Wholesale RDP Redispersible Polymer Powder

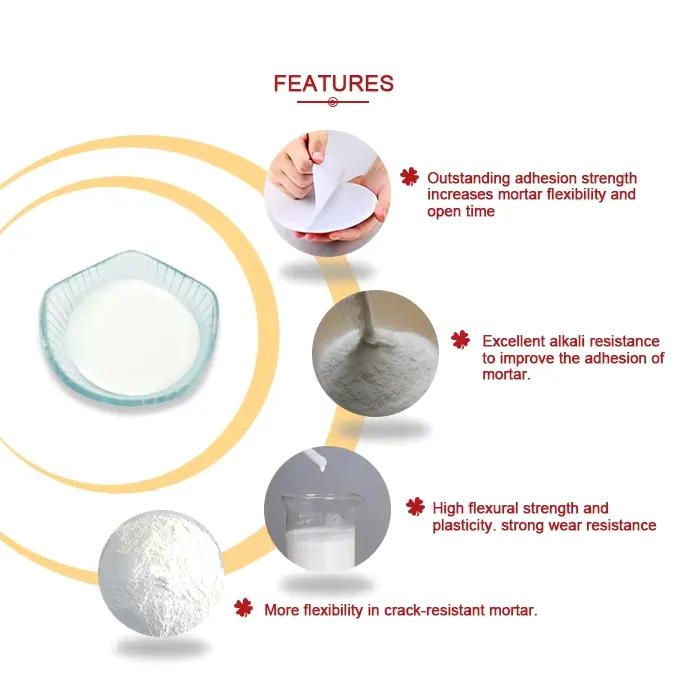

Features

RDP Redispersible Polymer Powder is a high-performance polymer additive that is odorless, tasteless and non-toxic. It appears as a white or slightly off-white free-flowing powder that can redisperse quickly in water to form a stable polymer emulsion. It has a variety of properties such as bonding enhancement, flexibilization, water resistance, crack resistance, wear resistance and workability improvement, and is widely used as construction materials, dry-mix mortars, tile adhesives, thermal insulation materials, cementitious waterproof coatings and decorative coating materials, etc.

Market Prospects

Hydroxypropyl Methyl Cellulose Manufacturing Process

Use Precautions

The optimal addition amount of RDP Redispersible Polymer Powder varies in different applications. Please weigh it accurately according to the specific application scenario and formula ratio, and disperse it fully in water under the recommended stirring conditions to avoid agglomeration or incomplete redispersion that impairs the application effect.

The performance of RDP Redispersible Polymer Powder is affected to a certain extent by the pH value and ionic strength of the mortar system. Before use, confirm and adjust the working system to the appropriate range to ensure the stability and bonding performance of RDP.

High temperature may cause thermal degradation of RDP Redispersible Polymer Powder and reduce its film-forming property, while high humidity can easily lead to caking and loss of redispersibility. Avoid extreme temperature and humidity during storage, transportation and use, and keep it within the recommended environmental range.

In multi-component dry-mix mortar systems, the mixing order of RDP Redispersible Polymer Powder has a key impact on the final product performance. It is generally recommended to mix RDP evenly with other dry powder components first, then add water and stir, to prevent uneven dispersion and weakening of bonding and crack resistance.

Before using RDP Redispersible Polymer Powder, evaluate its compatibility with other additives in the system (such as cement, fly ash, water reducers, thickeners, etc.) to avoid reduced bonding strength, poor water resistance or structural defects caused by incompatibility.

●FREE SAMPLE

*Customization is always available, please mark down your need in cart or just contact us.

Project Monitoring

Shipping Order Track

Instructions for Use

VIP Customer Service

Intact Guarantee

Characteristics

- Excellent Redispersibility

- Hydrophilic protective colloid is wrapped on the surface of RDP particles. This structure enables the powder to quickly disintegrate and redisperse in water, forming a stable and uniform polymer emulsion with consistent performance as the original latex.

- Strong Bonding Adhesion

- RDP forms a continuous and flexible polymer film after water dispersion and film-forming. This film can form firm physical and chemical bonds with inorganic cementitious materials and various substrates, significantly enhancing the bonding strength and interface adhesion of the system.

- Excellent Crack Resistance

- The flexible polymer film formed by RDP has good elongation and toughness. It can effectively relieve the internal stress generated by the shrinkage and deformation of cementitious materials during curing, inhibit the generation and expansion of microcracks, and improve the crack resistance of the hardened product.

- Good Water Resistance

- The dense polymer film formed by RDP can fill the capillary pores and microcracks of the cementitious matrix, forming an effective water-repellent barrier. It reduces the water absorption rate of the material and enhances the water resistance and impermeability of the final product.

Main Function

Construction Industry:

RDP is a key additive for dry-mix mortars, used to improve the bonding performance and mechanical properties of mortar. It can significantly enhance the adhesion, flexibility, crack resistance and water resistance of mortar. At the same time, it improves the workability of mortar, extends the open time and boosts construction efficiency.

Coating Industry:

RDP is widely used in water-based coatings as a film-forming agent, binder and toughening agent. It can improve the film-forming property, adhesion and durability of coatings. Enhance the flexibility and scrub resistance of the coating film, making the coating more smooth and uniform.

Pharmaceutical Industry:

In the pharmaceutical field, RDP can be used as a binder, film-forming agent and sustained-release material for tablets and granules. It can improve the hardness and stability of preparations. Optimize the drug release rate to ensure the uniform release of active ingredients, and enhance the bioavailability of drugs.

Food Industry:

RDP is used in the food industry as a binder, stabilizer and thickener, and is widely applied in baked goods, dairy products and convenience foods. It can improve the water retention and shape retention of food, making the texture more delicate and elastic. At the same time, it extends the shelf life of food and maintains its flavor.

Other Industries:

RDP is also widely used in textiles, papermaking, adhesives and other fields. It can be used as a binder, thickener and modifier to improve product quality and performance. Meet the specific needs of different fields and provide customers with customized solutions.

Performance | Index |

Appearance | White powder, free-flowing |

Solid content (wt%) | ≥98.0 |

Ash content (wt%) | 10±2% |

Bulk density (g/L) | 300-500 |

Protective colloid | Polyvinyl alcohol |

Particle size | ≤4% greater than 400um |

pH value | 6-8 |

Glass transition temperature Tg (DSC) °C | Not fixed |

Minimum film-forming temperature (°C) | 0~5℃ |

HOT SELLING CELLULOSE SERIES

CELLULOSE MANUFACTURERS & SUPPLIERS

NQ is an influential cellulose ether manufacturer in China. We are committed to the research, development, production and sales of hpmc, hemc and hec. High-quality products and first-class services make us do better!

We providing high-quality and best cellulose ether price for many countries and region.

✅️ 16 years of global production and sales experience;

✅️ Cellulose Ether Factory in China, complete supply chain system;

✅️ Cellulose ether annual production capacity of 50,000, to provide a stable supply, fast delivery;

✅️ 98.2% customer satisfaction, NQ professional team do our best to meet your needs.