Aramid Flame Retardant Workwear Fabric

Features

Color Customization

Color selection: We offer rich color options, black, dark blue, gray, red, yellow, green, etc. From basic tones to bright colors, it can meet the different needs of customers. In addition, specific colors can be customized according to the customer’s brand or company logo.

Color durability: Considering that work clothes need to be washed and worn frequently, we will ensure that customized colors have good durability and washable.

Weave Texture Customization

Texture: We offer plain, twill, satin, mesh, etc. According to customer’s needs and working environment, we can design different woven textures. For example, for work scenarios that require higher wear resistance, tighter woven textures can be selected; For environments that require better air permeability, you can choose a looser texture.

Custom process: By adjusting the parameters and process of the braiding machine, we ensure that the custom texture can be accurately achieved. This includes choosing the appropriate yarn tension, weave density, and weave mode.

Product MOQ

Please note our minimum order quantity of Aramid Fabric. For the conventionalAramid Fabric in stock, there is no MOQ. For customized Aramid Fabric, the MOQ needs to be confirmed according to the actual situation because the customized requirements are different.

Customization

NQ helps you throughout the entire project: color, weave mode, width, length, etc. Contact us or indicate your request on the form.

Large or Small Order

Order single or thousands item at a time. Our warehouse and flexible shipping is available for last-minute, tight-deadline orders.

●FREE SAMPLE ●FREE RETURNS

*Customization is always available, please mark down your need in cart or just contact us.

Project Monitoring

Shipping Order Track

Instructions for Use

VIP Customer Service

Intact Guarantee

Description

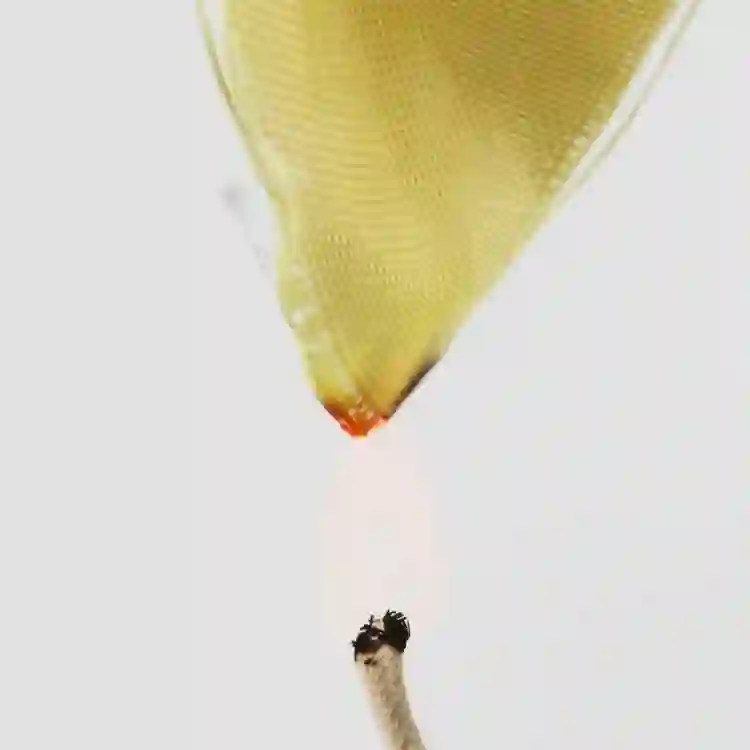

- Aramid Flame Retardant Workwear Fabric is a highly sought-after protective material in modern industrial safety applications. It boasts excellent flame retardancy, superior thermal stability, remarkable durability, and high comfort levels, making it the ideal choice for workwear fabrics.

- The core component of this fabric is aramid fiber, which possesses extremely high thermal stability and flame retardancy. Even under extreme heat, it maintains its structural integrity and performance, forming an insulating layer to effectively block flame spread and reduce heat radiation to protect the wearer.

- Apart from its outstanding flame retardancy, Aramid Flame Retardant Workwear Fabric also demonstrates excellent heat resistance. It maintains stable physical and chemical properties under extreme high temperatures, resisting deformation and melting, thus ensuring the safety of wearers during prolonged exposure to high heat.

- Durability is another key feature of this fabric. The high strength of aramid fiber provides exceptional abrasion, tensile, and tear resistance, ensuring a long service life even under harsh working conditions involving frequent friction, stretching, and compression.

- Comfort is also a priority in Aramid Flame Retardant Workwear Fabric. Its excellent breathability and moisture absorption capabilities quickly evacuate body heat and sweat, keeping the wearer dry and comfortable. The fabric’s soft and lightweight texture enhances its fit, reducing the burden on the wearer.

- In terms of color and texture, Aramid Flame Retardant Workwear Fabric offers a diverse range of options. From classic blacks and grays to vibrant yellows and reds, and even customized colors and textures upon request, it caters to both protective performance and aesthetic preferences.

- Moreover, this fabric boasts impressive customization capabilities. Whether it’s color, texture, or size specifications, it can be tailored precisely to meet the specific needs of different industries and work scenarios. This customization ability enables the fabric to provide a more comprehensive and professional protective solution for customers.

Main Function

Firefighting

- Firefighters frequently face direct threats from high temperatures and flames during fire rescue missions. Workwear made of Aramid Flame Retardant Workwear Fabric effectively blocks flames and high temperatures, providing firefighters with necessary protection to safely carry out their duties.

