Aramid Fiber Pull Tape

Features

1.Aramid Fiber Pull Tape has good insulation and flame retardancy, making it widely used in electric power and aviation and other fields. In general, Aramid Fiber Pull Tape, with its high strength, high temperature resistance, chemical resistance, light weight, wear resistance and good dimensional stability, performs well in pipelines and other applications requiring high strength, high wear resistance and high temperature properties.

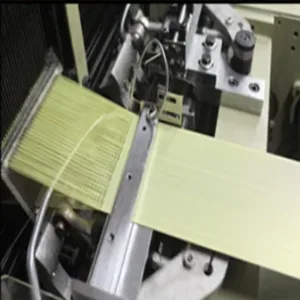

2.Weaving process: Plain weave, Twill weave, Groove weave, Herringbone weave, etc., support customization.

3.Color: including red, blue, yellow, black, white, etc., and a variety of colors for choice, support customization.

Product MOQ

Please note our minimum order quantity of Aramid Fiber Pull Tape.For the conventional Aramid Fiber Pull Tape in stock, there is no MOQ. For customized Aramid Fiber Pull Tape, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

●FREE SAMPLE ●FREE RETURNS

*Customization is always available, please mark down your need in cart or just contact us.

Project Monitoring

Shipping Order Track

Instructions for Use

VIP Customer Service

Intact Guarantee

Description

Aramid Fiber Pull Tape is a type of high-performance pull tape made from aramid fibers. This fiber possesses numerous unique physical and chemical properties, including high strength, high modulus, heat resistance, chemical resistance, abrasion resistance, and cut resistance. These properties make Aramid Fiber Pull Tape suitable for a wide range of applications, including pipeline fixation and protection, cable routing and support, aerospace applications, and other industrial fields that require high strength, abrasion resistance, and heat resistance.

Specifically, aramid fiber, the material used in Aramid Fiber Pull Tape, is a type of polyamide fiber developed by DuPont, commonly known as Kevlar. This fiber is renowned for its exceptional strength and durability, and is used in the manufacture of bulletproof vests, parachutes, fishing nets, and as a substitute for glass fiber in circuit board substrates. Additionally, aramid fiber is available in various forms such as continuous filaments, crimped staple fibers, chopped fibers, pulp, and aramid paper, which are widely used in tires, optical cables, bulletproof materials, ropes, specialty yarns, blended yarns, needle-punched/spunlaced nonwoven fabrics, friction materials, sealing materials, and composite materials.

Main application field

Pipeline Fixing And Protection:

In the oil, gas, chemical and other industries, it is used to fix and protect the pipeline to prevent the pipeline from being damaged by external forces.

Cable Wiring And Support:

In the power, communication and other industries, it is used for cable wiring, fixing and support to ensure the stability and safety of the cable.

Aerospace Field:

Due to its characteristics of light weight, high strength and high temperature resistance, Aramid Fiber Pull Tape has also been widely used in the aerospace field, such as the fixing and support of aircraft cables.

Other Industrial Sectors:

In the shipbuilding, automobile, construction and other industries, there are also Aramid Fiber Pull Tape figures, used for a variety of occasions requiring high strength, high wear resistance and high temperature resistance.

Specification

Product Name | Aramid Woven Tape |

Type | Plain/Twill/Herringbone (custom) |

Material | 100% Para/Meta Aramid |

Width | 5mm-100mm |

Thickness | 0.5mm-5.5mm |

Technics | Woven |

Yarn Count (Denier) | 1000D-3000D |

Color | Red, blue, yellow, black, white, etc. |

Place of Origin | China |

Feature | Heat-resistant, flame retardant, chemical-resistant,heat-Insulation, cut&abrasion resistant, high strength, high modulus |

Packing | Rolls |

Brand Name | NQ |

Application | Firefighting, garment, bags, industry etc. |

Certification | ISO9001, SGS,CE |

MOQ | No MOQ for regular models |

OEM | Support OEM/ODM services |

Sample | Free |

Product Name | Aramid Woven Tape |

Type | Plain/Twill/Herringbone (custom) |

Material | 100% Para/Meta Aramid |

Width | 5mm-100mm |

Thickness | 0.5mm-5.5mm |

Technics | Woven |

Yarn Count (Denier) | 1000D-3000D |

Color | Red, blue, yellow, black, white, etc. |

Usage | Garment, Industry, Firefighter, Aerospace, WORKWEAR, Anticutting Gloves/ Firefighter Uniform/ Anti Cutting Fabrics/ Wear Resisting |

Feature | Heat-resistant, flame retardant, chemical-resistant,heat-Insulation, cut&abrasion resistant, high strength, high modulus |

Packing | Rolls |

Brand Name | NQ |

Application | Firefighting, garment, bags, industry etc. |

Certification | CE, ASTM, SGS, ISO, BSCI |

MOQ | No MOQ for regular models |

OEM | Support OEM/ODM services |

Sample | Free |

FAQ

KEVLAR® Fabric is made with genuine DuPont™ KEVLAR® fiber. DuPont™ and KEVLAR® are registered trademarks of E.I.

Aramid Tapes are narrow widths of woven fabric woven from KEVLAR® fibers with a strong selvage edge. This prevents fraying and unraveling of fabric at the edges. The narrow widths eliminate the cutting of wider aramid fabrics down to size and increases accuracy and productivity.

Aramid fibres have high tenacity and high resistance to stretch, to most chemicals, and to high temperature. They are well known for their relatively lightweight and resistance to fatigue and damage. Because of these properties, aramid fibres are widely used and accepted for making body armour.These include pipe fixing and protection, cable routing and support, aerospace and other industrial areas requiring high strength, wear resistance and high temperature resistance.

Some people ask about the difference between aramid and Kevlar. The answer is, no difference exists. Kevlar® is the trademarked brand name for the aramid fiber made by DuPont™. However, due to it being the first para-aramid developed, its name is synonymous with the term aramid.

- Expensive: In aspects of cost, the material is more expensive than most other materials, due to its complex manufacturing process and high demand.

- Brittle: Easily prone to cracking under high impact or stress loads.

- Conductive: The electrical conductive characteristic can cause problems in some applications.

Consult Your NQ Aramid Woven Tape Wholesale And Packaging Specialist

We help you avoid pitfalls and deliver the quality and value you need for aramid woven tape and aramid woven tape on time and on budget.