Products Categories

Featured Products

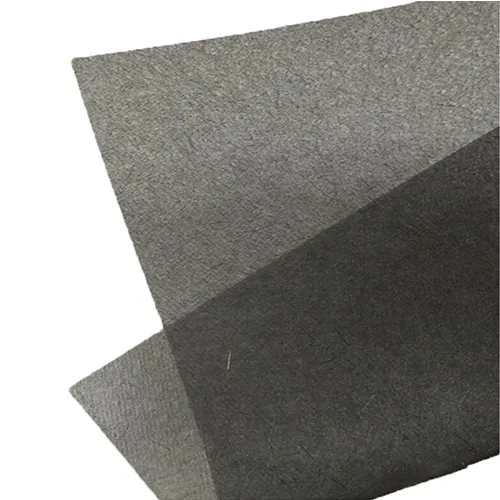

Carbon Fiber Chopped Strand Mat

Carbon Fiber Chopped Strand Mat (CSM) is a non-woven reinforcement composed of randomly oriented short carbon fibers bonded together into a uniform mat structure. It delivers high tensile strength, excellent stiffness, and superior impact resistance. Widely used in composite manufacturing, CSM enhances dimensional stability and surface finish, making it ideal for molding complex geometries in automotive, aerospace, marine, and industrial applications.

Product MOQ

Please note our minimum order for carbon fiber mat. For different specifications of carbon fiber mat, the MOQ is different. For customized carbon fiber mat, due to different customization requirements, the MOQ needs to be confirmed according to the actual situation.

Customization

NQ factories can customize different widths and lengths according to project needs to ensure optimal use of materials.

There is also flexibility in the packaging, which can be customized according to customer requirements, including packaging materials, labels, printing, etc., to meet the needs of different projects.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

Carbon Fiber Chopped Strand Mat, abbreviated as CFCSM, is a non-woven mat product made of chopped carbon fiber strands. It is produced by cutting glass fibers into short lengths of approximately 50 millimeters, uniformly distributing them in a random direction, and bonding them into a mat-like form using polyester powder or polyester emulsion binder.

CFCSM boasts a range of excellent performance characteristics. Firstly, it has a uniform mass per unit area and is free from stains, impurities, and other defects, ensuring overall material quality. Secondly, CFCSM possesses moderate hardness and good flexibility, making it convenient to handle and use. Furthermore, it is easily and completely impregnable, resulting in fewer bubbles and excellent processability, providing favorable conditions for subsequent processing.

Additionally, CFCSM exhibits excellent mold-filling and mold-covering capabilities, suitable for shaping complex-shaped products. Its mechanical properties and chemical resistance are also outstanding, enabling CFCSM to maintain stable performance in various environments.

In summary, Carbon Fiber Chopped Strand Mat is a non-woven mat product made of chopped carbon fiber strands, characterized by its uniform mass per unit area, moderate hardness, good flexibility, easy impregnation, excellent processability, mold-filling and mold-covering capabilities, as well as superior mechanical properties and chemical resistance.

Specification

- Fiber Type: High-modulus, high-strength PAN-based carbon fibers

- Fiber Length: 25–50 mm (1–2 inches) controlled fiber length for optimal reinforcement

- Basis Weight: 50–300 g/m², customizable per application requirements

- Mat Thickness: 0.3–1.5 mm, depending on basis weight and binder content

- Binder System: Thermosetting resin binder compatible with epoxy, polyester, vinyl ester systems

- Density: 1.6–1.8 g/cm³, ensuring structural integrity and consistent quality

- Tensile Strength: Typically 3000–6000 MPa, dependent on fiber grade

- Fiber Orientation: Randomly distributed to provide isotropic reinforcement characteristics

- Standard Roll Width: 1000–2500 mm, customizable according to production needs

- Standard Roll Length: 50–100 meters per roll, subject to customer specification

Color customization

We offer a wide range of standard colours, including classic black, understated grey, and vibrant reds, blues, greens, oranges, purples, silvers, whites and browns.

NQ manufacturers have excellent customization capabilities and can tailor unique colors for Carbon Fiber Mat to the specific needs of their customers. Our professional technical team will use advanced dyeing and coating technology to precisely match the color sample or sample provided by the customer to ensure that the customized Carbon Fiber Mat color is accurate, bright and long-lasting.

