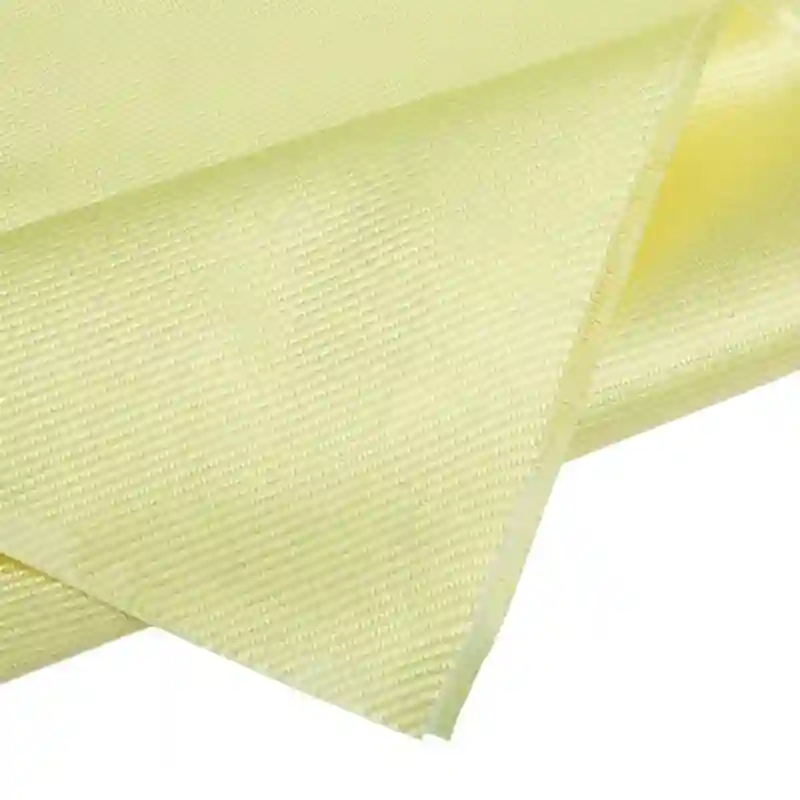

Aramid Stab Fabric

Features

Colour

Our factory has advanced dyeing and printing technology and is able to customize the colors of Aramid Stab Fabric according to customer requirements.

- Standard colors: We offer a range of standard colors for customers to choose from, such as black, gray, yellow, blue, red, green, etc. These colors are in line with industry norms and meet the needs of most customers.

- Custom color: If the customer needs a specific color or color combination, our factory can customize the production according to the color sample provided by the customer. Whether it is a bright color or a low-key dark color, we can accurately restore the effect that customers expect.

- Camouflage patterns: To meet the needs of the military and outdoor sectors, we also offer custom camouflage patterns. Customers can choose different camouflage styles and color combinations according to their needs to achieve the best camouflage effect.

Braided Texture

Plain Weave: Plain weave is one of the most basic weaving methods, in which the longitude and latitude lines are interwoven vertically to form a uniform grid structure. This textured Aramid Stab Fabric offers excellent stability and wear resistance, making it ideal for the field of protective equipment.

Twill Weave: Twill weave is a slight change on the basis of plain weave, so that the longitude and latitude are interwoven at a certain Angle to form an oblique texture. This textured Aramid Stab Fabric provides increased elasticity and flexibility while maintaining stability, making it suitable for use in protective equipment that requires flexibility.

Satin Weave: Satin weave is a more complex weave in which the latitude and longitude are thinly interwoven, creating a smooth surface and a distinct sheen. This textured Aramid Stab Fabric has an elegant look and is suitable for high-end protective gear and fashion accessories.

Checkerboard Weave: A regular checkerboard pattern is formed through the interweaving of longitude and latitude lines. This texture of Aramid Stab Fabric is decorative while maintaining protective performance, and is suitable for special purpose protective clothing.

Honeycomb Weave: Honeycomb weave takes hexagons as the basic unit and forms a honeycomb texture through the interweaving of longitude and latitude lines. This textured Aramid Stab Fabric has excellent air permeability and tensile resistance, making it suitable for making breathable and comfortable protective equipment.

