- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

Carbon fiber tubes are essentially composite rods made of carbon fibers that are bonded together with resin. They are popular because of their high strength-to-weight ratio and stiffness. To steer smart choices, the core text addresses sizing, wall thickness, fiber orientation, and finish options for actual-world applications.

Carbon fiber tubes are popular due to their high strength and stiffness combined with a very low weight, along with strong fatigue resistance and good thermal stability.

Custom tubes targeted for specific diameters, layups, and finishes are readily available for given loads, environments, and integration requirements.

Carbon fibers provide the strength, while a polymer resin matrix, typically epoxy, contributes toughness and long term durability. Typical fiber orientations are unidirectional for maximum axial stiffness and strength, plain weave for balanced properties, and twill for improved drape and impact performance.

• Aircraft Structures – Used in wings, fuselages, and other structural parts.

• Spacecraft – Found in satellites and space exploration vehicles.

Versus aluminum and steel, carbon fiber tubes provide comparable or greater stiffness to weight with much less mass, which reduces fuel consumption and emissions in lightweight body parts, drive shafts, and roll structures. They resist corrosion, such as salt water in coastal areas, reducing maintenance in the long run.

• Chassis Components – Reducing the weight of car frames.

• Driveshafts – Providing strong, lightweight alternatives to traditional materials.

Filament winding circles fibers around a mandrel in exacting patterns. Winding angles tune unidirectional properties and load paths. Low angles, approximately 0–20 degrees, boost axial strength for ski poles and fishing rods, while ±45° layers add torsion control for hockey sticks and bicycle frames.

• Bicycles – Frames and handlebars.

• Water Sports – Paddleboards and rowing shells.

• Golf Clubs – Lightweight, strong shafts.

Pultrusion pulls continuous fibers through resin and a heated die to cure into steady shapes. This process produces uniform cross-sections with close tolerances, which is perfect for high-volume production of standard sizes.

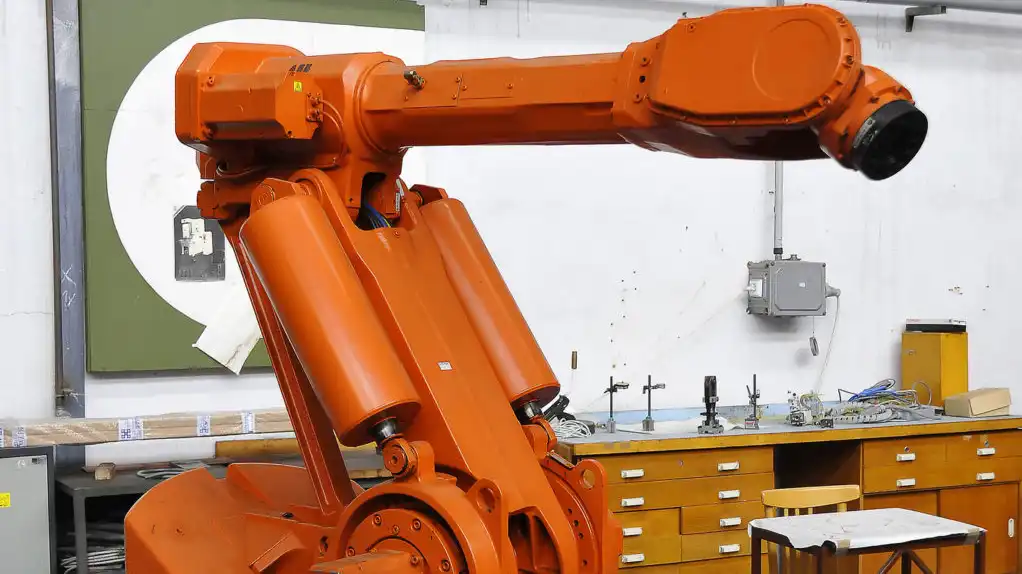

• Robotics – Lightweight, strong robotic arms.

• Construction – Reinforcement materials and structural components.

