- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

If you’ve been exploring advanced materials for aerospace, automotive, marine, or sporting goods, chances are you’ve heard of prepregs. These pre-impregnated fibers have become the standard for high-performance applications where strength, lightweight properties, and precision matter most.

In this guide, you’ll learn what prepregs are, their different types, properties, applications, and how to choose the right ones for your projects.

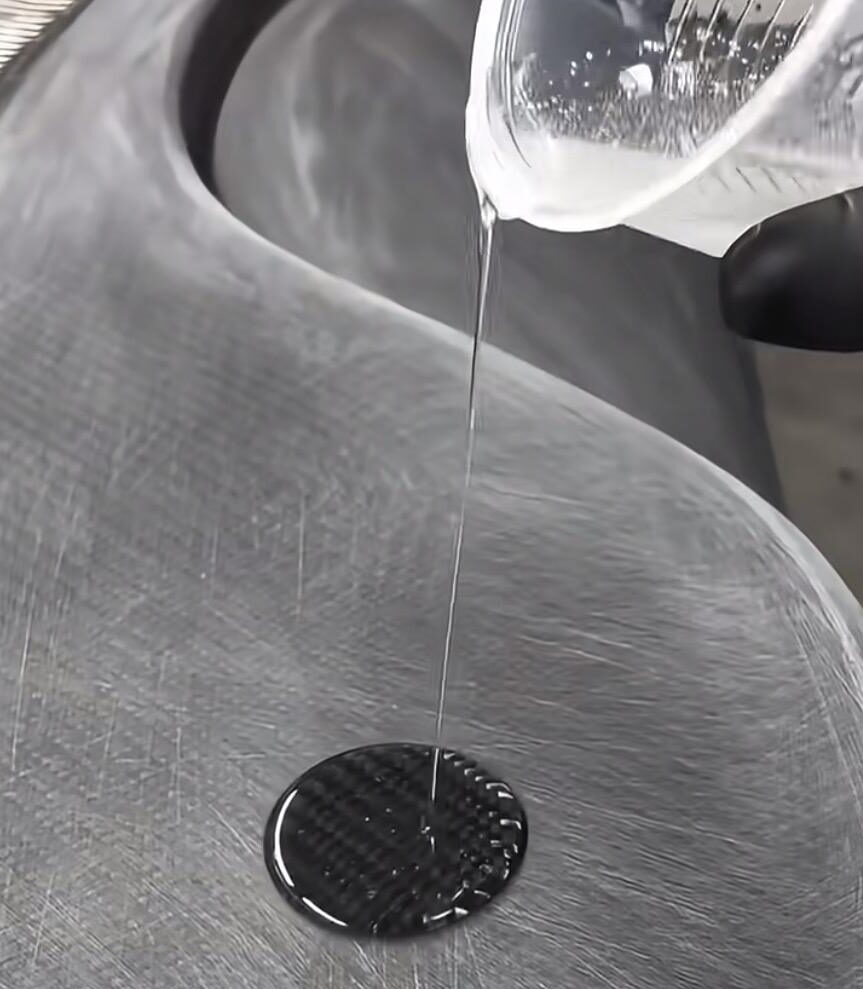

A prepreg (short for “pre-impregnated”) is a composite reinforcement fiber, such as carbon fiber, fiberglass, or Kevlar, that has been pre-impregnated with a resin system, typically epoxy. The resin is distributed consistently across the fiber, making the material ready for curing under heat and pressure.

This means you don’t need to manually apply resin. Instead, prepregs allow for:

Precise resin-to-fiber ratio

Clean, efficient processing

Stronger and more consistent parts

👉 Keywords included: what is prepreg, prepreg composites, pre-impregnated carbon fiber

Compared with wet layup or resin infusion, prepregs offer several clear advantages:

Consistency – Every layer has the right resin ratio

Superior Quality – Less chance of voids and defects

Strength-to-Weight Efficiency – Essential for high-performance structures

Time Savings – Faster and cleaner processing

Scalability – Reliable for both small projects and large-scale manufacturing

For demanding projects, prepregs are the smarter choice.

