Aramid Fabric Motorcycles

Features

Colors

Aramid Fabric Motorcycles come in a wide array of colors to suit the rider’s personal preferences and riding style. Standard color options include black, gray, red, blue, yellow, and white, which are popular choices for riders looking for a classic or neutral look. However, the factory’s customization capabilities truly shine when it comes to more unique and vibrant hues.

The factory is able to dye the aramid fabric in virtually any color, allowing riders to choose from a nearly limitless palette. Whether you prefer a subtle shade of purple or a bold neon green, the factory can accommodate your request. Additionally, they can offer color gradients or patterns, such as stripes or checks, to add even more visual interest to your motorcycle.

Weaving Methods

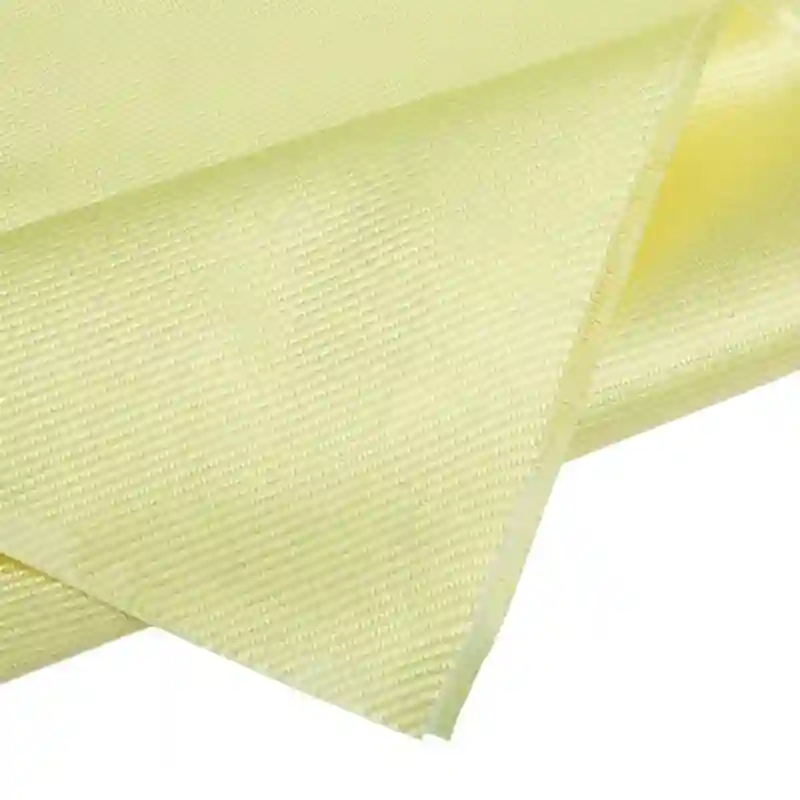

The weaving methods used for Aramid Fabric Motorcycles are equally as diverse as the color options. Standard weaving techniques include plain weave, twill weave, and satin weave, each offering a unique visual texture and feel. Plain weave is the most common and results in a simple yet durable fabric, while twill weave creates a diagonal pattern that adds visual interest. Satin weave, on the other hand, produces a smooth and shiny surface, ideal for riders who prefer a sleek and polished look.

However, the factory’s customization capabilities extend beyond standard weaving methods. They are able to create custom weaves using advanced textile machinery, allowing for intricate patterns and designs to be incorporated into the fabric. Whether you want a specific logo or insignia woven into the fabric or a unique geometric pattern, the factory can make it happen.

Product MOQ

Please note our minimum order quantity of Aramid Fabric. For the conventionalAramid Fabric in stock, there is no MOQ. For customized Aramid Fabric, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

●FREE SAMPLE ●FREE RETURNS

*Customization is always available, please mark down your need in cart or just contact us.

Project Monitoring

Shipping Order Track

Instructions for Use

VIP Customer Service

Intact Guarantee

Description

In the world of motorcycles, the application of innovative materials has always been crucial in enhancing performance and improving riding experiences. Aramid Fabric, also known as aromatic polyamide fiber, has become a favored choice among motorcycle manufacturers and riders due to its superior performance and unique advantages.

Aramid Fabric boasts qualities such as lightness with high strength, wear and temperature resistance, impact durability, and excellent stability. These features make it an ideal material for motorcycle manufacturing. By using Aramid Fabric, motorcycle manufacturers can create lighter, stronger, and more durable body structures, thereby enhancing the overall performance and riding experience of the motorcycle.

For motorcycle riders, the application of Aramid Fabric is not limited to bodywork coverings. It can also be used to produce safety gear such as riding apparel and helmets. This fabric provides riders with additional protection, reducing the risk of injury in accidents. Additionally, Aramid Fabric’s excellent wear and heat resistance ensure the stability and reliability of riding apparel and helmets in harsh environments.

In conclusion, Aramid Fabric plays an increasingly important role in the motorcycle industry with its outstanding performance and broad application prospects. It not only enhances the performance and durability of motorcycles but also provides riders with safer and more comfortable riding experiences. With continuous technological advancements and broadening applications, Aramid Fabric is expected to play a more significant role in the motorcycle sector.

