China Carbon Fiber Mat Factory & Manufacturer

- 16 years + of manufacturing experience.

- OEM&ODM, fast delivery.

- Custom logo & package.

- Free sample & wholesale price.

- CE, ASTM, SGS, ISO, BSCI and other related certifications.

years

Manufacturing Experience

Projects

We had finished

Clients

Over the world

Satisfaction

Wholesale CARBON FIBER MAT IN CHINA

NQ is a leading manufacturer of carbon fiber mat, with advanced production equipment and technical team,ensure that the product has high strength, high modulus, and excellent heat resistance.Our products are high-performance, diverse, customized, and widely used in fields such as aerospace, automotive manufacturing, new energy, and chemical engineering.

Advanced Carbon Fiber Air Laid Net Machine

NQ’s carbon fiber air laying machine is made of high quality fiber material, which has the advantages of high production efficiency, strong controllability, environmental protection and energy saving, and wide applicability.

Powerful Production Scale

Our factory has various kinds of punching needle production lines 3, 6 weaving production lines and other high-end equipment, combined with innovative technology and high-quality raw materials, to achieve efficient and standardized production of carbon fiber MATS.

Rigorous Quality Control

NQ has established a strict and comprehensive quality control system, carefully selecting and rigorously controlling every step from raw material procurement to finished product delivery. All carbon fiber mat products have passed CE, ASTM, SGS, and BSC certifications, ensuring that the stability and consistency of the products reach industry-leading levels.