Extremely strong and lightweight

Used in aerospace, motorsports, drones, and defense applications

Available in rolls, sheets, or ready-to-use kits

👉 Keywords: prepreg carbon fiber, carbon prepreg, pre-preg carbon fiber

|

More affordable than carbon

Flexible and durable

Ideal for marine, automotive, and construction applications

👉 Keywords: fiberglass prepreg, pre-impregnated fiberglass

Kevlar Prepreg: Superior impact resistance for safety equipment and aerospace components

Flax Prepreg: Sustainable choice for eco-friendly designs

👉 Keywords: kevlar prepreg, flax prepreg

The most widely used system

Known for temperature resistance, durability, and strong bonding

Common in aerospace and automotive prepregs

👉 Keywords: epoxy prepreg, epoxy resin prepreg

The prepreg viscosity–temperature curve shows how resin flow changes with heat. This ensures the resin spreads correctly during curing, preventing voids and ensuring strong bonding.

Zero-bleed prepregs are designed so that resin does not escape during curing. This results in dimensionally stable laminates with cleaner surfaces.

Special prepregs come with adhesive layers (like prepreg standard adhesive 70) that improve bonding between layers.

Prepregs require refrigerated storage to keep resin stable. Proper handling extends shelf life and avoids resin crystallization.

Prepregs are used across multiple industries:

Aerospace – Aircraft fuselages, wings, and interiors

Automotive & Motorsports – Carbon fiber panels, chassis, and spoilers

Marine – High-performance boats, surfboards, and yachts

Sports Equipment – Golf clubs, tennis rackets, bicycles, skis

DIY & Prototyping Kits – Drone frames, RC models, and custom projects

👉 Keywords: carbon fiber prepreg kit, prepreg composites, composite prepreg

👉 Prepregs clearly outperform traditional methods where precision and quality are essential.

| Method | Strength | Weight | Cost | Ease of Use | Finish Quality |

|---|---|---|---|---|---|

| Wet Layup | Medium | Heavy | Low | Messy | Average |

| Resin Infusion | High | Medium | Medium | Complex | Good |

| Prepregs | Very High | Lightest | Medium-High | Easy & Clean | Excellent |

Even with prepregs, some issues may occur:

Prepreg release film has bulges → Usually caused by trapped air or poor vacuum bagging.

Resin defects → May occur if prepreg is expired or cured incorrectly.

Storage problems → Leaving prepregs unrefrigerated can cause resin crystallization.

Solution: Always check shelf life, follow curing guidelines, and work with certified suppliers.

When sourcing prepregs, consider these factors:

Fiber Type – Carbon fiber for performance, fiberglass for affordability, Kevlar for impact resistance

Resin System – Epoxy is most common; thermoplastic options are emerging

Format – Rolls, woven fabrics, unidirectional tapes, or pre-cut kits

Curing Requirements – Autoclave vs out-of-autoclave solutions

Supplier Reliability – Look for quality assurance and industry certifications

💡 Tip: For smaller projects, start with a prepreg carbon fiber kit to test results before scaling up.

Prepregs are the gold standard in composites—combining strength, precision, and lightweight performance. Whether you’re working in aerospace, automotive, or industrial applications, choosing the right prepreg ensures consistent results and long-term durability.

Connect with an NQ expert to discuss your product needs and get started on your project.

Contact NowWhat is a prepreg in composites?

A prepreg is a reinforcing fiber—such as carbon, fiberglass, or Kevlar—that has been pre-impregnated with resin. This ensures uniform resin distribution, reduced waste, and superior part quality compared with wet layup or infusion methods.

What is prepreg carbon fiber used for?

Carbon fiber prepregs are widely used in aerospace, motorsports, and sporting equipment. They offer exceptional strength-to-weight performance, enabling lightweight designs without sacrificing durability or safety.

What does zero bleed prepreg mean?

Zero bleed prepreg means the resin stays within the laminate during curing. This prevents resin loss, ensures dimensional stability, and delivers a cleaner, more precise finish for advanced structural parts.

Can prepregs be processed without an autoclave?

Yes. Many manufacturers now offer out-of-autoclave prepregs, which can be cured using ovens or hot presses. While autoclaves achieve maximum quality, out-of-autoclave prepregs make production more cost-efficient for smaller manufacturers.

How should prepregs be stored to maintain quality?

Prepregs must be stored in freezers at controlled temperatures to slow down resin activity. Proper storage extends shelf life, prevents crystallization, and ensures consistent performance during curing.