, combine fiberglass cloth with epoxy resin rather than polyester resin. Epoxy bonds more effectively, creating stronger and more durable waterproof reinforcements.

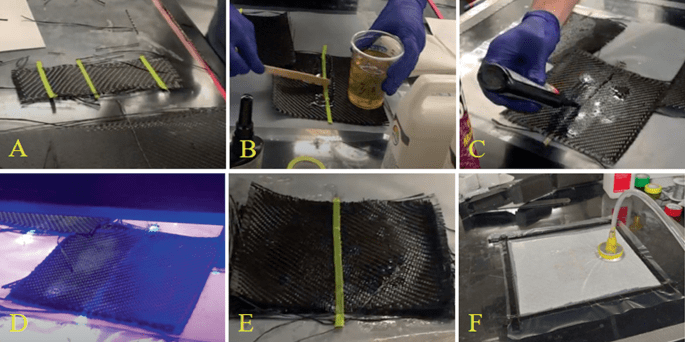

Materials You’ll Need:

Repair Process:

Whether you’re building high-performance vehicles, sports equipment, or industrial structures, carbon fiber offers an unmatched strength-to-weight ratio, stiffness, and durability. For more budget-friendly reinforcement, fiberglass cloth provides a strong and versatile alternative.

By understanding material properties, applications, and costs, you can make smarter decisions for your projects and ensure long-lasting, reliable results.

Connect with an NQ expert to discuss your product needs and get started on your project.

Q1: What are the main types of carbon fiber materials?

A: The main types are PAN-based, pitch-based, and rayon-based. PAN-based is the most common, offering an excellent balance of strength and flexibility. Pitch-based fibers provide extreme stiffness, while rayon-based fibers are rare and used for niche applications.

Q2: Is carbon fiber stronger than steel?

A: Yes. For its weight, high-performance carbon fibers can be up to five times stronger than steel while being significantly lighter.

Q3: Why is carbon fiber more expensive than other materials?

A: The high cost comes from the energy-intensive and complex carbon fiber manufacturing process—heating precursors to up to 3,000 °C in controlled environments, followed by meticulous layering, curing, and finishing. Skilled labor and precision tooling further contribute to the premium price.

Q4: Can fiberglass replace carbon fiber?

A: Fiberglass is cheaper and easier to work with but offers lower strength and stiffness. For high-performance or load-bearing applications, advanced carbon fiber is preferred.

Q5: What is fiberglass cloth used for?

A: Fiberglass cloth is commonly used in marine, automotive, construction, and industrial repairs, offering good strength and corrosion resistance at low cost.

Q6: How do I choose between fiberglass and carbon fiber?

A: Choose fiberglass for cost-sensitive, non-critical projects. Choose carbon fiber when you need maximum performance, long-term durability, and lightweight efficiency.