Professional

Advanced manufacturing technology

High Quality

High quality CE, ASTM, SGS, ISO, BSCI certification

Cost Effective

Direct factory price

Customized

Different sizes, colors, designs, OEM/ODM

Service

Excellent customer service

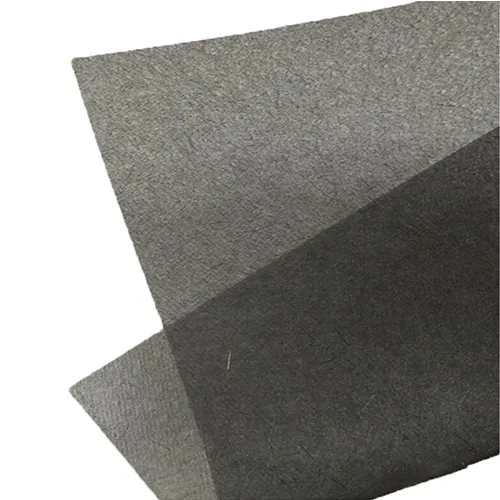

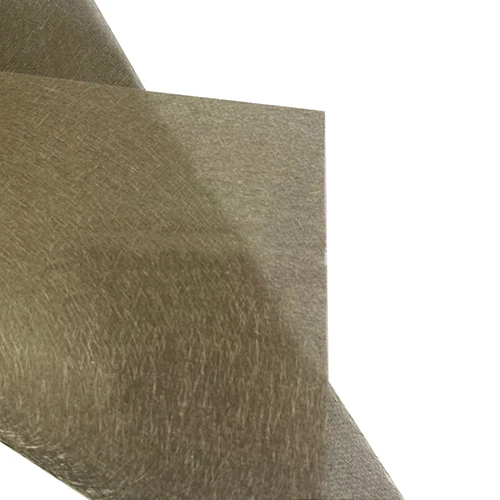

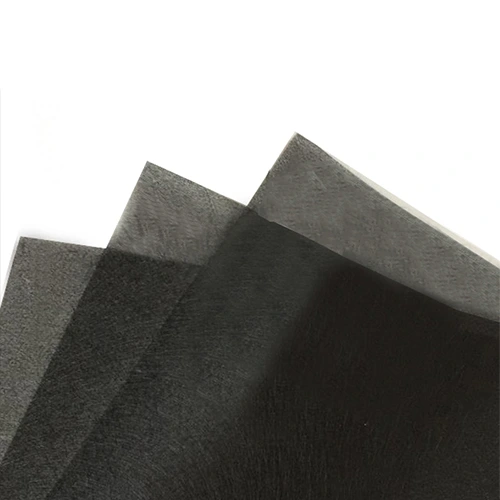

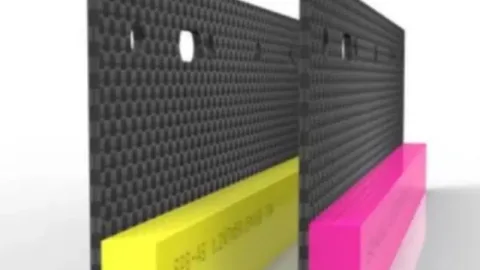

HOT SELLING CARBON FIBER MAT SERIES

NQ presents a diverse selection of Carbon Fiber Mat products, renowned for their featherweight, impeccable smoothness, robust modulus, unparalleled strength, exceptional rigidity, resistance to extreme temperatures, thermoplastic adaptability, and resilience to corrosion.These mats find applications in various industries, including aerospace engineering, automotive production, structural reinforcement in buildings, protective clothing, interior design, bulletproof applications, wall restoration, and numerous other domains. We cater to the precise requirements of our customers by offering Carbon Fiber Mats in various specifications and fiber weights.

BOOST YOUR BUSINESS WITH CUSTOM CARBON FIBER MAT

Size Customization

The common sizes of carbon fiber mat are width 100mm-1600mm, length 100-400m, thickness 2mm, 3mm, 5mm, 7mm, 10mm, 12mm, 14mm. In order to better adapt to the application scenario, improve the use effect and satisfaction, NQ will provide comprehensive size customization services. Whether it is width, length or thickness, they can be accurately adjusted according to your specific needs.

Weight Customization

The common weight of carbon fiber mat is 5-60gsm. In order to make your project more precise and efficient, whether it is to enhance the strength of the material, improve thermal conductivity, or optimize electrical conductivity, we can meet your needs through precise weight customization.

Label Customization

To meet your personalized needs, achieve brand recognition, information transmission, anti-counterfeiting, and traceability, NQ provides label customization services. The customized content includes product name, specifications, model, production date, batch number, logo, brand slogan, brand color, safety warning signs, environmental protection signs, special purpose signs, etc.

Package Customization

To ensure the safety and quality during transportation and storage, we provide you customized packaging services. We will use isolation film to effectively prevent fiber damage caused by friction during the packaging process.We will wrap an additional layer of moisture-proof paper around the outer layer of the isolation film to prevent the carbon fiber mat from getting damp. We will clearly label the product name, specifications, quantity, and manufacturer information for easy identification and traceability.

Carbon Fiber Mat Specification

Brand Name | NQ |

Product Name | Carbon fiber mat |

Material | 100% Carbon Fiber |

Width | 100mm-1600mm |

Length | 100-400m |

Thickness | 2mm,3mm,5mm,7mm,8mm,10mm,12mm,14mm |

Weight | 5-60gsm |

Color | Black |

Technics | Nonwoven |

Style | Plain, Twill, Jacquard, Hexagonal, Plaid, Stripe, Other |

Feature | High Modulus, High Strength, High Temperature Resistance |

Surface | Glossy/ Matte/ 50% Glossy |

Carbon Yarn | Toray Carbon Fiber |

Certificate | CE, ASTM, SGS, ISO, BSCI |

Sample | Availiable |

Application | Aerospace,Auto Industry,Sporting Equipment,New Energy Field,Environmental Protection,Other Fields |

Place of Origin | Jiangsu, China |

Product | Carbon fiber mat/felt/tissue/web |

Material | Carbon fiber |

Weight | 10g, 20g, 30g, 50g, 60g or customized |

Width | 125cm or customized |

Length | 300m/roll |

Moisture content | ≤0.5% |

Surface resistivity | <10Ω |

Fiber diameter | 6-7 um |

Binder content | 3%-20% |

NQ CARBON FIBER MAT HIGH QUALITY PRODUCTION PROCESS

1. Raw Material Preparation

Select and prepare high-quality carbon fiber and chemical fiber yarn as raw materials. Carbon fiber is the main raw material, usually derived from the high-temperature carbonization and graphitization process of polyacrylonitrile fiber. Chemical fiber yarn is used to enhance spinning performance and ensure fiber uniformity.

2. Textile Forming

The raw materials are made into raw mat through a textile process. This includes the mixing, knitting or wet pressing of fibers to form a mat body with a certain strength and density. During the textile process, the length, diameter and connectivity of the fibers can be strictly controlled to ensure the uniformity and stability of the mat layer.

3.Pre-Impregnation

In order to improve the strength and hardness of the original mat, a pre-impregnation treatment is performed. The original mat is placed in a pre-impregnation liquid composed of resin, solvent and curing agent for impregnation, so that the fiber and resin are fully in contact and cured. This step is crucial to improving the mechanical properties of carbon mat.