Metallurgy And Steel Manufacturing

- High temperatures, sparks, and flying molten metal are common hazards in the metallurgy and steel manufacturing processes. Workers wearing workwear made of Aramid Flame Retardant Workwear Fabric can reduce the risk of burns from flying debris and ensure their safety in high-temperature environments.

Oil And Gas Industry

- Drilling, refining, and transportation processes in the oil and gas industry involve flammable and explosive risks. Workers need to wear flame-resistant workwear to prevent injuries caused by fires and explosions. Aramid Flame Retardant Workwear Fabric offers excellent flame retardancy, suitable for the specific working environment of this industry.

Electrical And Electronics Industry

- Workers in the manufacturing, maintenance, and operation of electrical and electronic equipment often need to contact electrical equipment and circuits. Workwear made of Aramid Flame Retardant Workwear Fabric can prevent fires and burns caused by electrical arcs, protecting workers’ safety.

Chemical Industry

- In the chemical industry, workers often handle flammable and explosive chemicals and solvents. Wearing workwear made of Aramid Flame Retardant Workwear Fabric can significantly reduce the risk of injuries to workers caused by chemical leaks or fire accidents.

Welding And Cutting Operations

- High-temperature sparks and flying slag are common hazards in welding and cutting operations. Workwear made of Aramid Flame Retardant Workwear Fabric can resist direct contact with these high-temperature substances, providing workers with necessary protection.

Specification

Model | Surface | weight/gsm | Thickness/mm | Density |

ZF-200P-60 | PPlain | 60 | 0.1 | 15*15 |

ZF-400P-80 | Plain | 80 | 0.11 | 9*9 |

ZF-400P-90 | Plain | 90 | 0.12 | 10*10 |

ZF-400P-110 | Plain | 110 | 0.13 | 12*12 |

ZF-400P-120 | Plain | 120 | 0.14 | 13*13 |

ZF-1000P-120 | Plain | 120 | 0.2 | 5*5 |

ZF-1000P-135 | Plain | 135 | 0.22 | 6*6 |

ZF-1000P-155 | Plain | 155 | 0.24 | 7*7 |

ZF-1000P-180 | Plain | 180 | 0.25 | 8*8 |

ZF-1000T-180 | Twill | 180 | 0.25 | 8*8 |

ZF-1000P-200 | Plain | 200 | 0.26 | 9*9 |

ZF-1000T-200 | Twill | 200 | 0.26 | 9*9 |

ZF-1000T-220 | Twill | 220 | 0.28 | 10*10 |

ZF-1500P-170 | Plain | 170 | 0.22 | 5*5 |

ZF-1500P-185 | Plain | 185 | 0.24 | 5.5*5.5 |

ZF-1500T-185 | Twill | 185 | 0.24 | 5.5*5.5 |

ZF-1500P-200 | Plain | 200 | 0.26 | 6*6 |

ZF-1500T-200 | Twill | 200 | 0.26 | 6*6 |

ZF-1500P-250 | Plain | 250 | 0.32 | 7.5*7.5 |

ZF-1500T-250 | Twill | 250 | 0.32 | 7.5*7.5 |

ZF-3000P-400 | Plain | 400 | 0.45 | 6*6 |

ZF-3000P-450 | Twill | 450*450 | 0.58 | 7*7 |

Model | Surface | weight/gsm | Thickness/mm | Density |

ZF-200P-60 | Plain | 60 | 0.1 | 15*15 |

ZF-400P-80 | Plain | 80 | 0.11 | 9*9 |

ZF-400P-90 | Plain | 90 | 0.12 | 10*10 |

ZF-400P-110 | Plain | 110 | 0.13 | 12*12 |

ZF-400P-120 | Plain | 120 | 0.14 | 13*13 |

ZF-1000P-120 | Plain | 120 | 0.2 | 5*5 |

ZF-1000P-135 | Plain | 135 | 0.22 | 6*6 |

ZF-1000P-155 | Plain | 155 | 0.24 | 7*7 |

ZF-1000P-180 | Plain | 180 | 0.25 | 8*8 |

ZF-1000T-180 | Twill | 180 | 0.25 | 8*8 |

ZF-1000P-200 | Plain | 200 | 0.26 | 9*9 |

ZF-1000T-200 | Twill | 200 | 0.26 | 9*9 |

ZF-1000T-220 | Twill | 220 | 0.28 | 10*10 |

ZF-1500P-170 | Plain | 170 | 0.22 | 5*5 |

ZF-1500P-185 | Plain | 185 | 0.24 | 5.5*5.5 |

ZF-1500T-185 | Twill | 185 | 0.24 | 5.5*5.5 |

ZF-1500P-200 | Plain | 200 | 0.26 | 6*6 |

ZF-1500T-200 | Twill | 200 | 0.26 | 6*6 |

ZF-1500P-250 | Plain | 250 | 0.32 | 7.5*7.5 |

ZF-1500T-250 | Twill | 250 | 0.32 | 7.5*7.5 |

ZF-3000P-400 | Plain | 400 | 0.45 | 6*6 |

ZF-3000P-450 | Twill | 450*450 | 0.58 | 7*7 |

Consult Your NQ Aramid Fabric Wholesale And Packaging Specialist

We help you avoid pitfalls and deliver the quality and value you need for aramid fabric on time and on budget.