Custom Carbon Fiber Fabric/Clothing Manufacturer

16+ industry manufacturing experience

Custom color Color: red, black, blue, etc

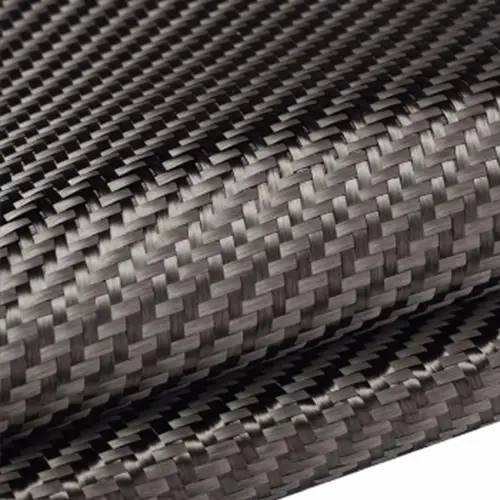

Custom textures: twill satin, etc.

Custom sizes: 1K, 12K,3K 2×2, etc.

CE, ISO and SGS and other international benevolence certification.

OEM and ODM services, door-to-door shipping.

years

Manufacturing Experience

Projects

We had finished

Clients

Over the world

Satisfaction

CUSTOM CARBON FIBER FABRIC MANUFACTURER

As the leading carbon fiber factory in China, NQ is a professional manufacturer and supplier that specializes in exporting high-quality carbon fiber products. We are equipped to meet customers’ demands for wholesale carbon fiber as well as customized solutions.

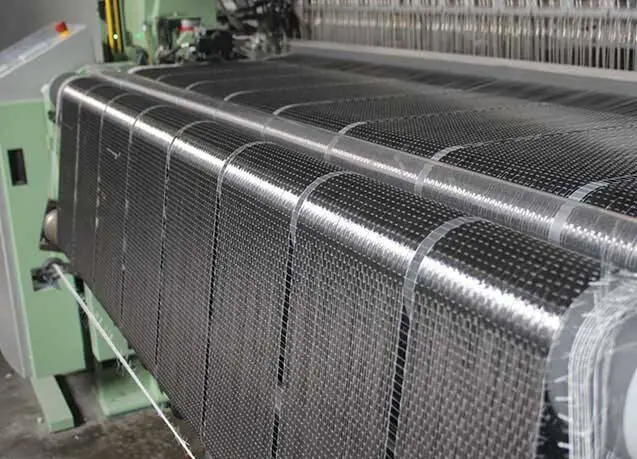

Fully Automatic and Highly Efficient 3D Orthogonal Weaving Machine

Our machines are able to directly weave complex three-dimensional structures, reducing subsequent processing steps and improving production efficiency. Through precise control systems, the stability of the product is ensured.

Multiple Certifications and Strict Quality Control

Our own production plant is certified to several standards including CE, ISO and SGS. We have established multiple quality control checkpoints throughout the production process to ensure that our products meet the highest standards.

High Carbon Content and Excellent Mechanical Properties

We use high-quality organic fibers such as polyacrylonitrile (PAN) as the raw materials for carbon fiber cloth. A high-temperature carbonization process at temperatures between 1000°C and 3000°C ensures a carbon content of more than 90%. Through our unique weaving structure, we achieve excellent mechanical properties.

Professional

Advanced manufacturing technology

High Quality

High quality CE, ASTM, SGS, ISO, BSCI certification

Cost Effective

Direct factory price

Customized

Different sizes, colors, designs, OEM/ODM

Service

Excellent customer service

CARBON FIBER FABRIC WE MADE

NQ offers a diverse range of carbon fiber fabric products that are lightweight, glossy, and possess high modulus, strength, rigidity, temperature resistance, thermoplasticity, and corrosion resistance. These fabrics are suitable for various applications, including aerospace, automotive manufacturing, building reinforcement, clothing, interior decoration, bulletproof materials, and wall repair.We provide different specifications and fiber weights of carbon fiber cloth tailored to the specific needs of our customers. Whether you require a precision aerospace component or a large-scale building reinforcement project, we can deliver carbon fiber cloth solutions that meet your requirements.

BOOST YOUR BUSINESS WITH CUSTOM CARBON FIBER FABRIC

NQ is an authority in the field of Carbon Fiber Fabric production. We recognize the critical balance between weave strength and dimensional specifications in the design of Carbon Fiber Fabric. Our meticulously manufactured Carbon Fiber Fabric performs exceptionally well in high temperatures, harsh climates, and corrosive environments, ensuring outstanding properties such as high strength, high modulus, lightweight, and fatigue resistance. As your trusted Carbon Fiber Fabric manufacturer, we offer tailored custom services and packaging solutions for a variety of Carbon Fiber Fabrics. Trust our expertise to meet your stringent standards and elevate your brand with our professional-grade Carbon Fiber Fabric.

Size Customization

We offer customized options in various sizes and specifications, including different weaves, weights per square meter, warp and weft densities, yarn types, widths, and thicknesses. Our goal is to provide the most suitable solutions for your products.Common weights include 120 g/m², 200 g/m², 240 g/m², 320 g/m², 360 g/m², 400 g/m², and 480 g/m². Typical widths are 1270 mm and 500 mm, while thicknesses include 0.25 mm, 0.35 mm, 0.40 mm, and more.