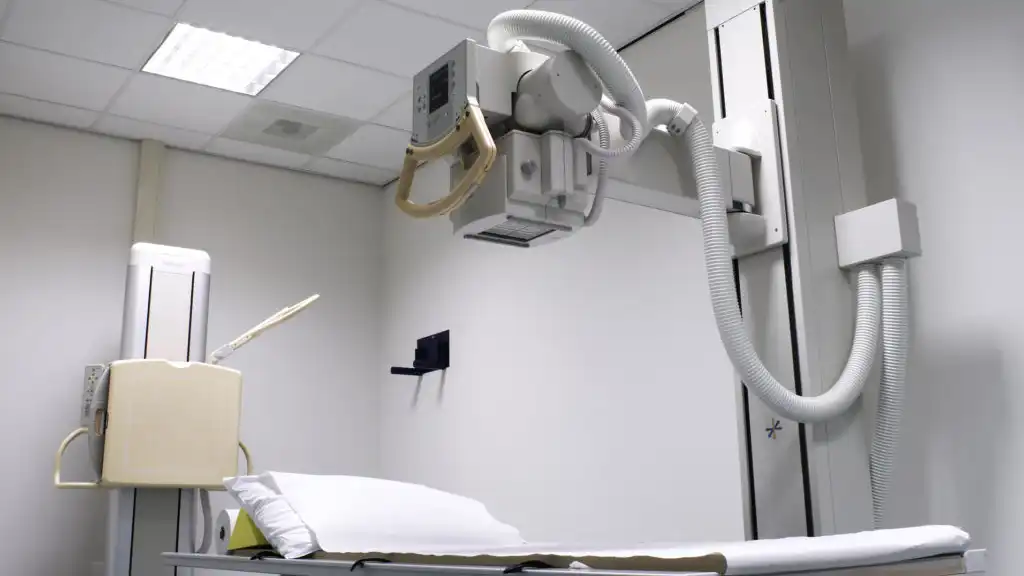

High-stress machine components in surgical robots and imaging supports employ tubes for stiffness without mass. The material’s radiolucency can reduce imaging artifacts in some configurations.

• Prosthetics – Lightweight, strong components.

• Imaging Equipment – Parts that don’t interfere with X-rays and other imaging technologies.

Carbon fiber tubes provide a combination of low weight, high strength, and consistent performance. Its success depends on explicit design goals, the right material specs, and smart joints that transfer loads without stress spikes.

Weight plummets when replacing metal with carbon fiber. In some builds, mass cuts are as high as 50% versus steel or aluminum, which is crucial in aerospace and UAV frames where every kilo saved can mean range or payload.

Bikes and robotics get a boost as well. A tube with a density approaching 1.54 g/cm³ can stand in for a denser metal member and still maintain its shape under load, so actuators exert less effort and batteries endure.

Carbon fiber tubes frequently attain tensile strength close to 3.5 GPa, and many commercially available tubes approach 2.6 GPa, combined with low density. This provides an excellent strength-to-weight ratio, valuable in everything from camera booms to drone arms to sail masts.

Damage is not always visible. Set inspection intervals, use torque-limited clamps, and specify impact-resistant outer plies in high-risk zones. Maintenance costs can be reduced by as much as 40% over a lifecycle due to corrosion problems and longer service intervals.

Carbon fiber doesn’t rust. In saltwater, where steel can shed roughly 0.1 mm of its thickness annually, composite tubes fare even better. This makes them perfect for marine masts, ROV frames, and coastal structures.

Take isolation washers or coatings to prevent galvanic coupling with aluminum. Seal cut edges to keep moisture out and to maintain strong glue bonds long term. Wash after salt water exposure and inspect your hardware for crevice corrosion even if the tube is good.

Customize stiffness by adjusting fiber angles, wall thickness, and modulus. Do you require torsion stiffness in a drive shaft? More benefits of carbon fiber tube can be achieved with ±45° angles.

Do you need axial strength in a tripod leg? Stack 0° plies with a thin 90° hoop. Tricky joints require attention. Bonded sleeves spread load better than point clamps. Fillets in bonded lugs reduce peel stress, and scarf joints increase shear area without adding weight.

