- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

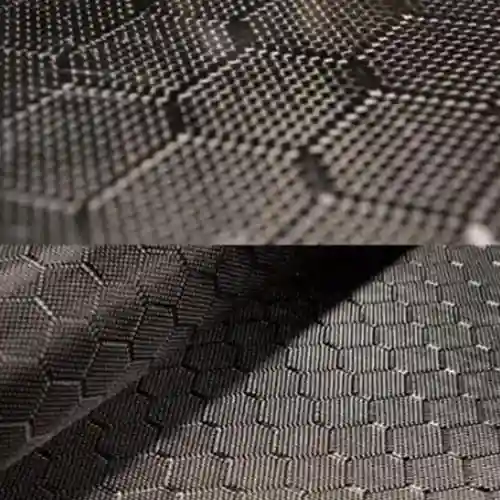

Carbon Fiber Pattern Fabric offers customizable color options beyond the classic black, allowing for personalized aesthetics in various applications. Through special dyeing techniques or hybrid yarn weaving, colors such as red, blue, gold, and silver can be integrated while maintaining the fabric’s signature carbon fiber look and high-performance properties. This customization enhances design flexibility for automotive, sports, fashion, and consumer electronics industries.

Please note our minimum order quantity for Carbon Fiber Fabric. For different specifications of Carbon Fiber Fabric, the MOQ is different. For customized Carbon Fiber Fabric, due to different customization requirements, the MOQ needs to be confirmed according to the actual situation.

NQ factories can customize different widths and lengths according to project needs to ensure optimal use of materials.

There is also flexibility in the packaging, which can be customized according to customer requirements, including packaging materials, labels, printing, etc., to meet the needs of different projects.

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

| Parameter | Specification Details |

|---|---|

| Model Range | NQ-TW200 (Twill) / NQ-PL300 (Plain) / NQ-HB400 (Herringbone) / NQ-DM600 (Diamond), etc. |

| Areal Weight | 200 g/m² to 600 g/m² (customizable) |

| Thickness | 0.25 mm to 0.70 mm, depending on yarn spec and weave density |

| Width Options | Standard widths: 1000 mm / 1270 mm / 1500 mm; custom widths available |

| Fiber Type | 3K / 6K / 12K high-strength PAN-based carbon fiber |

| Pattern Types | Twill, Plain, Herringbone, Honeycomb, Diamond, and other custom patterns |

| Color Options | Standard carbon black; optional red, blue, metallic, or custom-colored finishes |

| Resin Compatibility | Epoxy, Polyester, Vinyl Ester |

| Process Adaptability | Suitable for hand lay-up, hot press, RTM, vacuum infusion, and other composite processes |

| Roll Length | Standard 50–100 meters per roll; custom lengths and packaging available |

For more product specifications, please contact our professionals!

Enhance Performance, Simplify Processing, Reduce Costs

Choose Carbon Fiber Fabric for exceptional strength and stability that elevates your product quality. Streamline your manufacturing, cut production time, and gain a competitive edge today!