Color Customization

We provide a wide range of color options, including black, red, yellow, orange, blue, and more. Based on your specific needs and preferences, we can customize colors to meet the requirements of your project. If you have any questions or need assistance, please don’t hesitate to contact us.

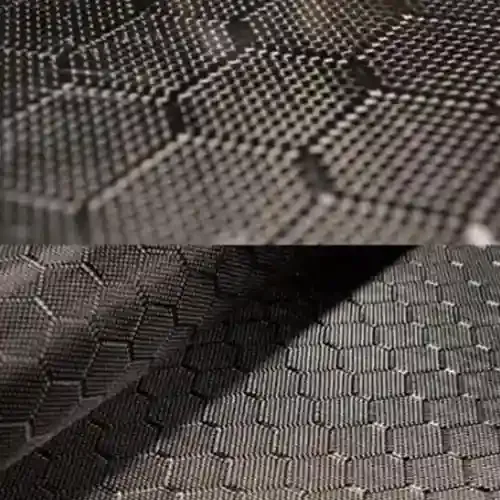

Customized Woven Texture

We can weave different fabric structures, such as plain weave, twill weave, satin weave, and three-dimensional weaving. Additionally, you can customize the orientation and weaving density of the fibers to achieve various weaving effects. Depending on the texture, we select different high-end multi-axial weaving machines and two-dimensional weaving machines to ensure the stability of the product quality you receive and to maximize the weaving effect.

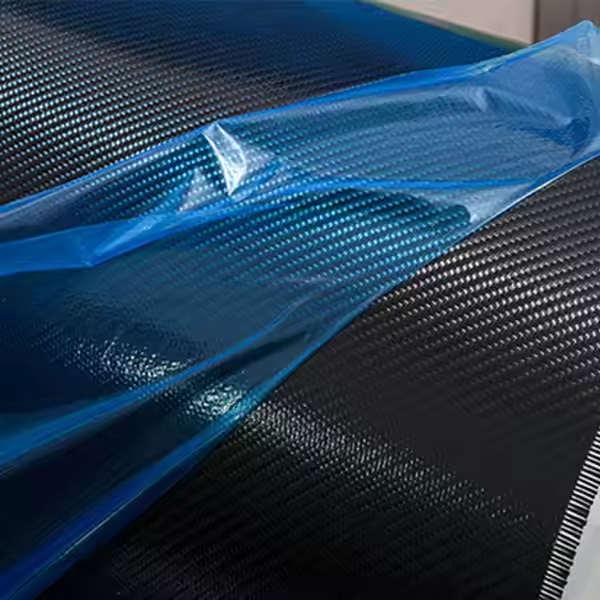

Customized Packaging

We will select suitable packaging materials, such as cardboard, plastic, and foam, based on your requirements and the characteristics of the product. These materials should have good shock resistance, moisture resistance, and compression resistance. You can also customize special packaging methods, such as anti-static, moisture-proof, or abrasion-resistant packaging paper or film.

Customized Labels

Labels contain essential information about the product and are made from durable materials, affixed prominently on the packaging. If the product is for export, the label content must also comply with the regulations of the target country. We have a professional label design team to meet various customization needs of our customers.

CARBON FIBER FABRIC SPECIFICATION

Brand Name | NQ |

Width | 1000mm,custom |

Supply Type | In-Stock Items |

Weight(g/㎡) | 120~800±20 g/㎡,custom |

Thickness(mm) | 0.15~0.7±0.06 mm,custom |

Place of Origin | China |

Applicable to the Crowd | Professionals in various fields such as architecture, aerospace, automotive, sports equipment, fire protection, electronics and more. |

Product Type | Carbon Fiber Fabric |

Style | Plain Weave Satin Weave |

Technics | Woven |

Square weight(g/㎡) | 120~800 g/㎡ |

Annual Production | 700,000 square meters |

Raw materials | 3K high-performance carbon fiber |

Environmental Protection | Sustainable Fabrics |

Characteristics | High strength/Lightweight/High modulus |

Attributes | Corrosion resistance/Fatigue resistance/High temperature |

Domain of use | Aerospace/automobile/Sports equipment/Building/Vessel/New energy |

Selling Point | Lightweight, |

NQ CARBON FIBER FABRIC CLOTH HIGH QUALITY PRODUCTION PROCESS

1. Raw Material Preparation

We typically use polyacrylonitrile (PAN) as the precursor fiber for our carbon fiber manufacturing. Ensuring the high quality of raw materials is the foundation for producing premium carbon fibers.

2. Spinning and Stretching

Using spinning machines, we process the polyacrylonitrile (PAN) precursor fibers into long filaments. Through a series of stretching processes, the fibers are elongated in the longitudinal direction while simultaneously increasing their strength and orientation.

3.Stabilization Treatment

After spinning and stretching, the fibers undergo chemical stabilization treatment, with the addition of specific chemicals to stabilize the fiber structure and prevent decomposition during subsequent high-temperature processing. This ensures the thermal stability of the fibers.

4. Carbonization Process

In an air atmosphere of around 200-300°C, the fibers undergo pre-oxidation treatment. Under the protection of inert gases (such as nitrogen), they are then heated to approximately 1700°C to complete the carbonization process. This step can further enhance the strength and modulus of the fibers.

