Products Categories

Featured Products

Twill Carbon Fiber Tube

Color customization

Carbon Fiber tubes come in a variety of colors, including the usual black, white, blue, red, yellow, color, and a variety of other color options. Customers can customize unique colors according to specific needs to match specific application scenarios or brand styles. The factory will use advanced technology and high-quality materials to ensure the stability and durability of customized colors, and provide customers with personalized carbon fiber square tube products.

Product MOQ

Please note our minimum order quantity of Carbon Fiber Tube. For the conventional Carbon Fiber Tube in stock, there is no MOQ. For customized Carbon Fiber Tube, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

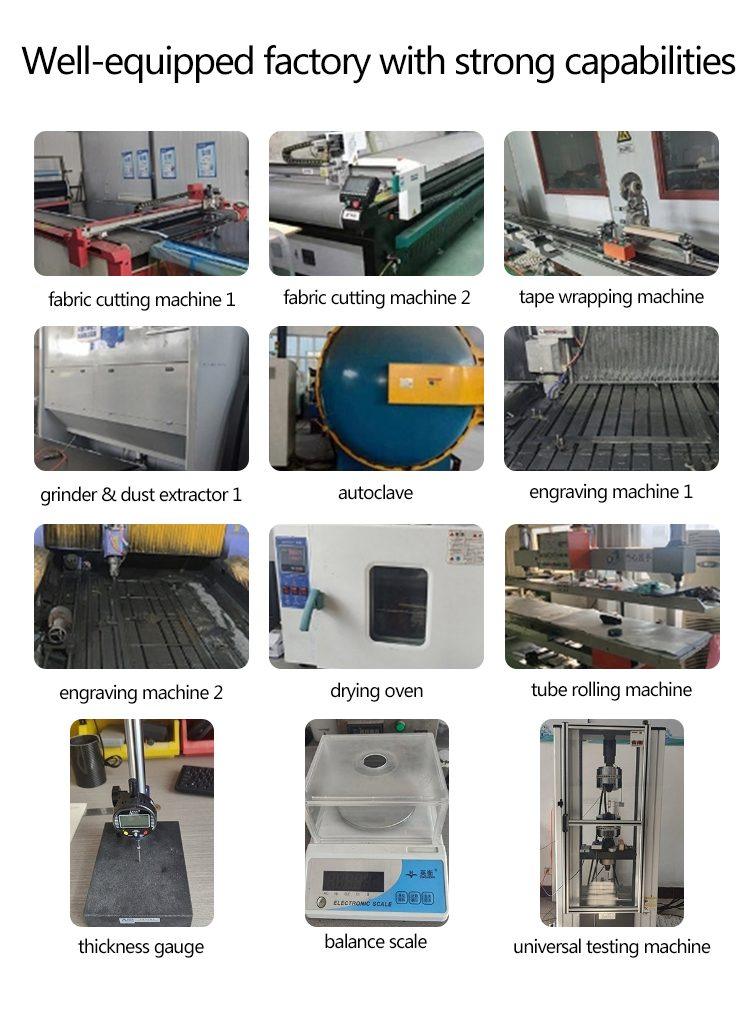

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

Twill Carbon Fiber Tube, crafted through a specialized weaving process known as twill, possesses numerous compelling characteristics. Its high strength surpasses traditional metal materials such as steel or aluminum, ensuring excellent performance in various demanding applications. Additionally, its lightweight nature makes it particularly prominent in fields requiring weight reduction, such as aerospace, automotive, and sports equipment. With its excellent corrosion resistance, Twill Carbon Fiber Tube maintains stable performance even in harsh environments.

In terms of customization capabilities, Twill Carbon Fiber Tube exhibits significant flexibility. Factories can customize carbon fiber tubes with different specifications and sizes according to customer needs, satisfying the demands of various complex application scenarios. Furthermore, by adjusting the carbon fiber content and weaving pattern, carbon fiber tubes with different mechanical properties can be produced to meet specific application requirements. Additionally, carbon fiber tubes feature unique appearance and decorative effects, and factories can provide various surface treatments and color options based on customer needs, achieving personalized customization.

The manufacturing process of Twill Carbon Fiber Tube involves multiple precisely controlled steps, including fiber pre-impregnation, weaving, forming, and curing. These steps ensure the excellent interlayer bonding and mechanical strength of the carbon fiber tube. Currently, the prepreg bagging/autoclave process is one of the most widely used manufacturing techniques, further enhancing the performance and quality of the carbon fiber tube.