4.Thermoforming And Curing

The pre-impregnated mat layer enters the hot pressing mold and is hot pressed and cured under high temperature and pressure. During the hot pressing process, the resin is evenly distributed and cured, which enhances the bonding strength between fibers and improves the density and hardness of the carbon mat. At the same time, different curing processes may be used according to product requirements, such as vacuum bag molding or hot autoclave molding.

5.Carbonization And Activation Treatment

After hot pressing and curing, the mat body enters the carbonization furnace and is carbonized at high temperature to carbonize the resin and form carbon fibers. This process requires strict control of the carbonization temperature and holding time, as well as the atmosphere conditions (such as the introduction of nitrogen as a protective gas) to ensure that the fibers are completely carbonized and form a high-quality carbon fiber structure. The carbonized mat body is further activated to improve its performance.

6.Inspection And Packaging For Storage

The carbon fiber mats that have been carbonized and activated are strictly inspected for quality, such as appearance quality, size specifications, mechanical properties, chemical composition, etc., to ensure that the products meet relevant standards and customer requirements. The qualified carbon fiber mats are cut, cut and rolled according to the specified size and properly packaged to prevent damage during transportation and storage.

THE ADVANTAGE OF THE CARBON FIBER MAT

Lightweight And Strong

Carbon fiber mat has an incredibly low density, but also amazingly high strength and high modulus. This unique physical property breaks the traditional material’s inherent concept of “heavy means strong”. It allows the product to maintain sufficient strength while greatly reducing weight, opening up new possibilities for the application field of lightweight design.

High Temperature Resistance

Under the severe challenge of high temperature environment, carbon fiber mat has shown extraordinary heat resistance. It can not only withstand extremely high temperatures without deformation, but also maintain its excellent mechanical properties, providing reliable material guarantee for aerospace, high temperature industry and other fields.

Chemically Stable

Carbon fiber mat has excellent chemical stability and shows extremely high resistance to a variety of corrosive media. Whether in acidic, alkaline or other harsh chemical environments, it can maintain its original performance unchanged, silently guarding the safety and stability of the product.

Strong Adsorption

Carbon fiber mat has excellent adsorption performance and can efficiently absorb harmful gases in the air and impurities in liquids, etc. Its adsorption capacity far exceeds that of traditional materials. This makes it play a pivotal role in environmental protection, purification and other fields.

Flexible Processing

Carbon fiber mat has good processing performance and can be processed and formed through a variety of processes to meet the needs of various complex shapes and sizes. This flexibility gives it greater freedom in product design and provides a broad space for the realization of creativity.

Wide Application

Carbon fiber mat has been widely used in aerospace, automobile manufacturing, sports equipment, electronics and other fields due to its unique advantages. It can not only improve the performance and reliability of products, but also achieve the goals of lightweight and energy saving, providing strong support for the cross-border integration and innovative development of different industries.

SF

Warehouse and factory

Total annual revenue

Skilled worker

WHY DO MORE THAN 400 CUSTOMERS WORLDWIDE CHOOSE NQ?

As a powerful manufacturer in the field of carbon fiber mat, NQ relies on its deep understanding of carbon fiber mat technology and exquisite craftsmanship, takes excellent quality as the cornerstone, takes technological innovation as the driving force, and takes a complete supply chain and service system as the support, providing numerous product solutions with excellent performance and reliable quality to customers around the world.

High Quality Assurance

NQ strictly selects raw materials to ensure that carbon fiber pads have excellent properties such as high strength, high modulus and low density. And has passed CE, ASTM, SGS, BSCI and other certifications.

Stable Supply Chain And Efficient Logistics

NQ works with a number of high-quality raw material suppliers around the world to ensure the high quality of raw material supply, including T300/T700/T800 carbon fiber. Plan the best transportation routes and distribution solutions to save you time and transportation costs.

Large-Scale Production And Competitive Prices

12 intelligent production lines, reduce production costs. Through long-term cooperation with excellent raw material suppliers, reduce raw material costs and ensure product quality.

Certificate

WHAT PEOPLES SAY ABOUT US

“I would like to express my sincerest gratitude and high respect to the NQ team. Since we started working together, NQ, as a leader in the field of international carbon fiber mat, has not only provided us with countless high-quality carbon fiber mat products, but also provided us with immeasurable help and support in technical support, market insights and customized services.”

Tom Lewis

Entrepreneur

“In the field of high-tech materials such as carbon fiber mat, NQ is not only our reliable partner, but also an important force leading the industry forward.Since we established a cooperative relationship with NQ, NQ has always won our trust and respect with its excellent product quality, advanced production technology and meticulous service. The carbon fiber mat produced by NQ has played a vital role in our products with its excellent performance and stable quality, greatly enhancing the competitiveness and market position of our products.”