5. Surface Treatment and Sizing

The carbonized carbon fibers undergo oxidation treatment to improve their surface properties and enhance bonding with matrix materials like resins. A sizing agent is applied to the fiber surface to protect the fibers from damage during subsequent processing and to strengthen the bond with the resin. Different sizing materials can be selected based on requirements.

6. Weaving and Molding

The treated carbon fiber filaments are woven into the desired fabric shapes. The weaving method can be chosen according to specific application needs, such as unidirectional, plain weave, or twill weave. Composite products are formed using processes like hot pressing.

7.Quality Control and Testing

Throughout the entire production process, we maintain comprehensive monitoring. Strict quality control and testing are conducted at multiple stages, including raw material inspection, process parameter control, and finished product performance testing, to ensure the carbon fiber fabrics meet high-standard requirements.

8. Post-processing and Packaging

The finished carbon fiber fabrics undergo necessary post-processing like washing and drying, then are packaged and stored. Packaging methods using rolls, moisture-proof films, and foams are employed to minimize damage during transportation. Customized packaging options are also available upon request.

CARBON FIBER FABRIC WHOLESALE IN NQ

Our expertise in carbon FIber fabric manufacturing makes us one of the most trusted carbon FIber fabric and cloth manufacturers in China. We have our own carbon fiber plant that produces a variety of carbon fiber fabrics and other products for the carbon fiber industry, allowing us to accept wholesale orders from customers looking to reduce costs. Our carbon fiber fabrics offer the following benefits:

High Strength and Lightweight

Carbon fiber fabric has extremely high strength, over 10 times that of steel, while its density is only a quarter of steel, significantly improving load-bearing capacity and energy efficiency.

High-Temperature Resistance

It can function normally at temperatures up to 800°C and, under certain conditions, withstand temperatures as high as 2000°C, making it an ideal material for high-temperature environments such as rockets and jet engines.

Strong Corrosion Resistance

Its smooth surface prevents the absorption of moisture and contaminants, offering excellent resistance to various acids, alkalis, and organic solvents, thus extending the product’s lifespan.

Good Conductivity

Carbon fiber fabric has certain conductivity, allowing it to be used as a filler material for conductors or semiconductors, giving it unique value in the electronics field.

High Design Flexibility

By altering fiber arrangement, weaving methods, and composite material designs, its properties can be flexibly adjusted to meet complex and specific application requirements.

Excellent Environmental Adaptability

With characteristics like low density, high modulus, and high vibration damping, carbon fiber fabric maintains excellent performance under various environmental conditions, making it an ideal material for reinforcement and repair applications.

SF

Warehouse and factory

Total annual revenue

Skilled worker

WHY DO MORE THAN 400 CUSTOMERS WORLDWIDE CHOOSE NQ?

NQ is dedicated to manufacturing high-quality carbon fiber fabric, which is widely used in aerospace, automotive, sports equipment, industrial applications, and more. Our carbon fiber fabric provides the structural reinforcement and strengthening you need, offering exceptional performance in lightweight construction, high-temperature environments, vibration damping, and durability. Whether for enhancing strength, improving thermal resistance, or adding advanced composite materials, our carbon fiber fabric delivers the reliability and performance required across various industries.

ISO And CE Certified Manufacturing

Our production processes and products are ISO and CE certified, ensuring the manufacture of high-quality carbon fiber fabric that meets our customers’ stringent standards.

Customizable Weaving Patterns And Colors

We use fully automatic three-dimensional cross-weaving machines for weaving. Whether it is plain, twill, satin, honeycomb, aramid blend, or black, blue, red, etc., we can provide customized solutions.

Wholesale Supply In Various Sizes

We offer a variety of specifications, including 120g/㎡, 200g/㎡, 320g/㎡, 400g/㎡, warp and weft options include 1K, 3K, 6K and 12K, as well as different thicknesses, warp and weft densities and lengths.

Competitive Pricing

Choosing our custom carbon fiber fabrics, you will not only get a high-quality product, but also gain a competitive advantage in the market. Eight dedicated production lines enable us to complete bulk orders in a timely manner, minimizing the risk of delivery delays.

Certificate

APPLICATION OF CARBON FIBER FABRIC

Aerospace

Carbon fiber fabric is widely used in the aerospace industry due to its high strength, lightweight, heat resistance, and fatigue resistance. It is employed in aircraft structures, satellites, drones, and rocket components to reduce weight and improve fuel efficiency, while also meeting the demands of extreme environments.

Using 1K-12K polyacrylonitrile (PAN) based fibers

Weight range of 120g/m² to 400g/m²

Weaving patterns include plain weave, twill weave, and satin weave

High tensile strength (>5000 MPa), high modulus (240-290 GPa)

Automotive Industry

In automotive manufacturing, carbon fiber fabric is used for lightweight designs in car bodies, chassis, and interior components. It helps improve vehicle performance, reduce energy consumption, and increase durability. High-performance racing cars and electric vehicles especially prefer carbon fiber materials to enhance speed and efficiency.

1K-12K PAN-based fibers

Weight range of 160g/m² to 600g/m²

Weaving patterns include plain weave, twill weave, and satin weave

High tensile strength (>5000 MPa), high modulus (240-300 GPa)

Sports Equipment

Carbon fiber fabric has extensive applications in high-end sports equipment, such as tennis rackets, bicycle frames, golf clubs, and skis. Its lightweight and high-strength properties provide athletes with better control and performance, while its durability extends the lifespan of the equipment.