With its unique properties and broad application prospects, Twill Carbon Fiber Tube has become an indispensable part of modern industry. Whether in aerospace, automotive, or sports equipment fields, it plays a crucial role, providing powerful support for various high-end applications.

Specification

- Material Structure

Made from high-strength twill weave carbon fiber fabric, featuring a clear and attractive surface pattern. - Outer Diameter Range

6 mm to 50 mm, customizable sizes available. - Wall Thickness Range

0.4 mm to 2.0 mm, thin-wall design. - Standard Length

1000 mm (1 meter), custom cut lengths available upon request. - Weight

Approximately 10 g to 300 g per meter, depending on size specifications. - Surface Finish

Matte or glossy finish, with optional special coatings. - Dimensional Tolerance

Outer diameter and wall thickness tolerance approximately ±0.1 mm.

Main applications

Sports and Recreation Industry

- Golf Clubs and Fishing Rods:

- The application of carbon fiber tubes in the sports and recreation industry began with golf clubs and fishing rods. Carbon fiber golf clubs, weighing only around 50g, are approximately half the weight of similarly sized steel clubs, providing better elasticity, resilience, reduced vibration, and improved balance.

- Carbon fiber fishing rods are favored for their high stiffness and sensitivity, reducing the athlete’s burden and enhancing the success rate of fishing.

- Tennis Rackets and Badminton Rackets:

- Carbon fiber tennis rackets are lighter than traditional wooden or metal rackets, reducing physical exertion for athletes and enhancing the pleasure of the sport. Carbon fiber tennis rackets also have a longer lifespan, further enhancing their appeal.

- Badminton rackets also benefit from the lightweight and high-strength properties of carbon fiber, providing better control and power transmission.

- Bicycles:

- Carbon fiber bicycles are the preferred choice for riders seeking high performance due to their lightweight and high modulus properties. Carbon fiber frames not only reduce the overall weight of the bike but also improve rigidity and stability, making cycling more comfortable and safe.

Aerospace Industry

- Aircraft Manufacturing:

- Carbon fiber composite materials are increasingly used in aircraft manufacturing, including fuselage, wing structures, and control devices. Compared to traditional metal materials, carbon fiber composite materials can significantly reduce the weight of aircraft, improving fuel efficiency and flight performance.

- For example, the mature application of CFRP (carbon fiber reinforced resin) in aircraft fuselage manufacturing provides the most effective way to reduce aircraft body mass. It is estimated that the use of carbon fiber composite materials in aircraft structures can reduce aircraft weight by up to 30%.

- Lightweighting:

- In the aerospace industry, the application of carbon fiber materials is crucial for achieving lightweighting, miniaturization, and high-performance. By using carbon fiber composite materials, the mass of spacecraft can be significantly reduced, improving fuel efficiency and extending service life.

- For example, the use of carbon fiber materials in spacecraft structures can reduce the weight of spacecraft, enhance payload capacity, and improve operational efficiency. Additionally, carbon fiber can be used to manufacture critical components such as thermal protection materials and solar panels.

Transportation Industry

- Automotive and Motorcycles:

- The application of carbon fiber composite materials in automotive and motorcycle manufacturing is gradually increasing, used in manufacturing bodywork, chassis, suspension systems, and braking systems. These applications can significantly reduce the weight of vehicles, improving fuel efficiency and performance.

- For example, the use of carbon fiber suspension springs and carbon fiber brake calipers enables vehicles to be lighter and more efficient. The high strength and high modulus properties of carbon fiber materials also ensure the reliability and durability of these components under extreme conditions.

- Rail Transportation:

- The application of carbon fiber composite materials in the rail transportation industry is also increasing, primarily used in the manufacturing of train bodies and internal structures. Compared to traditional metal materials, carbon fiber composite materials have higher strength and lower density, significantly reducing the weight of trains and improving operational performance.

Other Applications

- Wind Turbine Blades:

- The application of carbon fiber composite materials in the manufacturing of wind turbine blades is also becoming increasingly widespread. Carbon fiber blades have higher strength and stiffness, enabling them to withstand greater wind forces and loads, improving the power generation efficiency and reliability of wind turbines.

- Construction Industry:

- The application of carbon fiber tubes in the construction industry includes bridges and truss structures. Their high strength and lightweight properties make carbon fiber tubes ideal construction materials, significantly enhancing the structural bearing capacity and service life.