Main Function

Body Panels and Fairings:

Aramid Fabric’s lightweight yet high-strength characteristics make it an excellent choice for motorcycle body panels and fairings. These parts are not only visually appealing but also provide excellent durability and resistance to scratches and impacts.

Chassis Components:

The chassis of a motorcycle is responsible for supporting the entire vehicle and must be both strong and lightweight. Aramid Fabric can be used in chassis components to reduce weight while maintaining strength, improving the overall performance and handling of the motorcycle.

Protective Gear:

Aramid Fabric’s excellent impact resistance and durability make it a popular material for motorcycle protective gear such as jackets, pants, and gloves. It offers riders additional protection from impacts and abrasions, reducing the risk of injury in accidents.

Helmets:

Helmets are a crucial safety component for motorcycle riders. Aramid Fabric can be used in the shell or liner of helmets to provide enhanced protection against impacts. Its lightweight and strong properties ensure that helmets remain comfortable to wear while providing maximum safety.

Exhaust Systems:

The high-temperature resistance of Aramid Fabric makes it suitable for use in motorcycle exhaust systems. It can be used as a heat shield or wrap around exhaust pipes to protect other components from excessive heat and improve the overall durability of the system.

Electrical Wiring:

Aramid Fabric’s excellent electrical insulation properties make it an ideal material for motorcycle electrical wiring. It can be used as a protective cover or sleeve for wires and cables, preventing damage and ensuring reliable performance.

Specification

Model | Surface | weight/gsm | Thickness/mm | Density |

ZF-200P-60 | PPlain | 60 | 0.1 | 15*15 |

ZF-400P-80 | Plain | 80 | 0.11 | 9*9 |

ZF-400P-90 | Plain | 90 | 0.12 | 10*10 |

ZF-400P-110 | Plain | 110 | 0.13 | 12*12 |

ZF-400P-120 | Plain | 120 | 0.14 | 13*13 |

ZF-1000P-120 | Plain | 120 | 0.2 | 5*5 |

ZF-1000P-135 | Plain | 135 | 0.22 | 6*6 |

ZF-1000P-155 | Plain | 155 | 0.24 | 7*7 |

ZF-1000P-180 | Plain | 180 | 0.25 | 8*8 |

ZF-1000T-180 | Twill | 180 | 0.25 | 8*8 |

ZF-1000P-200 | Plain | 200 | 0.26 | 9*9 |

ZF-1000T-200 | Twill | 200 | 0.26 | 9*9 |

ZF-1000T-220 | Twill | 220 | 0.28 | 10*10 |

ZF-1500P-170 | Plain | 170 | 0.22 | 5*5 |

ZF-1500P-185 | Plain | 185 | 0.24 | 5.5*5.5 |

ZF-1500T-185 | Twill | 185 | 0.24 | 5.5*5.5 |

ZF-1500P-200 | Plain | 200 | 0.26 | 6*6 |

ZF-1500T-200 | Twill | 200 | 0.26 | 6*6 |

ZF-1500P-250 | Plain | 250 | 0.32 | 7.5*7.5 |

ZF-1500T-250 | Twill | 250 | 0.32 | 7.5*7.5 |

ZF-3000P-400 | Plain | 400 | 0.45 | 6*6 |

ZF-3000P-450 | Twill | 450*450 | 0.58 | 7*7 |

Model | Surface | weight/gsm | Thickness/mm | Density |

ZF-200P-60 | Plain | 60 | 0.1 | 15*15 |

ZF-400P-80 | Plain | 80 | 0.11 | 9*9 |

ZF-400P-90 | Plain | 90 | 0.12 | 10*10 |

ZF-400P-110 | Plain | 110 | 0.13 | 12*12 |

ZF-400P-120 | Plain | 120 | 0.14 | 13*13 |

ZF-1000P-120 | Plain | 120 | 0.2 | 5*5 |

ZF-1000P-135 | Plain | 135 | 0.22 | 6*6 |

ZF-1000P-155 | Plain | 155 | 0.24 | 7*7 |

ZF-1000P-180 | Plain | 180 | 0.25 | 8*8 |

ZF-1000T-180 | Twill | 180 | 0.25 | 8*8 |

ZF-1000P-200 | Plain | 200 | 0.26 | 9*9 |

ZF-1000T-200 | Twill | 200 | 0.26 | 9*9 |

ZF-1000T-220 | Twill | 220 | 0.28 | 10*10 |

ZF-1500P-170 | Plain | 170 | 0.22 | 5*5 |

ZF-1500P-185 | Plain | 185 | 0.24 | 5.5*5.5 |

ZF-1500T-185 | Twill | 185 | 0.24 | 5.5*5.5 |

ZF-1500P-200 | Plain | 200 | 0.26 | 6*6 |

ZF-1500T-200 | Twill | 200 | 0.26 | 6*6 |

ZF-1500P-250 | Plain | 250 | 0.32 | 7.5*7.5 |

ZF-1500T-250 | Twill | 250 | 0.32 | 7.5*7.5 |

ZF-3000P-400 | Plain | 400 | 0.45 | 6*6 |

ZF-3000P-450 | Twill | 450*450 | 0.58 | 7*7 |

Consult Your NQ Aramid Fabric Wholesale And Packaging Specialist

We help you avoid pitfalls and deliver the quality and value you need for aramid fabric on time and on budget.