1K – 12K fiber bundles such as 3K and 6K

Weight range of 150g/m² to 300g/m²

Weaving patterns include plain weave, twill weave, and satin weave

High tensile strength (>5000 MPa), high modulus (240-300 GPa)

Construction and Civil Engineering

Carbon fiber fabric plays a crucial role in the reinforcement and repair of building structures. It can be used to strengthen bridges, tunnels, columns, and other construction components, improving load-bearing capacity and seismic resistance. Additionally, it performs exceptionally well in corrosive environments, extending the lifespan of buildings.

1K to 12K fiber bundles

Weight range of 200g/m² to 600g/m²

Weaving patterns include plain weave, twill weave, and satin weave

High tensile strength (>5000 MPa), high modulus (240-300 GPa)

Wind Energy

In the wind energy sector, carbon fiber fabric is widely used in the production of wind turbine blades. Its lightweight and high-strength characteristics allow the blades to maintain stability under high wind pressure while reducing overall weight, thus improving energy generation efficiency.

3K to 12K fiber bundles

Weight range of 200g/m² to 600g/m²

Weaving patterns include plain weave, twill weave, and satin weave

High tensile strength (>5000 MPa), high modulus (240-300 GPa)

Combined with epoxy resin

Electronics and Communications

Due to its conductivity and ability to shield electromagnetic interference, carbon fiber has unique applications in electronic product housings, antennas, and shielding materials. It offers lightweight solutions while enhancing the product’s resistance to interference and durability.

1K to 12K fiber bundles

Weight range of 150g/m² to 400g/m²

Weaving patterns include plain weave, twill weave, and satin weave

High tensile strength (>5000 MPa), high modulus (240-300 GPa)

WHAT PEOPLES SAY ABOUT US

“Since we started using this Carbon Fiber Fabric, our sports equipment product line has seen significant improvement. As a well-known sports equipment manufacturer in the UK, we have always been searching for materials that are both lightweight and strong, and this carbon fiber fabric perfectly meets our needs. Its high-strength properties allow our equipment to perform exceptionally well under heavy loads, while the lightweight design greatly enhances the user experience. What’s more impressive is its excellent fatigue resistance, maintaining stable performance even under long-term use and extreme conditions. From a business perspective, the cost-effectiveness of this material is outstanding. While the initial investment is slightly higher, its long-term durability and improved customer satisfaction have left us very pleased, and we plan to continue bulk purchasing in the future.”

Robert Smith

Entrepreneur

“In the automotive parts industry, material selection is crucial. We chose this Carbon Fiber Fabric mainly due to its perfect combination of strength and weight. With the increasing trend of automotive lightweighting, this material is undoubtedly our ideal choice. It not only significantly improves fuel efficiency but also reduces the risk of damage during accidents while maintaining vehicle body strength. Additionally, we highly appreciate the processability of this material—it is easy to mold and cut, greatly enhancing our production efficiency. Although there are other similar carbon fiber products on the market, this material stands out in terms of cost-effectiveness and supplier service. We have established a long-term partnership with the supplier and look forward to more collaboration opportunities in the future.”

Sophia Lee

Entrepreneur

“As a professional composite materials distributor based in Germany, we have always been searching for high-quality carbon fiber fabrics to meet our customers’ needs. This Carbon Fiber Fabric is undoubtedly a gem we’ve found. Its consistent quality and exceptional performance have vast potential across industries such as aerospace, automotive manufacturing, and sports equipment. The feedback from our customers has been overwhelmingly positive, especially praising its high strength, lightweight, and excellent weather resistance. Additionally, the supply chain for this material is very reliable—the supplier consistently delivers on time, and the pricing is reasonable. This enables us to stay competitive in the market and provide excellent service to our clients. We are very confident in this Carbon Fiber Fabric and plan to further expand our collaboration with its supplier in the future.”

Michael Brown

Entrepreneur

CARBON FIBER FABRIC SUPPLIER FAQ

What is your MOQ?

Our MOQ is usually 1x20ft container.But we accept lower quantity for your trial order. Please feel free to inform us your plan for

purchasing, we will offer the price correspond to your qty. And we hope your would increase your order qty after you check our

product quality and know our services.

What is the shipping port?

We ship the goods via Shanghai port.

How many colors are available?

We can do custom color when reach our MOQ qty.

Our regular colors are white, yellow, green, blue, orange, red etc.

What format of the file do you need if I want to do my own design?

For printing label design, we need AI or PDF file for set up the print-plate.

What is your delivery time?

The time of delivery is about 20~30days after we receive the deposit.

What is your sample time?

Usually we will take 7-10 days to make the samples.

Which Shipment way is available?

By sea to your designated port.

Which Payment way is workable?

1. Irrevocable L/C, Cash, PayPal, Credit card and T/T money transfers.

2.30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo.

3.L/C ( Irrevocable LC at sight)

If you need custom size such as gram weight and mesh size etc or private logo pls feel free inquiry us!

CARBON FIBER FABRIC FAQ

What is carbon fiber fabric?