Features

- High Tensile Strength

Twill carbon fiber tubes offer exceptional tensile strength, ensuring superior load-bearing capacity for demanding applications. - Excellent Stiffness and Rigidity

With a high modulus of elasticity, these tubes provide outstanding structural stiffness and dimensional stability. - Lightweight Construction

Significantly lighter than metal alternatives, enabling weight reduction and improved efficiency in end-use products. - Superior Fatigue Resistance

Designed to withstand repeated stress and vibration cycles, enhancing durability and extending service life. - Corrosion and Chemical Resistance

Resistant to moisture, chemicals, and harsh environments, reducing maintenance needs and increasing reliability. - Precision Dimensional Tolerance

Manufactured with tight tolerances (typically ±0.1 mm) for consistent quality and easy integration into assemblies. - Thermal Stability

Maintains mechanical properties across a wide temperature range, suitable for various industrial conditions. - Attractive Surface Finish

The twill weave pattern provides a smooth, visually appealing surface that enhances product aesthetics.

Model | | Outer Dimensions (mm) | Wall Thickness (mm) | Length (mm) | Fiber Type | Fiber Specification |

NQ-20×20-T3 | 20 × 20 | 26 × 26 | 3 | 300 | T700 | 3K |

NQ-30×30-T4 | 30 × 30 | 36 × 36 | 4 | 400 | T700 | 3K |

NQ-40×40-T5 | 40 × 40 | 46 × 46 | 5 | 500 | T700 | 3K |

NQ-50×50-T6 | 50 × 50 | 56 × 56 | 6 | 600 | T700 | 3K |

For more product specifications, please contact our professionals!

By adopting CNC precision processing technology and automatic detection systems and integrating automated winding, curing, and cutting processes, the production speed is increased by 20% to 30%. Multi-station collaborative operation reduces manual intervention and reduces the error rate.