Ripple Weave: Through a special weaving process, the surface of the Aramid Stab Fabric is formed into undulating ripple texture. This texture is not only beautiful, but also increases the impact resistance of the material and is suitable for occasions where additional protection is required.

Product MOQ

Please note our minimum order quantity of Aramid Fabric. For the conventionalAramid Fabric in stock, there is no MOQ. For customized Aramid Fabric, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

●FREE SAMPLE ●FREE RETURNS

*Customization is always available, please mark down your need in cart or just contact us.

Project Monitoring

Shipping Order Track

Instructions for Use

VIP Customer Service

Intact Guarantee

Description

- Aramid Stab Fabric, a unique high-performance protective material, has gained widespread recognition in the market for its superior physical properties and extensive application fields.

- Firstly, the core of Aramid Stab Fabric lies in its use of aramid fibers. These fibers, characterized by high strength and modulus, endow Aramid Stab Fabric with excellent tensile strength and cut resistance. Whether facing sharp object penetration or other forms of physical impact, it provides reliable protection for wearers.

- Secondly, the weaving technology of Aramid Stab Fabric is exquisite. Through precision weaving techniques, aramid fibers are woven into various textures and patterns, not only visually appealing but also ensuring the stability and durability of the material. Whether it’s plain weave, twill weave, or other complex textures, customization is possible to meet the needs of different occasions and applications.

- Moreover, Aramid Stab Fabric offers excellent comfort. Despite its robust protective capabilities, the material itself remains lightweight and flexible, ensuring wearers will not feel constrained or uncomfortable during prolonged use. This makes Aramid Stab Fabric an ideal choice for long-wearing applications, whether in the workplace or during outdoor activities.

- Additionally, Aramid Stab Fabric boasts remarkable durability and stability. It can withstand various harsh environments, including high temperatures, humidity, and chemical corrosion. This means that regardless of extreme weather conditions or chemically contaminated environments, Aramid Stab Fabric maintains its protective performance, providing users with lasting protection.

- To cater to the needs of different users, Aramid Stab Fabric offers personalized customization services. Users can choose specific colors, textures, and specifications based on their preferences and requirements. Our professional team ensures that every user receives a satisfactory product and provides comprehensive consultation and support throughout the process.

Main Function

Safety And Protective Applications

Military and Police Equipment: Aramid Stab Fabric is commonly used in the manufacturing of bulletproof vests, stab-resistant vests, helmets, and other personal protective equipment for military personnel and police officers.

Civilian Protective Clothing: In civilian use, Aramid Stab Fabric is also applied in the production of stab-resistant vests, cut-resistant gloves, and other protective gear for specific occupations such as security guards and delivery personnel to protect against knife cuts and stabs.

Transportation Industry

Aircraft Seats and Airbags: Due to its lightweight yet high-strength properties, Aramid Stab Fabric is used in the manufacturing of aircraft seats and airbags, enhancing passenger safety.

Automotive Safety Components: In the automotive sector, Aramid Stab Fabric finds applications in car seats, airbags, door liners, and other components, improving overall vehicle safety.

Industrial Applications

Cut Resistance: In industries like machinery manufacturing and metalworking, Aramid Stab Fabric is used to make protective clothing, aprons, and other protective gear to safeguard workers from cuts and stabs.

High-Temperature Protection: Its heat-resistant properties allow Aramid Stab Fabric to be utilized in the production of high-temperature workwear, fireproof blankets, and other protective equipment.

Sports and Recreation

Outdoor Sports Equipment: Aramid Stab Fabric’s lightweight, abrasion-resistant, and stab-resistant properties make it a popular choice for outdoor sports gear such as hiking boots and cycling attire, enhancing safety during outdoor activities.

Extreme Sports Gear: In extreme sports like rock climbing and skateboarding, Aramid Stab Fabric is utilized in the production of protective clothing and gear to provide additional protection for athletes.

Other Applications

Medical Devices: Aramid Stab Fabric finds use in the medical industry, specifically in the manufacturing of protective components for surgical gowns, drapes, and other medical equipment, enhancing safety during surgical procedures.