Jack Harris

Entrepreneur

“The carbon fiber mat produced by NQ, with its excellent physical properties, stable chemical properties and wide application potential, has not only greatly enhanced the market competitiveness of our products, but also brought unprecedented use experience to our customers. The delivery of each batch of products is a perfect interpretation of the “craftsman spirit”, which makes us deeply feel NQ’s persistent pursuit of quality and continuous innovation in technology.”

Jennifer Johnson

Entrepreneur

APPLICATION OF CARBON FIBER MAT

Carbon fiber mat, as an outstanding representative of high-performance composite materials, has shown wide application potential in aerospace, automotive industry, sporting equipment, new energy, environmental protection and other fields due to its unique physical and chemical properties. Carbon fiber mat, with its excellent performance and wide applicability, is constantly promoting technological innovation and industrial upgrading in various industries, showing huge market potential and application value.

Aerospace

In the aerospace field, carbon fiber mat is highly favored due to its light weight and high strength. It can be used in the manufacture of aircraft structural parts, such as fuselage, wings and tail, effectively reducing the weight of the aircraft and improving fuel efficiency and flight performance. In addition, carbon fiber mat can also be used to manufacture aircraft engine components, such as blades, air inlets, etc., as well as avionics equipment, such as radar antennas, communication antennas, etc. These applications not only improve the overall performance of aircraft, but also promote the development of aerospace technology.

Carbon fiber mat:3mm/5mm/8mm/10mm(thickness)

Auto Industry

In the automotive industry, carbon fiber mat is increasingly used. It can be used to manufacture automobile bodies, engine covers, wheel covers and other parts, significantly improving the lightweight of automobiles and thereby reducing fuel consumption and carbon emissions. Carbon fiber mat also plays an important role in the battery systems, motors and electronic control systems of electric vehicles and hybrid vehicles due to its good electrical and thermal conductivity and electromagnetic shielding properties.

Carbon fiber mat:3mm/5mm/8mm/10mm(thickness)

Sporting Equipment

In the field of sporting equipment, carbon fiber mat is widely used in the manufacturing of golf clubs, tennis rackets, bicycle frames and other products due to its lightweight and high strength properties. These products not only have beautiful appearance and superior performance, but also significantly improve athletes’ performance.

Carbon fiber mat:3mm/5mm/8mm/10mm(thickness)

New Energy Field

Carbon fiber mat is an important material in new energy batteries, with excellent conductivity, stability and processability. It can be used as a conductive current collector for battery poles to improve the energy density and electrochemical performance of the battery. Carbon fiber mat plays an important role in the fields of lithium-ion batteries, nickel-hydrogen batteries, supercapacitors and fuel cells.

Carbon fiber mat:3mm/5mm/8mm/10mm(thickness)

Environmental Protection

In the field of environmental protection, carbon fiber mat is widely used for thermal insulation in high temperature environments such as photovoltaic thermal fields, heat treatment equipment and semiconductor thermal fields due to its high temperature resistance and ablation resistance.

Carbon fiber mat:3mm/5mm/8mm/10mm(thickness)

Other Fields

Carbon fiber mat can also be used in the manufacture of medical devices (such as surgical bone screws, orthotics, prostheses, etc.), reinforcement of building materials, housings of electronic equipment, etc. Its application areas are constantly expanding and deepening.

Carbon fiber mat:3mm/5mm/8mm/10mm(thickness)

CARBON FIBER MAT SUPPLIER FAQ

What is your MOQ?

Our MOQ is usually 1x20ft container.But we accept lower quantity for your trial order. Please feel free to inform us your plan for

purchasing, we will offer the price correspond to your qty. And we hope your would increase your order qty after you check our

product quality and know our services.

What is the shipping port?

We ship the goods via Shanghai port.

How many colors are available?

We can do custom color when reach our MOQ qty.

Our regular colors are white, yellow, green, blue, orange, red etc.

What format of the file do you need if I want to do my own design?

For printing label design, we need AI or PDF file for set up the print-plate.

What is your delivery time?

The time of delivery is about 20~30days after we receive the deposit.

What is your sample time?

Usually we will take 7-10 days to make the samples.

Which Shipment way is available?

By sea to your designated port.

Which Payment way is workable?

1. Irrevocable L/C, Cash, PayPal, Credit card and T/T money transfers.

2.30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo.

3.L/C ( Irrevocable LC at sight)

If you need custom size such as gram weight and mesh size etc or private logo pls feel free inquiry us!

