Wholesale MHEC Methyl Hydroxyethyl Cellulose Powder

Features

Market Prospects

Methyl Hydroxyethyl Cellulose Manufacturing Process

Use Precautions

●FREE SAMPLE

*Customization is always available, please mark down your need in cart or just contact us.

Project Monitoring

Shipping Order Track

Instructions for Use

VIP Customer Service

Intact Guarantee

Characteristics

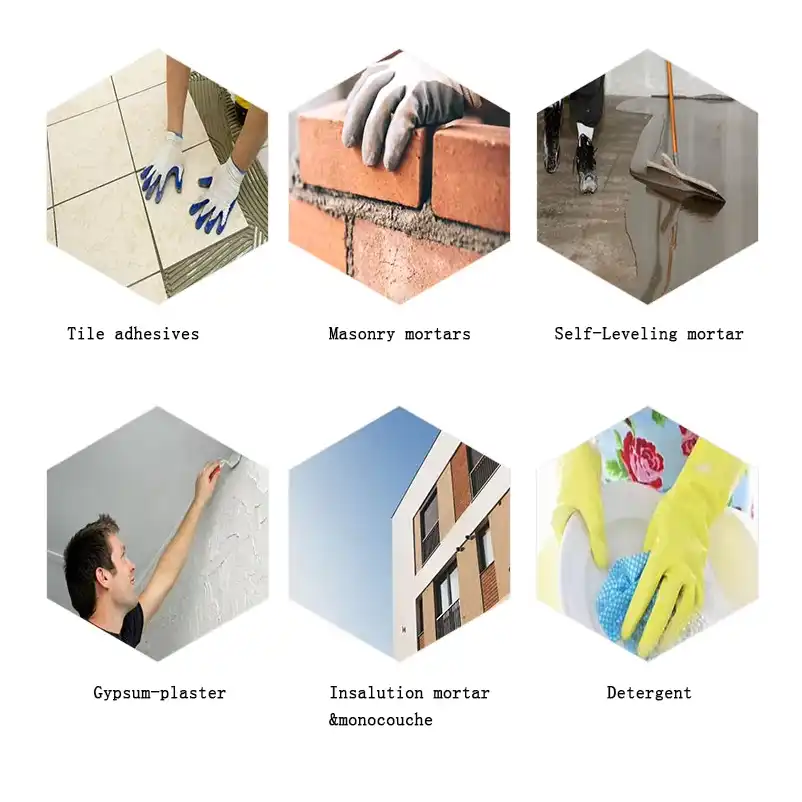

- In the building materials field, MHEC can be used as a water-retaining agent, thickener and adhesion modifier for dry-mixed mortar, tile adhesive and self-leveling floor, improving the construction performance and bonding strength of materials;

- In the coatings industry, it is used as a thickener and stabilizer to control the rheology of water-based coatings and prevent pigment sedimentation and coating sagging;

- In the daily chemical industry, MHEC is used as a thickener and moisturizer for skin care products and shampoos, optimizing the texture and use experience of products;

- In the pharmaceutical field, it acts as a binder and sustained-release matrix material for tablets and topical gels, regulating drug release rate and improving the stability of preparations.

Main Function

Name | METHYL HYDROXY ETHYL CELLULOSE(MHEC) |

Viscosity (Mpa.s) | 50,000 to 200,000 it can be customized |

Ash.% | ≤3% |

Content of methoxyl (%) | 24.0 – 33.0 |

Content of hydroxy propyl (%) | 4.0 – 12.0 |

Temperature of gelation | 50-68℃ |

Moisture | ≦5% |

Application | Wall Putty Powder,Tile Adhesive,Cement/Gypsum Based Products , etc. |

Function | Water Retention, High Adhesive,Anti-slip,Excellent Workability |

HOT SELLING CELLULOSE SERIES

CELLULOSE MANUFACTURERS & SUPPLIERS

NQ is an influential cellulose ether manufacturer in China. We are committed to the research, development, production and sales of hpmc, hemc and hec. High-quality products and first-class services make us do better!

We providing high-quality and best cellulose ether price for many countries and region.

✅️ 16 years of global production and sales experience;

✅️ Cellulose Ether Factory in China, complete supply chain system;

✅️ Cellulose ether annual production capacity of 50,000, to provide a stable supply, fast delivery;

✅️ 98.2% customer satisfaction, NQ professional team do our best to meet your needs.