Carbon fiber fabric is a textile material woven from carbon fibers, which are fibers about 5–10 micrometers in diameter composed mostly of carbon atoms. These fibers are known for their high stiffness, high tensile strength, low weight, high chemical resistance, high-temperature tolerance, and low thermal expansion. These properties make carbon fiber fabrics ideal for reinforcing materials in various high-performance applications.

Key Characteristics:

High Strength-to-Weight Ratio: Carbon fiber fabrics provide significant strength while remaining lightweight, making them suitable for applications where reducing weight is crucial without compromising structural integrity.

High Stiffness: The rigidity of carbon fibers contributes to the structural stiffness of the composite materials they reinforce, which is essential in applications requiring minimal flexing or deformation.

Thermal and Chemical Stability: Carbon fibers exhibit high resistance to temperature variations and chemical exposures, ensuring durability in harsh environments.

Applications:

Carbon fiber fabrics are widely used in industries such as aerospace, automotive, sports equipment, and civil engineering. They are often combined with polymer matrices to form carbon fiber-reinforced polymers (CFRP), which are utilized in manufacturing aircraft components, high-performance car parts, bicycle frames, and structural elements in construction.

In summary, carbon fiber fabric is a versatile material that enhances the mechanical properties of composites, offering strength, stiffness, and durability across various advanced engineering applications.

Is carbon fiber fabric expensive?

Yes, carbon fiber fabric is generally considered more expensive than traditional materials due to its advanced properties and manufacturing processes. The price of carbon fiber fabric varies based on factors such as weave pattern, fiber type, weight, and supplier.

Price Ranges:

Standard Modulus Carbon Fiber: Typically used in general applications, prices usually range from $20 to $60 per meter.

Intermediate Modulus Carbon Fiber: Offers improved strength over standard types and can cost between $60 to $120 per meter.

High Modulus Carbon Fiber: Known for unmatched rigidity and strength, this type often comes at a premium price, ranging from $150 to $300 per meter.

For example, a 3K 200g plain carbon fiber fabric is available at prices ranging from $9 to $14 per square meter.

Factors Influencing Price:

Fiber Type: Higher modulus fibers, which offer greater stiffness and strength, are more expensive.

Weave Pattern: Complex weaves like twill or satin can increase the cost compared to plain weaves.

Fabric Weight: Heavier fabrics (higher GSM) use more material, leading to higher prices.

Supplier and Quantity: Prices can vary between suppliers, and bulk purchases often reduce the cost per unit.

In summary, while carbon fiber fabric is more costly than traditional materials, its exceptional properties make it a valuable investment for applications requiring high strength-to-weight ratios and durability.

Can carbon fiber be used for clothing?

Carbon fiber, renowned for its high strength-to-weight ratio and durability, is primarily used in applications like aerospace, automotive, and sports equipment. Its integration into everyday clothing is limited due to factors such as stiffness, cost, and manufacturing complexities.

Innovative Applications in Clothing:

Protective Gear: Carbon fibers are utilized in specialized protective clothing, such as racing suits, where materials like Nomex and Kevlar are combined with carbon fibers to enhance fire resistance and durability. However, these suits are typically designed for specific professional contexts and are not common in everyday apparel.

Exoskeleton-Assisted Apparel: Recent advancements have led to the development of hiking pants incorporating carbon fiber components. For instance, Arc’teryx Equipment and Skip collaborated to create the Mo/Go pants, featuring lightweight electric motors at the knees attached to carbon fiber structures. These pants provide a 40% boost to leg muscles during uphill walks, effectively acting as a wearable exoskeleton to alleviate knee pain.

Challenges in Everyday Clothing:

Despite these innovations, widespread use of carbon fiber in regular clothing faces challenges:

Flexibility and Comfort: Carbon fiber’s inherent stiffness can restrict movement, making it less suitable for garments that require flexibility.

Cost: The high production cost of carbon fiber materials can be prohibitive for mass-market clothing.

Manufacturing Complexity: Integrating carbon fibers into fabrics requires specialized manufacturing processes, complicating large-scale production.

In summary, while carbon fiber is not commonly used in everyday clothing due to its rigidity and cost, it finds niche applications in specialized apparel where its unique properties offer significant benefits.

Is carbon fiber fabric strong?

Yes, carbon fiber fabric is renowned for its exceptional strength, particularly its high tensile strength and stiffness, making it a preferred material in various high-performance applications.

Mechanical Properties:

Tensile Strength: Standard carbon fiber fabrics exhibit ultimate tensile strengths around 600 MPa, while high modulus variants can reach approximately 350 MPa.

Young’s Modulus: The stiffness of carbon fiber fabrics is notable, with Young’s modulus values typically around 70 GPa for standard fabrics and up to 85 GPa for high modulus types.

Comparison with Other Materials:

When compared to materials like E-Glass fiberglass and Kevlar fabrics, carbon fiber fabrics generally offer higher tensile strength and stiffness. For instance, E-Glass fiberglass fabrics have tensile strengths around 440 MPa and Young’s modulus values near 25 GPa, while Kevlar fabrics exhibit tensile strengths around 480 MPa and Young’s modulus values approximately 30 GPa.

Applications:

Due to these superior mechanical properties, carbon fiber fabrics are extensively used in industries such as aerospace, automotive, and sports equipment manufacturing, where high strength-to-weight ratios are crucial.

