- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

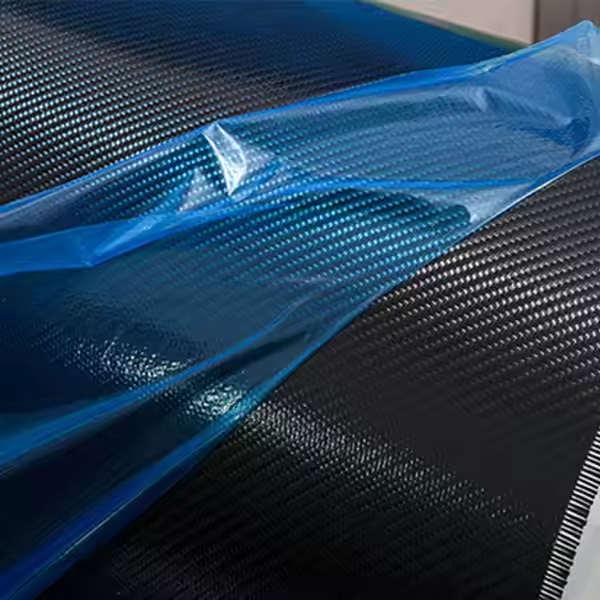

NQ has established itself as a prominent provider of prepreg composites for over 16 years. Our carbon fiber prepregs are designed for ease of use while maintaining the strength, durability, and reliability that clients expect from carbon fiber materials. We are dedicated to fulfilling the diverse needs of our clients across various industries and capacities.We offer a range of products, including rolls, sheets, and pre-cut segments, accommodating orders of all sizes. Whether you are a hobbyist in need of a single roll or a fabricator requiring large quantities of custom materials, we are committed to meeting your specific requirements.

Please note our minimum order quantity for Carbon Fiber Fabric. For different specifications of Carbon Fiber Fabric, the MOQ is different. For customized Carbon Fiber Fabric, due to different customization requirements, the MOQ needs to be confirmed according to the actual situation.

NQ factories can customize different widths and lengths according to project needs to ensure optimal use of materials.

There is also flexibility in the packaging, which can be customized according to customer requirements, including packaging materials, labels, printing, etc., to meet the needs of different projects.

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

Product name | Carbon fiber prepreg |

Material | Carbon fiber+epoxy resin |

Shape | Carbon rod |

Dimensions | Customized |

Thickness | Lightweight |

Weight | 60gsm-600gsm |

Surface | Smooth |

Style | Twill, Plain, Cross, UD |

Yarn Type | 3k 6k 12k 24K |

Size | Customized size |

Feature | Light weight/ high strength |

Technology | Hot-melt |

OEM service | Accepted |

Product type | Carbon fiber |

Curing temperature | 150℃ |

Storage temperature | < -18℃ |

Sample | Avaialble |

Application | Electronics/Sports Product/Automobile |

Package | Carton box |

Place of origin | Jiangsu,China |

For more product specifications, please contact our professionals!

Enhance Performance, Simplify Processing, Reduce Costs

Choose Carbon Fiber Fabric for exceptional strength and stability that elevates your product quality. Streamline your manufacturing, cut production time, and gain a competitive edge today!