CARBON FIBER MAT FAQ

Is carbon fiber fabric expensive?

Yes, carbon fiber fabric is generally considered expensive. Its price is influenced by multiple factors, including material quality, production costs, specific specifications, and application requirements. Due to the complex and costly manufacturing process of carbon fiber, as well as its demand in high-end applications such as aerospace, automotive racing, and sports equipment, the price of carbon fiber fabric tends to be high. However, the specific price may vary depending on different specifications, quality, applications, and market supply and demand conditions.

Can carbon fiber be used as a fabric?

Yes, carbon fiber can be used as a fabric. It has unique properties like lightweight, high strength, and durability, making it suitable for various applications in aerospace, automotive, sports equipment, and industrial fields. While it tends to be more expensive than traditional fabrics, its exceptional performance often justifies the higher cost.

Is carbon fiber cloth safe?

Carbon fiber cloth is generally considered safe, but there are some potential safety concerns to be aware of. While it does not release harmful substances and is resistant to high temperatures and corrosion, the dust generated during its processing can be harmful if inhaled over long periods. Additionally, its conductive properties may cause electromagnetic interference or static discharge in electrical devices. Therefore, it’s important to take proper precautions like wearing protective gear during processing and avoiding contact with fire sources to ensure safe use of carbon fiber cloth.

Why is carbon fiber so expensive?

Carbon fiber is expensive primarily due to its high raw material costs, significant proportion of electricity expenses, complex and costly production processes, as well as the high costs associated with its superior performance. These factors collectively contribute to the relatively high price of carbon fiber.

Is carbon fiber a luxury?

Carbon fiber is a high-performance material, not inherently a luxury. Its cost is justified in specialized applications requiring lightweight, high strength. While some luxury goods may use it for aesthetics, it’s not a necessity for the material.

Is carbon fiber better than leather?

Carbon fiber and leather each have their strengths. Carbon fiber excels in high-performance applications due to its incredible strength, lightness, and resistance to chemicals and high temperatures. Leather, on the other hand, offers a luxurious feel, natural appearance, and good breathability for clothing, furniture, and other applications where aesthetics are important. The choice depends on the specific requirements and intended use.

Which is stronger, 3K or 12K carbon fiber?

12K carbon fiber is stronger than 3K carbon fiber in terms of strength, as it contains a higher number of fiber strands and can withstand greater loads. However, 3K carbon fiber is preferred in some applications requiring lightweight design due to its lighter weight.

Is carbon fiber cloth waterproof?

Carbon fiber cloth is waterproof, thanks to its inherent material properties and often enhanced with additional waterproof coatings. However, under extreme weather conditions like heavy rain or storms, its waterproof performance may be challenged, so it’s important to consider the specific conditions and structural needs before application.

What are the pros and cons of carbon fiber?

Carbon fiber is much lighter than aluminum, but it is also more expensive and not as malleable. Aluminum is cheaper and can be shaped into various forms, but it is also heavier and more prone to corrosion. Ultimately, the best choice will depend on the application and the desired outcome.

How long do carbon fiber wallets last?

Carbon fiber wallets are renowned for their fantastic strength-to-weight ratio. They deliver exceptional durability and are scratch, impact, and corrosion resistant. If you take good care of them, they can last for five years to decades.

Is carbon fiber stronger than leather?

At the end of the day, the choice between a carbon fiber wallet or a leather wallet is going to depend on your daily life and personal choices. But when it comes to durability, resilience, and security, carbon fiber is the obvious winner.

Are carbon fiber panels worth it?

You might have heard that this material is crazy strong, but do you know just how strong it can be? It can withstand significant bumps and scrapes and is resistant to corrosion from a huge variety of chemicals. As well as that, it fares really really well when it comes up against heat.

Is carbon fiber better than Kevlar?

Carbon Fiber is known to be top choice in aerospace and industrial applications due to its high tensile strength, low density, high rigidity, and thermal conductivity. In fact, Carbon Fiber yields the highest material strengths across the board when compared to Kevlar or Fiberglass options.

Does carbon fiber scratch easily?

Carbon fiber is enjoying increasing popularity in the watch world. It is light, scratch-resistant and has an interesting structure that is immediately recognizable as carbon, making each watch unique. However, the processing is complex.

Is carbon fiber hard to clean?

Cleaning with water and soap or a mild cleanser: If the carbon fiber surface is not particularly dirty, a simple rinse with warm water may suffice to remove any film or residue from its surface.