- Compatible with carbon fiber prepregs such as T300, T700, T800

- Supports a variety of resin systems such as epoxy and phenolic

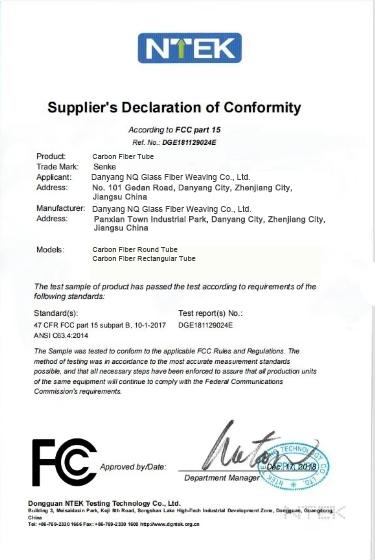

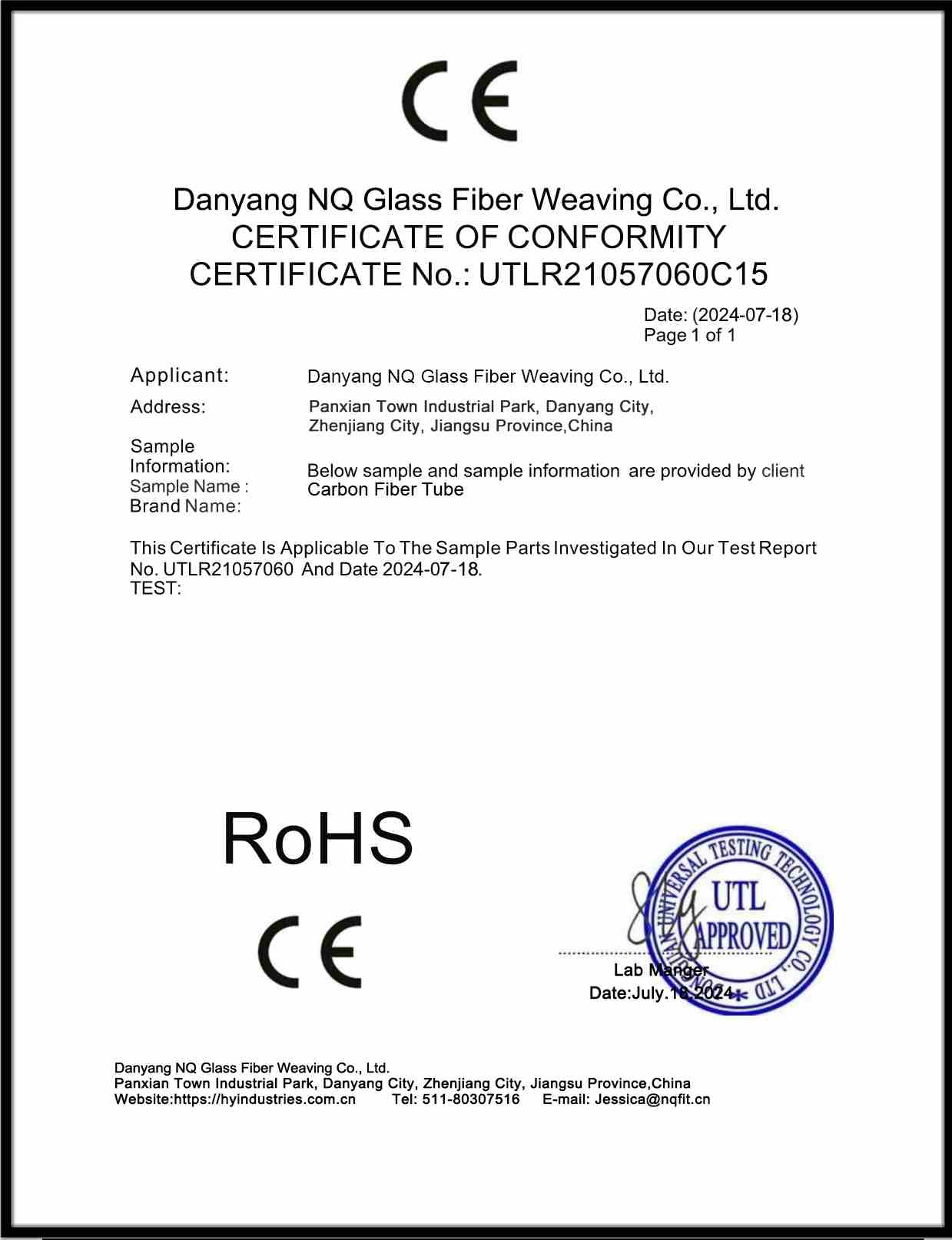

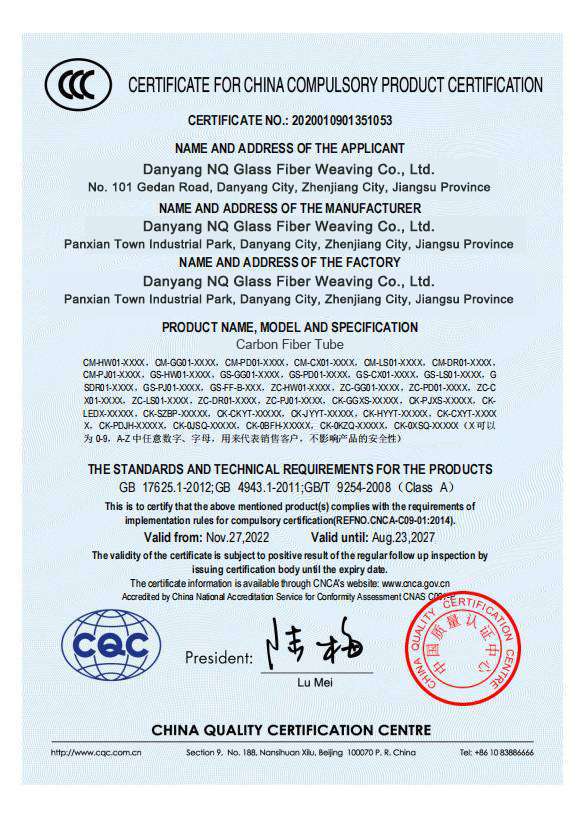

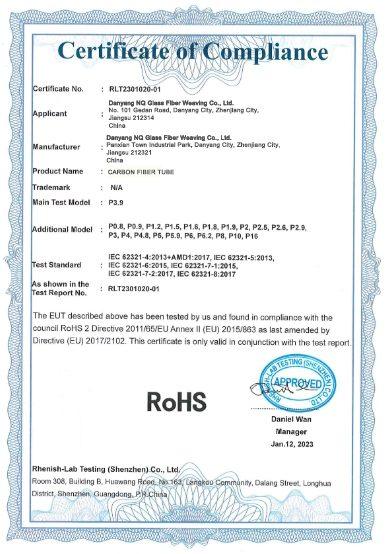

- ISO 9001, CE, SGS, and ASTM standards

- 40 automated production lines to ensure on-time delivery

- In-house Strictly Testing Lab for 6-step internal inspection

Enhance Performance, Simplify Processing, Reduce Costs

Experience the power of Carbon Fiber Tubes—lightweight, ultra-strong, and corrosion-resistant. Perfect for industries demanding high performance and durability. Elevate your products with precision-engineered tubes that combine advanced materials with cutting-edge manufacturing. Choose carbon fiber tubes for unmatched strength, reduced weight, and superior reliability.