Carbon fiber has low thermal expansion, so dimensions remain consistent across large temperature changes. This property underpins optics mounts, sensor booms, and measurement rigs where micrometer drift counts.

Matrix selects the temperature window. Typical epoxies deal with approximately -40 to 120 °C. High-Tg systems go higher but cost more. For hot zones around motors or brakes, incorporate heat shields and vent paths.

Innovation will depend on tested performance under actual strain. These projects require environmental resistance, fatigue, and impact data to establish safe limits, select coatings, and schedule maintenance. Record all outcomes, including procedures, masses, cycles, breakdowns, and photos, to inform design adjustments and assist certification in mission-critical utilization.

Temperature, humidity, UV, and chemicals are the main environmental considerations to monitor. Carbon fiber resists corrosion, so tubes withstand salt spray, de-icing fluids, and many solvents. However, resins and joints can still degrade.

Certain applications require clear coats with UV blockers, nano-ceramic finishes or barrier films. For heat, high-Tg resins assist. For fuel or hydraulic fluids, choose resin systems validated in immersion tests.

Carbon fiber tubes fare well under repeated loading cycles when constructed with suitable ply angles and toughened resins. That is crucial in aerospace struts, bike frames, paddle shafts, and camera booms.

High fatigue resistance leads to a longer service life and fewer inspections. That cuts downtime and spares. With recycled fibers on the rise, possibly as high as 30% by material, fatigue databases for recycled content will be crucial.

Which future tubes will contain thin sensors for strain, impact, and temperature? These range from fiber Bragg grating to printed piezoresistive inks to low-power edge nodes.

Real-time data flags overloads in drones, microcracks in racing masts, and heat spikes in EV chassis tubes. Coupling sensors with hybrid tubes, carbon with Kevlar for impact regions, can isolate and localize incidents, then notify precision repairs.

Anticipate broader specs for recycled carbon grades, pitch-based UHM fibers and hybrid tubes with Kevlar or basalt. These new process standards will cover automated fiber placement, 3D-printed mandrels and renewable energy curing.

Explicit stiffness class, impact grade and sensor-ready tube labeling will accelerate cross-industry adoption, reduce costs and enable new use cases in automotive, sports and light robotics.

Carbon fiber tubes now occupy critical positions across numerous industries. Drones elevate more equipment with less mass. Tripods stay stiff with less shake. Robotic arms act fast with precise control. Bike frames and paddle shafts reduce weight but maintain strength in sports. The gains come from low mass, high stiffness, tight tolerances, and clean fatigue life.

Need assistance selecting tube size, layup, or finish? Come on, reach out and share your spec!

Connect with an NQ expert to discuss your product needs and get started on your project.

Contact NowWhat are the most common industrial uses of carbon fiber tubes?

Carbon fiber tubes are utilized in various applications including aerospace, drones, robotics, medical devices, automotive components, sporting goods, and industrial rollers. Providing high stiffness and low weight, they enhance performance, efficiency, and handling in challenging applications.

Why choose carbon fiber tubes over aluminum or steel?

They offer superior strength to weight and stiffness to weight ratios. That trims mass, boosts acceleration, slashes energy consumption and decreases vibration. They resist corrosion and fatigue, which extends service life in harsh environments.

How are carbon fiber tubes manufactured?

Most tubes are manufactured by roll-wrapping or filament winding pre-impregnated carbon fiber on a mandrel, then cured. Pultrusion is used for constant profiles. Layup angle and fiber grade govern stiffness, strength, and torsion characteristics.

Can carbon fiber tubes handle high temperatures?

Typical epoxy tubes are fine up to around 120 to 150 degrees Celsius. For higher temperatures, select high-temperature resins or cyanate ester systems. Always pair the resin system and safety factor to your operating environment.

What future trends will shape carbon fiber tube development?

Anticipate speedier automated manufacturing, more reasonable prices, hardier resins, improved recyclability, and online design utilities. Hybrid tubes with aramid or basalt layers and smart sensing features will grow in use in mobility, energy, and medical.