Main applications

Aerospace Industry

- Wings and Tail Fins: CFCSM is used in the manufacture of wings and tail fins, effectively reducing weight and improving flight performance and fuel efficiency. Its high strength and lightweight properties make it an ideal material for aircraft.

- Aerospace Engines: CFCSM is utilized in the production of components for aerospace engines, enhancing their performance and reliability. Carbon fiber composites can withstand extreme conditions such as high temperatures and pressures, making them suitable for aerospace engine applications.

- Helicopters: The application of CFCSM significantly reduces the weight of helicopters, improving their performance and hovering capabilities. Additionally, its excellent damping and fatigue resistance properties enhance the safety and service life of helicopters.

Automotive Sector

- Vehicle Bodies and Components: CFCSM is used in the manufacture of automotive bodies and components, significantly reducing the overall vehicle weight and lowering fuel consumption. The lightweight advantage of carbon fiber composites makes vehicles more environmentally friendly and energy-efficient.

- Wheel Hubs: As an essential part of a vehicle, wheel hubs need to bear the weight of the entire vehicle and loads. CFCSM’s high strength and lightweight properties make it an ideal material for wheel hubs.

Medical Field

- X-ray Assisting Equipment: CFCSM is utilized in the production of bed panels, headrests, and radiation positioning plates for X-ray, CT, and ultrasound equipment. Its high X-ray transparency gives carbon fiber materials a unique advantage in the medical field.

- Bone Fixation Plates: CFCSM is used in the manufacture of bone fixation plates, helping reduce infection at the fracture site and promoting healing. Its elastic modulus is closer to human bone, providing a better treatment experience for patients.

Semiconductor Industry

- Carrier Transport: Carbon fibers in CFCSM can freely transport charge carriers, improving the performance of semiconductor devices.

- Enhancing Semiconductor Performance: Carbon fiber materials can increase the response speed and sensitivity of semiconductors, reduce power consumption, and accelerate the speed of transistors.

Features

- High Strength-to-Weight Ratio: Enables manufacturing of lighter yet stronger parts, reducing material costs and improving product performance.

- Consistent Quality: Uniform fiber distribution ensures reliable mechanical properties and reduces production defects.

- Improved Durability: Enhanced impact and fatigue resistance lowers product failure rates and extends service life.

- Easy Processing: Compatible with multiple resin systems, simplifying manufacturing and reducing production time.

- Thermal & Chemical Resistance: Suitable for harsh environments, reducing maintenance and replacement frequency.

- Dimensional Stability: Minimizes warping and shrinkage, ensuring tight tolerances and high-quality finishes.

- Cost Efficiency: Optimized mat weight and performance balance help control overall composite costs without sacrificing quality.

Product | Carbon fiber mat/felt/tissue/web |

Material | Carbon fiber |

Weight | 10g, 20g, 30g, 50g, 60g or customized |

Width | 125cm or customized |

Length | 300m/roll |

Moisture content | ≤0.5% |

Surface resistivity | <10Ω |

Fiber diameter | 6-7 um |

Binder content | 3%-20% |

For more product specifications, please contact our professionals!

- Advanced Carbon Fiber Air Laid Machine

NQ’s machine uses high-quality fibers for high efficiency, precise control, energy saving, and wide application. - Powerful Production Capacity

Equipped with 3 punching needle lines and 6 weaving lines, using advanced tech and quality materials for efficient, standardized carbon fiber mat production. - Strict Quality Control

NQ enforces rigorous QC from raw materials to delivery. All mats meet CE, ASTM, SGS, and BSC standards for top industry stability and consistency.

Maximize Strength, Improve Impact Resistance, Simplify Fabrication

Discover the power of Carbon Fiber Chopped Strand Mat — engineered to provide exceptional tensile strength and isotropic reinforcement thanks to its randomly oriented fibers. Its lightweight and flexible structure enhances impact resistance while enabling easy molding of complex shapes. Designed for seamless integration with multiple resin systems, it streamlines production and reduces waste. Choose Carbon Fiber Chopped Strand Mat to deliver durable, high-performance composites with consistent quality and cost efficiency.