Products Categories

Featured Products

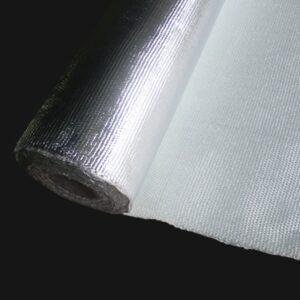

Aluminized Fiberglass Fabric

Aluminized Fiberglass Fabric is a high-performance composite made of strong fiberglass cloth laminated with aluminum foil or film. It offers excellent heat reflection—over 95% of radiant heat—and high temperature resistance. The fiberglass layer adds strength and insulation, making it ideal for thermal protection, insulation, welding blankets, and fire curtains. This material enhances safety and extends equipment lifespan, making it a reliable choice for demanding industrial environments.

- High Heat Reflection: Reflects over 95% of radiant heat

- Excellent Temperature Resistance: Suitable for extreme environments

- Strong Insulation: Reduces heat transfer effectively

- Durable & Tear-Resistant: Reinforced by fiberglass base

- Flexible & Easy to Handle: Can be cut, sewn, or shaped as needed

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese fiberglass manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

Features

1. Superior Heat Reflection

- Feature: The aluminized surface reflects up to 97% of radiant heat, significantly reducing heat transfer.

- Benefit: Protects equipment and personnel from high-temperature environments, enhancing safety and reducing cooling costs.

2. High Temperature Resistance

- Feature: The fiberglass base can withstand continuous temperatures up to 550°C (1022°F), while the aluminum layer endures up to 150°C (302°F).

- Benefit: Ensures durability and reliability in high-heat applications, minimizing maintenance and replacement needs.

3. Excellent Mechanical Strength and Tear Resistance

- Feature: Fiberglass provides high tensile strength and resistance to tearing.

- Benefit: Extends the service life of the material, reducing downtime and operational costs.

4. Flexibility and Ease of Fabrication

- Feature: The fabric is pliable and can be cut, sewn, or shaped to fit various applications.

- Benefit: Allows for customized solutions in complex installations, improving efficiency and adaptability.

5. Chemical and Moisture Resistance

- Feature: The aluminum layer offers resistance to oils, solvents, and moisture.

- Benefit: Suitable for use in harsh environments, reducing the risk of material degradation and associated costs.

Specification

Type:

- Self-adhesive, non-self-adhesive

Thickness

- Ranges from 0.09 mm to 3.0 mm, accommodating various insulation and mechanical strength requirements.

Weight

- Varies between 75 g/m² and 1900 g/m², suitable for applications from lightweight protective clothing to heavy-duty industrial insulation.

Width

- Standard widths include 1000 mm, 1200 mm, and 1500 mm, with custom widths available upon request.

Color

- Typically silver, due to the aluminum foil layer. Some manufacturers offer additional colors like white, black, or yellow to meet specific application needs.

Weave Patterns

- Available in various weaves such as plain, twill, satin, and honeycomb, affecting the fabric’s flexibility and strength.

Temperature Resistance

- The fiberglass base can withstand continuous temperatures up to 550°C (1022°F).

- The aluminum foil layer typically resists temperatures up to 150°C (302°F), depending on the adhesive used.

Main applications

1.Automotive and Transportation

- Application: Used in heat shields, engine covers, and exhaust wraps.

- Advantage: Reflects up to 95% of radiant heat, protecting components from heat damage and improving vehicle performance.

2. Aerospace and Defense

- Application: Employed in thermal insulation for spacecraft, protective clothing, and equipment covers.

- Advantage: Withstands extreme temperatures, ensuring the safety and reliability of aerospace components.

3. Construction and Building Materials

- Application: Integrated into fire-resistant insulation panels and reflective barriers.

- Advantage: Enhances fire safety and energy efficiency in buildings by reflecting radiant heat.

4. Industrial Safety and Protective Gear

- Application: Fabricated into fire-resistant clothing, welding blankets, and safety curtains.

- Advantage: Provides protection against sparks, molten metal, and high temperatures, ensuring worker safety.

5. Marine Industry

- Application: Used for insulating shipboard and submarine hulls, as well as engine components.

- Advantage: Offers thermal insulation and moisture resistance, enhancing onboard safety and comfort.

6. Power Generation

- Application: Applied to insulate turbines, generators, and steam pipes.

- Advantage: Improves thermal efficiency and protects equipment from heat-related damage.

📌 Notes:

- Thickness: Ranges from 0.09 mm to 3.00 mm, suitable for various insulation and mechanical strength requirements.

- Weight: Varies between 115 g/m² and 1900 g/m², accommodating applications from lightweight protective clothing to heavy-duty industrial insulation.

- Width: Standard widths include 1000 mm, 1200 mm, and 1500 mm; custom widths are available upon request.

- Color: Typically silver due to the aluminum foil layer; some models offer white to meet specific application needs.

- Weave Patterns: Available in plain, 4H satin, and 8H satin weaves, affecting the fabric’s flexibility and strength.

- Temperature Resistance: The fiberglass base can withstand continuous temperatures up to 550°C (1022°F). The aluminum foil layer typically resists temperatures up to 150°C (302°F), depending on the adhesive used.

- Self-Adhesive Options: Certain models (e.g., NQ-ALFW600) feature a high-temperature pressure-sensitive adhesive backing for ease of installation, suitable for applications requiring quick sealing.

For more product specifications, please contact our professionals!

Premium quality: With 25 production lines and cutting-edge fiberglass textile technology, we ensure top-quality fiberglass materials through strict quality control.

Competitive price: By choosing our custom fiberglass fabric, you’ll enjoy top-quality products, competitive pricing, and timely delivery—helping you save costs and avoid delays.

Fully Customize: As your trusted fiberglass fabric manufacturer, we provide tailor-made customization services and packaging solutions for various fiberglass products, including weight, texture length, etc.