Construction and Civil Engineering: In the field of construction and civil engineering, Aramid Stab Fabric is employed in the production of safety nets, protective covers, and other protective equipment to safeguard construction workers from accidental injuries.

Specification

Model | Surface | weight/gsm | Thickness/mm | Density |

ZF-200P-60 | PPlain | 60 | 0.1 | 15*15 |

ZF-400P-80 | Plain | 80 | 0.11 | 9*9 |

ZF-400P-90 | Plain | 90 | 0.12 | 10*10 |

ZF-400P-110 | Plain | 110 | 0.13 | 12*12 |

ZF-400P-120 | Plain | 120 | 0.14 | 13*13 |

ZF-1000P-120 | Plain | 120 | 0.2 | 5*5 |

ZF-1000P-135 | Plain | 135 | 0.22 | 6*6 |

ZF-1000P-155 | Plain | 155 | 0.24 | 7*7 |

ZF-1000P-180 | Plain | 180 | 0.25 | 8*8 |

ZF-1000T-180 | Twill | 180 | 0.25 | 8*8 |

ZF-1000P-200 | Plain | 200 | 0.26 | 9*9 |

ZF-1000T-200 | Twill | 200 | 0.26 | 9*9 |

ZF-1000T-220 | Twill | 220 | 0.28 | 10*10 |

ZF-1500P-170 | Plain | 170 | 0.22 | 5*5 |

ZF-1500P-185 | Plain | 185 | 0.24 | 5.5*5.5 |

ZF-1500T-185 | Twill | 185 | 0.24 | 5.5*5.5 |

ZF-1500P-200 | Plain | 200 | 0.26 | 6*6 |

ZF-1500T-200 | Twill | 200 | 0.26 | 6*6 |

ZF-1500P-250 | Plain | 250 | 0.32 | 7.5*7.5 |

ZF-1500T-250 | Twill | 250 | 0.32 | 7.5*7.5 |

ZF-3000P-400 | Plain | 400 | 0.45 | 6*6 |

ZF-3000P-450 | Twill | 450*450 | 0.58 | 7*7 |

Model | Surface | weight/gsm | Thickness/mm | Density |

ZF-200P-60 | Plain | 60 | 0.1 | 15*15 |

ZF-400P-80 | Plain | 80 | 0.11 | 9*9 |

ZF-400P-90 | Plain | 90 | 0.12 | 10*10 |

ZF-400P-110 | Plain | 110 | 0.13 | 12*12 |

ZF-400P-120 | Plain | 120 | 0.14 | 13*13 |

ZF-1000P-120 | Plain | 120 | 0.2 | 5*5 |

ZF-1000P-135 | Plain | 135 | 0.22 | 6*6 |

ZF-1000P-155 | Plain | 155 | 0.24 | 7*7 |

ZF-1000P-180 | Plain | 180 | 0.25 | 8*8 |

ZF-1000T-180 | Twill | 180 | 0.25 | 8*8 |

ZF-1000P-200 | Plain | 200 | 0.26 | 9*9 |

ZF-1000T-200 | Twill | 200 | 0.26 | 9*9 |

ZF-1000T-220 | Twill | 220 | 0.28 | 10*10 |

ZF-1500P-170 | Plain | 170 | 0.22 | 5*5 |

ZF-1500P-185 | Plain | 185 | 0.24 | 5.5*5.5 |

ZF-1500T-185 | Twill | 185 | 0.24 | 5.5*5.5 |

ZF-1500P-200 | Plain | 200 | 0.26 | 6*6 |

ZF-1500T-200 | Twill | 200 | 0.26 | 6*6 |

ZF-1500P-250 | Plain | 250 | 0.32 | 7.5*7.5 |

ZF-1500T-250 | Twill | 250 | 0.32 | 7.5*7.5 |

ZF-3000P-400 | Plain | 400 | 0.45 | 6*6 |

ZF-3000P-450 | Twill | 450*450 | 0.58 | 7*7 |

Consult Your NQ Aramid Fabric Wholesale And Packaging Specialist

We help you avoid pitfalls and deliver the quality and value you need for aramid fabric on time and on budget.