- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

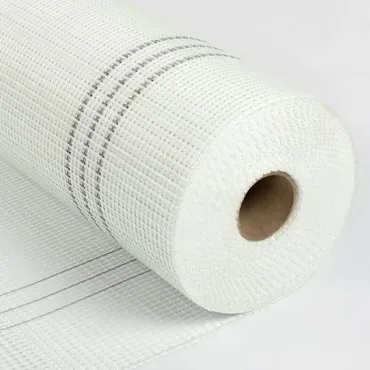

Silicone coated fiberglass mesh is a high-temperature resistant fiberglass reinforcement mesh used in fireproofing, wall insulation, HVAC duct wrap, and EIFS systems. With excellent tensile strength, flame resistance, and anti-aging performance, it ensures long-lasting durability in harsh environments.

Please note our minimum order quantity of Fiberglass mesh. For the conventional Fiberglass mesh in stock, there is no MOQ. For customized Fiberglass mesh, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

Danyang NQ Glass Fiber Weaving Co., Ltd. — A trusted Chinese Carbon fiber manufacturer with 16+ years of experience, 500+ skilled staff, and 2,560+ production machines delivering quality you can rely on.

Item Number | Yarn(Tex) | Mesh size(mm) | Density Count/25mm | Finished weight(g/m2) | Tensile StrengthX20cm | Woven Structure | Content of resin%(≥) | ||||

Warp | Weft | Warp | Weft | Warp | Weft | Warp | Weft | ||||

NQ 5X5-70 | 45X2 | 200 | 5 | 5 | 5 | 5 | 70 | 550 | 850 | Leno | 18 |

NQ 5X5-80 | 67X2 | 200 | 5 | 5 | 5 | 5 | 80 | 700 | 850 | Leno | 18 |

NQ 5X5-90 | 67X2 | 250 | 5 | 5 | 5 | 5 | 90 | 700 | 1050 | Leno | 18 |

NQ 5X5-110 | 100X2 | 250 | 5 | 5 | 5 | 5 | 110 | 800 | 1050 | Leno | 18 |

NQ 5X5-125 | 134X2 | 250 | 5 | 5 | 5 | 5 | 125 | 1200 | 1300 | Leno | 18 |

NQ 5X5-135 | 134X2 | 300 | 5 | 5 | 5 | 5 | 135 | 1300 | 1400 | Leno | 18 |

NQ 4X4-135 | 100X2 | 250 | 4 | 4 | 6 | 6 | 135 | 1000 | 1300 | Leno | 18 |

NQ 5X5-145 | 134X2 | 360 | 5 | 5 | 5 | 5 | 145 | 1200 | 1300 | Leno | 18 |

NQ 4X5-150 | 134X2 | 300 | 4 | 5 | 6 | 5 | 150 | 1300 | 1300 | Leno | 18 |

NQ SX5-160 | 134X2 | 400 | 5 | 5 | 5 | 5 | 160 | 1450 | 1600 | Leno | 18 |

NQ 4X4-160 | 134X2 | 300 | 4 | 4 | 6 | 6 | 160 | 1550 | 1650 | Leno | 18 |

NQ 4X5-165 | 134X2 | 350 | 4 | 5 | 6 | 5 | 165 | 1300 | 1300 | Leno | 18 |

For more product specifications, please contact our professionals!

Premium quality: Our production process and products are certified by ISO, CE, SGS, etc., to meet your high standards.

Competitive price: By choosing our fiberglass mesh, you can purchase high-quality products at a lower cost and reduce the overall project budget while maintaining construction quality.

Fully Customize: As a fiberglass mesh manufacturer, we provide various customized solutions in specifications, meshes, and weights to meet your different applications.

Effortless Reinforcement with Premium Adhesive-Backed Fiberglass Mesh

Maximize project efficiency with our high-strength self-adhesive fiberglass mesh. Engineered for quick application and superior durability, this fiberglass mesh with adhesive reduces labor costs and material waste, ensuring consistent, long-lasting reinforcement across various substrates. Choose reliability and speed — choose our sticky fiberglass mesh roll.