In summary, carbon fiber fabric’s remarkable strength and stiffness make it a highly sought-after material for applications demanding superior mechanical performance.

How to fabricate carbon fiber

1. Prepare raw materials:

- The main raw materials are polypropylene fiber and polystyrene fiber. Polypropylene fibers are mainly used to make basic fabrics, while polystyrene fibers are used to make carbon fibers.

- Fiber treatment:

- Polystyrene fiber pretreatment: Put the polystyrene fiber into the mixing tank, add a small amount of oxidant to dissolve and cycle stirring until the fiber is fully soaked.

- Fiber carbonization: The pre-treated fiber is put into a carbonization furnace and carbonized under high temperature (usually above 1000°C) and oxygen deprivation to convert it into carbon fiber. This process removes non-carbon elements (such as hydrogen, oxygen, and nitrogen) from the fiber, leaving a fiber composed mostly of carbon.

- Carbon fiber manufacturing:

- There are two main ways to manufacture carbon fiber: carbonized fiber and graphitized fiber. Carbonized fiber is obtained by pyrolysis, carbonization and graphitization of organic fiber, which has lower cost but lower strength and modulus. Graphitized fibers are manufactured by chemical vapor deposition, which is more expensive but also has higher strength and modulus.

- Carbon fiber cloth manufacturing:

- The production of carbon fiber cloth requires the preparation of carbon fiber yarn, loom, weft cylinder, warp cylinder and loom and other equipment and materials.

- Carbon fiber yarn is made of the above carbon fiber through spinning, twisting, twisting and other processes.

- The weaving methods of carbon fiber cloth include flat weaving, twill weaving, jacquard weaving, hook weaving and so on, of which flat weaving is the most commonly used method. During the weaving process, the yarn is cycled out in both warp and weft directions to form a carbon fiber cloth.

- After the braiding is completed, the carbon fiber cloth needs to undergo post-treatment to strengthen its performance and appearance, such as heat curing, resin impregnation, surface coating, etc.

- Molding process (molding method of carbon fiber products) :

- There are many kinds of molding methods for carbon fiber products, including winding molding, injection molding, stamping molding, oven molding, drawing molding and autoclave molding. These molding methods are suitable for different products and production needs, such as tubular, roller, rod and other shapes of products.

How to apply carbon fiber fabric

Applying Carbon Fiber Fabric involves multiple steps and considerations, with specific methods varying depending on the application field (such as aerospace, automotive manufacturing, sports equipment, etc.). Below are general application steps and precautions:

I. Preparation Stage

- Material Selection:

- Choose the appropriate carbon fiber fabric specification and type (such as unidirectional cloth, woven cloth, etc.) based on application requirements.

- Consider the compatibility of carbon fiber with the resin matrix and select a suitable resin system.

- Design:

- Conduct structural design according to application requirements, determining the layering direction and number of carbon fiber fabric layers.

- Perform finite element analysis (FEA) or other simulation methods to optimize the design plan.

- Tool Preparation:

- Prepare molds, release agents, vacuum bagging films, sealing tapes, and other auxiliary tools.

II. Surface Treatment

- Clean and degrease the surfaces of the carbon fiber fabric and substrate to ensure good bonding performance.

III. Layering and Molding

- Layering:

- Layer the carbon fiber fabric onto the mold according to the design requirements.

- Ensure no wrinkles, bubbles, or other defects during the layering process.

- Resin Impregnation:

- Perform resin impregnation operations according to the requirements of the selected resin system.

- Methods such as hand lay-up, resin transfer molding (RTM), vacuum bagging, etc., can be used for resin impregnation and curing.

- Curing:

- Cure the resin according to the curing conditions of the resin system.

- Control the temperature, pressure, and time during the curing process to ensure complete curing.

IV. Post-Processing

- Demolding:

- After curing is complete, remove the finished product from the mold.

- Trimming:

- Conduct necessary trimming and sanding on the finished product to remove burrs, flash, etc.

- Inspection:

- Inspect the finished product for quality to ensure it meets design requirements and usage standards.

V. Application Precautions

- Safety Protection:

- Wear appropriate personal protective equipment (such as gloves, masks, goggles, etc.) during operation to prevent irritation to the skin and eyes from carbon fiber dust and resin.

- Environmental Control:

- Maintain a clean and well-ventilated working environment to avoid the impact of dust and moisture on product quality.

- Quality Control:

- Strictly control raw material quality, process parameters, and operational specifications to ensure stable and reliable product quality.

- Sustainable Development:

- Pay attention to the recycling and reuse of carbon fiber materials, promoting green manufacturing and the development of a circular economy.

In summary, applying carbon fiber fabric is a process that involves multiple steps and factors, requiring comprehensive consideration of material selection, design, process parameters, quality control, and more. Through scientific and reasonable application and strict quality control measures, the excellent performance of carbon fiber fabric can be fully utilized and various application requirements can be met.

Carbon fabric properties

Carbon fiber fabric is a textile material woven from carbon fibers, renowned for its exceptional mechanical properties and versatility.

Mechanical Properties:

High Strength-to-Weight Ratio: Carbon fiber fabric offers significant strength while remaining lightweight, making it ideal for applications requiring both durability and reduced weight.

High Stiffness: The material exhibits notable rigidity, contributing to structural integrity in various applications.

