- +86-13775339109

- Jessica@nq-fiberglass.cn

- No 61 Fangxian, Danyang, Jiangsu

Every fiberglass swimming pool begins with one essential element: fiberglass. For manufacturers, the strength, durability, and finish of the pool shell all depend on the quality of the fiberglass materials used.

In this guide, we’ll walk you through the step-by-step process of making a fiberglass pool and show why choosing premium fiberglass is the key to producing stronger, longer-lasting, and more competitive pool shells.

Every fiberglass pool begins with a precision-engineered mold. This mold determines the exact shape, size, and contours of the finished pool.

For manufacturers, maintaining high-quality molds reduces waste and ensures consistent results. But the mold is only the foundation—the fiberglass and resin layers make the real difference.

Once the mold is ready, a gelcoat is sprayed onto its surface. This gelcoat forms the smooth, glossy inner finish of the pool.

However, gelcoat alone is fragile. Without high-quality fiberglass reinforcement, it can crack or blister. This is why manufacturers must use the right fiberglass to support this layer.

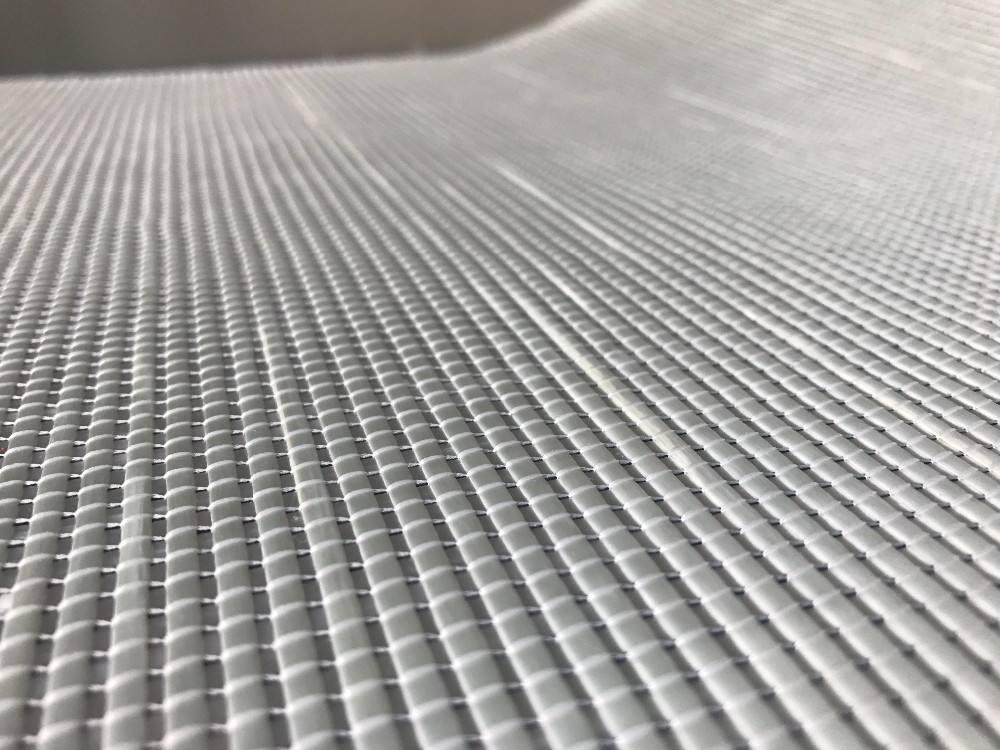

This is the core step of pool manufacturing—and where the choice of fiberglass material makes the biggest difference.

The process:

Benefits of premium fiberglass:

To create a pool shell capable of withstanding decades of pressure, additional reinforcements are applied:

Poor-quality fiberglass can compromise this step, leading to weak shells. High-grade fiberglass ensures that even when soil shifts or ground pressure changes, the pool remains stable.

Once the layers are applied, the pool shell is left to cure under controlled conditions.

Manufacturers who use premium fiberglass materials experience fewer defects, meaning less rework, less waste, and lower costs in the long run.

While the pool is made in a factory, final installation takes place on-site:

For pool builders, installation speed is a major advantage. For manufacturers, it’s an opportunity to supply shells that are easy to install, lightweight, and structurally sound.

High-quality fiberglass pool shells ensure that fiberglass swimming pool shell installations last 25–30 years without major issues, unlike inferior fibers that may cause cracking or water leakage.

Smooth, durable fiberglass pool shells reduce warranty claims, leading to happier customers and stronger brand reputation.

Fiberglass that wets out quickly saves labor costs and minimizes waste, benefiting fiberglass pool manufacturers’ efficient production.

With the right fiberglass pool shell, manufacturers can market their fiberglass pools as stronger, more durable, and easier to maintain than competitors.

| Feature | Standard Fiberglass | Premium Fiberglass |

|---|---|---|

| Strength | Moderate, may delaminate over time | Exceptional, high structural integrity |

| Resin Content | Inconsistent, lower quality resin | Optimal, high-quality vinyl ester resin |

| Fiberglass Type | Random mat only | Combination of CSM and Woven Roving |

| Processing | Difficult to wet out, more air bubbles | Easier to process, fewer voids |

| Durability | Limited lifespan, prone to cracking | Long-lasting, resistant to impact |

| Warranty Costs | Higher due to frequent repairs | Lower with fewer warranty claims |

| Customer Satisfaction | Mixed reviews | Highly positive, repeat customers |

Manufacturing a fiberglass swimming pool is not just about molds, resins, or gelcoats—it all begins with the right fiberglass. Using high-grade materials ensures smoother processing, stronger shells, and satisfied end-users who recommend your pools again and again.

If you want to reduce production risks, cut warranty costs, and deliver pools that last for decades, your choice of fiberglass supplier will make all the difference.

Connect with an NQ expert to discuss your product needs and get started on your project.

Contact Now