Tensile Strength: Standard carbon fiber fabrics have an ultimate tensile strength of approximately 600 MPa, while high modulus variants can reach around 350 MPa.

Young’s Modulus: The stiffness of carbon fiber fabrics is notable, with Young’s modulus values typically around 70 GPa for standard fabrics and up to 85 GPa for high modulus types.

Physical Properties:

Thermal Expansion: Carbon fiber fabric has a low coefficient of thermal expansion, meaning it undergoes minimal dimensional changes with temperature fluctuations, which is crucial in precision applications.

Chemical Resistance: The material is resistant to many chemicals, enhancing its durability in corrosive environments.

Applications:

Due to these properties, carbon fiber fabric is extensively used in industries such as aerospace, automotive, sports equipment, and construction, where high performance and reliability are essential.

In summary, carbon fiber fabric’s unique combination of high strength, stiffness, and lightweight characteristics makes it a preferred material for applications demanding superior mechanical performance.

Carbon fiber fabrication process

The fabrication of carbon fiber involves transforming precursor materials into high-performance fibers through several key stages:

1. Precursor Selection:

Polyacrylonitrile (PAN): The most commonly used precursor, PAN is favored for its ability to produce fibers with high tensile strength.

Rayon and Petroleum Pitch: Alternative precursors that can yield fibers with different properties, suitable for various applications.

2. Spinning:

Wet or Dry Spinning: The chosen precursor is dissolved and extruded through spinnerets into fibers.

Drawing: The extruded fibers are stretched to align polymer chains, enhancing the fiber’s mechanical properties.

3. Stabilization (Oxidation):

Heating in Air: The spun fibers are heated in air at temperatures around 300°C to stabilize them, preventing melting during subsequent high-temperature processes.

Chemical Crosslinking: This step forms a thermally stable structure, making the fibers suitable for carbonization.

4. Carbonization:

High-Temperature Heating: The stabilized fibers are heated in an inert atmosphere (e.g., argon) at temperatures around 2000°C.

Structural Transformation: This process removes non-carbon elements, resulting in fibers composed of approximately 93–95% carbon.

5. Graphitization (Optional):

Further Heating: For fibers requiring higher stiffness, this step involves heating the carbonized fibers to temperatures between 2500–3000°C.

Crystalline Alignment: This process aligns the crystalline structure for enhanced mechanical properties.

6. Surface Treatment:

- Improving Matrix Bonding: The fiber surface is treated to enhance bonding with resins or other matrices, improving the performance of composite materials.

7. Fiber Sizing and Winding:

Application of Sizing Agents: A protective coating is applied to the fibers to facilitate handling and processing.

Winding: The treated fibers are wound onto bobbins for storage or further processing into fabrics or preforms.

This comprehensive fabrication process results in carbon fibers with exceptional strength-to-weight ratios, making them ideal for applications in aerospace, automotive, and sports industries.

Carbon fabric uses

Carbon fiber fabrics are woven materials made from carbon fibers, prized for their exceptional strength-to-weight ratio and versatility. These fabrics are utilized across various industries due to their unique properties.

Key Applications:

Aerospace and Automotive Industries: Carbon fiber fabrics reinforce composite materials used in aircraft and vehicle components, enhancing performance while reducing weight.

Sports Equipment: Items like bicycle frames, golf club shafts, and tennis rackets benefit from the lightweight and strong characteristics of carbon fiber fabrics.

Musical Instruments: Components such as violin bows, guitar necks, and even entire instruments are crafted using carbon fiber fabrics for improved durability and consistency.

Firearms: Certain firearm parts are made with carbon fiber fabrics to reduce weight without compromising strength.

Flexible Heating Elements: When woven into fabrics, carbon fibers can serve as flexible heating elements in applications like heated clothing and blankets.

Microelectrodes: Single carbon fibers are used to create microelectrodes for detecting biochemical signals, essential in various scientific studies.

Dentistry: Carbon fiber posts are employed in restorative dental procedures, providing support in root canal treatments.

Rail Transport: Carbon fiber fabrics are used in manufacturing train bogies, reducing weight and contributing to energy efficiency.

These diverse applications highlight the adaptability and importance of carbon fiber fabrics in modern manufacturing and technology.

How to cut carbon fiber fabric

Cutting carbon fiber fabric is a process that requires precise operation, as carbon fiber fabric features high strength, low density, and thin thickness. Inappropriate cutting methods may lead to material damage or performance degradation. Below are some basic steps and precautions for cutting carbon fiber fabric:

I. Preparation

- Tool Selection:

- Choosing the right cutting tool is crucial. For small-scale or manual operations, sharp scissors or blades can be used. However, for large-scale production or applications requiring high-precision cutting, a professional carbon fiber fabric cutting machine is recommended.

- Ensure that the cutting tool is sharp and in good condition to avoid producing burrs or tears during the cutting process.

- Work Area:

- Select a clean, tidy, and well-ventilated work area for cutting operations. Carbon fiber fabric cutting may generate dust, so it is necessary to ensure the safety and hygiene of the work area.

- Material Fixation:

- Use clamps or other methods to fix the carbon fiber fabric on the cutting platform to prevent movement or deformation during the cutting process.

II. Cutting Operation

- Marking and Planning:

- Before cutting, use a pencil or marker to clearly mark the lines and shapes to be cut on the carbon fiber fabric. This helps ensure the accuracy and consistency of the cutting.

- Plan the cutting sequence and path to improve cutting efficiency and reduce material waste.

- Slow and Stable Cutting:

- During the cutting process, keep your hand stable and apply moderate force. Avoid cutting quickly or with excessive force, as this may lead to material damage or inaccurate cutting.

- For complex shapes or curved cuts, more precise operations and multiple adjustments to the cutting path may be required.

- Inspection and Trimming:

- After cutting, carefully inspect the cut edges for smoothness, burrs, or tears. If necessary, use sandpaper or other tools for trimming.

- Check whether the cut size and shape meet the requirements, and make adjustments or re-cut if necessary.

III. Precautions

- Safety Protection:

- When cutting carbon fiber fabric, dust and fiber fragments may be generated. Therefore, appropriate personal protective equipment (such as masks, gloves, and goggles) should be worn to prevent inhalation or skin contact.

- Pay attention to the safety and ventilation conditions of the work area, and keep fire sources and flammable substances away from the cutting area.

- Material Properties:

- Carbon fiber fabric has high strength and brittleness, so special care should be taken during the cutting process to avoid material damage.

- Considering the (albeit low) conductivity of carbon fiber fabric, extra attention should be paid to electrical safety in cutting environments involving electrical equipment.

- Cutting Precision and Efficiency:

- For applications requiring high-precision cutting, a professional carbon fiber fabric cutting machine is recommended. These devices are usually equipped with advanced control systems and cutting software, enabling high-precision automated cutting.

- While considering cutting efficiency, cutting quality and material utilization should also be taken into account. Optimize the cutting path and reduce waste generation to improve overall production efficiency.

In summary, cutting carbon fiber fabric requires careful preparation, precise operation, and attention to safety protection. By selecting the appropriate cutting tool, planning the cutting path, and following correct operational procedures, the cutting process can be carried out smoothly, ensuring stable and reliable cutting quality.

How to make carbon fiber fabric

The production of carbon fiber fabric is a complex and meticulous process involving multiple key steps. Below is a general overview of the manufacturing process for carbon fiber fabric:

I. Raw Material Preparation

The primary raw materials for carbon fiber fabric are carbon-containing organic fibers, such as polyacrylonitrile (PAN), pitch, and viscose fibers. Among these, PAN-based carbon fibers are the most common, accounting for over 90% of total carbon fiber production, due to their relatively simple production process and excellent mechanical properties. These raw materials are specially treated in preparation for the subsequent spinning and carbonization processes.

II. Spinning and Stretching

- Spinning: The prepared organic polymer raw materials undergo a polymerization reaction to generate high-molecular-weight polymer solutions. These solutions are then stretched into fine filaments through a spinning process. During spinning, parameters such as spinning speed and stretching tension are strictly controlled to ensure the quality of the filaments.

- Stretching: The fine filaments obtained from spinning require further stretching to improve their strength and orientation. The stretching process typically involves multiple stages, with each stage making the filaments thinner and stronger.

III. Pre-oxidation and Carbonization

- Pre-oxidation: The stretched filaments are subjected to pre-oxidation treatment in an oxidation furnace. The purpose of pre-oxidation is to partially oxidize the organic components in the filaments, forming a stable ladder structure, which lays the foundation for the subsequent carbonization process. Pre-oxidation temperatures generally range from 200°C to 300°C.

- Carbonization: The pre-oxidized filaments are then subjected to high-temperature carbonization treatment in a carbonization furnace. During carbonization, the organic components in the filaments decompose and escape, leaving a fiber structure mainly composed of carbon. Carbonization temperatures generally range from 1000°C to 2000°C. After carbonization, the filaments have a carbon content of over 90%, becoming true carbon fibers.

IV. Weaving and Surface Treatment

- Weaving: The carbonized filaments are woven to form carbon fiber fabric. Weaving methods vary, such as plain weave, twill weave, and satin weave, to meet the needs of different fields. During weaving, the directionality of the fibers must be considered to ensure that the final product has excellent mechanical properties.

- Surface Treatment: To improve the adhesion performance and surface flatness of the carbon fiber fabric, it is usually subjected to surface treatment. These treatments include resin impregnation, hot pressing, chemical treatment, and other processes. These processes help the carbon fiber fabric better bond with other materials.

V. Quality Inspection and Packaging

The completed carbon fiber fabric undergoes rigorous quality inspection, including tests for strength, modulus, density, and other indicators. Qualified carbon fiber fabric is then packaged and shipped to downstream customers for further processing or use.

In summary, the production process of carbon fiber fabric involves multiple key steps and complex processes. Each step requires strict control of parameters and conditions to ensure the quality and performance of the final product. With continuous technological advancements and innovations, the manufacturing process of carbon fiber fabric will continue to improve and optimize.

Is carbon fiber fabric bulletproof

- Kevlar: An aramid fiber known for its exceptional strength and energy-absorbing properties, commonly used in ballistic vests and helmets.

- Ultra-High-Molecular-Weight Polyethylene (UHMWPE): A type of polyethylene with high abrasion resistance and strength-to-weight ratio, utilized in various ballistic applications.

- Aramid Fabrics: Including materials like Nomex, these are used in advanced protective clothing, offering flame resistance and durability.